Choosing between ABS and LR certified bulb flat steel can significantly impact your marine project’s approval and performance. Many shipyards face costly delays when their steel documentation doesn’t meet specific classification society requirements. Understanding these differences streamlines your procurement process.

ABS and LR bulb flat steel follow different certification standards despite similar mechanical properties. ABS certification comes from the American Bureau of Shipping, while LR certification follows Lloyd’s Register rules. Both ensure marine-grade quality but have distinct testing protocols, documentation requirements, and approval processes for various vessel types.

Having supplied both ABS and LR certified materials to shipyards worldwide, I’ve seen how proper certification selection prevents project delays. The following sections break down the key distinctions that matter most for your specific marine applications.

What is ABS grade steel1?

Many marine fabricators struggle to understand what exactly makes ABS grade steel1 different from ordinary structural steel. This confusion can lead to using non-compliant materials that fail classification society surveys.

ABS grade steel1 is marine structural steel2 certified by the American Bureau of Shipping for shipbuilding applications. It comes in normal strength grades (A, B, D, E) and high strength grades (AH32-DH40) with specific chemical composition, mechanical properties, and testing requirements that ensure reliability in marine environments.

Comprehensive Understanding of ABS Grade Steel Specifications

ABS grade steel1 represents a comprehensive quality system rather than just material specifications. The certification process ensures every production batch meets strict marine service requirements.

The grading system follows a logical pattern that indicates both strength and toughness properties. Normal strength grades A through E all have 235 MPa minimum yield strength3 but different impact toughness requirements. Grade A has no specified impact testing, while Grade E requires Charpy V-notch testing at -40°C for Arctic service.

ABS Grade Steel Classification System:

| Grade Type | Grade Designation | Yield Strength (min) | Impact Test Temperature | Key Applications |

|---|---|---|---|---|

| Normal Strength | A | 235 MPa | Not required | Non-critical areas above waterline |

| Normal Strength | B | 235 MPa | 0°C | General hull structures |

| Normal Strength | D | 235 MPa | -20°C | Cold environment service |

| Normal Strength | E | 235 MPa | -40°C | Arctic vessel construction |

| High Strength | AH32-DH32 | 315 MPa | Varies by grade | Weight-critical structures |

| High Strength | AH36-DH36 | 355 MPa | Varies by grade | Main hull strength members |

| High Strength | AH40-DH40 | 390 MPa | Varies by grade | Special high-stress applications |

Chemical composition requirements are strictly controlled for weldability and toughness. Carbon content typically ranges between 0.16-0.18% depending on thickness and strength grade. Manganese content varies from 0.90-1.60% to achieve desired strength without compromising toughness. Silicon, phosphorus, and sulfur limits ensure consistent quality.

Manufacturing process controls distinguish ABS steel from ordinary structural steel. ABS-approved mills must follow specific procedures for steel making, rolling, and heat treatment. Each production batch undergoes rigorous testing including tensile tests, impact tests, bend tests, and often ultrasonic examination.

Certification and documentation provide traceability from mill to final application. ABS surveyors witness production and testing, then issue material certificates for each plate or section. This documentation must accompany the steel throughout fabrication and is reviewed during vessel construction surveys.

What is bulb flat1?

Many marine engineers initially confuse bulb flat1s with other steel sections, leading to design errors and structural inefficiencies. Understanding the unique properties of bulb flat1s optimizes marine structure design.

A bulb flat1 is a steel section with a flat web and a bulb-like protrusion at one edge, designed to provide maximum section modulus2 with minimal weight. It serves as an efficient stiffener in ship hulls, decks, and bulkheads where standard flat bars lack sufficient stiffness for marine structural requirements.

