Procurement for an offshore platform is a high-stakes puzzle. A single batch of substandard steel can delay a billion-dollar project, cause safety failures, or lead to catastrophic corrosion. Your role is to build a supply chain that is as robust as the platform itself.

This guide provides a framework for procuring steel for offshore platforms. It covers material selection based on platform type and zone, explains key certifications, and outlines procurement steps to ensure quality, compliance, and on-time delivery from qualified mills and suppliers.

You are not just buying steel. You are sourcing the primary component for a structure that must survive decades of hurricanes, saltwater, and extreme loads. Let’s navigate this complex process together, from understanding what you’re building to securing the right materials.

What are offshore platforms1 made of?

Picture a skyscraper, but one that stands in the open ocean, fighting waves 24/7. You cannot use regular building materials here. The choice of material is the first and most critical engineering decision, dictating the platform’s lifespan, safety, and maintenance cost.

Offshore platforms are primarily made of steel. Specifically, they use high-grade, low-alloy carbon-manganese steels2 with controlled yield strength3 and exceptional toughness. These steels are often produced to offshore-specific standards like API 2W4, API 2H, or EN 10225, and are certified by classification societies for use in the harsh marine environment.

The term "steel" is too broad. The exact grade, thickness, and treatment of the steel change dramatically depending on the platform’s function and the specific structural member. Let’s look at the main components and their material demands.

Deconstructing an Offshore Platform: The Material Blueprint

An offshore platform is a system of systems. Each part has a unique job, and the steel must be tailored accordingly. Using a one-size-fits-all approach is inefficient and risky. We need to break down the structure.

The Main Structural Types and Their Steel:

Most large offshore platforms1 for oil and gas are fixed platforms. Their main structural element is the jacket, a welded space frame made of tubular steel members. Let’s examine its parts:

-

Jacket Legs and Piles: These are the largest diameter tubes. They carry the entire platform’s weight and drive into the seabed.

- Steel Requirement: Very high thickness (often 50-100mm+), high yield strength3 (e.g., 355 MPa or higher), and superior through-thickness properties (Z-direction quality). This last point is critical to prevent lamellar tearing in the thick welds. Steels like API 2W4 Grade 50 or EN 10225 S355G10+M are common.

-

Jacket Braces (Diagonals and Horizontals): These connect the legs, providing stability against waves and currents.

- Steel Requirement: High strength-to-weight ratio. They often use steels with yield strength3s of 355 MPa to 460 MPa. Good low-temperature toughness is essential, as they are in the splash and submerged zones. Grades like API 2H Grade 50 are frequently specified.

-

Deck Structure (Topside): This is the working platform that holds the drilling rig, production equipment, and crew quarters.

- Steel Requirement: Similar to shipbuilding. It uses plates and sections (I-beams, bulb flats, angles). The steel needs good strength and weldability. In the atmospheric zone, corrosion is managed with coating systems. Common grades include ASTM A709 Grade 50 or marine grades5 like ABS AH36.

-

Special Components: This includes risers (pipes bringing oil up) and conductors (housing for drilling).

- Steel Requirement: For risers, the steel must resist internal pressure, corrosion from sour gas (H2S)6, and fatigue. This requires special line pipe steels with precise chemistry, often with quenched and tempered (Q&T) processing for high strength.

Here is a table summarizing the application and typical steel specs for key components:

| Platform Component | Primary Load/Challenge | Typical Steel Grade Examples | Key Material Properties |

|---|---|---|---|

| Jacket Legs / Piles | Axial compression, driving stresses, thick welds. | API 2W4 Grade 50, EN 10225 S355G10+M | High yield strength3 (355-460 MPa), Z35 quality, excellent low-T toughness. |

| Jacket Braces (X & K) | Buckling resistance, wave impact, fatigue. | API 2H Grade 50, EN 10225 S355G10+N | High strength, good Charpy impact values at -20°C to -40°C. |

| Deck Beams & Girders | Bending from equipment weight, fatigue. | ASTM A709 Gr50, ABS EH36 | High strength, good weldability. |

| Deck Plating | Distributed load, corrosion (atmospheric). | ABS AH36, ASTM A709 Gr50 | Standard strength, good surface for coating. |

| Riser Pipe | Internal pressure, sour service, fatigue. | API 5L X65 PSL2, with sour service resistance. | High strength, controlled hardness, HIC/SSCC tested. |

| Splash Zone Cladding | Extreme corrosion, abrasion. | Stainless Steel (316L) or Nickel Alloy cladding welded onto carbon steel. | Maximum pitting/crevice corrosion resistance. |

Understanding this blueprint is the first step in procurement. You don’t just order "platform steel." You procure a list of specific items: "API 2H Grade 50 tubulars for braces, 24" OD x 1.5" WT," and "ABS AH36 plate for deck, 20mm thick." This precision is what separates professional procurement from simple material buying.

