Your shipping quote seems too high, or your project budget is over. Often, the problem is a simple error in calculating the weight of the steel you ordered. A small mistake here multiplies into a big cost.

*To calculate the weight of an L-shaped steel section, use the formula: Weight = [(A + B – t) t Length Density]. ‘A’ and ‘B’ are leg lengths, ‘t’ is thickness, Length is in meters, and Density is 7850 kg/m³ for steel. This gives weight in kilograms.**

Knowing how to calculate weight is a basic but crucial skill. It affects costing, logistics, and even structural design. I will guide you from the universal principle to specific formulas for angles and plates, and clarify a common confusion between material weight and load capacity.

How do you calculate the weight of a steel section?

You see a complex steel beam. Calculating its weight seems difficult. But all calculations start from one simple, universal principle. Forget the shape; focus on the volume of metal.

You calculate the weight of any steel section by finding its cross-sectional area, multiplying by its length to get volume, and then multiplying by the density of steel (approximately 7850 kg per cubic meter). The formula is: Weight = Cross-Sectional Area x Length x Density.

The Universal Rule: Volume x Density

The core idea is straightforward. Steel has a known, constant density. If you can figure out how much space a piece of steel occupies (its volume), you know its weight. The challenge lies in finding the volume for irregular shapes. Let’s break down the process into clear, actionable steps.

Step 1: Understand the Components

Every calculation needs these three elements:

- Cross-Sectional Area (A_c): This is the area of the steel profile as you would see it if you cut it straight across. For an L-angle, it’s the area of the "L" shape. For an I-beam, it’s the "I" shape. This is measured in square millimeters (mm²) or square meters (m²).

- Length (L): The length of the steel piece in meters (m).

- Density (ρ) of Steel: This is a fixed value: 7850 kilograms per cubic meter (kg/m³). It is the weight of one cubic meter of steel. Sometimes people use 7.85 grams per cubic centimeter (g/cm³), which is the same number.

Step 2: Apply the Formula

The fundamental weight formula is:

Weight (kg) = Cross-Sectional Area (m²) x Length (m) x 7850 (kg/m³)

To use this, you often need to work in consistent units. A common practical approach is to calculate area in mm², length in m, and use a conversion factor.

- 1 m² = 1,000,000 mm²

- So, Density in kg/mm²/m is: 7850 kg/m³ / 1,000,000 mm²/m² = 0.00000785 kg/(mm²*m)

This gives a very small number. A more user-friendly version is:

Weight (kg) = (Cross-Sectional Area in mm²) x (Length in m) x 0.00785

(Here, 0.00785 = 7850 / 1,000,000)

Step 3: Find the Cross-Sectional Area for Different Sections

This is the only part that changes. You need the geometric formula for the area of the shape.

- Rectangle (Plate, Flat Bar): Area = Width (W) x Thickness (t)

- Circle (Round Bar): Area = π x (Diameter/2)²

- Complex Sections (I-beam, Angle, Channel): You can decompose them into simple rectangles. For an L-angle, it’s two rectangles minus the overlapping corner square.

Practical Tools and Shortcuts

Engineers and suppliers don’t calculate from scratch every time.

- Standard Tables: Every steel profile has published standard tables. For an

L 100x100x10, the table lists its weight per meter (e.g., 15.1 kg/m). You just multiply by length. - Online Calculators: Many websites and apps do this instantly.

- The "Rule of Thumb" for Plates: For steel plate, a quick mental check is: 1 m² of 1 mm thick plate weighs 7.85 kg. So, a 10mm thick plate of 1m² weighs 78.5 kg.

This table illustrates the process for common sections:

| Section Type | Key Dimensions | Area Calculation (in mm²) | Weight per Meter (kg/m) = Area(mm²)*0.00785 |

|---|---|---|---|

| Flat Plate/Bar | Width (W), Thickness (t) | Area = W * t |

W * t * 0.00785 |

| Round Bar | Diameter (D) | Area = π * (D/2)² |

[π * (D/2)²] * 0.00785 |

| L-Angle (Equal) | Leg (A), Thickness (t) | Area = (2A - t) * t |

(2A - t) * t * 0.00785 |

| I-Beam | Height (H), Flange Width (B), Web & Flange thickness (tw, tf) | Complex sum of rectangles. | Always use standard table value. |

Understanding this principle empowers you. You can verify supplier quotes. You can estimate weights for non-standard parts. You are no longer just reading numbers from a table; you know where they come from.

