You receive a perfect batch of certified marine L-shaped steel, only to find it warped, rusted, and damaged before fabrication even begins. This waste is not an accident; it’s the direct result of poor storage and handling. I’ve seen too many projects lose time and money this way.

Proper storage and handling of L-shaped steel at shipyards requires a systematic approach. Store steel off the ground on level, sturdy supports to prevent bending and water contact. Separate different sizes and grades clearly. Handle with appropriate lifting gear, like wide nylon slings, to avoid surface damage and edge bending. Protect the material from rain, salt spray, and soil contamination. Implement a clear "First-In, First-Out" (FIFO) inventory system to prevent long-term storage corrosion.

You now have the core principles. But these principles must be applied to every stage, from the initial delivery at your yard to the moment the steel is lifted for fabrication. Let’s break down these broad rules into specific, actionable answers for the critical situations you face every day.

How should steel be stored?

Your storage yard space is limited, and materials arrive constantly. Throwing steel on the ground seems easy, but it guarantees damage, rust, and safety hazards. Poor storage directly eats into your profit margin through material loss and rework.

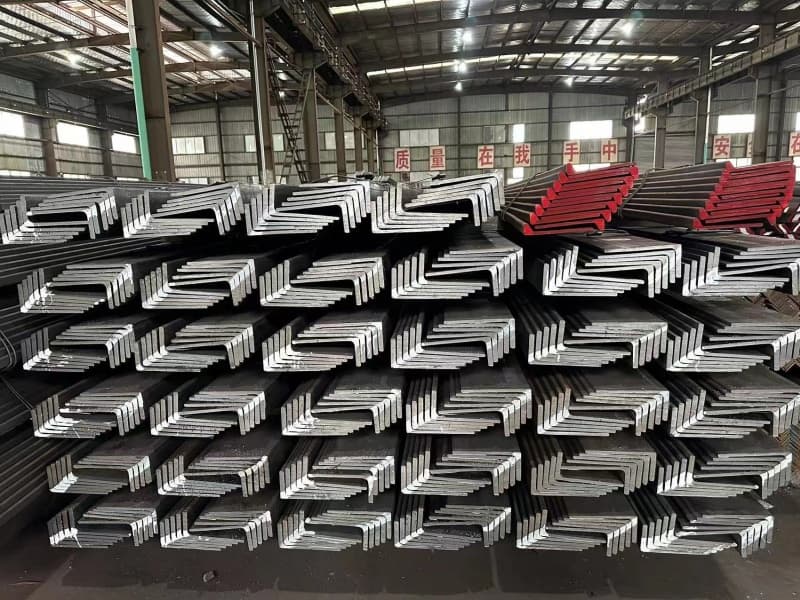

Steel should be stored flat, off the ground, on level and stable supports like timber or concrete blocks. Supports must be placed close enough to prevent sagging or bending under the steel’s own weight. Different grades, sizes, and batches must be separated and clearly marked. The storage area should be clean, dry, and well-organized to allow safe access for inspection and handling equipment.

The goal of storage is preservation and accessibility. This requires attention to three key areas: the foundation, the organization, and the environment. Neglecting any one compromises the entire system.

The Three Pillars of Effective Steel Storage

Good storage is not random. It is built on three interlocking principles that prevent physical and chemical damage.

- Structural Support: This prevents permanent deformation (bending, warping) of the steel sections.

- Organizational Clarity: This prevents mix-ups, loss, and damage during retrieval.

- Environmental Protection: This slows down the chemical process of corrosion.

A Detailed Guide to Steel Storage Practices

This table translates the pillars into specific, actionable rules for a shipyard environment.

| Storage Principle | Specific Action Required | Why It’s Critical for L-Shaped Steel | Common Mistake & Consequence |

|---|---|---|---|

| Support Off the Ground | Use timber sleepers, concrete blocks, or steel racks. Place supports at regular intervals (e.g., every 1-1.5 meters for long angles). Ensure all supports are level and stable. | Prevents contact with ground moisture, mud, and standing water. Distributes weight evenly to avoid permanent sag or camber in the long leg of the angle. | Storing directly on dirt or asphalt. This traps moisture, causes rapid underside rust, and can bend the steel if the ground settles unevenly. |

| Prevent Bending & Distortion | Store bundles flat. Do not store long sections on their edge without specialized racks. For tall bundles, use additional vertical supports or cradles. | L-shaped steel is prone to twisting (torsion) and bending if improperly supported. Once bent, it is very difficult and costly to straighten for precise ship framing. | Leaning bundles against a wall. This puts uneven stress, causing a permanent curve that makes the angle unusable for straight frames. |

