Picture this: a massive cargo ship, its steel plates slowly eaten away by the relentless sea. The cost? Millions in repairs and downtime. This isn’t just a scene from a documentary; it’s a daily battle for businesses like yours. Corrosion is the silent enemy of every marine vessel. If you work with marine steel, you know the constant worry about rust and structural failure. But what if you could turn this massive problem into a manageable one? I’ve seen too many projects suffer from premature failure, and the root cause is often the same: inadequate corrosion protection.

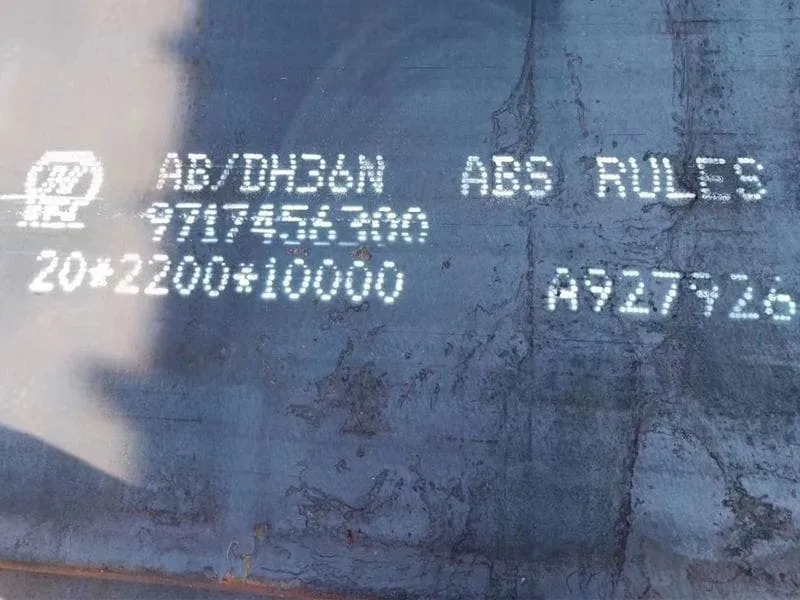

To protect marine steel plates from corrosion, you need a multi-layered defense system. The best methods combine high-quality, corrosion-resistant base materials with effective barrier coatings and smart maintenance practices. Selecting the right steel grade, like AH36 or EH36 with superior corrosion resistance, is the critical first step. Then, applying robust coatings such as epoxy or zinc-rich primers creates a physical barrier against seawater and salt spray. Finally, implementing a regular inspection and maintenance schedule ensures the longevity of your investment and prevents costly failures.

You now understand the basic framework for fighting corrosion. However, the devil is in the details. To build a truly effective defense, we must break down each component of this system. The following sections will answer the key questions that every serious buyer and project manager must ask. We’ll look at prevention strategies, compare protection methods, explore material enhancements, and review specific treatments. This knowledge is not just theoretical; it’s based on years of supplying steel to projects across the globe, from the shipyards of Southeast Asia to the oil platforms in the Middle East.

How to prevent marine corrosion?

Imagine launching a new vessel, only to have it docked for repairs within a year. The financial and reputational damage can be devastating. Prevention is not just a cost; it’s your most valuable investment. A proactive approach stops corrosion before it starts, saving you immense trouble down the line.

Preventing marine corrosion requires a systematic approach focused on design, material selection, and protective systems. Start by choosing inherently corrosion-resistant steel grades designed for marine service. Then, apply a complete coating system, including primer, intermediate, and topcoat, specifically formulated for immersion or splash zone exposure. Crucially, incorporate cathodic protection (like sacrificial anodes or impressed current systems) to defend any coating defects. Finally, establish a strict plan for routine inspection and maintenance to catch issues early.

Let’s dive deeper into this systematic approach. Think of corrosion prevention as building a fortress. You need strong walls, vigilant guards, and a plan to fix any breaches immediately.

The Three Pillars of Corrosion Prevention

A robust prevention strategy stands on three interconnected pillars. Ignoring any one of them creates a weak point that corrosion will exploit.

- Material and Design: This is the foundation. You cannot prevent corrosion effectively if you start with the wrong material.

- Barrier and Electrochemical Protection: This is your active defense system during service.

- Inspection and Maintenance: This is your ongoing surveillance and repair protocol.