Detailed Analysis of Bulb Flat Steel Characteristics and Advantages

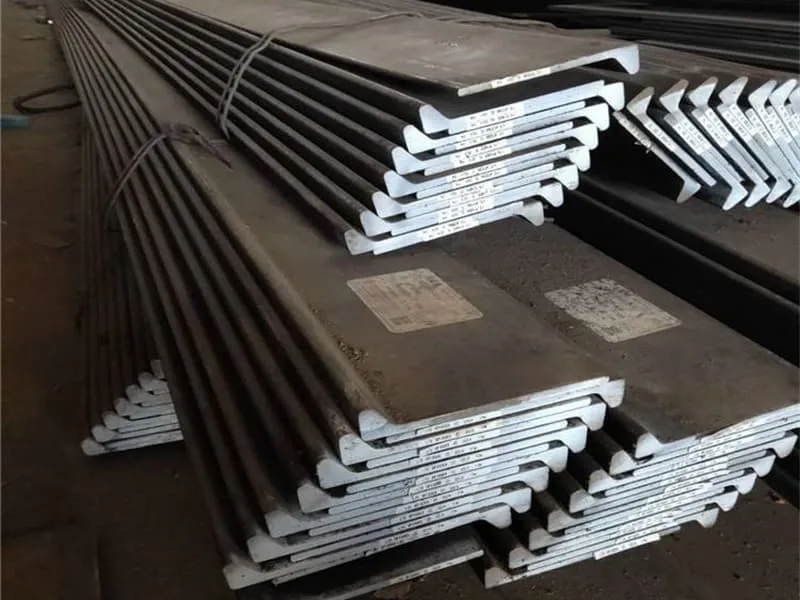

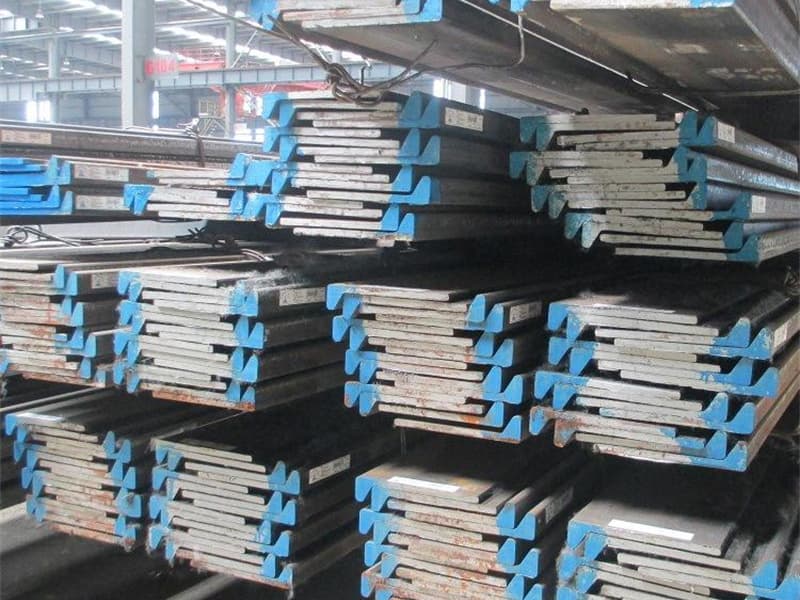

Bulb flats offer unique structural advantages that make them indispensable in shipbuilding and offshore construction. Their distinctive shape provides optimal material distribution for marine applications.

The geometric configuration maximizes bending resistance efficiently. The flat web facilitates connection to plates, while the bulb adds material where stress is highest during bending. This creates a section that outperforms flat bars of equivalent weight by 30-50% in bending stiffness3.

Bulb Flat Standard Size Ranges:

| Series | Web Height (mm) | Web Thickness (mm) | Bulb Width (mm) | Bulb Thickness (mm) | Section Modulus (cm³) |

|---|---|---|---|---|---|

| Small | 80-120 | 6-8 | 18-22 | 10-12 | 15-35 |

| Medium | 130-200 | 7-10 | 22-26 | 11-14 | 40-120 |

| Large | 210-300 | 9-14 | 26-32 | 13-18 | 130-280 |

| Extra Large | 310-430 | 12-18 | 32-40 | 16-22 | 300-600 |

Manufacturing processes for bulb flat1s involve specialized rolling mills. The sections are hot-rolled from continuous cast billets in dedicated rolling stands that form the bulb profile. Tolerances for straightness, twist, and dimensions are stricter than for general structural sections.

Structural efficiency drives bulb flat1 selection in marine applications. The high section modulus2-to-weight ratio reduces steel weight4 in vessels, increasing payload capacity. The symmetrical shape provides consistent behavior under load from different directions.

Connection details and fabrication considerations favor bulb flat1s in shipbuilding. The flat web simplifies welding to hull plating compared to angled sections. Standard sizes ensure material availability, while the consistent profile facilitates automated cutting and welding processes.

What are the three types of steel bars?

Project planners often specify the wrong type of steel bars for marine applications1, resulting in compatibility issues and performance limitations. Understanding bar classifications prevents these mismatches.

The three primary types of steel bars are reinforcing bars (rebar)2, merchant bars3, and special quality bars4. Each category serves different purposes with distinct manufacturing standards, mechanical properties, and application ranges in marine and construction projects.

Comprehensive Classification of Steel Bars and Their Marine Applications

Steel bars encompass diverse product forms with specific characteristics suited to different structural functions. Proper selection requires understanding these fundamental categories.

Reinforcing bars (rebar) provide tensile strength in concrete structures. They feature surface deformations for better bond with concrete and are produced to ASTM A615, A706, or equivalent standards. Grades 40, 60, and 75 indicate minimum yield strength in ksi, with higher grades offering better strength but reduced ductility.

