You just paid for a container of bulb flats. The steel arrives, but you find rust, wrong dimensions, or surface cracks. Now you face project delays and claim headaches. A proper pre-shipment inspection stops this.

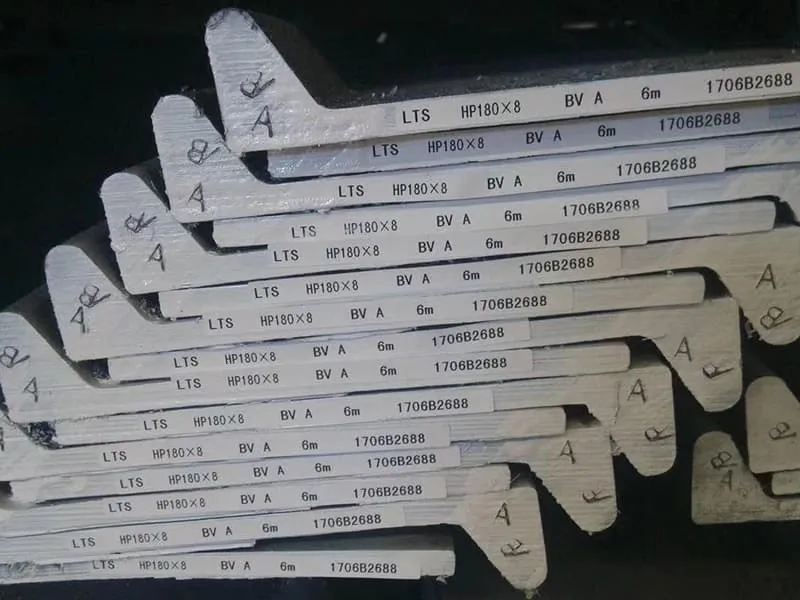

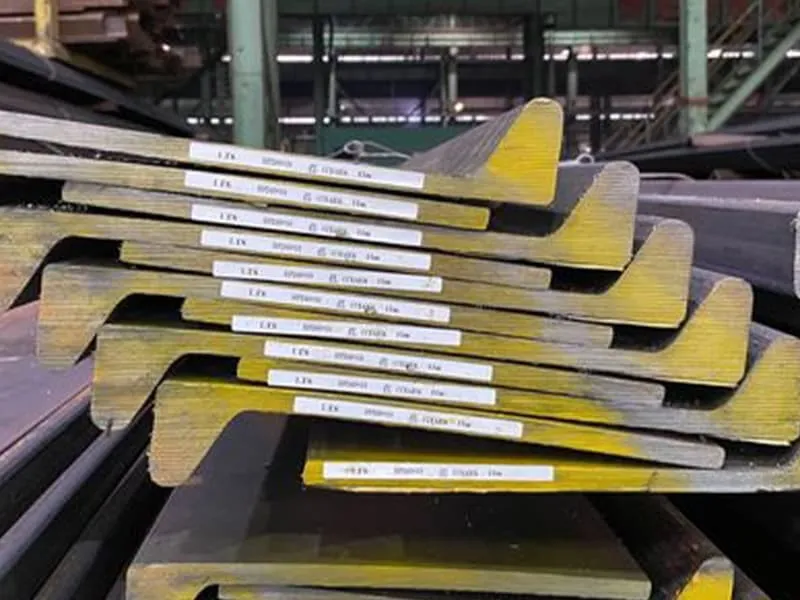

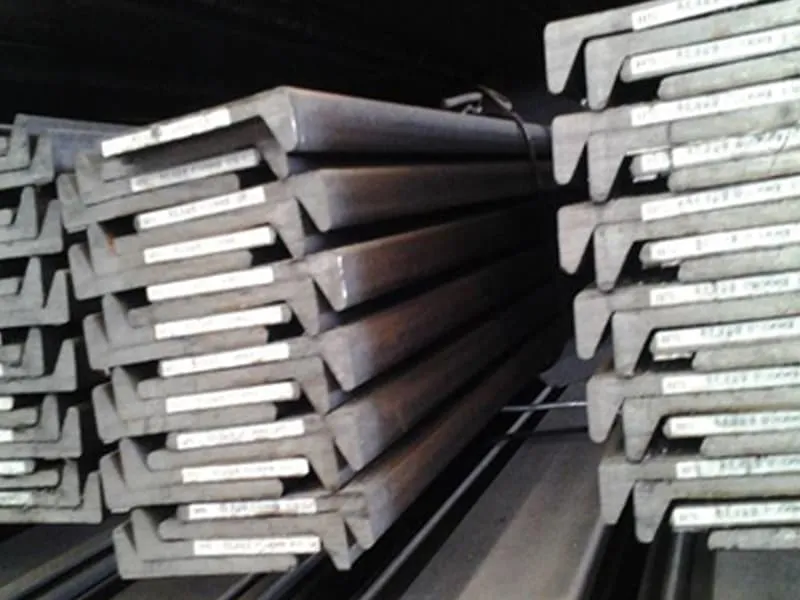

Inspecting bulb flat steel before loading involves checking dimensions, visual surface quality, straightness, and verifying Mill Test Certificates. Use calipers, straightedges, and visual checks against purchase order specifications. For critical projects, hire a third-party inspector like SGS or BV to perform the check at the supplier’s mill.

I often tell clients about Gulf Metal Solutions from Saudi Arabia. Their main frustration was "quality inconsistency." They never knew what would arrive. Our offer of third-party inspection support gave them control and peace of mind. Let me show you the exact steps we follow and recommend to every buyer.

How to inspect steel structure?

Inspecting a large steel structure on-site is hard. Hidden problems can lead to failure. A systematic method is the only way to guarantee safety and quality.

To inspect a steel structure, follow a process: First, review all material certificates. Second, conduct visual checks for rust, welds, and damage. Third, use tools to check dimensions, alignment, and thickness. Fourth, perform non-destructive testing (NDT) like ultrasonic tests for internal flaws on critical connections.

Inspecting a finished structure is different from inspecting raw materials. You need to check both the parts and how they are put together. Let’s break down the two main phases.

Phase-Based Inspection: Materials vs. Erection

A good inspection plan covers the steel before and after construction. This table outlines the focus for each phase.

| Inspection Phase | What to Check | Tools & Methods | Acceptance Criteria |

|---|---|---|---|

