A shipyard in Saudi Arabia recently received bulb flat steel with surface defects. This experience reinforced the importance of thorough pre-shipment quality verification.

Bulb flat steel quality verification involves checking mill certificates, conducting visual inspection, performing dimensional measurement, arranging third-party testing, and verifying surface preparation. These steps ensure the material meets specification requirements and classification society standards before shipment to prevent fabrication issues.

Quality verification prevents costly problems during ship construction. Let me guide you through the essential checks that ensure material reliability.

How to check good quality steel1?

A contractor from Qatar developed a systematic quality checking procedure after receiving substandard materials. Their method became their standard practice.

Good quality steel shows uniform surface texture, precise dimensions, proper markings, complete documentation, and consistent mechanical properties. Verification involves checking mill certificates, conducting visual inspection, measuring dimensions, and verifying chemical composition meets specified grade requirements for marine applications.

Comprehensive Quality Assessment Methods

Checking steel quality requires a systematic approach that covers multiple aspects. Each verification method provides different information about the material’s condition and properties.

Documentation Review Process2

Start with thorough document examination. Check mill test certificates for completeness and accuracy. Verify the certificates include chemical analysis and mechanical test results. Confirm classification society approval stamps are present and valid. Ensure heat numbers match between documents and material markings. Review any third-party inspection reports if available.

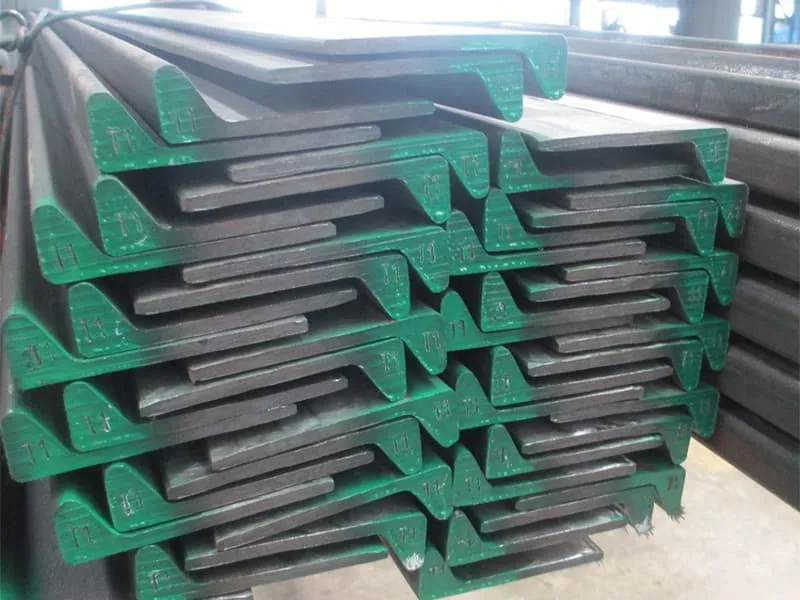

Visual Inspection Standards3

Conduct detailed visual examination of the steel surface. Look for uniform color and texture across all pieces. Check for surface defects like cracks, pits, or laminations. Examine edges for straightness and proper conditioning. Verify surface preparation meets specified standards. Identify any rust, scale, or contamination that might affect performance.

Dimensional Verification4

Measure critical dimensions using calibrated tools. Check thickness at multiple points along the length. Verify width and height dimensions meet specified tolerances. Measure straightness using precision straightedges. Confirm length matches ordered specifications. Check cross-sectional dimensions for consistency.

Surface Quality Assessment5

Evaluate surface condition against requirements. For shot blasted surfaces, verify cleanliness and profile depth. Check painted surfaces for uniform coverage and adhesion. Verify any special surface treatments meet specifications. Look for handling damage or transportation marks. Ensure protective coatings are intact and undamaged.

Marking and Identification Check

Verify all required markings are present and legible. Check grade designations match purchase order requirements. Confirm heat numbers provide proper traceability. Look for manufacturer identification and logos. Verify classification society marks if required. Ensure markings are permanent and correctly located.

Sample Testing Arrangement6

Arrange for representative sample testing when needed. Select samples from different locations in the shipment. Conduct chemical analysis to verify composition. Perform mechanical tests to confirm properties. Check non-destructive testing results if specified. Compare test results with certificate values.

Quality Verification Checklist

| Check Category | Specific Items | Tools Required | Acceptance Criteria |

|---|---|---|---|

| Documentation | Mill certificates, approvals | Visual review | Complete and accurate |

| Visual | Surface defects, color | Good lighting, magnifier | No major defects |

| Dimensional | Thickness, width, length | Calipers, tape measure | Within tolerance |

| Marking | Grade, heat number | Visual inspection | Clear and correct |

| Surface | Preparation, coating | Profile gauge, visual | Meets specification |

We implement these quality checks for all shipments. Clients in Vietnam and Philippines receive materials that meet their exact requirements.