Steel Bar Type Specifications and Uses:

| Bar Type | Common Standards | Surface Features | Typical Sizes | Primary Applications |

|---|---|---|---|---|

| Reinforcing Bars | ASTM A615, A706 | Deformed surface | #3-#18 (10-57mm) | Concrete reinforcement, foundations |

| Merchant Bars | ASTM A36, A529 | Plain or deformed | 1/4"-3" (6-76mm) | General construction, fabrication |

| Special Quality | ASTM A479, A564 | Various finishes | 1/8"-6" (3-150mm) | Marine fittings, fasteners, machinery |

| Cold Finished | ASTM A108 | Smooth surface | 1/4"-6" (6-150mm) | Shafting, precision components |

| Alloy Steel | ASTM A322 | Plain | 1/4"-4" (6-100mm) | High strength applications |

Merchant bars serve general construction and fabrication purposes. This category includes rounds, squares, flats, and angles produced to commercial quality standards like ASTM A36. These bars have broader chemical ranges and fewer testing requirements than special quality bars4.

Special quality bars meet specific property requirements for demanding applications. They include stainless steel bars for corrosion resistance, alloy steel bars for high strength, and leaded steel bars for improved machinability. Marine applications often require special quality bars4 with enhanced corrosion resistance.

Manufacturing processes significantly influence bar properties. Hot-rolled bars retain mill scale and have normalized properties. Cold-finished bars undergo additional processing for improved surface finish and dimensional accuracy. Heat-treated bars achieve specific mechanical properties through quenching and tempering.

Marine applications demand careful bar selection based on environment and function. Stainless steel bars (316/L) resist saltwater corrosion in fittings and fasteners. High-strength alloy bars serve in critical machinery components. Carbon steel bars require protective coatings when used in marine atmospheres.

What are the 4 types of light bulbs?

This question seems unrelated to steel products but actually reveals a common search confusion between structural bulbs and lighting bulbs1. Understanding this distinction helps clarify technical communications in marine projects.

The four main types of light bulbs are incandescent, fluorescent, LED, and halogen, but this question often arises from confusion with structural bulb flats2. In marine construction, "bulb" refers to the bulb-like protrusion3 in bulb flat steel sections, not lighting components.

Clarifying Terminology: Structural Bulbs Versus Lighting Bulbs in Marine Context

The term "bulb" creates frequent confusion between structural engineering and general lighting contexts. This clarification prevents misunderstandings in project specifications and procurement.

Structural bulb flats feature a bulb-like protrusion3 at one edge of a flat web. This bulb increases the section modulus efficiently, making these sections ideal for stiffening ship hulls and decks. The term describes a steel profile, not a lighting device.

Terminology Comparison Table:

| Context | "Bulb" Meaning | Key Characteristics | Typical Applications | Relevant Standards |

|---|---|---|---|---|

| Structural Engineering | Bulb flat section | Steel profile with bulb edge | Ship stiffeners, construction | ABS, LR, DNV rules |

| Lighting | Light bulb | Glass envelope with filament/LED | Illumination | Electrical safety standards |

| Architecture | Bulbous design | Rounded structural elements | Decorative features | Building codes |

| Piping | Bulb valves | Valve with bulb-shaped body | Fluid control | ASME standards |

Lighting bulbs serve entirely different functions as illumination devices. Incandescent bulbs use a heated filament, fluorescent bulbs use gas discharge, LED bulbs use light-emitting diodes, and halogen bulbs use a tungsten filament in halogen gas. These have no relation to structural steel sections.

The confusion arises from similar terminology in different technical fields. Project documents must specify "bulb flat steel" clearly to distinguish from lighting components. This prevents procurement errors and ensures correct material delivery.

Technical communication best practices help avoid this confusion. Engineers should use complete terms like "bulb flat steel sections" in specifications. Procurement departments should verify material codes against project requirements. Suppliers should confirm order details when terminology appears ambiguous.

In marine projects, context usually clarifies the meaning. Structural discussions naturally refer to bulb flats, while electrical discussions refer to lighting. However, interdisciplinary meetings require careful terminology to prevent misunderstandings between different technical teams.

Conclusion

Understanding ABS vs LR certification differences ensures proper bulb flat steel selection for your specific marine projects. Correct terminology usage prevents procurement errors and project delays.

-

Discover the various types of lighting bulbs and their applications in this informative resource. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand how structural bulb flats enhance ship design and construction. ↩ ↩ ↩ ↩ ↩

-

Learn about the significance of bulb-like protrusions in improving structural integrity in marine projects. ↩ ↩ ↩ ↩ ↩

-

Discover how special quality bars meet specific requirements for demanding marine environments. ↩ ↩ ↩ ↩