Shipping marine steel is not easy. I have seen many projects delayed and budgets broken because of bad shipping practices. You need to plan every step to avoid damage and extra cost. This article will show you the best way to do it.

To transport marine angle steel safely by sea, you must focus on correct packing, expert loading, and strong securing. Use specific methods for steel coils and angle bars. Follow international rules for cargo safety. Always check the ship is right for your steel to prevent accidents.

Getting your steel to the port is just the first step. The real test starts when loading begins. A small mistake here can cause big problems later. Let’s look at the details that make your shipment a success.

How do you transport heavy steel coils?

Picture a huge, heavy steel coil rolling on the deck. It can damage everything, including the ship itself. This is a real fear for any shipper. Preventing this movement is your most important job.

Transport heavy steel coils by placing them on strong wooden cradles or steel racks. Secure them with steel straps and chocks. Always load the coils with their axis running from one side of the ship to the other. This stops them from rolling during the voyage.

A Detailed Plan for Steel Coil Transport

Moving steel coils is a technical job. You cannot just put them in the hold. You need a clear plan. The plan covers the material, the position, and the securing method.

First, you must prepare the cargo hold. The deck must be clean, dry, and level. You often use dunnage. Dunnage is material like wood planks put under the cargo. It protects the steel from moisture and helps spread the weight.

The coil’s orientation is critical. The axis must be athwartships. This means it runs side-to-side across the ship. Why? Because a ship rolls from side to side much more than it pitches forward and back. A coil placed with its axis along the ship’s length could easily roll. Placing it athwartships uses the ship’s own structure to block any rolling movement.

Next, you need proper bedding. Coils are heavy. Their weight is concentrated in a small area. Without support, they can dent the deck or crush their own packaging. We use specially made wooden cradles or steel frames. These cradles hold the bottom curve of the coil securely.

Finally, you secure the coil. Steel lashings (straps or chains) are the standard. You attach these lashings to strong points on the ship’s structure called pad eyes. The lashings pull the coil down into its cradle. You also use chocks. Chocks are wedges placed next to the coil to prevent any side-to-side movement.

Here is a simple checklist for loading steel coils:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Hold Preparation | Clean and level the deck, lay dunnage. | Creates a flat, dry base and prevents corrosion. |

| 2. Coil Orientation | Position coil with axis athwartships (side-to-side). | Uses ship’s structure to resist rolling from waves. |

| 3. Bedding & Support | Place coil on a strong wooden or steel cradle. | Spreads the immense weight and prevents deformation. |

| 4. Securing | Apply steel lashings to pad eyes, add side chocks. | Prevents any lifting, rolling, or sliding movement. |

| 5. Final Check | Inspect all lashings and supports after first day at sea. | Ensures nothing has loosened as the ship moves. |

From my experience with clients like Gulf Metal Solutions, communication is key. Before loading, we always send detailed packing and securing plans. We ask for photos from the loading port. This gives the buyer confidence. It also helps avoid arguments later if damage occurs. A coil that is properly secured will arrive in perfect condition, ready for their project.

How to load steel coils on a ship?

You have the coils at the port. The ship is waiting. Now, the wrong crane operation can bend or scratch the steel. This ruins its value. A careful loading process protects your investment.

Load steel coils onto a ship using spreader beam1s attached to the crane. The spreader beam1s connect to the coil’s core. This lets you lift the coil evenly. Never lift a coil with slings around its body, as this can damage the steel and is very unsafe.

The Critical Lifting and Stowing Process

Loading is a ballet of heavy machinery. Every move must be precise. The goal is to transfer the coil from the truck to its final spot on the ship without a single scratch. This requires the right equipment and skilled workers.

The most important tool is the spreader beam1. This is a long, strong bar that hangs from the crane hook. Cables from the ends of the spreader beam1 go into the core of the steel coil. The coil is lifted by its inner diameter. This method is clean and safe. It puts no pressure on the outer layers of steel, which could deform them.

Sometimes, you see workers using slings. They wrap straps around the coil’s body. This is a bad practice. It squeezes the coil. It can damage the outer layers and change the coil’s shape. It is also less stable during the lift. A coil can slip from slings. We never allow this for our shipments.