What materials are used for offshore structures?

Steel dominates, but it doesn’t work alone. Imagine a platform leg without its protective coating, or a critical valve made from the wrong alloy. The material system for an offshore structure is a multi-layered defense, where each layer has a specific, vital role.

The primary material is specialized offshore steel1l](https://masteel.co.uk/offshore-steels/)[^2]. This is supported by corrosion protection systems3 like high-performance coatings4, cathodic protection anodes5 (aluminum/zinc), and non-ferrous metals. Non-metallics like concrete (for gravity bases), specialized elastomers, and fireproofing materials6 are also used in specific applications.

Thinking only about the base steel is a major oversight. The integrated material system determines long-term integrity. Let’s explore the full material palette and how each element contributes to the structure’s survival.

The Material Ecosystem: Beyond the Base Steel

An offshore structure is a composite entity. Its longevity depends on the successful interaction of different material families. Procurement must account for this entire ecosystem, not just the bulk tonnage of steel.

1. The Structural Core: Offshore Steels

We have covered the grades. The key point is their certification path. These steels are not commodity products. They are produced under:

- Project-specific specifications: Often stricter than standard API or EN norms.

- Third-party inspection: Surveyors from classification societies (DNV, ABS, BV) or client representatives witness testing at the mill.

- Advanced processing: Many plates for critical nodes undergo ultrasonic testing (UT) to detect internal flaws and are often supplied with beveled edges ready for welding.

2. The Corrosion Defense Layers

This is a system of systems:

- Coatings: Multi-layer, high-build epoxy systems are standard. For the splash zone, glass flake reinforced epoxy or thick polyurethane is used. The coating specification includes surface preparation (blasting to Sa 2½), film thickness, and application procedures.

- Cathodic Protection (CP) Anodes: These are consumable parts made from aluminum-zinc-indium alloys or zinc. They are welded to the submerged structure. Procurement must specify the alloy type, net weight, current capacity, and core material. They are as important as structural steel.

- Cladding and Weld Overlays: For ultra-harsh areas (splash zone, riser tie-ins), carbon steel is clad with a layer of corrosion-resistant alloy7 (CRA) like 316L stainless steel or Inconel 625. This is often procured as a pre-fabricated bi-metallic product.

3. Complementary and Specialized Materials

- Concrete: Used in gravity-based structures8 (GBS) for ballast and weight. Also used in floatover decks for temporary buoyancy.

- Grout: High-strength cementitious grout is used to fill the annulus between jacket legs and piles, creating a solid connection.

- Elastomers and Polymers: Used for seals, gaskets, flexible pipes, and insulation. They must resist seawater, UV, and hydrocarbons.

- Fireproofing Materials: Intumescent coatings or cementitious sprays applied to structural members on the deck to maintain strength in a fire.

The Procurement Implication:

You are managing a Multi-Material Bill of Materials (BOM). A streamlined approach involves finding suppliers who can handle multiple categories. For example, while we specialize in the structural and offshore steel2 plates and sections, we coordinate with trusted partners for anodes or coatings for clients who need a simplified logistics chain. The table below shows the procurement complexity:

| Material Category | Examples | Key Procurement Considerations | Typical Source |

|---|---|---|---|

| Primary Structural Steel | API 2H/2W plates & sections, tubulars. | Mill certification, project-specific testing, traceability, dimensional tolerances. | Certified Steel Mills (via suppliers like us). |

| Cathodic Protection | Aluminum alloy anodes, reference electrodes. | Alloy chemistry certification, design life output, welding procedure. | Specialized CP material manufacturers. |

| Coatings | Epoxy primer, intermediate, polyurethane topcoat. | Product data sheets, compatibility, application conditions, volume calculation. | Major coating companies (e.g., Jotun, Hempel, PPG). |

| Special Alloys | 316L Clad plate, Duplex stainless fittings. | Weld procedure specs, corrosion test reports, precise dimensions. | Special steel mills or processors. |

| Bulk Materials | Concrete, grout, fireproofing. | Mix design approval, strength testing, delivery logistics to fabrication yard. | Local ready-mix or specialty material suppliers. |

Procurement success means ensuring all these materials arrive at the fabrication yard on time, with the right paperwork, and are compatible with each other. It’s a massive coordination effort that starts with a deep understanding of the material ecosystem.

