You are building a ship. The ocean is unforgiving. Your reputation and safety depend on every beam and frame. Using uncertified or lower-grade steel might seem like a way to save money upfront. But this decision can lead to catastrophic failures, costly repairs, and rejected projects.

You should use BV certified marine L-shaped steel because Bureau Veritas certification guarantees the material meets strict international standards for strength, toughness, and weldability in marine environments. It provides independent verification of quality, ensures regulatory compliance for vessel construction, and protects your investment by minimizing the risk of structural failure.

Choosing BV steel is not just about buying a product. It is about adopting a system of assurance. Many suppliers offer "marine steel," but only steel with proper classification society approval comes with a traceable guarantee of performance. This guarantee matters to shipyards, owners, and insurers. Let me explain the specific reasons and technical details so you understand why this certification is non-negotiable for serious marine projects.

What are the properties of BV grade steel1?

Imagine steel that must not crack in icy waters, must resist constant corrosion, and must hold its shape under massive stress. Ordinary steel cannot do this. BV grade steel1 is engineered specifically for these challenges. Its properties are a carefully balanced recipe for survival at sea.

BV grade steel1, such as BV A or BV D, offers enhanced yield strength2 (often 235 MPa minimum), excellent low-temperature toughness verified by Charpy impact tests, and good weldability3 with controlled carbon content. These properties ensure structural integrity in the harsh, dynamic marine environment.

The properties defined by Bureau Veritas are not arbitrary. They are the result of decades of naval architecture and failure analysis. Each property addresses a specific threat faced by ships.

A Detailed Breakdown of Key BV Steel Properties

We can break down the essential properties into three main categories: mechanical strength, toughness, and chemical composition4 for fabrication.

1. Mechanical Strength: The Backbone of the Structure

The steel must support the ship’s weight, cargo, and wave loads without permanently deforming.

- Yield Strength (ReH): This is the most critical strength indicator. It is the stress level where steel stops behaving elastically (springing back) and starts to deform permanently. For standard BV grades, the minimum yield strength2 is 235 MPa. This high threshold ensures frames and hulls can withstand heavy loads.

- Tensile Strength (Rm): This is the maximum stress the steel can take before breaking. BV specifications5 set a required range, for example, 400-520 MPa for some grades. This range ensures the steel is strong but not too brittle.

2. Toughness and Impact Resistance: Fighting Brittle Fracture

Cold temperatures make steel brittle. A collision or stress in cold water can cause a brittle fracture that propagates rapidly through the structure.

- Charpy V-Notch Impact Test6: This is the standard test for toughness. A notched sample is struck by a pendulum at a specified low temperature. The energy absorbed to break it is measured in Joules.

- BV’s Requirement: BV mandates testing at temperatures as low as -20°C or -40°C, depending on the grade and intended service. High impact energy values at these temperatures prove the steel will remain ductile and crack-resistant in frigid sea conditions.

3. Chemical Composition: The Recipe for Weldability and Corrosion Resistance

The amounts of elements like carbon, manganese, and sulfur are tightly controlled.

- Carbon Equivalent (Ceq): This is a calculated value that predicts the steel’s hardenability and weldability3. A lower Ceq means the steel is less prone to forming hard, crack-sensitive zones after welding. BV sets maximum Ceq limits to ensure safe and reliable welding during ship construction.

- Low Sulfur & Phosphorus: These elements are impurities. High sulfur causes "hot shortness" (cracking during hot working), and high phosphorus increases cold brittleness7. BV specifications5 keep them at very low levels.

Here is a simplified table comparing key properties for common BV normal strength grades:

| Property / Grade | BV A | BV B | BV D | BV E |

|---|---|---|---|---|

| Minimum Yield Strength (ReH) | 235 MPa | 235 MPa | 235 MPa | 235 MPa |

| Tensile Strength (Rm) | 400-520 MPa | 400-520 MPa | 400-520 MPa | 400-520 MPa |

| Impact Test Temperature | 0°C | -20°C | -40°C | -60°C |

| Key Application | General structures in non-critical, warmer waters | Primary hull structures | Critical structures in cold waters | Extremely critical parts in Arctic service |

When you choose BV-certified L-shaped steel from a partner like us, you are not just getting a shape. You are getting this full package of guaranteed properties. This is what delivers "stable quality," which was a top priority for our client Gulf Metal Solutions. They need to know every batch of angle steel they fabricate will perform identically, ensuring the safety and approval of the final vessel.

