Trying to find a reliable source for L-shaped steel in China can feel like navigating a maze. You’re hit with endless options, unsure about quality, price, or which mill truly delivers. This list cuts through the noise, giving you the clear information you need to make a confident sourcing decision.

The top L-shaped steel manufacturers in China include industry leaders like Baowu Group and Ansteel Group, which lead in volume and advanced production, alongside specialized mills in Shandong and Hebei that offer competitive pricing and flexible service for marine and structural steel needs. Their collective output, driven by scale, government support, and modern infrastructure, makes Chinese steel both high-quality and cost-effective on the global market.

%[Top 10 L-Shaped Steel Manufacturers in China Ranking](Who are the Top 10 L-Shaped Steel Manufacturers in China? "Top 10 L-Shaped Steel Manufacturers in China Ranking")

This ranking isn’t just about size; it’s a practical guide. I’ve seen how choosing the right partner impacts everything from project timelines to your bottom line. The following sections will answer the key questions you have about the Chinese steel industry, from the biggest players to why their prices are competitive. Let’s explore what makes each manufacturer stand out.

Who is the largest steel manufacturer in China?

Looking for the undisputed leader in China’s steel industry? You need to know who sets the standards in production and quality. This giant’s output isn’t just a number; it influences global prices and availability for products like the L-shaped steel you need.

Baowu Steel Group is definitively the largest steel manufacturer in China and the world. It was formed by merging former giants Baosteel and Wuhan Iron & Steel, and it produces over 120 million tons of crude steel annually. Its leadership comes from massive scale, cutting-edge technology, and a complete product portfolio that includes premium-grade marine steel plates and structural sections.

Understanding Baowu’s Dominance and What It Means for You

Baowu’s position is built on several pillars that are important for international buyers to understand.

Scale and Integration: Baowu operates dozens of production bases across China and has integrated its operations from raw material sourcing (like iron ore and coking coal) to finished product manufacturing. This vertical integration gives them significant cost control and supply chain stability. For you, this means they can handle massive, long-term orders with consistency. However, their minimum order quantities (MOQs) can be very high, and they primarily serve other large corporations or state projects. As a B2B wholesaler like us at CN Marine Steel, we maintain long-term cooperation with certified mills, including Baowu’s tier-one suppliers, to access their high-quality products without you needing to meet those prohibitive MOQs directly.

Technology and Product Quality: Baowu invests heavily in research and development. They produce some of the highest-grade steel in China, including special grades for shipbuilding (marine steel plates), offshore platforms, and other demanding applications. Their products often meet and exceed international standards like ABS, DNV, GL, and CCS. When you see steel from a mill affiliated with or supplying Baowu, you can be more confident in its metallurgical properties and traceability. We leverage these partnerships to source materials for clients like Gulf Metal Solutions in Saudi Arabia, who require stable quality and third-party inspection support.

Market Influence and Pricing: As the market leader, Baowu’s official pricing often acts as a benchmark for the entire Chinese steel market. When Baowu adjusts its prices, other mills typically follow. This doesn’t mean they are always the cheapest. Their premium products command premium prices. The "cheap" perception of Chinese steel more often comes from midsized and smaller mills that compete on cost for standard grades. Here’s a simple comparison:

| Aspect | Baowu Group (The Leader) | Typical Midsized Mill (Our Common Partners) |

|---|---|---|

| Primary Advantage | Ultimate scale, top-tier R&D, premium grades | Agility, competitive pricing, flexible MOQ |

| Best For | Mega-projects, critical applications (e.g., hull of large tankers) | Most commercial shipbuilding, structural projects, general fabrication |

| Order Flexibility | Low (Very high MOQs, long lead times) | High (Flexible MOQ, faster turnaround) |

| Price Point | Benchmark (Often higher for premium products) | Highly competitive |

| Buyer Access | Difficult for foreign SMEs | Accessible via experienced trading partners/wholesalers |

In practice, very few international buyers deal directly with Baowu. They work through large trading houses or specialized wholesalers like us. Our role is to bridge that gap. We consolidate orders, manage logistics from production hubs like Liaocheng in Shandong, and provide the English-speaking support and SGS inspection coordination that direct mills often lack. So, while Baowu is the largest producer, your most efficient path to their quality often lies with a reliable intermediary who understands both the mill’s processes and your specific needs.