What does it mean to test the quality of parts before shipment?

A shipowner from Mexico asked about pre-shipment testing1 importance. Understanding the process helped them establish their own quality standards.

Testing quality before shipment means verifying materials meet all specified requirements through inspection, measurement, and testing procedures. This ensures the products will perform as expected in their intended applications and prevents problems during subsequent fabrication, assembly, or service use.

Pre-Shipment Quality Assurance Process

Pre-shipment quality testing represents the final verification before materials leave the supplier. This process ensures customers receive products that meet their expectations and requirements.

Purpose and Objectives

The primary purpose is defect prevention2 and quality assurance3. Testing identifies any non-conforming materials4 before shipment. It verifies that products meet all specified requirements. The process provides documented evidence of quality compliance. It builds customer confidence in the supplied materials. Ultimately, it prevents costly problems at the customer’s facility.

Testing Scope and Coverage

Quality testing covers multiple aspects of the product. It includes dimensional accuracy and geometrical properties. The testing verifies mechanical properties meet specifications. Chemical composition is checked against grade requirements. Surface condition and preparation are assessed. Documentation completeness and accuracy are verified.

Testing Methods and Procedures

Different testing methods serve different purposes. Destructive testing uses samples to verify properties. Non-destructive testing examines materials without damage. Visual inspection assesses surface and apparent quality. Measurement checks dimensional compliance. Documentation review verifies paperwork accuracy.

Sampling Plans and Statistics

Testing typically uses statistical sampling approaches. The sample size depends on lot size and criticality. Random sampling ensures representative selection. Acceptance criteria define pass/fail boundaries. Sampling plans balance cost and risk effectively. Proper sampling provides reliable quality assessment.

Documentation and Record Keeping

Comprehensive documentation supports the testing process. Test reports detail methods and results. Certificates provide official quality statements. Inspection records document visual assessments. Measurement records show dimensional compliance. These documents provide quality evidence and traceability.

Problem Identification and Resolution

The process includes handling non-conformances. Identified problems trigger investigation procedures. Root cause analysis determines problem sources. Corrective actions address immediate issues. Preventive actions avoid future occurrences. The resolution process ensures continuous improvement.

Pre-Shipment Testing Benefits

| Benefit | Description | Impact |

|---|---|---|

| Defect Prevention | Identifies problems before shipment | Reduces customer complaints |

| Compliance Assurance | Verifies specification compliance | Ensures regulatory acceptance |

| Cost Reduction | Prevents rework and returns | Lowers total cost of ownership |

| Customer Confidence | Provides quality evidence | Builds trust and relationships |

| Process Improvement | Identifies improvement opportunities | Enhances supplier capabilities |

We conduct comprehensive pre-shipment testing1 for all orders. Our clients appreciate the quality assurance3 and problem prevention.

How to check the grade of steel?

A fabricator from Romania received mislabeled steel that caused welding problems. Implementing proper grade verification prevented recurrence.

Steel grade verification involves checking permanent markings, reviewing mill certificates, performing spark testing, conducting chemical analysis, and verifying mechanical properties. Positive Material Identification using portable XRF analyzers provides quick and accurate grade confirmation for critical applications like shipbuilding.

Comprehensive Grade Identification Techniques

Verifying steel grade ensures the material matches specified requirements for the application. Multiple methods provide different levels of certainty and serve different purposes.

Marking and Documentation Review

Start with the simplest verification methods. Check permanent grade markings stamped on the steel. Verify the markings match purchase order requirements. Review mill test certificates for grade designation. Confirm heat numbers provide traceability to production records. This method provides initial grade confirmation.

Spark Testing Method

Spark testing offers quick field identification. The method involves grinding the steel and observing spark patterns. Carbon steel produces straight streams with few branches. Alloy steels create more complex patterns with multiple branches. Stainless steel shows short, straw-colored sparks. Experienced operators can distinguish between major steel types.

Chemical Analysis Verification

Laboratory analysis provides definitive grade identification. Spectrochemical analysis measures elemental composition accurately. The results are compared against grade specification limits. This method confirms the presence and concentration of alloying elements. It also checks for undesirable elements that might affect performance. Laboratory analysis offers the highest accuracy.

Positive Material Identification

Portable XRF analyzers enable rapid grade verification. These devices measure elemental composition without damaging the material. The results instantly show whether the steel matches the specified grade. PMI testing can screen entire shipments quickly. It provides reliable results for most common steel grades. This method has become standard practice in quality assurance.

Mechanical Property Testing

Tensile testing verifies mechanical properties associated with the grade. Yield strength, tensile strength, and elongation must meet requirements. Impact testing confirms toughness characteristics. Hardness testing provides additional property verification. These tests ensure the steel performs as expected for its grade designation.

