Offshore platforms are engineering giants facing extreme forces. Every component must be reliable, and the humble L-angle is a critical piece of this puzzle, often overlooked until it fails.

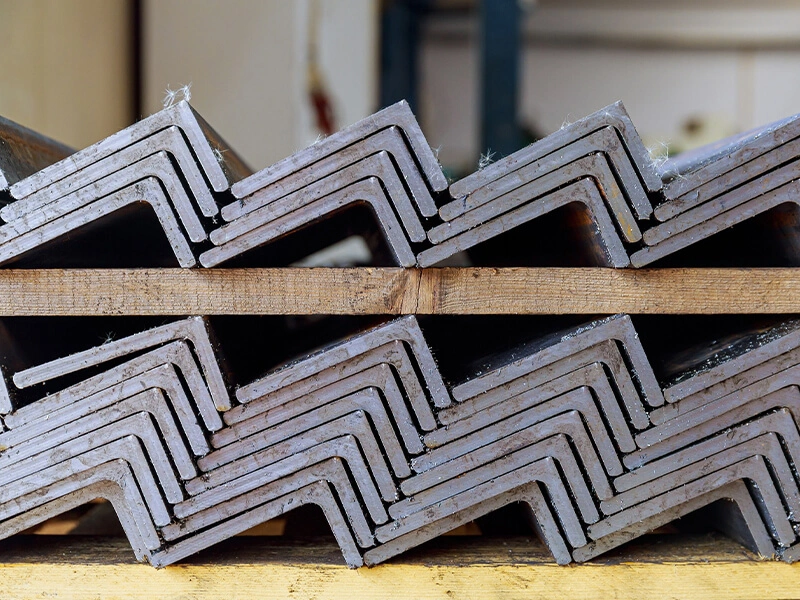

L-shaped steel, or angle bar, plays a vital role in offshore platforms as secondary stiffeners for deck plates and walls, primary framing for walkways and equipment supports, and reinforcement brackets at structural connections. Its 90-degree shape provides efficient strength in two directions for marine fabrication.

I’ve supplied marine angle steel to projects in the North Sea and the Gulf of Mexico. It’s not glamorous, but when you see miles of it forming the skeleton of a living quarters or supporting a critical pipe rack, you understand its importance. Let’s explore where and why it’s used.

What is the L-angle1 in steel structure?

In structural engineering, an L-angle1 is more than just a bent piece of metal. It is a fundamental section with specific geometric properties that determine how it resists loads. On an offshore platform, these properties are pushed to their limits.

In steel structures, an L-angle1 is a rolled steel section with two legs forming a 90-degree angle. It is classified as an "equal leg angle" (both legs same length) or an "unequal leg angle." Its structural behavior is complex, resisting load through a combination of bending, buckling, and axial forces depending on its orientation.

Think of it as a versatile but specialized tool. You wouldn’t use a screwdriver to hammer a nail. Similarly, you must understand how an L-angle1 works to use it correctly offshore.

The Structural Mechanics and Design Considerations

The L-angle1‘s simplicity hides a complex engineering reality. Designers must account for its unique properties.

Key Geometric Properties:

- Section Modulus (Z)2: This measures the section’s resistance to bending. For an L-angle1, it is different about its two principal axes (x-x and y-y). It is strongest when load is applied parallel to one of the legs.

- Radius of Gyration (r)3: This measures the section’s resistance to buckling. L-angle1s have different radii about their two axes. They are more prone to buckling about the "weak" axis.

- Centroid and Shear Center: These two points are not in the same place for an L-angle1. This can cause twisting (torsion) when a load is applied, which must be considered in design.

Designing with L-Angles Offshore:

Offshore codes (API, ISO, DNV) have specific rules for using angles.

- Connection Design: How the angle is connected is crucial. It is typically connected along one leg only. This creates eccentricity—the load path does not go through the center of the angle. This eccentricity generates additional bending moments that must be calculated. Connections are often designed as "pinned" to simplify this analysis.

- Slenderness Ratio (λ)4: This is the effective length divided by the radius of gyration. Offshore structures, subject to dynamic wave loads, have strict limits on slenderness to prevent vibration and fatigue issues. Angles used as struts or braces must be checked carefully.

- Fatigue Considerations: In cyclic wave loading, welded details on angles are potential fatigue "hot spots." The weld toe at the end of an angle stiffener is a critical location. Good welding procedure and profile are essential.

Why Specific Marine Grades are Mandatory:

An L-angle1 on an offshore platform cannot be generic. It must be a marine-grade angle.

- Material Toughness: Platforms in cold waters require angles with guaranteed Charpy Impact Toughness5 at low temperatures (e.g., -20°C or -40°C). Grades like S355J2, S355K2, or S355G2 provide this.