Why is Chinese steel so cheap?

You hear "cheap Chinese steel" and might worry about hidden costs or poor quality. The low price tag can be confusing, especially when you need reliable materials for critical projects. Let’s break down the real reasons behind the cost advantage.

Chinese steel is relatively cheap due to massive production scale, significant government support in the past, lower domestic labor and energy costs, and highly efficient, modernized logistics networks. These factors combine to create a lower baseline cost, which is then passed on in competitive global pricing, particularly for standard commodity grades.

The Complex Truth Behind Competitive Pricing

The term "cheap" needs careful examination. It’s not a single reason but a system of interconnected advantages.

Economies of Scale: This is the most straightforward factor. China produces over half of the world’s steel. Mills operate at unparalleled volumes, spreading fixed costs (like plant investment and R&D) over a huge number of tons. This unit cost reduction is fundamental. When a mill can run its blast furnaces and rolling mills continuously at near-full capacity, its efficiency maximizes and cost per ton minimizes. For bulk orders of standard L-shaped steel or marine plates, this scale benefit is directly reflected in the price.

Historical Government Subsidies and Control: It’s important to acknowledge history. For decades, the Chinese government actively supported the steel industry as a pillar of economic development. This came in the form of low-interest loans, subsidized energy (coal and electricity), and support for raw material imports. While today’s market is far more commercialized and many inefficient subsidies have been cut, this foundational support helped build the world’s largest and most integrated steel infrastructure. The legacy is a mature industry with lower barriers to continuous operation. However, it also led to overcapacity in some standard product segments, which increases competition and keeps prices low.

Operational Cost Advantages: Although rising, labor costs in Chinese heavy industry remain lower than in Western Europe, North America, or Japan. More importantly, China has built a fully integrated supply chain. From domestic iron ore and coking coal (though much high-grade ore is imported) to the massive ports that ship finished products, every link is optimized for cost. Logistics, especially domestic rail and port fees, are highly efficient for bulk commodities. When we ship from Shandong to Dammam port for a client in Saudi Arabia, we benefit from this streamlined, high-volume export system.

Product and Market Segmentation: Not all Chinese steel is equally "cheap." The pricing varies dramatically by grade and mill.

- Commodity Grades: Standard structural angles (like common L-shaped steel), rebar, and basic hot-rolled coil are where price competition is fiercest. Many mills produce these, leading to thin margins. This is the source of the "cheap" stereotype.

- Specialized Grades: High-strength marine steel plates, corrosion-resistant alloys, or bulb flat steel for shipbuilding are more expensive. They require advanced technology and stricter quality control. Mills like Baowu or specialized producers charge more for these. The price is competitive globally but not "cheap."

The key for you is to match the product grade to your application. If you need standard sections for general construction, the commodity market offers very low prices. For critical marine applications, you pay for advanced metallurgy, but still at a cost typically below European or Japanese mills. Our job is to guide you to the right mill for your budget and quality needs, ensuring the "cheap" price doesn’t come with hidden risks like inconsistent quality or poor surface finish—a pain point we solved for Gulf Metal Solutions by offering pre-shipment inspection.

Which is the world top 5 steel plant?

When sourcing globally, knowing the top players helps you gauge market trends and quality benchmarks. These giants shape the industry’s technological and pricing landscape, which ultimately affects your supply options and costs.

The world’s top 5 steel-producing companies are China Baowu Steel Group, ArcelorMittal (Luxembourg/global), Ansteel Group (China), Nippon Steel Corporation (Japan), and Shagang Group (China). They are ranked by annual crude steel production volume, with Baowu consistently holding the top position by a significant margin.

A Closer Look at the Global Steel Elite

This ranking is about raw output, but each company has a distinct profile that influences the global market in different ways. Understanding these profiles helps you make smarter sourcing decisions.