| 1. Incoming Material Inspection | Mill Test Certificates (MTC), grade marks, dimensions, surface condition. | Review documents, use calipers, tape measure, visual check. | MTC matches PO, dimensions are within tolerance, no major pitting or cracks. |

| 2. Fabrication & Welding Inspection | Weld profiles, weld seams, cut edges, bolt holes. | Visual check, weld gauges, ultrasonic testing (UT) for critical welds. | Welds are continuous, with no cracks or undercut. Hole sizes and positions are correct per drawings. |

| 3. Erection & Assembly Inspection | Column plumb (verticality), beam alignment, bolt tightness, coating integrity. | Spirit level, theodolite, torque wrench, visual check for paint damage. | Structure is aligned per design drawings. All bolts are properly tightened. Coating is not damaged. |

The most critical step is often the first one: checking the material certificates. If the steel itself is wrong, the entire structure is compromised.

Connecting Raw Material Inspection to Structural Safety

The inspection of bulb flats before loading is the first step of structural inspection. If you let bad material leave the factory, you create problems for every later stage.

Think of it this way. A bulb flat with a slightly undersized bulb might still pass a quick look. But when hundreds of them are welded to a hull plate, the collective loss of strength can be significant. Or, a small surface crack can grow into a major fracture under the dynamic stress of waves.

This is why we encourage our clients to think beyond the simple checklist. You are not just checking a product. You are verifying the first link in a safety chain. When Gulf Metal Solutions started using third-party inspectors at our mill, they stopped having fabrication delays. Their workshops no longer had to reject pieces or rework them. This saved them more money than the inspection cost. A good pre-shipment inspection for raw steel is the most cost-effective quality control you can buy.