- Weldability: Offshore fabrication involves extensive welding, often in less-than-ideal conditions. The steel must have a low Carbon Equivalent Value (CEV) to prevent hydrogen-induced cold cracking. The chemistry of marine grades is controlled for this.

- Through-Thickness Properties: If an angle is welded in a way that puts stress through its thickness (like a bracket welded flat to a plate), Z-quality steel may be specified to prevent lamellar tearing.

The Practical Implication:

When we supply Marine Angle Steel, we are not just supplying a shape. We are supplying a structural component with verified mechanical properties that allow the engineer’s design calculations to be valid in the real world. This traceability is non-negotiable.

What is the L-angle used for?

On an offshore platform, every kilogram of steel must justify its place. The L-angle earns its place through a wide range of indispensable, practical applications that are fundamental to the platform’s function and safety.

L-angles1 are used to stiffen thin deck and wall plates against buckling, construct lightweight frames for walkways2, staircases, and handrails, create supports and brackets for pipes3, cables, and equipment, and form the secondary structural framework4 for buildings and modules on the topsides.

From the helideck to the lowest deck, you will find L-angles1 performing critical jobs. Their use is a balance of strength, weight, and fabricability.

A Comprehensive Tour of L-Angle Applications Offshore

Let’s take a detailed walk through a typical platform and catalog the uses of L-angles1.

1. Primary and Secondary Stiffening:

This is the most structurally significant use.

- Deck Plate Stiffeners: Under the main deck plates, L-angles1 are welded as stiffeners. They run between primary girders (I-beams), breaking the large plate into smaller panels. This prevents the deck from deflecting under the weight of drilling equipment, containers, and cranes. They are typically welded with one leg vertical.

- Bulkhead and Wall Stiffeners: Inside living quarters, equipment rooms, and around the perimeter walls, L-angles1 provide stiffness to the wall panels, resisting wind and accidental impact loads.

2. Framing for Platforms and Walkways:

The entire network of access ways is built with angles.

- Walkway Grids: The main frames of grated walkways are constructed from L-angles1. Two angles are often placed back-to-back to form a rectangular hollow section (RHS) for the main beams, providing good strength in all directions.

- Stair Stringers and Tread Supports: The side frames of stairs (stringers) are made from heavy L-angles1. The individual steps (treads) are supported by smaller angles welded to the stringers.

- Handrail and Toe-Kick Posts: The vertical posts for safety handrails and the low toe-kick rails along deck edges are often L-angles1.

3. Supports and Brackets (Piping & Equipment):

This is where fabrication flexibility5 shines.

- Pipe Supports and Clips: L-angles1 are the base material for millions of pipe supports. They are cut, welded, and drilled to create custom clips, hangers, and stanchions that hold the complex network of pipelines in place.

- Cable Tray Ladders and Supports: The frames for electrical cable trays are almost exclusively made from L-angles1.

- Equipment Skid and Base Frames: Smaller equipment items are often mounted on simple skids fabricated from L-angles1.

4. Architectural and Module Framing:

- Panelized Wall Systems: The internal walls of living quarters and control rooms are often non-load-bearing panels. These panels have a lightweight frame made of L-angles1 to which insulation and cladding are attached.

- Door and Window Frames: All doors, hatches, and windows are set into frames made of L-angles1.

Case Study: Gulf Metal Solutions’ Use Case

Gulf Metal Solutions purchases our Marine Angle Steel6 for fabricating replacement walkway sections and equipment supports for offshore rigs in the Arabian Gulf. Their need is for consistent quality and precise dimensions. The angles must have a clean surface for welding and coating, and the leg lengths must be uniform so their fabricators can produce identical modules quickly. Our supply of certified S355J2 angles7 with SGS inspection reports gives them the confidence that their fabricated parts will fit perfectly during offshore installation, minimizing costly rework.

| Platform Zone | Specific Application of L-Angle | Typical Size & Grade | Primary Load Consideration | Key Requirement |

|---|---|---|---|---|

| Main Deck | Plate stiffeners under crane operating area | 150x90x12, S355K2 | Bending from concentrated loads | High yield strength, Fatigue resistance |

| Living Quarters | Internal wall stud framing, door frames | 75x75x6, S275JR | Minor axial load, provides attachment | Good formability, Surface for drywall |

| Pipe Racks | Vertical supports and horizontal braces for pipes | 100x100x10, S355J2 | Axial compression, some bending | Good buckling resistance, Weldability |

| Helideck Perimeter | Safety net support frame, edge framing | 120x120x10, S355J2+G (Galvanized) | Impact, corrosion | High toughness, Corrosion protection |

| Cellar Deck (Splash Zone) | Staircase stringers, equipment brackets | 150x100x12, S355G2+M | Corrosion, wave impact | Marine grade toughness, Coating adhesion |

What materials are used for offshore structures?