Microstructural Examination

Metallographic examination reveals the steel’s internal structure. The microstructure should match expectations for the grade. Grain size and distribution affect mechanical properties. Phase composition determines performance characteristics. Inclusions and imperfections indicate quality issues. This method requires specialized equipment and expertise.

Grade Verification Method Comparison

| Method | Accuracy | Speed | Cost | Skill Required |

|---|---|---|---|---|

| Marking Check | High | Very Fast | Low | Low |

| Documentation | High | Fast | Low | Medium |

| Spark Test | Low | Fast | Low | High |

| Chemical Lab | Very High | Slow | High | Medium |

| PMI XRF | High | Fast | Medium | Medium |

| Mechanical Test | High | Slow | High | High |

We use appropriate verification methods based on application criticality. Clients receive confirmed grade materials for their projects.

What is the quality test of steel?

A quality manager from Saudi Arabia needed to establish comprehensive testing procedures. Systematic testing improved their material acceptance standards.

Steel quality testing includes chemical analysis, mechanical property verification, dimensional inspection, surface quality assessment, and non-destructive examination. These tests ensure the material meets specified requirements for composition, strength, dimensions, and surface condition according to applicable standards and specifications.

Comprehensive Steel Testing Methodology

Steel quality testing involves multiple procedures that verify different aspects of material properties and characteristics. Each test serves specific purposes in the overall quality assessment.

Chemical Composition Analysis

Chemical analysis determines the elemental composition of the steel. Spectrometry provides rapid and accurate element measurement. Traditional wet chemistry offers alternative verification methods. The analysis checks major elements like carbon, manganese, and silicon. It also verifies trace elements and impurities. The results must fall within specified ranges for the grade.

Mechanical Property Testing

Mechanical testing verifies strength and ductility characteristics. Tensile testing measures yield strength, tensile strength, and elongation. Impact testing determines toughness at specified temperatures. Hardness testing assesses resistance to indentation. Bend testing evaluates ductility and soundness. The tests confirm the steel can withstand service loads.

Dimensional and Geometrical Inspection

Dimensional checks verify size and shape compliance. Thickness, width, and length measurements use calibrated tools. Straightness and flatness assessments ensure geometrical accuracy. Cross-sectional dimensions are verified against specifications. Tolerances are checked against applicable standards. Proper dimensions ensure fit and function in assembly.

Surface Quality Examination

Surface inspection assesses condition and preparation. Visual examination identifies defects like cracks and pits. Surface roughness measurements quantify texture characteristics. Coating thickness verification ensures proper protection. Surface cleanliness checks remove contaminants. Proper surface condition supports performance and durability.

Non-Destructive Testing

NDT methods examine materials without causing damage. Ultrasonic testing detects internal flaws and imperfections. Magnetic particle inspection finds surface cracks in ferromagnetic materials. Dye penetrant testing reveals surface defects in all materials. Radiographic testing provides internal structure images. These methods ensure material integrity without destruction.

Metallurgical Examination

Metallurgical tests examine internal structure and properties. Macroscopic examination assesses overall structure and defects. Microscopic analysis evaluates grain size and distribution. Inclusion content determination checks cleanliness. Phase identification confirms heat treatment results. These tests provide deep understanding of material characteristics.

Steel Quality Test Overview

| Test Category | Specific Tests | Standards | Purpose |

|---|---|---|---|

| Chemical | Spectrometry, wet chemistry | ASTM A751 | Verify composition |

| Mechanical | Tensile, impact, hardness | ASTM A370 | Confirm strength properties |

| Dimensional | Measurement, straightness | ASTM A6 | Ensure size compliance |

| Surface | Visual, roughness, coating | Various | Assess condition |

| Non-Destructive | UT, MPI, DPT | ASTM E165, E709 | Detect flaws |

| Metallurgical | Macroscopic, microscopic | ASTM E3, E45 | Examine structure |

We conduct appropriate testing based on application requirements. Our clients receive fully verified materials for their critical applications.

Conclusion

Thorough quality verification before shipment ensures bulb flat steel meets all requirements and performs reliably in shipbuilding applications. Systematic testing prevents problems and supports successful project outcomes.

-

Explore this link to understand the significance of pre-shipment testing in ensuring product quality and compliance. ↩ ↩ ↩

-

Learn about defect prevention strategies that can save costs and enhance product reliability. ↩ ↩

-

Discover best practices in quality assurance that can help improve your manufacturing processes. ↩ ↩ ↩

-

Understand the steps to take when dealing with non-conforming materials to maintain quality standards. ↩ ↩

-

Understanding surface quality assessment can help you evaluate the steel’s performance and longevity. ↩

-

Knowing how sample testing is arranged can provide insights into the reliability of the steel’s quality. ↩