1. China Baowu Steel Group: As discussed, it’s the undisputed volume leader. Its strategy is "big and comprehensive," focusing on everything from basic iron ore to high-tech automotive and electrical steel. For you, Baowu represents the pinnacle of scale and high-end capability in China, but direct access is challenging.

2. ArcelorMittal: Headquartered in Luxembourg but operating globally, ArcelorMittal is the most internationalized company on the list. It has plants in the Americas, Europe, Africa, and Asia (including a joint venture in China). ArcelorMittal is known for its strong R&D, sustainability focus, and production of advanced high-strength steels. For international projects requiring certification to European or American standards (like ASTM), ArcelorMittal is a primary source. However, their prices are generally higher than Chinese mills for equivalent commodity grades.

3. Ansteel Group (Angang Steel): Another Chinese state-owned giant, Ansteel is particularly strong in steel plates, including thick plates for shipbuilding, bridges, and pressure vessels. They are a key domestic competitor to Baowu in the high-end plate segment. For marine steel plates, Ansteel is a Tier-1 supplier in China, and their products are widely used in domestic and international shipbuilding.

4. Nippon Steel Corporation: Japan’s leader is synonymous with extreme quality and precision. They excel in producing advanced steel for the automotive industry, electronics, and high-performance infrastructure. While their total volume is less than the Chinese giants, their technological prowess and premium brand allow them to command the highest prices in the market. For critical components where failure is not an option, Nippon Steel is often the benchmark.

5. Shagang Group: China’s largest private steel enterprise, Shagang is known for its remarkable efficiency and cost control. It focuses heavily on long products (rebar, wire rod) and hot-rolled coil. Shagang exemplifies the agile, market-driven model in China. They can adjust production quickly based on market demand, making them a very competitive source for standard structural steel products.

Here is how they compare from a buyer’s perspective:

| Company | Home Country | Key Strength | Typical Price Level | Best For Buyers Who Need… |

|---|---|---|---|---|

| Baowu Steel | China | Scale, Vertical Integration, High-end Plates | Medium to High (benchmark) | Large-volume, high-grade plates, projects with Chinese standards |

| ArcelorMittal | Luxembourg/Global | International Presence, Advanced Grades, Sustainability | High | Projects requiring EU/UK/US standards, global supply consistency |

| Ansteel Group | China | Heavy Steel Plates, Shipbuilding Grades | Medium to High | Marine and construction plates, reliable quality from China |

| Nippon Steel | Japan | Ultimate Quality & Precision, Advanced Technology | Very High | Critical automotive/engineering applications where cost is secondary |

| Shagang Group | China | Efficiency, Cost Control, Standard Long Products | Low to Medium | Large volumes of standard rebar, wire rod, competitive pricing |

For most of our clients—importers, marine wholesalers, and project contractors in countries like Vietnam, Mexico, and Saudi Arabia—the Chinese mills (Baowu, Ansteel, Shagang, and their tier-two partners) offer the best balance of quality, price, and volume. We navigate this ecosystem daily, connecting you to the right tier of this global top 5 network without the complexity of dealing with their corporate headquarters directly.

Who is the biggest supplier of steel1?

You need a reliable flow of material, not just a one-time purchase. The "biggest supplier" can mean different things: the largest producer, the largest exporter, or the most reliable partner for your specific needs. Let’s clarify who holds which title.

China is the world’s biggest supplier of steel1 in terms of both production and export volume. Within China, Baowu Steel Group2 is the biggest single-company supplier. For global buyers, a network of Chinese mills and wholesalers forms the most significant supply base for a wide range of steel products.

Defining "Biggest Supplier" in a Practical Sense

The title "biggest" isn’t monolithic. From our daily operations with clients from the Philippines to Romania, we see it break down into three key areas.

1. Biggest Producer Nation – China: This is the macro view. China’s annual steel production3 is greater than the combined output of the next nine countries (including India, Japan, and the USA). This massive domestic industry is the foundation of the global supply. It means that regardless of where you buy steel physically, a significant portion of the raw material or semi-finished product likely originated in China. The country’s export volume consistently leads the world, supplying everything from raw billet to finished L-shaped sections to global markets. This dominance gives Chinese-based suppliers, both mills and traders, a structural advantage in availability and price competitiveness.