Steel is the undisputed king, but "steel" is a vast kingdom. An offshore platform uses a carefully selected family of steel products, each chosen for a specific role based on its properties, cost, and fabricability.

The primary material is certified high-strength low-alloy (HSLA) steel1 plate and tubulars for the main structure (jacket, piles, deck girders). Secondary materials include L-angles and bulb flats for framing/stiffening, stainless steel (316, duplex)2 for corrosion-prone parts, specialty coatings, and fire protection materials.

Building a platform is like assembling a giant, survival-oriented kit. Every material has passed rigorous tests to earn its place. Let’s look at the full material list.

The Complete Material System for Offshore Survival

The materials work together as a system to provide strength, durability, and safety for 30+ years.

1. Primary Structural Steel:

This forms the load-bearing skeleton. The grades are defined by stringent offshore standards.

- Plates (for legs, nodes, decks): Grades like S355G2/G3, S420G2/G3, S460G2/G3 (EN 10225). These are normalized (N) or thermomechanically rolled (M) for toughness. Thickness can exceed 100mm. They require Ultrasonic Testing (UT)3 and often Through-Thickness (Z) testing.

- Tubulars (for jacket braces and legs): Made from the above plates, formed and welded into large-diameter pipes. They follow API 5L or structural pipe specs.

- Forgings and Castings: Used for complex, highly stressed components like node joints or crane pedestal connections. They offer superior integrity in complex shapes.

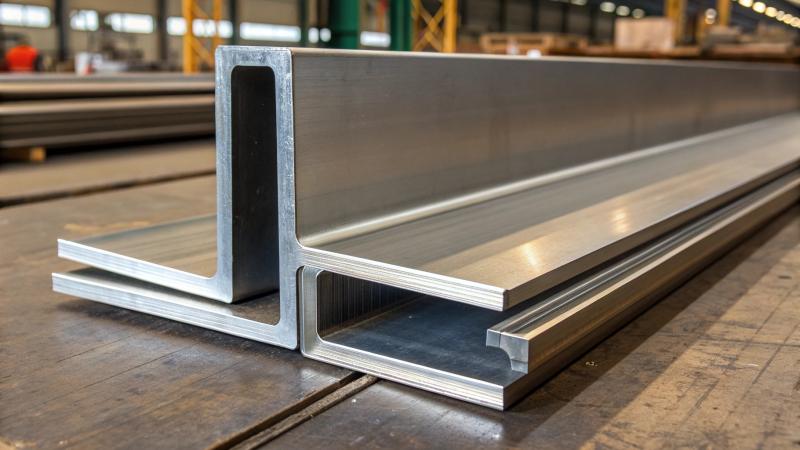

2. Secondary Structural Steel (Profiles and Sections):

This is the category for L-angles and similar products.

- L-Shaped Steel (Angle Bar): As detailed, for stiffening and framing.

- Bulb Flat Steel: The most common stiffener in ship-shaped hulls and some deck areas. More efficient than a flat bar.

- I-Beams, H-Beams, Channels: Used as primary beams and girders for deck framing.

3. Corrosion Protection System:

Steel cannot survive alone. A multi-layer defense is applied.

- Coatings: A typical system includes a shop primer (zinc silicate), high-build epoxy intermediate coats, and a polyurethane finish coat. The coating specification is as important as the steel grade.

- Cathodic Protection (CP)4: For the submerged jacket and piles. Sacrificial anodes made of aluminum or zinc alloys are welded to the structure. They corrode sacrificially to protect the steel.

4. Fire and Blast Protection (F&BP):

For oil & gas platforms, this is critical for safety.

- Passive Fire Protection (PFP)5: Materials like cementitious sprays6 or intumescent epoxy paints are applied to structural members. They insulate the steel, keeping it below ~500°C for a specified period (60, 90, 120 minutes) to maintain strength during a fire.

5. Specialist Metals:

- Stainless Steel: 316/L for handrails, ladders, and small pipes. Duplex (2205) or Super Duplex (2507) for critical seawater piping and fasteners in warm, aggressive waters.

- Fasteners: High-strength bolts (ASTM A325, A490 equivalents), often with hot-dip galvanizing or other coatings. They must match the strength of the connected parts.