What is marine grade structural steel?

All steel used on a ship is not the same. Marine grade structural steel1 is a specialized family of materials designed for one purpose: to form the strong, durable, and reliable skeleton of a vessel. It is the difference between using regular cloth for a sail and using heavy-duty, treated canvas.

Marine grade structural steel1 is a type of carbon or low-alloy steel manufactured to the strict rules of classification societies like BV. It has guaranteed strength, toughness at low temperatures, good weldability, and often improved corrosion resistance to withstand the marine environment’s unique stresses.

This steel forms the ship’s backbone—the keel, frames, girders, and bulkheads. Its job is to handle static loads (the weight of the ship), dynamic loads (waves slamming), and local stresses (cargo loading). Let’s explore what makes it different from construction steel you might use in a building.

The Defining Characteristics and Rules for Marine Steel

Marine structural steel is defined by a set of rules, not just a chemical formula. These rules cover the entire journey from the mill to the shipyard.

1. Governed by Classification Society Rules2

Unlike generic steel standards (like ASTM A36), marine steel is produced under the rules of societies like Bureau Veritas (BV), American Bureau of Shipping (ABS), or Lloyd’s Register (LR). These are private organizations that set technical standards for ship safety. Their rules are often more stringent than national standards. Mills must be approved by these societies to produce such steel. Our long-term cooperation is with mills that hold these vital approvals.

2. The Critical Importance of Through-Thickness Properties3

For key structural parts, steel must be strong in all directions. Standard rolling processes can align impurities, causing weakness in the through-thickness direction (the "Z-direction"). This can lead to lamellar tearing under stress.

- Z-grade Steel4: Marine standards specify "Z-grade" qualities (e.g., BV D36 Z25). This means the steel has been tested and guaranteed to have a minimum level of ductility in the through-thickness direction, preventing this dangerous type of failure.

3. Delivery Condition and Processing

Marine steel is often delivered in a specific condition to optimize its properties.

- Normalized (N): The steel is heated and cooled in a controlled way to refine its grain structure. This improves toughness and consistency, especially for thicker sections. Much of the plate and L-angle steel we supply is in the normalized condition.

- Thermo-Mechanical Control Process (TMCP)5: This is a more advanced rolling process that achieves high strength and toughness without expensive alloying elements, and it also offers excellent weldability.

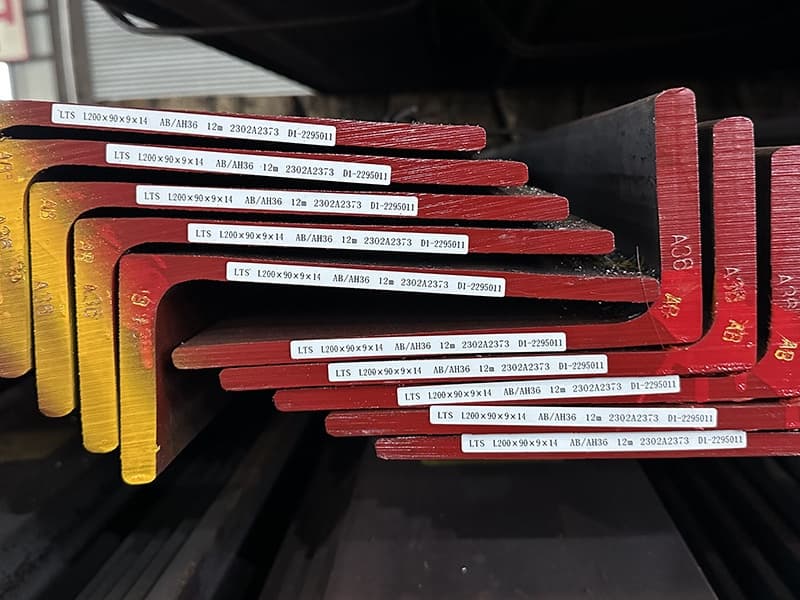

4. Traceability and Certification

Every single piece of marine structural steel must be traceable. As discussed in our previous article, the Mill Test Certificate (MTC)6 is mandatory. For marine grade, this MTC is not just a factory report; it is a certificate of compliance with a specific class rule (e.g., "BV Rule Note NR 216"). This document is scrutinized by the classification surveyor during the ship’s construction.

