You juggle three suppliers for plates, two for sections, and another for special profiles. A delay from one vendor stalls your entire production line. Your project manager demands answers, but you’re stuck coordinating between multiple companies. This fragmentation is the hidden tax on your project’s efficiency.

An integrated marine steel supply solution provides a single source for all your material needs—plates, angles, bulb flats, and special sections. This integration ensures material compatibility, simplifies logistics and documentation, reduces procurement overhead, and offers a unified point for quality control and technical support throughout your project lifecycle.

Managing multiple suppliers creates complexity, risk, and hidden costs. An integrated approach transforms procurement from a collection of transactions into a streamlined partnership. Let’s explore what "integration" truly means and how it delivers tangible benefits from the design office to the launch dock.

What is the meaning of integrated steel?

You hear the term "integrated steel mill1," but your supplier talks about an "integrated supply solution2." The concepts are related but different. Confusing them means you might miss the real advantage offered by a coordinated supplier.

"Integrated steel" primarily refers to an integrated steel mill1, where the entire production process—from iron ore smelting in a blast furnace to final rolling—occurs on one site. In a supply context, an integrated supply solution2 means a supplier who bundles various products and services (sourcing, logistics, technical support3) into a single, seamless package for the buyer, acting as a unified interface to multiple mills.

Both concepts are about reducing fragmentation and improving control. The mill integrates processes for quality and cost. The supplier integrates services for convenience and reliability. Let’s examine both to see how they benefit you as the end-user.

Two Layers of Integration: The Mill and The Supply Chain

Integration happens at two levels in the journey of steel to your project. Understanding both shows you where value is added.

Layer 1: The Integrated Steel Mill (Upstream)

This is about production. An integrated mill controls the process from raw material to semi-finished product.

- Process: Iron Ore + Coke -> Blast Furnace (Molten Iron) -> Basic Oxygen Furnace (Steel) -> Continuous Caster (Slab) -> Rolling Mill (Plate/Coil).

- Advantages for Marine Steel:

- Superior Chemistry Control: Starting from virgin materials allows precise adjustment of alloying elements to meet strict marine grade specifications.

- Consistency: Large-scale, continuous production leads to more uniform properties across batches.

- Economies of Scale: Lower production cost per ton.

- Your Implication: When your supplier sources from an integrated mill (like our partner mills in Shandong), you get the benefit of this controlled, high-volume production quality.

Layer 2: The Integrated Supply Solution (Downstream – Our Role)

This is about service and delivery. Here, "integration" means we combine different elements for you.

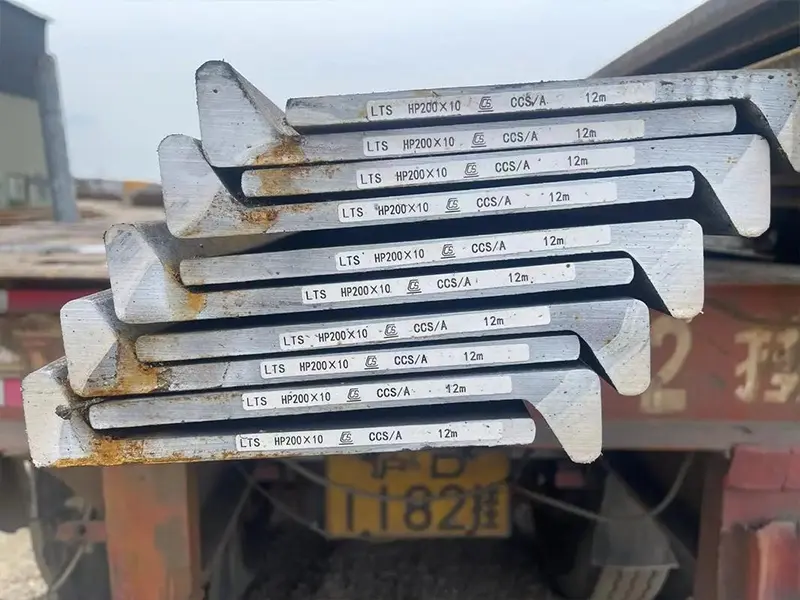

- Product Integration: We don’t just sell plates. We supply the full range needed for a ship or offshore module: Plates, Bulb Flats, Angles, L-sections. All are sourced to compatible marine standards (e.g., all ABS AH36).

- Service Integration: We bundle the product with essential services:

- Sourcing & Procurement: We deal with multiple mills or large distributors to gather your full material list.

- Quality Assurance: We manage certification, and can arrange third-party inspection (SGS) for the entire order.

- Logistics & Shipping: We consolidate all items into optimized shipments (containers, breakbulk).

- Documentation: We provide a unified certificate and shipping document package.

