Seeing the freight quote for your bulb flat steel shipment can be a shock. Transport costs can sometimes rival the material cost itself. I once worked with a shipyard in Vietnam that almost cancelled an order because the shipping fees were unexpectedly high.

You can reduce freight costs for bulb flat steel by consolidating orders to fill containers, optimizing packing to maximize space, choosing the right Incoterm (like FOB), and partnering with a supplier who has strong freight forwarder relationships for competitive bulk rates. Every cubic meter you save translates directly to lower costs.

For our B2B clients, controlling total landed cost is a top priority. The factory price is just one part. Smart logistics management makes your purchase truly competitive. Let’s explore practical strategies you can use, starting with the fundamental principles of reducing freight charges.

How to reduce freight charges?

Many importers simply accept the first freight quote they receive. This is a missed opportunity. Freight charges are not fixed. They are negotiable and highly dependent on how you structure your shipment. A contractor in Qatar saved 18% on their last shipment just by adjusting their loading plan.

To reduce freight charges, focus on decreasing the shipment’s volumetric weight, negotiating better rates with forwarders, selecting slower but cheaper transit times, and minimizing port handling fees through efficient documentation and packing. It’s a combination of planning, negotiation, and execution.

A Tactical Approach to Lowering Freight Bills

Reducing charges requires you to understand what you are paying for. A freight quote includes ocean freight, fuel surcharges, terminal handling charges (THC), documentation fees, and more. You can influence each one.

1. Attack the Volumetric Weight

Ocean freight for breakbulk and containers is often charged per cubic meter (CBM) or per freight ton (weight or volume, whichever is greater). Bulb flats are long and oddly shaped, which can create wasted space.

- Strategy: Work with your supplier to design a packing layout that nests the bulbs together tightly. Use strong steel straps to compress the bundle, reducing its overall dimensions. Even a 10% reduction in volume can mean a 10% reduction in the base ocean freight cost.

2. Negotiate, Don’t Just Accept

- Leverage Volume: If you are a regular importer, consolidate your annual forecast and negotiate a contract rate with a freight forwarder. Even sporadic importers can ask for quotes from 3-4 forwarders.

- Use Your Supplier’s Network: A good supplier ships daily. They have negotiated rates with forwarders based on their large volume. When we quote CFR or CIF to clients in Saudi Arabia or Mexico, we use these pre-negotiated rates, which are often better than what a small buyer can get alone.

3. Choose Transit Time Wisely

- Direct vs. Transshipment: A direct vessel from Qingdao to Dammam is faster but may be more expensive than a route that transships in Singapore. If time is not critical, the slower route can save money.

- Shipping Line: Premium lines cost more. For sturdy steel, a reliable but less expensive line is often perfectly adequate.

4. Minimize Ancillary Fees

- Documentation: Ensure all documents (Commercial Invoice, Packing List, Bill of Lading) are 100% accurate. Mistakes cause delays and amendment fees.

- Packing: Use returnable steel cradles instead of disposable wooden frames if possible. This can reduce packing material costs and sometimes even customs issues with wood treatment certificates.

Here is a table comparing common cost centers and reduction tactics:

| Freight Cost Component | What It Is | How to Reduce It |

|---|---|---|

| Ocean Freight (Base Rate) | The core cost to move the container or cargo by sea. | Negotiate contract rates, optimize volume, choose slower transit. |

| Bunker Adjustment Factor (BAF) | Fuel surcharge. | Usually non-negotiable, but part of the total quote to compare. |

| Terminal Handling Charges (THC) | Fees for loading/unloading at port. | Compare quotes; some terminals are cheaper. Efficient packing speeds handling. |

| Documentation Fees | Fees for Bill of Lading, etc. | Some forwarders bundle these. Ask for a detailed breakdown and challenge unnecessary fees. |

| Inland Haulage | Trucking from factory to port and port to your yard. | For FOB, your forwarder handles destination haulage. Get multiple trucking quotes locally. |

The key is proactive management. Don’t view freight as a simple line item. View it as a process you can optimize. This mindset leads directly to the next question: how to minimize the overall shipping cost.

How to minimize shipping cost?