Breaking Down the Prevention Strategy

Here is a more detailed look at what each pillar entails and how they work together.

| Prevention Pillar | Key Actions | Why It Matters | Common Pitfall to Avoid |

|---|---|---|---|

| Material & Design | Select certified marine-grade steel (e.g., ABS, DNV, LR grades). Specify AH/DH/EH series for high strength and toughness. Design to avoid water traps and ensure good drainage. Use compatible metals to prevent galvanic corrosion. | High-quality steel has a finer microstructure and controlled chemistry (like added Copper, Chromium, Nickel) for better inherent resistance. Good design eliminates spots where water and salt can accumulate, which are corrosion hotspots. | Using generic structural steel instead of purpose-built marine plate. Overlooking crevices and joints in design drawings. |

| Barrier & Electrochemical Protection | Apply a full multi-layer coating system (blast cleaning + primer + epoxy/polyurethane topcoat). Install sacrificial zinc or aluminum anodes on the hull and in ballast tanks. For larger vessels, use an Impressed Current Cathodic Protection (ICCP) system. | Coatings are the first line of defense, physically blocking water and oxygen. Cathodic protection is the essential backup; it actively "sacrifices" another metal or uses electric current to protect the steel, even if the coating is scratched. | Applying coatings over improperly cleaned surfaces. Using undersized or depleted anodes. Failing to activate or monitor ICCP systems. |

| Inspection & Maintenance | Conduct regular visual and ultrasonic thickness checks on hull plates. Schedule dry-docking for thorough inspection and recoating. Immediately repair any coating damage (holidays, scratches). Monitor and replace sacrificial anodes on time. | Corrosion is a continuous process. Regular checks find problems when they are small and cheap to fix. Letting minor damage go unrepaired allows corrosion to accelerate rapidly underneath. | Having no formal inspection schedule. Treating coating repairs as a low-priority task. Not keeping records of anode consumption. |

From my experience working with clients like Gulf Metal Solutions in Saudi Arabia, the most successful projects are those where prevention is planned from the very first purchase order. They don’t just buy steel; they buy a material solution that includes guidance on handling, storage, and initial protection before fabrication even begins. For instance, we always recommend storing plates off the ground and under cover, even at the warehouse, because prevention starts the moment the steel leaves the mill. A small investment in proper storage prevents surface rust that can compromise later coating adhesion. This level of detail is what separates a simple supplier from a true partner in your project’s longevity.

What is the best method to protect steel from corrosion?

You’re faced with a dozen options for corrosion protection. Each salesperson claims their product is the best. This confusion can lead to a costly mismatch between the method and your actual application. Choosing the wrong protection is as bad as having none at all.

There is no single "best" method for all situations. The most effective strategy is a tailored combination of methods suited to the steel’s role and environment. For submerged hull areas, a high-performance epoxy coating paired with sacrificial anodes is the industry standard. For structural parts above deck, a zinc-rich primer with polyurethane topcoat offers excellent weather resistance. The key is to layer different types of protection (material, barrier, cathodic) to create a robust, fail-safe system.

To understand why a combined approach is superior, we need to evaluate the common methods critically. Each has strengths and weaknesses, and their effectiveness changes dramatically based on the application.

Evaluating Common Protection Methods

Let’s compare the main contenders. Think of it as choosing tools for a job. You wouldn’t use a hammer to screw in a bolt.

- Coatings (Barrier Protection): This is the most visible and widely used method. It works by physically isolating the steel from the corrosive environment.

- Cathodic Protection (CP): This is an electrochemical method. It forces the steel to become the cathode of an electrochemical cell, which stops it from corroding.

- Corrosion-Resistant Alloys: This method changes the material itself by adding alloying elements like chromium, nickel, and molybdenum to create stainless steel or other resistant grades.

A Detailed Comparison for Marine Use

The table below breaks down where each method shines and where it may fall short in a harsh marine setting.

| Protection Method | How It Works | Best For / Strengths | Limitations / Weaknesses |

|---|---|---|---|

| High-Performance Coatings (Epoxy, Polyurethane) | Forms an impermeable plastic-like film over the steel surface. | Hulls, decks, superstructures. Excellent barrier if intact. Wide range of colors and finishes. Good chemical resistance. | Can be damaged by impact, abrasion, or UV degradation (for some types). Requires perfect surface preparation. Difficult to repair perfectly in the field. |

| Sacrificial Anodes (Zinc, Aluminum) | A more active metal (anode) is electrically connected to the steel. The anode corrodes instead of the steel. | Hulls, ballast tanks, rudders, submerged structures. Simple, reliable, no external power needed. Automatically protects small coating defects. | Anodes are consumed and must be replaced regularly. Less effective in high-resistance environments (fresh water). Can be inefficient for very large structures. |

| Impressed Current Cathodic Protection (ICCP) | Uses an external power source to force a current through the steel, making it cathodic. | Large vessels, offshore platforms, long pipelines. Can protect very large areas. Output is adjustable. Long-term cost-effective for big assets. | High initial cost and complexity. Requires continuous power and monitoring. Needs expert design and installation. Risk of over-protection. |

| Hot-Dip Galvanizing | Steel is dipped in molten zinc, forming a metallurgical bond and a thick zinc coating. | Small fixtures, railings, gratings, structural sections above the splash zone. Provides both barrier and sacrificial protection. Very durable and abrasion-resistant. | Not practical for large plates or assembled structures. The coating can be damaged during welding or cutting, requiring touch-up. Appearance may not be suitable for all applications. |