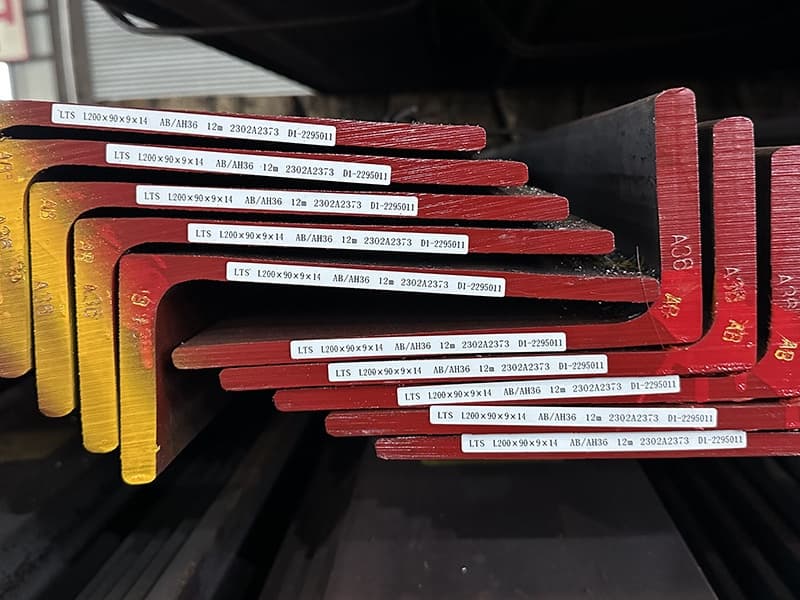

| Separation & Identification | Use physical spacers between different sizes/grades. Attach weather-resistant tags or paint markings to each bundle with heat number, grade (e.g., DH36), size, and arrival date. | Prevents using the wrong material in construction, which is a serious quality and safety issue. Enables the FIFO system. | Mixing all incoming steel in one pile. This leads to time wasted searching, accidental use of incorrect specs, and older steel being buried and corroding. |

| Environmental Control | Ideally, store under a roof or waterproof tarpaulin. Ensure good air circulation to reduce condensation. Keep the area free of grass, weeds, and debris. | Protects the mill scale and any shop primer from degradation. Salt air in coastal shipyards is especially corrosive; shelter is the first line of defense. | Leaving steel exposed to rain and sun. This accelerates rust, degrades packaging, and causes "packing stain" corrosion where sections touch. |

From my experience supplying to shipyards in Vietnam and Thailand, the condition of the storage yard is the first thing a good project manager checks. A chaotic, muddy yard signals future problems with material quality. We advise our clients, like the fabricators in Saudi Arabia, to prepare the storage area before the steel arrives. This means having the timber blocks ready and the layout planned. When we ship, we use protective packaging—like the waterproof wrapping Gulf Metal Solutions praised—but that packaging is only the first layer of defense. Its job is to get the steel to you in perfect condition. Your job is to maintain that condition from the truck to the cutting torch. Proper storage is that maintenance plan.

What is the best way to store steel?

You want an ideal system. The "best" way balances maximum protection with practical reality and cost. An impractical, perfect system is useless; a cheap, careless system is expensive. The best method is the one you will consistently follow.

The best way to store steel is in a dedicated, covered storage building with a concrete floor, using organized racking systems. For L-shaped steel, this involves horizontal stacking on level rack arms or in custom cradles that support the full length. This method provides complete weather protection, prevents physical damage, enables excellent inventory control via FIFO, and maximizes safety and space efficiency. For open yards, systematic stacking on treated timber with robust waterproof covering is the minimum best practice.

The "best" solution depends heavily on your budget, climate, and volume. We can define "best" by evaluating options against key performance criteria: protection, accessibility, cost, and safety.

Evaluating Storage Solutions: From Ideal to Practical

We can think of storage methods on a spectrum, from the most protected to the most basic.

- Fully Enclosed Storage: This is the gold standard for critical marine materials.

- Covered/Canopy Storage: This is a strong compromise for most shipyards.

- Open Yard with Rigorous Protocol: This is the minimum viable system for harsh environments.