What kind of steel is used in oil pipelines?

A pipeline is the lifeline of an offshore platform. A leak or rupture is an environmental and economic disaster. The steel in these pipes must do more than just contain pressure; it must resist internal corrosion, external impacts, and the fatigue of the seabed.

Oil pipelines, especially offshore, use high-strength, low-alloy (HSLA) steel grades1 categorized under API 5L standards2. Common grades are X52, X60, X65, X70, and higher. For offshore and sour service (H2S present), the steel requires enhanced toughness, controlled hardness, and specific chemistry to resist Hydrogen Induced Cracking (HIC)3 and Sulfide Stress Corrosion Cracking (SSCC)4.

"Pipeline steel" is a family of specialized products. Choosing the right grade involves understanding the transport medium, the environment, and the installation method. Let’s delve into the specifications that make pipeline steel unique.

The Anatomy of a Pipeline: Steel Grades and Critical Properties

Offshore pipelines are engineering marvels. They lie on the seabed, facing constant pressure, temperature changes, and potential corrosion from both inside and out. Their steel is meticulously engineered.

The API 5L Standard: The Common Language

This standard defines the requirements for line pipe. The "X" number denotes the minimum yield strength in ksi (thousands of pounds per square inch). An X65 pipe has a minimum yield strength of 65 ksi (approximately 448 MPa).

- Grades: X42, X46, X52, X56, X60, X65, X70, X80, etc. Higher numbers mean stronger, potentially thinner-walled pipes, which are lighter and cheaper to install.

- Product Specification Levels (PSL): This is crucial.

- PSL1: Standard requirements for chemistry and mechanicals.

- PSL2: Stricter requirements. It mandates Charpy V-Notch impact testing5 for toughness, tighter chemistry control, and more rigorous non-destructive testing (NDT). Virtually all major offshore pipelines use PSL2 pipe.

Special Requirements for Offshore and Sour Service:

- Low Temperature Toughness: Offshore pipelines can experience cold seabed temperatures. The steel must have excellent impact energy absorption at these temperatures (e.g., at -10°C or -20°C) to prevent brittle fracture.

- HIC/SSCC Resistance: This is for pipelines carrying "sour" hydrocarbons (containing H2S).

- HIC (Hydrogen Induced Cracking): Atomic hydrogen from corrosion can diffuse into the steel and cause internal cracks. HIC-resistant steel has very low levels of impurities (Sulfur, Phosphorus) and a controlled microstructure.

- SSCC (Sulfide Stress Corrosion Cracking): Cracking under the combined action of tensile stress and H2S. It is prevented by limiting the steel’s hardness (typically to a maximum of 250 HV or 22 HRC) and controlling microstructure.

- Seam Type: Offshore pipelines are usually Submerged Arc Welded (SAW)6 for large diameters or Seamless for smaller diameters and high-pressure applications. The weld seam must be as strong and tough as the parent metal.

Procurement Specifications for Pipeline Steel:

When procuring, the purchase order will specify much more than just "API 5L X65." A typical spec includes:

- Grade: API 5L X65 PSL27.

- Size: Outside Diameter (OD) and Wall Thickness (WT).

- Length: Random or specified.

- End Finish: Plain end or beveled for welding.

- Coating: External (e.g., Fusion Bonded Epoxy – FBE) and internal (e.g., epoxy liner).

- Supplemental Requirements: Often referencing NACE MR0175/ISO 151568 for sour service, and specifying:

- Maximum Carbon Equivalent (CE) for weldability.

- Charpy impact test temperature and minimum energy.

- HIC test acceptance criteria (e.g., NACE TM0284, with crack length ratio < 15%).