Minimizing cost is about the big picture, not just haggling over rates. It involves strategic decisions made before you even place the order. A wholesaler in the Philippines used to order small quantities monthly, incurring high per-unit shipping costs. We helped them shift to quarterly consolidated orders.

To minimize total shipping cost, consolidate multiple purchases into full container loads (FCL), choose the most cost-effective Incoterm for your situation (e.g., FOB for large buyers), plan shipments during low season periods, and ensure packaging is optimized for both protection and space efficiency. This holistic approach targets the root causes of high costs.

Strategic Planning for Cost-Effective Shipping

Think of shipping cost as a formula: (Material + Packing) + (Freight + Insurance) + (Import Duties + Taxes) + (Inland Transport). You can optimize almost every variable.

1. The Power of Consolidation: FCL vs. LCL

This is the single most impactful decision.

- Less than Container Load (LCL): You pay for the space you use in a shared container. The rate per CBM is much higher than FCL. You also pay for origin and destination warehouse handling fees (LCL Service charges).

- Full Container Load (FCL): You pay for the entire container (20ft or 40ft), regardless of whether you fill it 100%. The cost per ton or per CBM plummets.

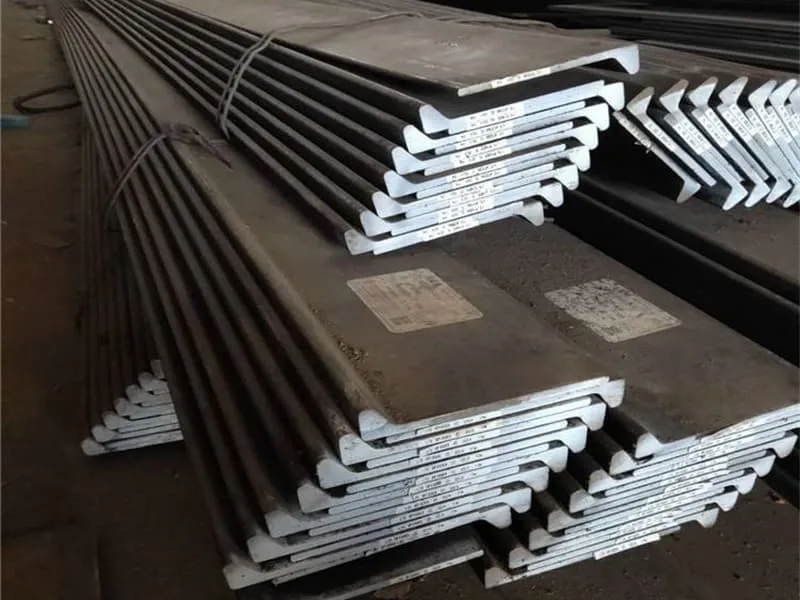

- Action: Plan your material needs. Combine bulb flat steel with other items like marine plates or angles to create a full container. We work with clients in Thailand and Romania to do this, using our flexible MOQ to help them reach economical shipment sizes.

2. Incoterms Selection: Who Controls the Cost?

- EXW (Ex-Works): You control and pay for everything from our factory gate onward. This gives you maximum control but also maximum complexity. You need your own freight forwarder in China.

- FOB (Free On Board): We deliver and load the goods onto the vessel at the Chinese port. You pay the main ocean freight and destination costs. This is a very common and balanced term for B2B. You can use your forwarder or ours to book the sea leg.

- CFR/CIF (Cost & Freight / Cost, Insurance & Freight): We arrange and pay for the ocean freight to your port (CIF includes insurance). We build this cost into our quote. This is simpler for you but gives you less visibility and control over freight costs.

- For cost minimization: Large, sophisticated importers often prefer FOB. They use their large shipping volumes to negotiate excellent ocean rates directly. Smaller importers may find CFR/CIF from a reliable supplier is simpler and still competitive due to the supplier’s volume discounts.

3. Timing is Money: Seasonality

- Freight rates fluctuate. Demand is high (and rates peak) before major holidays (Chinese New Year, Christmas) and during peak manufacturing seasons.

- Plan Ahead: Place orders and schedule shipments during off-peak periods (e.g., Q2 or Q3) if your project timeline allows. This can lead to significant savings.

