A shipyard in Saudi Arabia recently asked me to explain bulb flat steel standards. Their project required specific grade compliance for classification approval.

Bulb flat steel commonly uses AH32, AH36, DH32, and DH36 marine grades following international standards like JIS G3194, DIN 59377, and classification society rules. These grades provide 315-355 MPa yield strength with varying toughness levels for different service temperatures and structural applications in shipbuilding.

Understanding bulb flat steel specifications ensures proper material selection. Let me break down the common grades and their applications.

What is the standard steel grade in the UK?

A contractor from Qatar needed UK-compliant materials for a vessel destined for European waters. The standards differed from their usual specifications.

The UK primarily follows European standards with BS EN 10025 for structural steels and specific marine grades equivalent to AH36/DH36. Common UK designations include S355 grades, with marine applications requiring additional certification from classification societies like Lloyd’s Register for shipbuilding compliance.

UK Steel Standard Framework

The UK steel standardization system combines European norms with specific British requirements, particularly for marine applications where safety is paramount.

BS EN 10025 Series Standards

The UK adopts the European EN 10025 standard for hot rolled products. S235, S275, and S355 represent the main non-alloy steel grades. The numbering indicates minimum yield strength in MPa. JR, J0, J2, and K2 suffixes denote impact toughness temperatures. These grades form the basis for general construction applications.

Marine Grade Equivalents

UK marine standards align with international practices. S355G2+N corresponds to AH32 marine grade. S355G3+N matches AH36 requirements. S355G4+N provides DH32 equivalent properties. S355G5+N offers DH36 level performance. The +N indicates normalizing rolling for enhanced properties.

Lloyd’s Register Requirements

As the UK’s primary classification society, LR sets additional requirements. LR Grade AH32 requires 315 MPa yield strength. LR Grade AH36 demands 355 MPa minimum yield. Impact testing temperatures vary by grade designation. Additional testing may include through-thickness properties. LR approval is mandatory for UK-flagged vessels.

Chemical Composition Specifications

UK standards maintain strict chemical controls. Carbon content typically ranges from 0.16% to 0.18%. Manganese levels vary from 0.90% to 1.60% depending on grade. Silicon is controlled below 0.50% for deoxidation. Sulfur and phosphorus limits ensure good weldability and toughness.

Testing and Certification

UK standards require comprehensive testing. Tensile tests verify mechanical properties. Impact tests confirm toughness characteristics. Bend tests assess ductility and soundness. Non-destructive testing may be specified. All testing follows BS EN ISO standards for consistency.

UK Standard Grade Comparison

| UK Designation | Equivalent Grade | Yield Strength (MPa) | Impact Test Temperature |

|---|---|---|---|

| S355G2+N | AH32 | 315 | +20°C |

| S355G3+N | AH36 | 355 | 0°C |

| S355G4+N | DH32 | 315 | -20°C |

| S355G5+N | DH36 | 355 | -20°C |

| S355G6+N | EH36 | 355 | -40°C |

We supply UK-compliant materials to clients serving European markets. Their vessels meet both regulatory and classification requirements seamlessly.

What are the different grades of steel plate?

A naval architect from Mexico needed to understand grade variations for optimal material selection in their new vessel design.

Steel plate grades include structural grades (A36, S235, S275), marine grades (AH32, AH36, DH36, EH36), higher-strength grades (AH40, DH40), and special grades with enhanced properties. Each grade offers specific yield strength, toughness characteristics, and chemical composition for different applications and service conditions.

Comprehensive Steel Grade Classification

Steel plate grades are systematically organized by strength, toughness, and application requirements. Understanding this classification helps in proper material specification.

Structural Steel Grades

General structural steels serve non-marine applications. A36 (USA) offers 250 MPa yield strength. S235 (Europe) provides 235 MPa minimum yield. S275 grades deliver 275 MPa yield strength. These grades have basic impact requirements. They work for buildings, bridges, and general fabrication.

Standard Marine Grades

Marine grades form the core of shipbuilding materials. AH32 provides 315 MPa yield strength with 0°C impact testing. AH36 offers 355 MPa yield strength also with 0°C impact requirements. These grades serve most commercial vessel applications in temperate waters.

Enhanced Toughness Marine Grades

Cold-temperature grades handle harsh environments. DH32 maintains 315 MPa strength with -20°C impact testing. DH36 provides 355 MPa strength with same -20°C toughness. EH36 offers 355 MPa strength with -40°C impact resistance for arctic operations.

Higher Strength Grades

Advanced grades reduce structural weight. AH40 and DH40 provide 390 MPa yield strength. EH40 maintains this strength with -40°C toughness. These grades allow thinner sections and weight savings. The applications include weight-critical vessel areas.

Special Property Grades

Specialized grades address specific needs. Z-quality steels offer improved through-thickness properties. Corrosion-resistant grades contain additional alloying elements. Fire-resistant steels maintain strength at elevated temperatures. Each special grade serves particular application challenges.