Once lifted, the crane operator moves the coil slowly over the ship’s open hold. The signalman on deck guides the operator. They must lower the coil gently onto its prepared cradle. The coil should land exactly in the center of the cradle. Even a small misalignment can make securing it harder and less effective.

Stowage planning happens long before loading. The ship’s chief officer creates a cargo plan2. This plan shows where each coil will go. The heaviest coils usually go at the bottom. This keeps the ship’s center of gravity low, which makes the voyage safer. The plan also considers the port order. Coils for the last port of discharge should be loaded last, on top of the others.

We learned this the hard way early on. One time, coils were loaded in the wrong port order. The ship had to spend extra time and money rearranging cargo at an intermediate port. Now, we double-check the stowage plan with the shipping line and our customer. This avoids costly mistakes and delays.

What is the rule of thumb for cargo securing?

You see all the lashings and chains. They might look strong. But if they are not calculated correctly, they are just for show. A storm will test them. Your cargo securing must pass that test.

The rule of thumb for cargo securing is that the lashings must be strong enough to withstand forces equal to the full weight of the cargo. For most sea voyages, you must plan for forces that can push cargo sideways with a strength of up to 1.0 times its weight, and push it forward with a strength of up to 1.8 times its weight.

Beyond the Basics: Calculating Securing Forces

The "rule of thumb" gives you a simple idea. But real securing is based on physics and calculation. You are not just tying cargo down. You are building a system that fights the ship’s movement.

Forces at sea are measured as accelerations, often compared to gravity (g). A force of 1.0g sideways means the cargo is pushed as if it weighed twice its actual weight. The CSM (Cargo Securing Manual) for every ship provides the exact design accelerations for different areas of the ship. The bow area experiences the highest forces.

The securing system works through friction and direct restraint. First, friction between the cargo and the deck helps. You can increase friction with rubber mats or by using materials with a high friction coefficient. But friction alone is never enough. This is where lashings come in.

Lashings provide direct restraint. Their job is to take the remaining force that friction cannot handle. To calculate the needed lashing capacity, you use a formula. It considers the cargo weight, the angle of the lashing, the friction, and the expected acceleration force. The lashing must have a Minimum Breaking Strength (MBS) that is much higher than the calculated load. A safety factor is always applied.

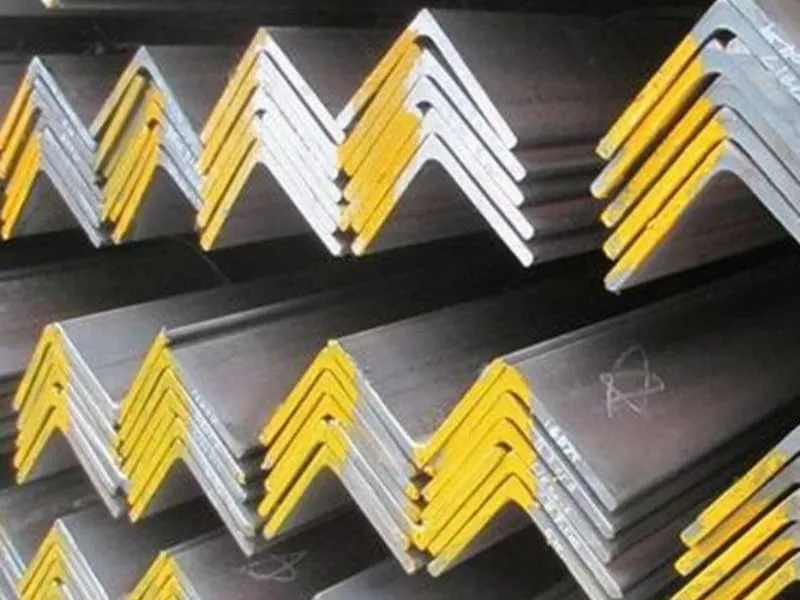

For marine angle steel, which is often bundled into lifts, the securing approach is different from coils. Angle bars are stacked and strapped together into a block. This block is then treated as a single unit. Lashings go over the top of the block and attach to the deck. You also use web lashings or nets to prevent individual bars from shifting upwards or sideways.