How to calculate weight of l angle?

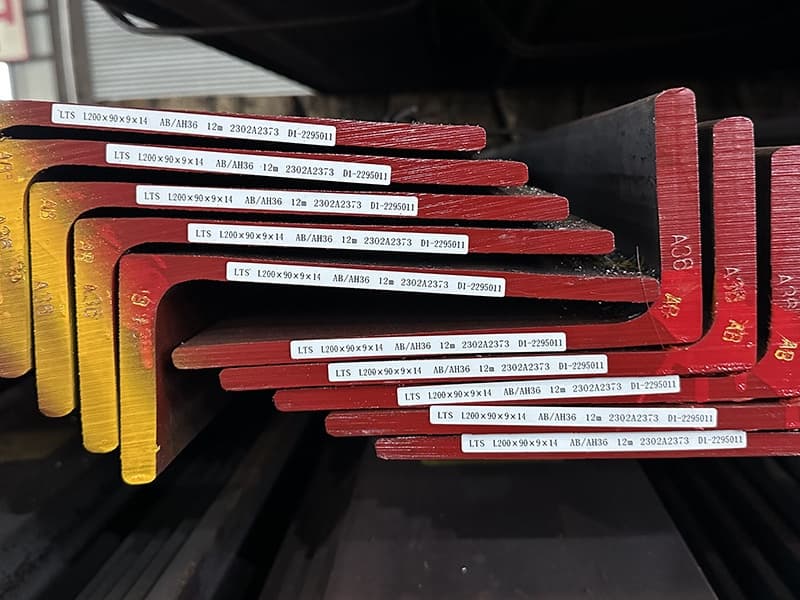

You have a list: 50 pieces of L 150x90x10, each 6 meters long. You need the total weight for the truck and the invoice. The specific formula for an angle is a direct application of the universal rule.

For an L-angle, the weight per meter (kg/m) is calculated as: (Leg1 + Leg2 – Thickness) Thickness 0.00785. For a total piece: Weight (kg) = [(A + B – t) t 0.00785] * Length (m). ‘A’ and ‘B’ are leg lengths, ‘t’ is thickness, all in millimeters.

The Dedicated Formula: Why (A+B-t)*t?

The formula (A + B - t) * t * Density is not magic. It comes from visualizing the L-shape as two rectangles that share an overlapping square at the corner. Let’s derive it and see how to use it perfectly.

Derivation: Two Rectangles Minus One Square

Picture an L-angle with legs A and B, both with thickness t.

- Think of it as a vertical rectangle: dimensions are

Atall andtwide. Its area isA * t. - Think of it as a horizontal rectangle: dimensions are

Blong andtwide. Its area isB * t. - Now, if you add

A*t + B*t, you have counted the small square at the corner (where the two legs meet) twice. This square has sides oftandt, so its area ist * tort². - The true cross-sectional area is:

(A*t) + (B*t) - (t*t). - Factor out

t: True Area =t * (A + B - t).

So, the formula (A + B - t) * t gives you the cross-sectional area in square millimeters (if A, B, t are in mm).

Applying the Formula: Step-by-Step Example

Let’s calculate the weight for one piece of L 150x90x10 that is 6 meters long.

- Identify dimensions: A = 150 mm, B = 90 mm, t = 10 mm.

- Calculate Area: Area = (150 + 90 – 10) 10 = (230) 10 = 2300 mm².

- Calculate Weight per Meter: Wt/m = 2300 * 0.00785 = 18.055 kg/m. (You can round to 18.06 kg/m).

- Calculate Piece Weight: Piece Weight = 18.055 kg/m * 6 m = 108.33 kg.

- Calculate Total Order Weight: For 50 pieces, Total = 108.33 kg/piece * 50 = 5,416.5 kg, or about 5.42 metric tons.

Important Considerations in Real Orders

- Tolerances: The calculated weight is theoretical. Actual rolled steel has tolerances. The actual weight may be 2-5% more or less. Commercial contracts often state "theoretical weight" for calculation, with final invoice based on "actual weight" from mill certificates or weighing.

- Unequal Angles: The formula works perfectly for unequal angles (A ≠ B). Just use the correct leg lengths.

- Standard vs. Actual: Always check if your dimensions are nominal (the name, like "L 100x100x10") or the actual measured size. For estimating, use nominal. For precise billing, refer to the mill certificate which may list the actual average thickness.