Comparing Storage Method Options

The table below compares the practical approaches to help you decide what "best" means for your operation.

| Storage Method | Description & Setup | Key Advantages | Key Limitations & Best For |

|---|---|---|---|

| Enclosed Warehouse with Racking | Steel structure building with concrete floor. Uses cantilever racks or bulk racking with adjustable arms. | Complete weather protection. No rust from rain or condensation. Superior organization. Easy visual inventory, perfect FIFO. Enhanced safety. Clean, uncluttered floor. Space-efficient. Racks use vertical space. | High initial investment. Not always feasible for very large sections or temporary yards. Best for: High-volume fabricators, critical component storage, regions with heavy rain/snow. |

| Covered Shed or Canopy | Open-sided structure with a solid roof. Steel is stored on timber sleepers on a compacted gravel or paved base. | Excellent rain/sun protection. Significant reduction in corrosion rate. Lower cost than a full warehouse. Good air circulation reduces condensation. | No side protection from wind-driven rain or salt spray. Ground moisture can still be an issue. Best for: Most general shipyards, especially in tropical or seasonal climates. |

| Open Yard with Systematic Protocol | Designated paved or compacted gravel area. Steel is stacked on level timber blocks. Each bundle is fully covered by a heavy-duty, tied-down tarpaulin. | Lowest initial cost. Highly flexible for changing inventory and bundle sizes. Can be implemented immediately. | High labor for covering/ uncovering. Higher corrosion risk if covers are damaged or neglected. Vulnerable to ground moisture and driving rain. Best for: Temporary project sites, very large bulk items, or when other options are not available. |

In reality, many successful shipyards use a hybrid approach. They have a covered shed for smaller, high-value sections like specific L-shaped steel for critical frames, and an organized open area with strict tarping rules for larger plates and bulk angles. The "best" system is the one that has clear written procedures and is enforced. For example, a contractor in Mexico we work with color-codes their tarps: blue for steel delivered within the month, green for older stock. This simple visual cue drives their FIFO system and flags potential corrosion issues. It’s not high-tech, but it is effective and consistently followed. That consistency is what makes it the "best" method for them.

How should mild steel slabs be loaded in bulk carrier?

This question seems far from shipyard storage, but it’s fundamentally connected. The principles of securing heavy, long steel cargo on a ship mirror the principles of storing it in your yard. Poor stowage at sea causes the damage you discover on delivery.

Mild steel slabs (or long sections like L-steel bundles) must be loaded in a bulk carrier as compact, uniform blocks to form a stable cargo mass. They are laid flat on leveled holds, with their length aligned with the ship’s fore-aft direction. Layers are separated by sturdy wooden dunnage. The entire block is then tightly secured using chains, wires, and turnbuckles to fixed points on the ship’s structure, preventing any movement during the voyage.

Loading a ship is macro-scale handling. The forces are enormous—rolling, pitching, and vibration. The goal is to turn thousands of individual pieces into a single, solid unit that moves with the ship, not inside it.

The Physics of Securing Heavy Cargo

At sea, cargo wants to move due to the ship’s motion. Securing is about overcoming inertia and friction.

- Creating a Solid Block: The first step is to pack the cargo tightly, eliminating voids. Gaps allow individual pieces to shift and gain momentum.

- Friction and Locking: Dunnage (wooden planks) increases friction between layers and helps distribute pressure.

- Positive Lashing: Securing gear (chains/wires) provides a direct physical restraint to hold the entire block in place against the ship’s structure.

Step-by-Step Principles for Loading Steel

The following table outlines the critical steps and their purposes, drawing a direct parallel to safe yard storage.

| Loading & Securing Step | How It’s Done | The Physical Principle | Parallel in Yard Storage |

|---|---|---|---|

| Hold Preparation & Leveling | The cargo hold is cleaned and leveled with sand or filler to create a flat, stable base. | Provides even weight distribution and prevents point loads that could damage the ship’s structure or cause cargo to tilt. | Equivalent to preparing a level, compacted ground or paved area in your yard. |

| Laying Dunnage | Wooden planks are laid on the hold floor, running perpendicular to the direction of the steel lengths. | Raises cargo off the hold floor for ventilation and drainage. Provides a high-friction surface and spreads the load. | Equivalent to placing timber sleepers to keep steel off wet ground. |

| Stowing in Fore-Aft Direction | Slabs or bundles are placed with their longest dimension running from the bow to the stern of the ship. | Aligns the cargo with the ship’s primary axis of motion (pitching). This is the most stable orientation and minimizes the tendency to roll sideways. | Similar to storing long angles in a straight, aligned manner to prevent twisting. |

| Building a Compact Block | Cargo is tightly packed, layer by layer. Gaps at the sides and ends are filled with smaller pieces or secured with timber. | Eliminates voids to prevent shifting. Turns many items into one solid mass with a high collective inertia. | Similar to neat, tight bundling of sections to make them a single, stable unit for handling. |

| Top-Tier Securing (Lashing) | Heavy-duty chains or steel wires are placed over the top tier, connected to lashing points (padeyes) on the ship’s sides and tightened with turnbuckles. | Provides positive restraint. Acts as a net holding the entire block down, counteracting lift and shift forces during heavy seas. | The yard equivalent is strapping bundles for crane lifts to prevent spillage, though forces are much smaller. |

Understanding this process is vital for a buyer. When you inspect steel upon delivery and find abrasion marks, edge damage, or even bends, the root cause often occurred during ocean transport due to inadequate securing or poor stowage. When we organize shipment for clients to Dammam or Manila, we work with experienced freight forwarders who understand these rules. We ensure the Bill of Lading mentions the cargo is "properly secured for sea transport as per IMO/IMSBC code." This is not just paperwork; it sets the standard for how the stevedores should handle and secure your valuable cargo, protecting your investment from the mill gate to your yard gate.