Strategic Choice Comparison:

| Your Profile & Priority | Recommended Strategy | Why It Minimizes Cost |

|---|---|---|

| Regular large-volume buyer (e.g., shipyard) | FOB Terms + Your own long-term freight contracts + FCL shipments. | You leverage your own volume for the best ocean rates and maintain full control. |

| Medium-sized project contractor | Work with supplier to consolidate orders for FCL. Use supplier’s CFR quote as a benchmark. | Achieves low FCL rates through supplier consolidation without the hassle of managing China logistics. |

| Smaller wholesaler / first-time importer | Start with supplier’s CIF/CFR quote for a full container. Consider group-buying with other local businesses. | Simplifies the process and benefits from the supplier’s logistics scale immediately. |

Minimizing cost is not about being cheap. It is about being efficient. It removes waste from the supply chain. This leads us to the practical question: how do you actually ship freight cheaply?

How to ship freight cheaply?

"Cheaply" does not mean cutting corners that risk your cargo. It means finding the most economical reliable method. The cheapest freight option that results in damaged steel or a 2-month delay is actually the most expensive. A fabricator in Myanmar learned this the hard way with a super-slow, discounted line.

To ship freight cheaply for heavy steel, prioritize Full Container Load (FCL) shipments, consider breakbulk shipping for very large or oversized pieces, use a freight forwarder that specializes in project cargo and heavy lift, and always balance the quoted rate with the carrier’s reliability and transit time. The goal is the lowest total cost of ownership, not just the lowest ticket price.

Evaluating Cost-Effective Shipping Methods for Steel

Different cargo types have different cheap solutions. For standard lengths of bulb flat steel (up to 12m or 14m), containers are typical. For longer lengths, you need other options.

1. Container Shipping (The Standard Solution)

- 20ft Standard Container: Internal length ~5.9m. Good for shorter steel cuts or other materials, but not for standard 12m bulbs.

- 40ft Standard Container: Internal length ~12.03m. Fits 12m steel perfectly. This is the most common and cost-effective method for most bulb flat shipments.

- 40ft High Cube Container: Offers extra height. Useful if you need to stack bundles vertically to maximize a shipment.

- Why it’s cheap (per ton): Containerization is efficient for ports and ships. FCL rates offer the best value. It also provides excellent protection from the elements.

2. Breakbulk Shipping (For Large Volumes or Long Lengths)

- What it is: Your steel is loaded directly into the ship’s hold as individual pieces or bundles, not inside a container.

- When it’s cheap: For shipments significantly larger than a few containers (e.g., hundreds of tons), or for pieces longer than 12 meters. You pay per freight ton (weight or volume), and for large volumes, this rate can become very competitive.

- Considerations: Requires more complex logistics at both ends (stevedores, special lifting). More exposed to weather during loading/unloading. Packaging must be extremely robust.

3. RORO (Roll-on/Roll-off)

- What it is: Your steel, packed on a trailer or in a Mafi flat-rack, is driven onto a special ship.

- When it’s cheap: For certain routes and for oversized, heavy pieces that are difficult to lift. Less common for standard steel profiles.

How to Choose the "Cheapest" Reliable Method:

| Your Shipment Profile | "Cheapest" Reliable Method | Key Considerations & Tips |

|---|---|---|

| 10-25 tons of 12m bulb flats. | 40ft FCL Container. | Maximize space use. Ensure bundles are strapped to container walls to prevent movement. This is our default for clients in Saudi Arabia and Malaysia. |

| 80+ tons of various steel (plates, angles, bulbs). | Breakbulk Shipment. | The volume discount becomes significant. You need a supplier experienced in breakbulk stowage and marking. |

| Single, very heavy fabrications (over 20 tons each). | Breakbulk or RORO. | Requires specialized lifting gear. The cost is in the handling, not just the freight. |

| Small sample order (under 3 CBM). | Air Freight is fastest, but LCL is the cheap surface option. | LCL will be cost-effective but slow. Air freight is for urgency, not cost savings. |

The Role of the Freight Forwarder:

A good forwarder doesn’t just book space. They advise on the best method. They know which lines offer good value on your specific route (e.g., China to Jebel Ali or Houston). When clients ask us for shipping help, we connect them with our partner forwarders who understand steel. This support was part of the solution for Gulf Metal Solutions, ensuring smooth shipping to Dammam port. Cheap freight is not about finding the lowest bidder; it’s about finding the most efficient expert.