In practice, the "best" solution is almost always a hybrid. For example, a ship’s hull uses high-performance coatings as the primary barrier. But because no coating is perfect, sacrificial anodes are welded onto the hull as a backup. This two-layer approach is non-negotiable for reliable protection. When we supply Marine Angle Steel or Bulb Flat Steel to a shipyard, we often discuss the client’s coating plan. For parts that will be hard to access or re-coat later, like internal structures, specifying a steel with slightly better inherent resistance (through chemistry) adds a valuable third layer of defense. This kind of integrated thinking—connecting the material choice to the protection plan—is what delivers real value and prevents failures.

How to make steel more corrosion resistant?

What if the steel itself could fight back? Beyond just adding external layers, you can enhance the base material. This is about building strength from the inside out. Starting with a more resistant steel gives every other protective method a better foundation to work on.

To make steel more corrosion resistant, you modify its chemical composition and microstructure during production. Adding specific alloying elements is the primary method. Elements like Copper (Cu), Chromium (Cr), Nickel (Ni), and Phosphorus (P) form a tighter, more stable rust layer that adheres to the steel and slows further corrosion. This is the principle behind "weathering steel" and improved marine grades. Controlling the rolling process and heat treatment further refines the grain structure for uniform performance.

Enhancing steel’s corrosion resistance is a sophisticated metallurgical process. It’s not just about throwing elements into the melt; it’s about precise control and understanding how these changes affect the steel’s entire behavior.

The Science Behind Corrosion-Resistant Steel

At its core, corrosion is an electrochemical reaction. Making steel more resistant means interfering with this reaction in a lasting way. There are two main avenues: altering the chemistry and controlling the physical structure.

- Alloying: The Chemical Shield: Adding certain elements changes the nature of the corrosion products that form on the steel’s surface.

- Microstructural Control: The Physical Defense: How the steel is made—its grain size and phase distribution—affects how uniformly it corrodes.

Methods and Their Impact in Marine Environments

The following table outlines the common enhancement techniques and what they mean for your marine application.

| Enhancement Method | Key Elements / Processes | How It Improves Resistance | Considerations for Marine Use |

|---|---|---|---|

| Adding Corrosion-Resistant Alloys | Copper (Cu), Chromium (Cr), Nickel (Ni), Phosphorus (P). | These elements promote the formation of a dense, protective oxide layer (patina) that dramatically slows the corrosion rate compared to ordinary steel. This is the basis for ASTM A871 / ASTM A588 weathering steels. | The "patina" develops best in alternating wet/dry cycles. In constantly submerged or high-splash zones, the benefit is reduced, and coatings are still required. Excellent for above-deck structures. |

| Producing Clean Steel | Advanced refining to reduce Sulfur (S) and Phosphorus (P) to very low levels. | Inclusions (impurities) in steel can become initiation sites for pitting corrosion, a dangerous localized attack. Cleaner steel has fewer of these weak points. | This is a fundamental quality marker. All good marine-grade steel (like AH36, DH36) undergoes this process. It improves weldability and toughness as well. |

| Microalloying with Niobium (Nb) & Vanadium (V) | Adding small amounts of Niobium or Vanadium during rolling. | These elements help form a very fine, uniform grain structure. A fine grain improves both strength and toughness, and can lead to more uniform corrosion rather than deep pitting. | This is common in high-strength, low-alloy (HSLA) marine plates. It’s part of what you pay for in higher-grade materials. The benefit is integrated into the plate’s overall performance. |

| Surface Modification | Cladding (explosive or roll-bonding) a corrosion-resistant alloy like stainless steel onto a carbon steel plate. | This gives you the corrosion resistance of stainless steel on the surface, with the strength and cost-effectiveness of carbon steel in the core. | A highly effective but expensive solution. Used in critical areas of chemical tankers or offshore structures where specific cargo or extreme conditions are present. |

It’s important to have realistic expectations. Making steel "more" corrosion-resistant does not make it "corrosion-proof" in seawater. Even highly alloyed steels will eventually corrode without additional protection. The goal is to create a more robust and predictable base material. When a client like Gulf Metal Solutions requests SGS inspection, part of what they are verifying is the actual chemical composition against the mill certificate. This ensures they are truly getting the enhanced steel they paid for. As a supplier connected to certified mills, we see this data for every batch. We know that a plate meeting the DH36 specification not only has the required strength but also a controlled chemistry that contributes to its longevity in marine service. This intrinsic quality is why you should always source from suppliers who provide full traceability and certification.