What are bulb flats used for?

You need to stiffen a ship’s hull. You can use a heavy angle bar or a lighter T-bar. The bulb flat offers a smarter solution: high strength with less weight.

Bulb flats are steel profiles with a bulb at one end. They are mainly used as longitudinal stiffeners in ship hulls and offshore structures. They are also used in bulkheads, deck beams, and as internal bracing. The bulb adds strength efficiently, which helps reduce the ship’s overall weight and improve fuel efficiency.

The bulb flat is a specialized product. Its shape is its advantage. Let’s look at where this shape works best.

Specific Applications and Advantages Over Other Profiles

Bulb flats have a specific job. They resist bending forces along their length. This makes them perfect for certain applications.

| Application | Role of the Bulb Flat | Why It’s Better Than Alternatives |

|---|---|---|

| Ship Hull Longitudinals | Attached to the inner side of the hull plating, running from bow to stern. | Provides more strength per kilogram than a flat bar. Lighter than an angle bar for the same stiffness, saving fuel. |

| Ship Bulkhead Stiffeners | Welded vertically or horizontally onto watertight walls inside the ship. | The flat back welds easily to the plate. The bulb gives stiffness to prevent the plate from buckling under water pressure. |

| Offshore Jacket Bracing | Used as secondary bracing members inside the legs of offshore platforms. | Performs well under the constant push and pull (cyclic loading) of ocean waves. |

| Foundation and Bracket Stiffening | Used to reinforce bases for heavy machinery on deck. | Easy to cut and weld into custom shapes, providing localized strength. |

The main alternative is an angle bar. An angle bar has two legs. It is good for connections. A bulb flat is like a simplified T-bar. It is designed for one job: to be a strong, lightweight stiffener.

The Inspection Focus Based on Application

Knowing the use helps you focus your inspection. For example, a bulb flat for a hull longitudinal needs perfect straightness. If it is bent, it will not fit snugly against the curved hull plate. This creates a poor weld.

For a bulkhead stiffener, the exact height of the bulb might be slightly less critical. But the flatness of the back is very important. It must make full contact with the bulkhead plate.

When our clients order bulb flats, we always ask about the application. This is not just small talk. If they are for a high-stress area on an ice-class vessel, we might recommend a higher grade like DH36 instead of AH36. We also know to pay extra attention to the low-temperature impact test results on the MTC. The right steel for the job makes inspection and final approval much smoother.

How strong is a steel flat bar?

You are designing a bracket. You want to use a simple flat bar. You need to know if it is strong enough to hold the load without bending or breaking.

The strength of a steel flat bar depends on its material grade and dimensions. Common mild steel flat bars have a yield strength of around 250 MPa. This means a 50mm x 10mm bar can support a static load of about 12.5 tons before it starts to bend permanently. The actual safe load is much lower, based on a safety factor.

Strength is not a single number. You need to think about different types of strength and the factors that change them.

Understanding Yield Strength, Load Capacity, and Influencing Factors

For engineers, "strength" usually means yield strength. This is the stress level where the steel starts to deform permanently. We can break this down.

| Type of Strength | Definition | Why It Matters for a Flat Bar |

|---|---|---|

| Yield Strength (Rp0.2) | The stress that causes a small, permanent deformation (0.2% strain). | This is the practical limit for design. Exceeding it means the part is permanently bent. |

| Tensile Strength (Rm) | The maximum stress the material can take before breaking. | This is the ultimate failure point. The safety factor is based on the yield strength, not this one. |

| Shear Strength | Resistance to forces trying to slide one part over another (like in a bolted connection). | Important for flat bars used as connection plates or gussets. |

The load a flat bar can hold is calculated with this formula: Load (kN) = Yield Strength (MPa) x Cross-Sectional Area (mm²) / 1000.

But many factors change the real-world strength:

- Material Grade: An S355 grade flat bar is about 40% stronger than a standard S235 grade bar.

- Thickness: Strength increases directly with thickness. A 12mm thick bar is 20% stronger than a 10mm thick bar of the same width.