2. Biggest Corporate Producer – Baowu Group: As already established, if you need a single corporate entity that can supply the most tons, it’s Baowu. They are a "supplier" primarily to other massive industries (automotive, appliance, shipbuilding) and national infrastructure projects. For an international buyer, they are often a source several steps removed in the supply chain. You access their output through large trading companies or specialized wholesalers who have the contracts and logistical capability to break down their massive output into shippable orders for ports like Dammam or Manila.

3. Your Biggest Potential Partner – The Agile Wholesaler/Mill Combination4: This is the most practical definition for an importer. The "biggest supplier" for you is the one that reliably meets your needs: stable quality, responsive communication, flexible MOQ, and full export support. For many of our clients, this isn’t a single mill but a partnership with a wholesaler like us who has deep ties with multiple certified mills.

We act as your single point of contact and manage a diversified supply base. For example:

- For Marine Steel Plates5 requiring specific classifications, we tap into our partnerships with plate specialists like Ansteel’s network or premium plate mills.

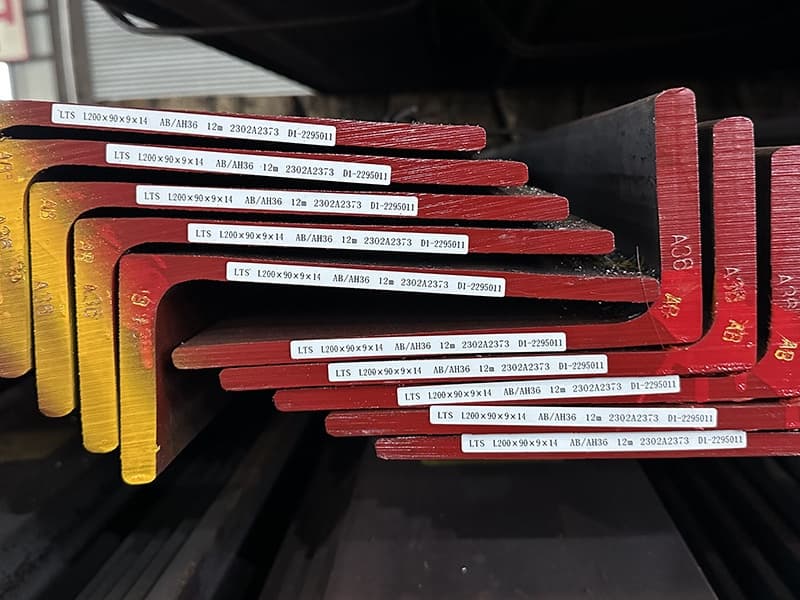

- For Marine Angle Steel and L-shaped sections, we work with highly efficient section mills in Hebei and Shandong that may not be in the global top 10 by volume but are top-tier in their product category and cost-effectiveness.

- For Bulb Flat Steel6, a niche product, we collaborate with a smaller number of specialized rolling mills.

This model solves the core pain points buyers like Gulf Metal Solutions had: delayed response, quality inconsistency, and lack of English support. We become their "biggest supplier" in terms of reliability and service, even if we aren’t the biggest in the world by tonnage. We offer the collective capacity and expertise of the Chinese steel industry, packaged with the service level international business requires.

Conclusion

Choosing the right L-shaped steel manufacturer in China means balancing scale, specialization, and service. The top players like Baowu set the quality standard, while the competitive market ensures value. Your best partner is one who connects you to this ecosystem reliably.

-

Understanding the criteria for the biggest supplier can help you make informed purchasing decisions. ↩ ↩

-

Explore Baowu’s role as a leading corporate producer and its impact on global steel supply. ↩

-

Discover the scale of China’s steel production and its implications for global markets. ↩

-

Understand how this model can enhance your steel procurement strategy. ↩

-

Learn about Marine Steel Plates and their importance in various industries. ↩

-

Find out about Bulb Flat Steel and its specialized applications in the industry. ↩