How to minimize transport cost?

Transport cost includes every movement from the mill to your workshop: factory-to-port, port-to-port, and port-to-your-door. Minimizing it requires looking at the entire chain. A common error is optimizing ocean freight but then overpaying for the final truck delivery.

To minimize total transport cost, integrate inland trucking with your ocean freight plan, choose the right port of discharge closest to your final destination, consider door-to-door service for simplicity and potential bundling discounts, and avoid unnecessary handling and storage at transshipment points. Streamlining the entire journey eliminates redundant expenses.

Optimizing the End-to-End Transport Chain

Think of the steel’s journey as a relay race. Each handover has a cost. Your goal is to have fewer, smoother handovers.

1. Inland Transport in China (Origin)

- Cost Factor: Distance from mill (Liaocheng, Shandong) to load port (e.g., Qingdao, Tianjin).

- Minimization Strategy:

- Port Selection: The nearest major port is usually cheapest. For us, Qingdao is the primary port, keeping trucking costs low for our clients.

- Truck Loading: Ensure the truck is fully utilized. We coordinate multiple orders going to the same port to share truck space when possible.

2. The Main Ocean Leg

We covered this with FCL vs. LCL and negotiation. The key for total transport is to choose the right port of discharge.

3. Inland Transport at Destination

This is often where costs spiral if not planned.

- Port of Discharge: Is it the major hub port (e.g., Jebel Ali, UAE) or a smaller direct port (e.g., Dammam, Saudi Arabia)? Shipping to a hub might have cheaper ocean freight, but the additional trucking or feeder vessel cost to your city may erase the savings.

- Example: For a client in Riyadh, Saudi Arabia, shipping directly to Dammam port (with onward trucking) is almost always cheaper than shipping to Jebel Ali and then trucking across the desert.

- Door-to-Door Service: Many forwarders offer a single price from our factory to your yard. This simplifies everything for you and allows the forwarder to optimize the entire chain, sometimes passing savings to you.

4. Avoiding Hidden Costs

- Demurrage & Detention: These are fees if the container is not unpacked and returned quickly. Have your unloading crew ready upon arrival. Use a forwarder that includes a sufficient free period.

- Storage: If you are not ready to receive, you will pay storage fees at the port. Coordinate the shipment date with your project schedule.

- Customs Clearance Delays: Incomplete or incorrect documents cause delays, which lead to storage and demurrage costs. We provide all necessary docs (Commercial Invoice, Packing List, MTC, CO) in English to facilitate fast clearance for our clients in Mexico, Vietnam, etc.

Total Cost Optimization Table:

| Transport Leg | Cost Drivers | How to Minimize Cost (Actionable Tips) |

|---|---|---|

| Origin Inland (China) | Truck type, distance, tolls, fuel. | Let your supplier handle this as part of FOB. They have local trucking contracts. |

| Ocean Freight | Container type, season, line, speed. | Book FCL, negotiate, consider slower transit, use supplier’s quoted CFR as a benchmark. |

| Destination Port Charges | THC, port dues, customs inspection fees. | Choose a port with efficient operations. Ensure perfect paperwork to avoid inspection delays. |

| Destination Inland | Distance from port, truck availability, road permits. | Crucial: Get multiple trucking quotes locally. Compare door-to-door vs. port pickup. For the Middle East, we often recommend direct discharge at Dammam or Jebel Ali. |

| Risk & Delay Costs | Demurrage, detention, storage. | Plan your receiving logistics in advance. Have your customs broker ready. |

For results-driven buyers, the message is clear: control involves oversight of the entire process. By understanding and actively managing each segment of the transport chain—from our mill gate to your storage yard—you convert random costs into a managed, optimized expense. This completes the picture of truly reducing the freight costs for your bulb flat steel.

Conclusion

Reducing freight costs for bulb flat steel requires a strategic mix of consolidation (FCL), smart Incoterm selection, logistical optimization, and managing the entire transport chain. This turns shipping from a cost center into a competitive advantage.