In simple terms, marine grade structural steel is "qualified" steel. It has passed a series of tests and controls defined by maritime engineers who understand the sea’s dangers. When you buy L-shaped steel labeled as "marine grade," you are paying for this qualification process. It is an investment in reliability. A project contractor in the Philippines or a shipyard in Romania cannot afford to use unqualified material, as the risk of rejection during survey is too high.

What type of steel is used in boats?

Boats range from small fishing dinghies to giant container ships. The type of steel used changes with the size, purpose, and operating environment of the vessel. Using the wrong type is like using a car engine in a tugboat—it might fit, but it will fail under real operating conditions.

Most modern boats and ships use mild carbon-manganese steels1, categorized into Normal Strength (Grade A, B, D, E) and Higher Strength Steels2 (Grades AH32/36/40, DH32/36/40, etc.). For severe conditions, special steels3 like Arctic grades or stainless steels are used for specific components. The exact type is determined by classification society rules for the vessel’s design.

The choice is systematic. Naval architects select steel grades based on the structural importance of the part and the lowest service temperature the vessel will encounter.

A Guide to Steel Selection for Different Vessels and Parts

We can look at this selection through two lenses: the grade of steel and its application on different vessel types.

1. Steel Grades and Their Purpose

-

Normal Strength Hull Structural Steel4 (Grade A, B, D, E): This is the workhorse for most hull structures. The letter indicates toughness level.

- Grade A: Used for non-critical parts in warmer waters (minimum impact test at 0°C).

- Grade B: Standard for many hull plates and sections (tested at -20°C).

- Grade D & E: Used for critical areas like the sheer strake or in cold environments (tested at -40°C and -60°C). L-shaped steel for frames in ice-class vessels would often be Grade D or E.

-

Higher Strength Steel (HSS) – Grades AH32/36/40, etc.: These have a higher yield strength (320, 360, 400 MPa). They allow for thinner, lighter structures while maintaining strength. Used in large container ships and bulk carriers to save weight and increase cargo capacity. "AH" means the steel is normalized; "DH" means it is normalized and has Grade D toughness.

-

Special Steels:

- Stainless Steel: Used for highly corrosive areas like chemical tanker cargo tanks, or for decorative/marine hardware.

- Arctic Grades: Steels with exceptional low-temperature toughness for icebreakers or offshore platforms in polar regions.

2. Application by Vessel Type

- Oil Tankers & Bulk Carriers: These large vessels extensively use Higher Strength Steels2 (AH36) for the hull to reduce weight. Critical areas might use DH36 for better toughness. The L-shaped steel for their web frames and stiffeners needs to match this grade requirement.

- Container Ships: Similar to tankers, they use HSS to maximize cargo space. The structure is subject to high dynamic loads from stacked containers.

- Fishing Vessels & Tugs: These smaller but rugged boats often use Normal Strength steels (Grade B or D). They operate in harsh conditions with frequent impacts, so good toughness is vital.

- Naval Vessels: Use specially developed high-strength, low-alloy (HSLA) steels5 for a combination of strength, toughness, and weldability, often with requirements for ballistic resistance.

The key takeaway is that "boat steel" is not one thing. It is a precise selection. For example, a client in Saudi Arabia building a service vessel for the Gulf might specify Grade B steel. A client in Myanmar constructing a river barge might use Grade A. But a client in Qatar building a liquefied natural gas (LNG) carrier will demand Grade DH36 or higher for its hull. Our role is to supply the exact type specified on the drawing, with the correct BV or other class certificate to prove it. This precision eliminates guesswork and "quality inconsistency" for our buyers.