Here is a comparison of securing methods for two common products we supply:

| Cargo Type | Primary Risk | Key Securing Method | Special Consideration |

|---|---|---|---|

| Steel Coils | Rolling | Athwartships placement, steel lashings over the top, side chocks. | The lashing must pull the coil down into its cradle to increase friction. |

| Marine Angle Steel (Bundles) | Sliding & Sifting | Block stacking, top-over lashings, perimeter nets or web straps. | The entire bundle must be unitized tightly; loose bars can become dangerous projectiles. |

After the cargo is secured, the work is not done. The crew must do regular inspections, especially after the first day of rough weather. Lashings can loosen. Chocks can shift. A good practice is to re-tension the lashings 24 hours after departure. This is a service I always request from the shipping company for our clients. It gives everyone peace of mind.

What is the utmost concern when steel cargoes are carried in a bulk carrier?

Choosing the wrong ship is the biggest risk. A standard bulk carrier is designed for loose cargo like grain or coal. Steel is different. Its heavy weight and hard surface can stress the ship in dangerous ways.

The utmost concern is the ship’s structural strength1. Steel cargo is extremely heavy and dense. If it is not loaded correctly, the weight can overstress the ship’s frames and hull. Also, if steel cargo shift2s, it can make the ship list heavily or even capsize, which is a major safety disaster.

The Hidden Dangers of Ship Structure and Cargo Shift

Many people think any big ship can carry steel. This is not true. The ship must be prepared, and the loading must follow a strict pattern to keep the ship safe and stable.

The first danger is point loading3. Imagine placing a heavy steel coil on a thin wooden floor. The floor might break. The same can happen to a ship. A ship’s hold has transverse frames for strength. If you place a heavy coil directly between these frames, the local deck plate might bend or crack. The solution is to always place heavy items like coils directly on top of these strong frames or over multiple frames using thick dunnage.

The second, more frightening danger is cargo shift2. Loose steel plates, angles, or pipes can slide. In a bulk carrier, if a large mass of steel slides to one side, the ship will tilt. This is called a list. A severe list can prevent the ship from righting itself. It can lead to flooding and sinking. The 2015 loss of the bulk carrier Bulk Jupiter, which was carrying steel coils, is a tragic example studied by the industry.

To prevent this, the loading must be trimmed4. Trimming means leveling the cargo so it fills all spaces and cannot move. For general steel products, you stow them tightly together, block by block, leaving no gaps. You use lashings, chains, and sometimes even wooden structures to lock everything in place.

Another critical factor is the ship’s stability calculations5. The ship’s officers must calculate the ship’s center of gravity after loading. Steel is so heavy that it dramatically affects this calculation. If too much weight is placed high up, the ship becomes "tender" – it will roll quickly and dangerously. If weight is too low, it becomes "stiff" – the rolls are very fast and harsh, which can also damage the ship and cargo. The goal is a stable, comfortable vessel.

This is why we are careful about who we work with. We prefer reputable shipping lines6 that have experience with steel. For our client in Saudi Arabia, Gulf Metal Solutions, we arranged shipment on a dedicated heavy-lift carrier for their first order. The cost was slightly higher, but the safety and reliability were worth it. Their feedback confirmed that the cargo arrived in perfect condition, with no issues from the voyage. Trust in the carrier is as important as trust in the steel supplier.

Conclusion

Safe sea transport for marine steel needs careful planning, correct methods, and a strong ship. Focus on proper packing, expert loading, and strict securing rules to protect your cargo and ensure a smooth delivery.

-

Understanding a ship’s structural strength is crucial for safe steel transport, preventing disasters and ensuring cargo integrity. ↩ ↩ ↩ ↩ ↩

-

Learning about cargo shift is vital for maintaining ship stability and preventing accidents during transport. ↩ ↩ ↩

-

Exploring point loading risks helps in understanding how to properly load steel cargo to avoid structural damage. ↩

-

Understanding trimmed loading techniques is essential for ensuring cargo safety and preventing movement during transit. ↩

-

Ship stability calculations are key to ensuring safe transport of heavy cargo, preventing capsizing and other hazards. ↩

-

Choosing reputable shipping lines ensures safety and reliability in transporting steel, protecting your investment. ↩