- Direction of Force: A flat bar is much stronger when the force pulls along its length (tension) than when the force pushes against its thin edge (buckling).

From Flat Bar to Bulb Flat: A Major Strength Increase

This brings us back to bulb flats. A bulb flat is essentially a flat bar with a bulb added. This small addition makes a huge difference.

Think about bending a ruler. It bends easily on its flat side. Now imagine gluing a rod along one edge of the ruler. It becomes much harder to bend. The bulb acts like that rod. It moves material away from the center, which dramatically increases the "section modulus." This is a measure of bending resistance.

For the same weight of steel, a bulb flat can be up to 5 times stiffer in bending than a simple flat bar. This is why bulb flats are used in ships and not simple flat bars. During inspection, checking the bulb dimensions (height and width) is a direct check on this added strength. A bulb that is too small means the product does not meet its design strength.

Which is better, CR or HR?

You need steel for a precise part. You see two options: Cold-Rolled (CR) and Hot-Rolled (HR). The price is different. You need to know which one is truly better for your job.

There is no single "better" option between Cold-Rolled (CR) and Hot-Rolled (HR) steel. The choice depends on your needs. HR steel is tougher, cheaper, and used for structural parts like ship frames. CR steel has tighter tolerances, a smoother finish, and is used for precise manufacturing or visible parts where appearance matters.

CR and HR are different processes that create different products. One is not an upgrade of the other. They are tools for different jobs.

A Detailed Comparison: Process, Properties, and Applications

The best way to choose is to compare their characteristics side-by-side.

| Characteristic | Hot-Rolled (HR) Steel | Cold-Rolled (CR) Steel |

|---|---|---|

| Manufacturing Process | Steel is rolled at high temperatures (above 1700°F). | Steel is rolled at room temperature, after it is already hot-rolled. |

| Surface Finish | Has a rough, scaled surface (mill scale). It is gray and non-shiny. | Has a very smooth, oily, and shiny surface. |

| Dimensional Tolerance | Tolerances are looser. Thickness and flatness can vary more. | Tolerances are very tight. Dimensions are precise and consistent. |

| Mechanical Properties | Softer, more ductile, easier to weld. Has normalized properties good for structural work. | Harder, stronger (due to work hardening), but can be less ductile. |

| Cost | Generally less expensive. | More expensive due to the extra processing. |

| Common Applications | I-beams, ship plates, bulb flats, construction frames. Anywhere high strength and weldability are key, and surface finish is not critical. | Automobile panels, appliances, furniture, metal cabinets. Where precise forming, a smooth finish, or painting is required. |

For all marine structural components—plates, bulb flats, angles—Hot-Rolled steel is the standard and correct choice. Its properties are ideal for the heavy welding and structural demands of shipbuilding.

Why Hot-Rolled is the Only Choice for Marine Bulb Flats

This is a critical point. Bulb flats for ships are always hot-rolled. Here is why.

First, weldability. HR steel has a normalized microstructure that is ideal for the high-heat input welding used in shipyards. CR steel, which is work-hardened, can have issues with heat-affected zones during welding.

Second, toughness. Marine steels like AH36 need good impact toughness at low temperatures. The hot-rolling process contributes to this. The cold-rolling process does not.

Third, scale. The mill scale on HR steel is not a defect for marine use. It is usually removed by shot blasting before painting in the shipyard. The smooth surface of CR steel offers no advantage here and costs more.

During pre-shipment inspection, you can easily tell them apart. HR bulb flats will have a bluish-gray oxide layer (mill scale) and slightly rounded edges. CR steel (if mistakenly supplied) would have sharp edges, a very smooth, metallic surface, and likely different mechanical properties that would not match the AH36/DH36 MTC. Recognizing this difference is a basic but vital part of a visual check.

Conclusion

A thorough pre-shipment inspection is your best defense against project delays and quality claims. By checking dimensions, surface quality, documentation, and understanding the product’s use and material, you ensure you receive steel that is fit for purpose.