What is an anti corrosive treatment for steel?

You have the steel plate in your yard. Now what? Anti-corrosive treatment refers to the practical steps you take to shield the steel, from the moment it arrives until the end of its service life. It’s the actionable plan that turns theory into reality.

An anti-corrosive treatment for steel is any process applied to its surface to prevent rust. For marine steel, this primarily involves surface preparation followed by coating application. The gold standard treatment is abrasive blasting to a "Sa 2.5" cleanliness standard, immediately followed by applying a compatible primer (like zinc silicate or epoxy). For long-term immersion, multi-coat epoxy or glass-flake reinforced systems are used. Treatments also include metal spraying (zinc/aluminum) and cathodic protection systems.

The term "treatment" covers a wide range of processes, each with a specific purpose and ideal application. A successful treatment is a sequence, not a single event.

The Sequence of Effective Treatment

A proper anti-corrosive treatment is a carefully choreographed sequence. Skipping or rushing any step compromises the entire system.

- Surface Preparation: The Most Critical Step: This is the foundation. No coating can adhere properly to a dirty, oily, or rusty surface.

- Primer Application: The Active Interface: The primer is specifically designed to bond to the clean steel and provide either sacrificial protection (zinc-rich) or excellent adhesion (epoxy).

- Intermediate/Topcoat Application: The Main Barrier: These coats build thickness and provide specific resistance to water, chemicals, abrasion, and UV light.

A Guide to Common Marine Anti-Corrosive Treatments

Here is a breakdown of the standard treatments, their processes, and where they are best applied.

| Treatment Type | Process Description | Key Standards / Specifications | Typical Marine Application Areas |

|---|---|---|---|

| Abrasive Blasting + Zinc Silicate Primer | Steel is blasted with grit to a near-white metal finish (Sa 2.5). A inorganic zinc silicate primer is sprayed on while the surface is still warm and active. | Surface Prep: ISO 8501-1 Sa 2.5. Coating: Often specified by shipowner or paint manufacturer (e.g., Jotun, Hempel, Int’l Paint systems). | Hull exterior (before topcoats), ballast tanks, internal spaces. Provides excellent cathodic protection at scratches (sacrificial action). |

| Multi-Coat Epoxy/Polyurethane System | After priming, multiple layers of epoxy (for immersion) or polyurethane (for UV exposure) are applied to achieve a specified dry film thickness (DFT). | DFT is measured per ISO 19840. Each coat is applied after the previous one has cured properly. System must be compatible. | Full hull coating, decks, superstructures, splash zones. Epoxy is for below waterline; polyurethane is for topsides and aesthetics. |

| Thermal Spray (Metalizing) | Molten zinc or aluminum is sprayed onto a blasted steel surface using a special gun. It creates a pure metallic coating bonded to the steel. | ISO 2063 specifies the process. Coating is porous, so it is usually sealed with a thin organic sealer. | Used on large, critical structural components, bridges, offshore platform legs. Very long life but expensive and requires specialized application. |

| Shop Primer / Pre-construction Primer | A thin coat (usually zinc-rich or epoxy) applied at the steel mill or fabrication shop to protect the plate during storage, transport, and initial fabrication. | Also called "blast primer" or "temporary primer." It must be compatible with the full coating system applied later. | Applied to all steel plates (Marine Plate, Angle Steel, Bulb Flat) before they leave the mill or storage yard. Prevents rust during the construction phase. |

The treatment must be appropriate for the stage of the project. For example, when we ship Marine Steel Plates to a fabricator in Vietnam, the plates often leave our partner mill with a shop primer already applied. This simple treatment prevents surface rust during ocean transit and storage—a frequent pain point for our clients. Then, during fabrication, the welds and cut edges are cleaned and treated locally before the full, final coating system is applied to the assembled structure. Understanding this sequence helps you plan and budget correctly. A common mistake is to specify the final coating but not account for the cost and time of proper surface preparation and priming in the fabrication shop. A good supplier should be able to advise on this entire workflow.

Conclusion

Fighting marine corrosion demands a layered strategy: start with the right steel, protect it with robust coatings and cathodic systems, and maintain it with unwavering diligence. This integrated approach is the only path to true longevity and safety at sea.