6. The "Meta-Material": Certification and Traceability

This is not a physical material but is absolutely critical. The Material Traceability Dossier7 includes:

- Mill Test Certificates (MTC 3.1/3.2)

- Third-Party Inspection Reports (SGS, DNV survey)

- Welding consumable certificates

- Coating inspection reports

Without this dossier, the platform cannot be certified. This is why our service model is built around providing clear, English SGS reports—it’s a core part of the deliverable.

What are the four types of steel structures?

This classification helps understand the fundamental ways steel is assembled to resist loads. Offshore platforms1 are hybrids, but they lean heavily on one primary type due to the nature of their environment.

The four main types of steel structures are: 1) Truss Structures2 (braced frames like offshore jackets), 2) Frame Structures3 (moment-resisting frames4 like building skeletons), 3) Arch Structures5, and 4) Shell Structures6 (plate structures like ship hulls). Offshore platforms1 primarily use truss structures for the substructure (jacket) and a combination of frame and shell for the topsides.

Each structure type has a different way of transferring loads. Choosing the right type is the first step in design. For offshore, the choice is dictated by the need to minimize weight while maximizing strength in deep water.

Analysis of Structure Types and Their Offshore Relevance

Let’s examine each type and see how it appears in the offshore world.

1. Truss Structures2

This is the dominant type for fixed offshore platforms (jackets).

- How it Works: Loads are carried along a triangulated network of members. Members are primarily in axial tension or compression. Bending is minimized.

- Offshore Application: The Jacket. The lattice substructure of a platform is a classic 3D truss. The legs and braces are tubular members connected at nodes. This design is extremely efficient for resisting the lateral forces of waves and wind over great heights in water. It uses material very efficiently, which is crucial because every extra ton of steel requires more support and costs more to install.

- Role of L-Angles7: In a main jacket truss, L-angles are not typically used for primary members due to their lower buckling resistance compared to tubes. However, they are used extensively for secondary bracing within the topsides modules and for access platforms on the jacket itself.

- How it Works: Loads are resisted by the bending strength of beams and columns connected at joints. These are moment-resisting frames4.

- Offshore Application: Topsides Buildings. The steel frame of the living quarters, the control room, and other enclosed modules is a moment frame. It must support its own weight, equipment, and resist wind loads. Here, L-angles are used as secondary beams, wall studs, and connection elements within the frame.

- How it Works: Loads are converted primarily into compressive stresses along the arch’s curve.

- Offshore Application: Limited. You might see arch-shaped braces in some specialized designs, but it is not a primary offshore structural type.

4. Shell Structures6 (Plate Structures)

- How it Works: Loads are carried by in-plane stresses in thin, curved or folded plates. Think of an eggshell or a submarine hull.

- Offshore Application: Hulls of Floating Platforms. Semi-submersibles, FPSOs (Floating Production Storage and Offloading vessels), and SPAR buoys use massive steel hulls that act as shell structures to resist hydrostatic pressure.

- Role of L-Angles7: In these hulls, L-angles (along with bulb flats) are the primary stiffeners. They are welded to the inside of the hull plate to prevent it from buckling under water pressure. This is a critical application where the L-angle’s performance is directly linked to the hull’s watertight integrity.

The Hybrid Nature of a Platform:

A fixed platform is a perfect example of hybrid design8:

- Substructure (Jacket): A 3D Truss.

- Topsides Deck Structure: A combination of Frame (primary girders and columns) and Plate (the deck plate itself).

- Topsides Modules: Primarily Frames with Plate walls and decks.

- Hulls of Floaters: Shell structures.

This hybrid approach uses the most efficient structural type for each part of the challenge. And throughout all these types, from the truss bracing to the shell stiffeners to the frame studs, you will find the versatile, reliable L-shaped steel playing its part.

Conclusion

L-shaped steel is a versatile, essential component in offshore platforms, serving as stiffeners, frames, and supports. Its success depends on using the correct marine-grade material within a hybrid structural system designed for the ocean’s extremes.

-

Gain insights into the different types of offshore platforms and their structural designs. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand how truss structures efficiently resist loads, especially in offshore applications. ↩ ↩ ↩ ↩ ↩

-

Learn about frame structures and their role in supporting buildings, particularly in offshore topsides. ↩ ↩ ↩ ↩ ↩

-

Explore the concept of moment-resisting frames and their critical role in building stability. ↩ ↩ ↩ ↩ ↩

-

Discover the unique properties of arch structures and their limited use in offshore designs. ↩ ↩ ↩ ↩ ↩

-

Find out how shell structures are used in floating platforms and their importance in resisting hydrostatic pressure. ↩ ↩ ↩ ↩

-

Understand the significance of L-angles in enhancing structural integrity, especially in offshore applications. ↩ ↩ ↩ ↩

-

Learn about hybrid design approaches in engineering and how they optimize structural efficiency. ↩