- The Root Radius: The formula assumes a sharp inside corner. Real angles have a rounded root. The formula is a simplified, standard method that gives a very accurate enough result for commerce. The published standard tables already account for this.

Here is a quick reference for common marine L-angle sizes:

| L-Angle Size (Nominal) | Thickness (t) | Calculated Weight/m (kg/m) | Typical Application in Shipbuilding |

|---|---|---|---|

| L 75x75x8 | 8 mm | (75+75-8)80.00785 = 8.93 kg/m | Light brackets, handrail supports. |

| L 100x100x10 | 10 mm | (100+100-10)100.00785 = 14.92 kg/m | Medium frames, secondary stiffeners. |

| L 150x90x12 | 12 mm | (150+90-12)120.00785 = 21.48 kg/m | Common bracket for deck-to-frame connection. |

| L 200x200x16 | 16 mm | (200+200-16)160.00785 = 48.23 kg/m | Heavy foundation frames, strongbacks. |

Mastering this formula lets you make quick estimates on site, check order lists, and understand cost breakdowns. It turns a abstract number into a logical result you can verify.

What is the formula for plate section weight?

A ship’s hull is mostly plate. Miscalculating plate weight leads to errors in displacement, stability, and cost. The formula is simpler than for sections, but scale makes accuracy critical.

The formula for steel plate weight is: Weight (kg) = Length (m) x Width (m) x Thickness (mm) x 7.85. The factor 7.85 comes from the steel density (7850 kg/m³), simplified for thickness in mm and area in m². Alternatively, Weight = Area (m²) x Thickness (mm) x 7.85.

The Simplicity and Scale of Plate Calculation

Plate is a simple rectangular volume. The challenge is not complexity, but managing large numbers and dealing with real-world variables like trimming and wastage. Let’s look at the formula, its variations, and practical application in shipbuilding.

The Standard Formula and Its Derivation

- Volume: Volume of a plate = Length (L) x Width (W) x Thickness (T).

- Units: If we use meters for L and W, and meters for T, then Volume is in m³. Weight = Volume (m³) x 7850 kg/m³.

- The Practical Shortcut: Shipbuilders think in millimeters for thickness. 1 meter = 1000 mm. So, if Thickness (T) is in mm, we need to convert it to meters: T (m) = T (mm) / 1000.

- Plug into the formula: Weight = L(m) x W(m) x [T(mm)/1000] x 7850.

- Simplify: Weight = L(m) x W(m) x T(mm) x (7850 / 1000).

- This gives: Weight (kg) = L(m) x W(m) x T(mm) x 7.85.

This 7.85 is the magic number. It means: Every square meter of steel plate, for every millimeter of its thickness, weighs 7.85 kg.

Example: Hull Plate Calculation

You need a hull plate piece: 8 meters long, 2 meters wide, 18 mm thick.

Weight = 8 m x 2 m x 18 mm x 7.85 = 16 m² x 18 x 7.85 = 288 x 7.85 = 2,260.8 kg (about 2.26 tons).

Practical Considerations for Real Procurement

- Plate Size vs. Required Piece: Mills sell plates in standard sizes (e.g., 6m x 1.5m, 8m x 2m). The nestable shapes you cut from them will have a different total area. Your calculation must be for the purchased plate size, not just the sum of the cut pieces. This includes kerf (cutting loss) and usable remnant.

- "Theoretical" vs. "Actual" Weight: Like angles, plates have thickness tolerances. A plate ordered as 20mm might have a nominal mid-thickness of 20.5mm or 19.7mm. The mill certificate lists the actual thickness and the actual weight. Invoicing can be based on theoretical weight (from ordered dimensions) or actual weight.

- Different Steel Densities: The 7.85 factor is for standard carbon steel. Some specialty steels (like high-nickel steels) have slightly different densities. Always confirm for non-standard materials.

This table shows quick estimates for common marine plate thicknesses per square meter:

| Plate Thickness (mm) | Weight per Square Meter (kg/m²) = Thickness x 7.85 | Typical Marine Application |

|---|---|---|

| 6 mm | 47.1 kg/m² | Internal bulkheads, non-watertight structures. |

| 10 mm | 78.5 kg/m² | Upper deck plating, superstructure. |

| 15 mm | 117.75 kg/m² | Side shell plating (smaller vessels). |

| 20 mm | 157 kg/m² | Bottom plating, main deck of cargo ships. |

| 25 mm | 196.25 kg/m² | Keel plate, sheer strake in larger vessels. |

| 30 mm | 235.5 kg/m² | Ice belt plating, critical areas of large tankers. |

From Plate Weight to Ship Weight

A ship’s lightship weight is essentially the sum of all plate and section weights, plus outfitting. Accurate plate weight calculation is the foundation of this. Naval architects use sophisticated software that models every plate. As a supplier or fabricator, your accurate calculation ensures your material supply aligns with the shipyard’s weight budget and stability calculations. When we supply plate to a client, providing accurate theoretical weight data is part of the service that helps them plan their logistics and costs.