Chemical Composition Variations

Grade differences stem from composition controls. Carbon content affects strength and weldability. Manganese enhances strength and toughness. Micro-alloying elements refine grain structure. Impurity controls ensure consistent performance. The composition determines the grade capabilities.

Steel Grade Application Matrix

| Grade Category | Common Grades | Yield Strength Range | Primary Applications |

|---|---|---|---|

| Structural | A36, S235, S275 | 235-275 MPa | Buildings, general fabrication |

| Standard Marine | AH32, AH36 | 315-355 MPa | Commercial vessels |

| Enhanced Toughness | DH32, DH36, EH36 | 315-355 MPa | Cold environment vessels |

| Higher Strength | AH40, DH40, EH40 | 390 MPa | Weight-critical structures |

| Special Grades | Various | Varies | Specific applications |

We help clients in Philippines and Vietnam select appropriate grades. Their projects achieve optimal balance between performance and cost.

What is the HS code for bulb flat steel?

An importer from Saudi Arabia needed correct HS codes for customs clearance. Using wrong codes caused delays in their previous shipments.

Bulb flat steel typically falls under HS code 7216.50 as "other angles, shapes, and sections" of iron or non-alloy steel. However, specific applications may use 7301.10 for sheet piling or 8906.00 for ship and boat parts, depending on the product’s exact specifications and intended use in final assembly.

HS Code Classification System

The Harmonized System provides standardized classification for international trade. Proper HS code assignment ensures smooth customs processing and correct duty assessment.

HS Code Structure Understanding

The HS code system uses six-digit codes globally. Chapters 72-83 cover base metals and articles. Chapter 72 addresses iron and steel products. The first two digits indicate the chapter. The next two specify the heading. The final two define the subheading. Countries may add additional digits for national requirements.

Primary Classification Options

HS 7216 covers angles, shapes, and sections. 7216.50 specifies "other angles, shapes, and sections." This category typically includes bulb flats. The classification applies to products not elsewhere specified. The steel must be iron or non-alloy type.

Alternative Classifications

Specific applications may use different codes. HS 7301 covers sheet piling and welded sections. This may apply to certain bulb flat applications. HS 8906 addresses ship and boat parts. Finished components might use this classification. The choice depends on product form and intended use.

Material Composition Considerations

Alloy steel bulb flats use different codes. HS 7228 covers other alloy steel angles and shapes. The classification changes with alloy content. The specific alloy elements affect code selection. Proper chemical analysis determines the correct classification.

Country-Specific Variations

Many countries add national subdivisions. The US uses HTSUS with 10-digit codes. China employs 13-digit codes for detailed classification. The EU uses the Combined Nomenclature system. Importers must verify destination country requirements. Using wrong codes causes customs delays.

Documentation Requirements

Proper classification requires complete documentation. Commercial invoices must describe products accurately. Certificates of origin confirm material source. Technical specifications help customs officers verify classification. Incorrect descriptions lead to misclassification and penalties.

HS Code Classification Guide

| Product Description | HS Code | Chapter/Heading | Notes |

|---|---|---|---|

| Bulb Flat Steel | 7216.50 | 72/16 | Most common classification |

| Alloy Steel Bulb Flat | 7228.70 | 72/28 | For alloy steel types |

| Ship Sections | 7301.10 | 73/01 | For specific ship applications |

| Finished Components | 8906.00 | 89/06 | For assembled ship parts |

| Sheet Piling | 7301.10 | 73/01 | When used as piling |

We provide correct HS code guidance to all international clients. Their shipments clear customs efficiently with proper documentation.

What are the standard sizes of flat bars?

A fabricator from Thailand needed standard flat bar sizes for structural calculations. Understanding available dimensions optimized their design.

Standard flat bars are available in widths from 20mm to 300mm and thicknesses from 3mm to 50mm, with common sizes including 50x6mm, 75x10mm, 100x12mm, and 150x16mm. Lengths typically range from 6 to 12 meters, with tolerances following international standards like ASTM A36, JIS G3194, or DIN 59377 for bulb flat variations.

Comprehensive Size Specifications

Flat bar sizes follow established standards that ensure interoperability and availability. Understanding these standards helps in material planning and design optimization.