What are the basic rules for cargo stowage and securing?

Whether on a ship or in your yard, the core rules for keeping heavy goods safe are universal. They are a formalized version of common sense, designed to counteract specific forces. Ignoring them leads to damage, loss, and danger.

The basic rules for cargo stowage and securing are: 1) Make the cargo fast (compact and solid), 2) Distribute weight evenly, 3) Use adequate dunnage to increase friction and prevent damage, 4) Apply proper lashings to secure the cargo against all directions of potential movement (forward, aft, sideways, and upward), and 5) Inspect and tighten lashings regularly during the voyage. These rules are codified in the IMO’s International Maritime Solid Bulk Cargoes (IMSBC) Code.

These rules form a systematic defense against movement. Each rule addresses a different weakness. You cannot skip one and expect the others to compensate.

The Five Fundamental Rules Explained

Let’s translate each formal rule into practical language for both sea transport and yard storage.

- Make Fast (Compactness): This is about removing internal movement.

- Even Weight Distribution: This is about stability and structural safety.

- Use of Dunnage: This is the interface layer that protects and grips.

- Proper Lashing: This is the active restraint system.

- Inspection and Maintenance: This is the acknowledgment that conditions change.

Applying the Rules: Ship vs. Shipyard

The table below shows how these universal rules apply in two different contexts: the hold of a bulk carrier and the storage yard of a shipbuilder.

| Basic Rule | Application in Ship Cargo Hold | Application in Shipyard Storage & Handling | Underlying Principle |

|---|---|---|---|

| 1. Make Fast (Compact Stowage) | Fill all voids with smaller pieces or timber to create a solid block. Avoid loose items on top. | Bundle L-shaped steel tightly with straps. Stack bundles neatly and squarely. Do not leave gaps within a stack that could cause collapse. | A solid mass resists internal shifting. Loose items can gain kinetic energy and become projectiles or cause pressure points. |

| 2. Even Weight Distribution | Spread the cargo evenly across the hold area. Avoid piling too much weight in one spot. | Place supports (timber blocks) evenly under long sections. Distribute the weight of stacked bundles across multiple support points. | Prevents overloading local areas (ship structure or ground), which can lead to deformation, collapse, or instability. |

| 3. Use Adequate Dunnage | Lay wooden planks between layers and against the ship’s structure to prevent metal-to-metal contact and increase friction. | Use timber sleepers to separate steel from the ground. Use wooden spacers between different bundles or layers to allow air flow and prevent packing stain. | Protects surfaces from abrasion damage. Increases the friction force that resists sliding. Allows for drainage and ventilation. |

| 4. Apply Proper Lashing | Use chains/wires with sufficient strength (Safe Working Load) to tie down the cargo block to the ship’s strong points (padeyes). | Use appropriate slings (nylon, not wire) for lifting to prevent edge damage. Secure loads on trucks with chains. In very windy areas, consider securing stacks. | Provides positive securing to counteract external forces (ship motion, crane acceleration, wind). |

| 5. Inspect & Tighten | Crew must inspect lashings at regular intervals during the voyage, especially after heavy weather, and re-tighten as needed. | Regularly inspect stored steel for signs of rust, sagging, or damage to supports/tarps. Check lifting gear for wear before each use. | Systems degrade over time. Environmental conditions (vibration, moisture, stress) change. Proactive inspection prevents failure. |

For a results-driven project manager, these rules are a checklist. When you walk your yard, you are essentially conducting a "cargo securing" inspection. Is the steel compact and solid in its stacks? Is the weight evenly distributed on the sleepers? Is the dunnage (timber) in good condition? Are the lifting slings proper and inspected? This mindset transforms storage from a passive dumping ground into an active part of your quality control system. It is the same mindset our dedicated sales reps use when advising clients on handling: we provide the knowledge not just to sell steel, but to ensure it reaches the fabrication line in the same perfect condition it left our partner mill.

Conclusion

Proper storage and handling of L-shaped steel is active asset preservation. By applying the fundamental rules of stowage and securing—from ship hold to shipyard—you prevent costly damage, ensure worker safety, and protect the integrity of your vessel’s build from the ground up.