- Hardness limits (e.g., 250 HV10 max).

Here is a comparison of pipeline steel for different applications9:

| Pipeline Type / Environment | Typical Steel Grade | Critical Properties | Why These Properties Matter |

|---|---|---|---|

| Shallow Water Offshore | API 5L X65 PSL27 | High strength, good low-T toughness. | Handles laying stresses, resists fracture from impact or buckling. |

| Deepwater Offshore | API 5L X65/X70 PSL2 | Very high strength, superior toughness at low T. | High pressure at depth, cold temperatures, difficult repair. |

| Sour Service Pipeline | API 5L X65 PSL27, with Sour Service qual. | HIC/SSCC resistance, controlled hardness. | Prevents catastrophic failure from internal H2S attack. |

| Arctic/Subsea | API 5L X65/X70 PSL2 | Exceptional toughness at very low temps (e.g., -40°C). | Prevents brittle fracture in ice-prone environments. |

Procuring this steel requires working with mills that have a proven track record in producing these high-specification products. It's not a commodity. The mill must provide extensive test reports, including HIC test results if required. For our clients in the Middle East and Southeast Asia involved in pipeline projects, we connect them with mills that specialize in these certified line pipe steels, ensuring the material meets the stringent project specs from day one.

What are the four types of steel structures?

You are planning a marine project. Is it a fixed platform, a floating dock, or a ship? Each requires a different structural philosophy. Applying the design principles of one type to another leads to inefficiency, overcost, or structural inadequacy.

In marine and offshore engineering, four primary types of steel structures are used: Framed (or Skeleton) Structures1, Plate Structures2, Shell Structures3, and Composite Structures4. Each type uses steel in a distinct way to carry loads, and understanding this determines both design and procurement strategy.

%[types of steel structures framed plate shell composite](https://cnmarinesteel.com/wp-content/uploads/2026/01/Flat-steel-ball108.webp "types steel structures")

This classification is fundamental. It tells you how the steel will be used, what shapes you need to buy, and what fabrication challenges to expect. Let's define each type and see its real-world marine application.

A Structural Taxonomy: Choosing the Right Framework

Each structure type optimizes steel for a specific load-bearing behavior. Your procurement list will look completely different depending on which type you are building.

1. Framed (Skeleton) Structures

- Concept: A network of linear members (beams, columns, braces) connected at nodes. The loads are carried through axial forces (tension/compression) and bending in the members.

- How Steel is Used: Steel is formed into efficient profiles with high section modulus5 for bending or optimized cross-sectional area for axial load.

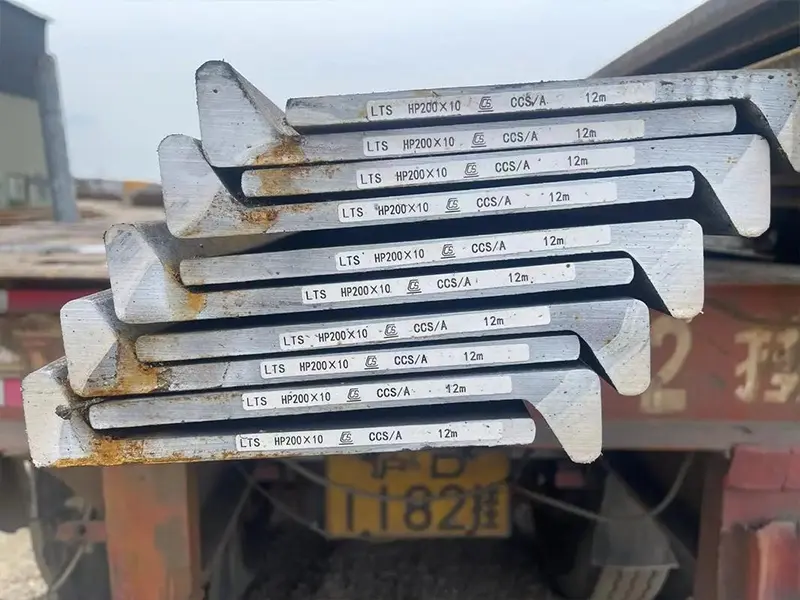

- Typical Steel Products: Tubulars (round, square), Wide-flange beams (I-beams, H-beams), Channels, Angle bars, Bulb flats.