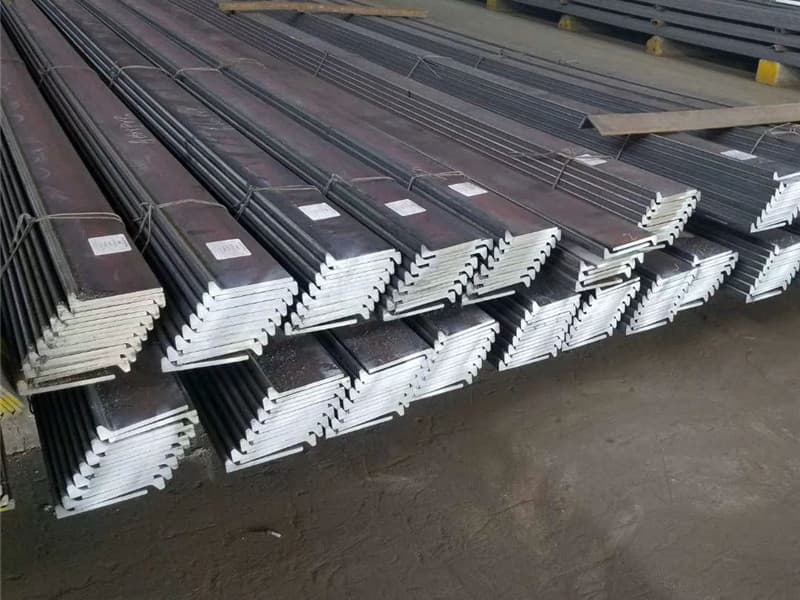

Width and Thickness Combinations

Standard sizes follow predictable patterns. Width increments typically increase by 5mm or 10mm. Common widths include 20, 25, 30, 40, 50, 60, 65, 75, 80, 100, 120, 150, 200, 250, and 300mm. Thickness progressions usually follow 3, 4, 5, 6, 8, 10, 12, 16, 20, 25, 30, 40, and 50mm. These combinations ensure wide availability.

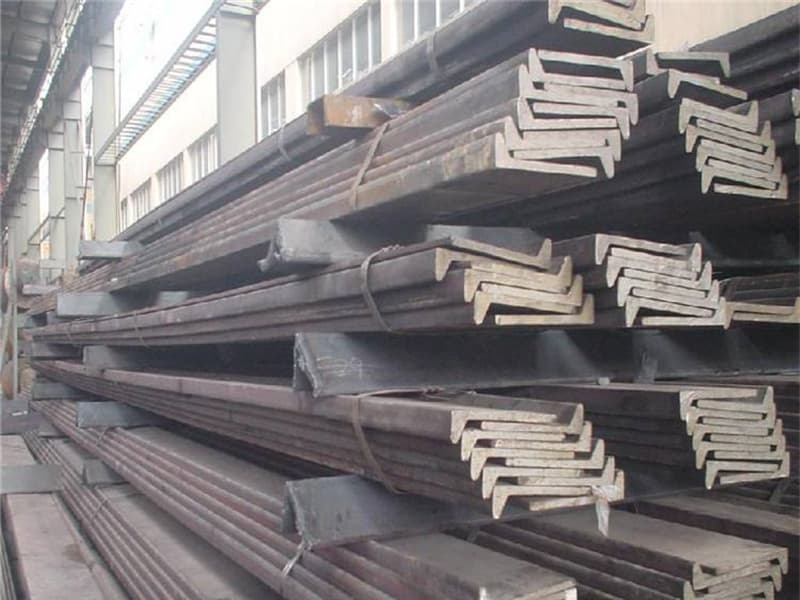

Bulb Flat Specific Dimensions

Bulb flats have additional dimensional parameters. The bulb size varies with the flat dimensions. Standard bulb heights range from 10mm to 35mm. Bulb thickness typically matches the web thickness. The total height includes both web and bulb dimensions. These parameters affect the section modulus significantly.

Length Standards and Tolerances

Standard lengths facilitate transportation and handling. 6 meters serves as the most common length. 9 meters and 12 meters are also widely available. Length tolerances typically allow ±100mm variation. Custom lengths are possible but may incur additional costs. The length selection affects material utilization.

Weight Calculations

Standard sizes enable accurate weight estimation. Weight per meter depends on width and thickness. For example, 100x12mm flat bar weighs approximately 9.42 kg/m. Bulb flats have higher weight due to the additional bulb mass. Weight calculations help in logistics planning and cost estimation.

Tolerance Standards

International standards define dimensional tolerances. Width tolerances typically range from ±1mm to ±3mm. Thickness tolerances vary from ±0.3mm to ±1.0mm. Straightness tolerances ensure fabrication suitability. The tolerance class affects both cost and application suitability.

Regional Size Variations

Different regions may prefer specific size ranges. European standards follow metric dimensions precisely. American standards may use inch-based sizing. Asian standards often mirror European practices. Understanding regional preferences helps in material sourcing.

Common Flat Bar Size Ranges

| Size Category | Width Range | Thickness Range | Typical Applications |

|---|---|---|---|

| Small Sections | 20-50mm | 3-10mm | Light fabrication, brackets |

| Medium Sections | 55-100mm | 6-16mm | Structural framing, supports |

| Large Sections | 105-200mm | 10-25mm | Heavy construction, beams |

| Extra Large | 205-300mm | 16-50mm | Special applications, bases |

| Bulb Flats | 100-400mm | 8-30mm | Shipbuilding, stiffeners |

We maintain comprehensive size inventories for client needs. Projects in Malaysia and Romania benefit from standard size availability and quick delivery.

Conclusion

Understanding bulb flat steel grades and standards ensures proper material selection and regulatory compliance. Standard sizes and correct classification support efficient procurement and fabrication.