What are the standard steel sections1 used in shipbuilding?

A ship’s structure is a complex 3D puzzle. It is not built from custom-made pieces. It is built from a library of standard, rolled steel sections. These sections are chosen for their efficiency in carrying specific types of loads. Using standard sections cuts cost, speeds up construction, and ensures predictable performance.

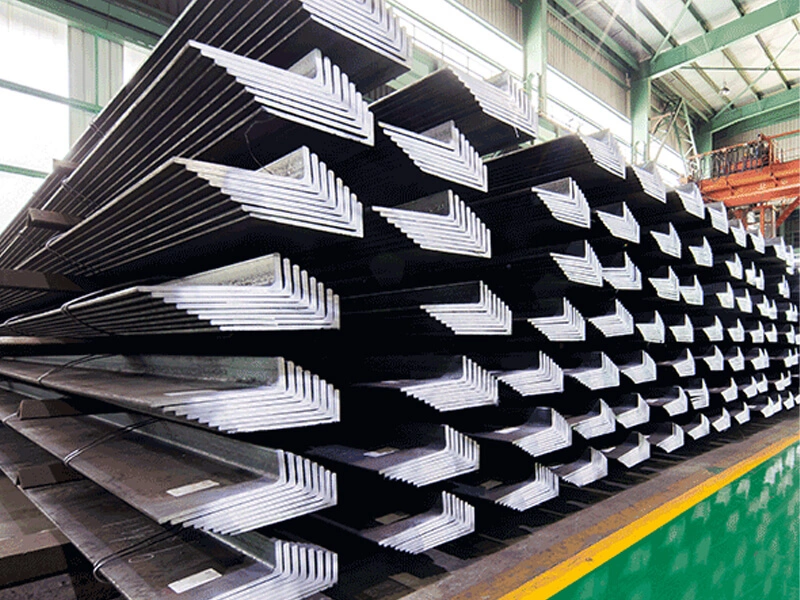

The standard steel sections1 in shipbuilding include plates (for hull shell), angles (L-shaped steel2 for frames and stiffeners3), bulb flats4 (for stiffeners3 with better efficiency), tees (cut from beams), channels5, and I-beams6 (for large girders and decks). L-shaped angle steel is one of the most common and versatile sections used throughout the vessel.

Each section has a specific job. Knowing which one to use where is fundamental to naval architecture and efficient procurement.

The Catalog of Shipbuilding Sections and Their Specific Roles

Let’s go through the main standard sections, explaining their shape, purpose, and typical applications on a ship.

1. Steel Plate

This is the most basic section, but it is fundamental.

- Shape: Flat, in various thicknesses and widths.

- Primary Use: To form the hull shell (the outer skin) and decks. The plates are welded together to create the watertight envelope of the ship.

- Special Types: Plate can be ordered as "floor plate" with a raised pattern for anti-slip on decks, or as "coiled plate" for automated production lines.

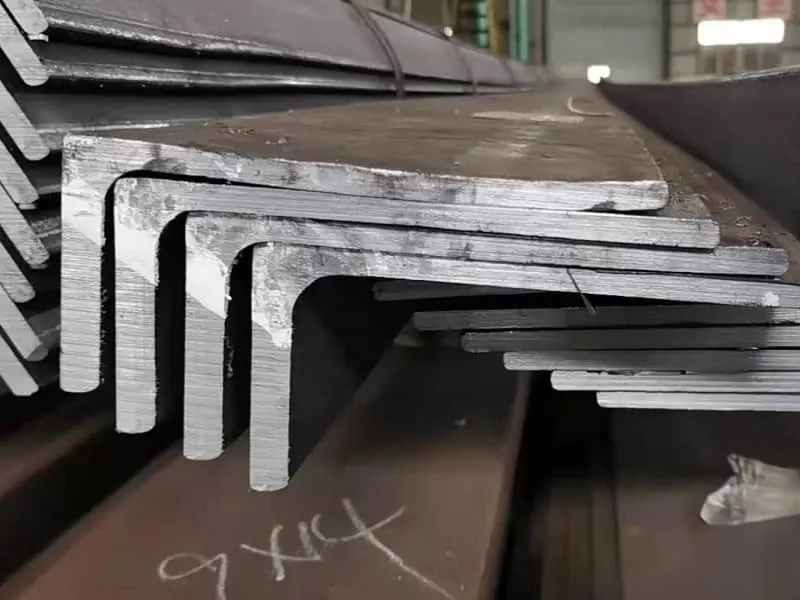

2. Angle Bar (L-Shaped Steel)

This is a workhorse section with immense importance.