- Marine/Offshore Examples: Offshore jacket platforms (tubular space frame6), shipyard gantry cranes (I-beam framework), port terminal buildings (steel frame).

- Concept: Loads are carried by in-plane stresses within large, thin plates. The plates are often stiffened to prevent buckling.

- How Steel is Used: Steel is used in the form of large, flat or curved plates. The primary material property is the yield strength7 of the plate material itself.

- Typical Steel Products: Heavy and medium steel plates, stiffening sections (bulb flats, angles) welded to them.

- Marine/Offshore Examples: Ship hulls (stiffened plate), barge hulls, offshore deck plating, lock gates, large storage tanks.

- Concept: A thin, curved surface that carries loads primarily through membrane stresses (tension, compression, shear in the plane of the shell). They are very efficient for containing pressure or covering large spaces.

- How Steel is Used: Steel plates are rolled or pressed into single or double curvature shapes and welded together.

- Typical Steel Products: Steel plates (often requiring special forming), pressure vessel quality (PVQ) steel8.

- Marine/Offshore Examples: Spherical or cylindrical LPG/LNG storage tanks on ships or offshore, submarine hulls, certain types of buoyancy modules.

- Concept: Steel works together with another material, most commonly concrete, to form a single structural element. The steel provides tensile strength, and the concrete provides compressive strength and fire protection.

- How Steel is Used: Steel is used as reinforcing bars (rebar)9, structural sections encased in concrete, or steel decks with concrete topping.

- Typical Steel Products: Reinforcing steel bars, structural sections (I-beams, columns), steel decking profiles.

- Marine/Offshore Examples: Concrete Gravity-Based Structures (GBS)10 for offshore platforms (steel reinforcing inside concrete), composite bridge decks in port approaches, some types of seawalls.

Procurement Strategy Based on Structure Type:

Your sourcing needs change completely:

| Structure Type | Procurement Focus | Key Supplier Capabilities Needed |

|---|---|---|

| Framed Structure | Sections and Tubulars. Precise lengths, ready-to-weld end-cuts, complex node materials (thick, Z-quality plates). | Ability to supply a wide range of sections (tubes, beams, angles) in high grades. Capacity for simple pre-fabrication (cutting, beveling). |

| Plate Structure | Large Plates and Stiffeners. Plate in specific thicknesses and widths, with good flatness. Large quantities of bulb flats or angles. | Access to plate mills, ability to handle large plate sizes, supply of matching stiffener profiles. |

| Shell Structure | Formable, High-Quality Plates. Plates that meet strict curvature and welding specs, often with special NDT requirements. | Connection to mills producing pressure vessel steel, understanding of forming tolerances. |

| Composite Structure | Reinforcing Steel and Encased Sections. Large quantities of rebar to specific grades, and structural sections with shear connectors. | Ability to source both rebar and structural steel, or coordinate between two specialized suppliers. |

For a company like ours, a project for a jacket platform (Framed) involves supplying tubulars and node plate. A project for a barge (Plate) involves supplying hull plate and miles of bulb flats. Understanding the structural type allows us to prepare the right inventory and logistics plan from the very first inquiry.

Conclusion

Successful offshore steel procurement requires detailed knowledge of platform components, a systems view of all materials, and a strategy tailored to the specific type of structure you are building.

-

Explore this link to understand the design and application of framed structures in marine projects. ↩ ↩ ↩ ↩ ↩

-

Learn about plate structures and their significance in marine applications by visiting this resource. ↩ ↩ ↩ ↩ ↩

-

Discover the efficiency and applications of shell structures in marine engineering through this informative link. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how composite structures combine materials for enhanced performance in marine projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding section modulus is crucial for design; explore this link for detailed insights. ↩ ↩ ↩ ↩

-

Understand the design and benefits of tubular space frames in marine structures by checking this resource. ↩ ↩ ↩ ↩

-

Learn about yield strength and its importance in structural design by checking this resource. ↩ ↩ ↩ ↩ ↩

-

Explore the characteristics and applications of PVQ steel in marine engineering through this link. ↩ ↩ ↩

-

Learn about the role of rebar in structural integrity and design by exploring this link. ↩ ↩

-

Discover the design and use of GBS in offshore platforms by visiting this informative resource. ↩