How to calculate how much weight a structure can hold?

You know the steel weighs 5 tons. But can the frame you built with it support 20 tons of cargo? This is a critical distinction. Material weight and load capacity are completely different concepts.

Calculating a structure’s load capacity is a complex engineering task. It involves analyzing the strength of the steel (yield strength), the geometry of the members (section modulus, moment of inertia), the type of load (static, dynamic, impact), the connection details, and safety factors. It requires structural engineering software or manual calculations based on design codes, not just a weight formula.

The Great Confusion: Weight of Steel vs. Weight it Can Hold

This is perhaps the most important conceptual leap. The weight of the steel is the force it exerts on the supports below it (gravity pulling it down). The load capacity is the force it can resist from external loads (cargo, wind, waves) before failing. They are related but governed by different rules.

Why You Cannot Simply "Calculate" It from Material Weight

A 100 kg steel beam can hold much more than 100 kg if properly designed. Conversely, a poorly designed 500 kg structure might collapse under its own weight. The load capacity depends on:

- Material Strength Properties: This is the starting point. The steel’s yield strength (e.g., 355 MPa for AH36) is the stress level at which it permanently deforms. The ultimate tensile strength is where it breaks. The certificate provides these values.

- Member Geometry and Section Properties: This is how the shape uses the material.

- Cross-Sectional Area: Governs capacity in pure tension or compression (for short columns).

- Section Modulus (S): The key property for bending strength. A higher S means the section can carry a larger bending moment. I-beams have high S for their weight.

- Moment of Inertia (I): The key property for stiffness (resistance to deflection). A high I means the beam will sag less under load.

- Radius of Gyration (r): The key property for buckling resistance in columns.

- Type and Configuration of Load: Is the load a point load in the middle of a span? A uniform load? Is it a static, permanent load or a dynamic, impact load (like a wave)? The load configuration determines the internal stresses (bending moment, shear force).

- Support Conditions: Is the beam simply supported at both ends? Or is it fixed (welded) at both ends? Fixed supports increase capacity.

- Connection Design: A chain is only as strong as its weakest link. A beam might be strong, but if the bolts or welds connecting it are weak, the structure will fail at the connection.

- Safety Factors: Engineering codes mandate safety factors (often between 1.5 and 2.0 or more). The allowable stress is the material yield strength divided by the safety factor. The structure is designed to keep working stresses below this allowable limit.

The Role of the Supplier in This Context

As a steel supplier, we do not perform structural calculations for our clients. That is the job of their engineer or naval architect. However, we provide the essential input data:

- Certified Material Properties: Our Mill Test Certificates provide the exact yield strength, tensile strength, and impact toughness of the steel delivered.

- Accurate Section Properties: For standard sections, we can provide or confirm the standard values for Area, Weight/m, and sometimes the Section Modulus from industry tables.

- Material Traceability: This ensures the steel in the structure matches the properties used in the design calculations.

This distinction is fundamental:

| Concept | What It Measures | Governing Factors | Who Determines It? |

|---|---|---|---|

| Weight of Steel | The mass/force of the material itself due to gravity. | Volume of steel and its density (7850 kg/m³). | Supplier/Buyer using the formulas discussed earlier. |

| Load Capacity of a Structure | The external force the assembled structure can safely support. | Material strength, member geometry, load type, connections, safety factors. | Licensed Structural Engineer or Naval Architect using design codes. |

For a project like those handled by Gulf Metal Solutions, they need both. They need us to supply L-shaped steel of a certified weight and grade (e.g., DH36). Their engineers then use that grade’s guaranteed strength (355 MPa yield) to calculate how to design frames and brackets that will safely hold the required loads for their client’s vessel. We supply the reliable ingredient; they create the final, safe recipe.

Conclusion

Calculate L-angle weight with (A+B-t)tL0.00785, and plate weight with LWT7.85. Remember, these give material weight, not structural capacity—a crucial distinction for safe design.