- Shape: An "L" shape with two legs (flanges) of equal or unequal length.

- Primary Use: Stiffeners and frames. Angles are welded to plates to provide rigidity and prevent buckling. They are used as frame ribs along the hull, deck beam stiffeners3, and bulkhead stiffeners3. Their simple shape makes them easy to fabricate and weld.

- Why it’s so common: It offers good strength-to-weight ratio and torsional stability. Our main product, marine L-shaped steel2, is supplied in BV grades precisely for these countless applications.

3. Bulb Flat

This is a more optimized version of a flat bar.

- Shape: A flat bar with a bulb (rounded protrusion) along one edge.

- Primary Use: Longitudinal stiffeners3. The bulb adds strength and stiffness in one direction without adding much weight. Bulb flats are very common as deck longitudinals and bottom longitudinals in modern ship design. They are more structurally efficient than simple flat bars.

4. Rolled Tee Bar

- Shape: A "T" shape.

- Primary Use: Similar to angles, used as stiffeners3, especially where a symmetric section is needed. Often used in bulkheads.

5. Channels and I-Beams (H-Beams)

These are larger, heavier sections.

- Shape: Channel is a "[", I-beam is an "I".

- Primary Use: Primary support members. These are used for deck girders, hold transverses, engine seatings, and other major structural elements that must support very high loads. They are not used as frequently as angles or bulb flats4, but they are critical where they appear.

Here is a summary table for quick reference:

| Section Name | Shape Description | Main Function in Shipbuilding | Common Location on Ship |

|---|---|---|---|

| Plate | Flat sheet | Hull shell, decks, bulkheads | Entire outer hull, all decks |

| Angle Bar (L-Steel) | L-shaped | Frames, stiffeners3, brackets | Hull frames, deck stiffeners3, bulkhead stiffeners3 |

| Bulb Flat | Flat bar with a bulb edge | Longitudinal stiffeners3 | Deck longitudinals, bottom longitudinals |

| Tee Bar | T-shaped | Stiffeners (symmetric) | Bulkheads |

| Channel / I-Beam | [ or I-shaped | Primary girders, major supports | Deck girders, engine foundations |

A practical shipbuilding project will use a combination of all these sections. A large importer or wholesaler like our clients in Vietnam or Mexico needs a supplier who can provide the full range, especially the high-volume items like plates and L-angles, all with the proper certification. Our business supports this by offering not just L-shaped steel2, but also marine plates and bulb flats4, ensuring our clients have a consistent source for their standard section needs. This one-stop capability, backed by BV certification, simplifies their supply chain and reduces risk.

Conclusion

Using BV-certified marine L-shaped steel is a smart decision for safety, compliance, and project success. It guarantees the material has the proven strength, toughness, and quality needed to withstand the ocean’s challenges, protecting both your investment and your reputation.

-

Understanding standard steel sections is crucial for efficient shipbuilding and cost management. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

L-shaped steel is versatile and widely used; exploring its applications can enhance your knowledge of ship structure. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Stiffeners prevent buckling; learning about them is key to ensuring ship structural integrity. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Bulb flats improve structural efficiency; learning about them can optimize ship design. ↩ ↩ ↩ ↩ ↩ ↩

-

Channels are essential for major supports; exploring their uses can improve your design knowledge. ↩ ↩ ↩ ↩ ↩

-

I-beams are critical for support; understanding their function can aid in structural planning. ↩ ↩ ↩

-

Explore the factors leading to cold brittleness and how it impacts steel performance in low temperatures. ↩