- Technical Support: One point of contact for all material-related queries.

The Contrast: Fragmented vs. Integrated Supply

| Aspect | Fragmented Sourcing (Multiple Suppliers) | Integrated Supply Solution (Single Supplier) |

|---|---|---|

| Point of Contact | 5+ salespeople. | One dedicated account manager. |

| Order Coordination | You manage timelines and compatibility. | Supplier coordinates production and delivery of all items to sync. |

| Quality Consistency | Risk of variation between suppliers’ sources. | Single quality standard applied across all materials. |

| Shipping Cost | Multiple shipments, higher total freight. | Consolidated shipments, lower cost per ton. |

| Problem Resolution | Finger-pointing between suppliers. | Single point of accountability. |

Our business model is built on this Layer 2 integration. We are not an integrated mill, but we provide an integrated supply service. We connect you, the buyer, to the advantages of integrated mill production, and then add the layer of logistical and administrative integration that makes your project run smoothly. This is what solves the pain points of delayed response and inconsistent quality highlighted by our clients.

Why is steel important in marine technology?

Could modern shipping exist without steel? Perhaps, but not on its current scale, safety, or cost. Steel is not just a material choice; it is the enabling foundation that allows us to build structures large and strong enough to conquer the ocean.

Steel is fundamental to marine technology because it offers an unmatched combination of high strength, good toughness, ease of fabrication (welding, cutting), and cost-effectiveness. This allows the construction of massive, seaworthy vessels and offshore platforms that can withstand extreme ocean forces, carry huge payloads, and have long service lives with proper maintenance.

Its importance is historical and systemic. No other material has matched steel’s balance of properties for primary marine structures. Let’s break down this "balanced portfolio" of properties and see why alternatives fall short for most applications.

The Unbeatable Portfolio: Steel’s Properties for the Sea

Marine technology demands materials that perform across a range of harsh conditions. Steel’s portfolio of properties makes it the default choice.

1. Structural Properties: The Core Mandate

- High Strength-to-Weight Ratio1: Modern high-strength steels (like AH40) allow for thinner hull plates, reducing weight and increasing cargo capacity. This directly impacts profitability.

- Toughness (Fracture Resistance)2: Marine steels are specifically alloyed and processed to absorb impact energy without brittle fracture, even in icy waters. Charpy impact testing is a mandatory certification.

- Fatigue Resistance3: Ships flex with every wave. Steel can withstand billions of these stress cycles without failing, a property engineered into marine grades.

2. Fabrication Properties: The Practical Enabler

- Weldability4: This is critical. Modern shipbuilding uses block construction. Steel’s ability to be welded quickly and reliably into massive sections is unparalleled. The development of low-carbon-equivalent marine grades was a key innovation.

- Formability5: Steel plates can be cold-bent or rolled into the complex curves of a ship’s hull and bow.

- Repairability: Damaged steel sections can be cut out and new sections welded in, almost anywhere in the world. This is crucial for a vessel’s 25+ year life.

3. Economic and Lifecycle Properties: The Business Case

- Material Cost6: Despite price fluctuations, steel remains the most cost-effective material per unit of strength for large structures.

- Recyclability7: At end-of-life, over 95% of a steel ship is recycled. This "cradle-to-cradle" cycle is a major environmental and economic advantage.

Comparison with Primary Alternatives:

| Material | Key Advantage vs. Steel | Key Disadvantage vs. Steel | Niche in Marine Tech |

|---|---|---|---|

| Steel | Best overall balance: strength, cost, weldability, toughness. | Heavy, requires corrosion protection. | Primary structure of ships, offshore platforms, port facilities. |

| Aluminum Alloy | Lighter (⅓ the density). | Cost is 3-5x higher, lower strength, difficult to weld, fire risk. | Superstructures (to lower center of gravity), high-speed ferries. |

| Fiber Reinforced Polymer (Composites) | Light, no corrosion. | Extremely high cost for large structures, poor fire resistance, hard to repair. | Specialized small craft (patrol boats, yachts), non-structural components. |

| Concrete | Low cost, good in compression. | Very heavy, poor in tension (needs rebar), brittle. | Gravity-based offshore platforms, some floating structures. |

The Role of an Integrated Supplier:

We don’t just sell a commodity; we provide access to this specific portfolio of properties. When you order "marine steel8," you are tapping into over a century of metallurgical development aimed at solving marine challenges. Our integrated solution ensures you get the right grade with the right properties for each part of your structure, supported by the documentation that proves it.

What are the advantages of steel metal?

You choose steel for your project. But have you listed all the reasons why? Beyond strength and cost, steel offers a suite of advantages that make it the backbone of modern industry, especially in the demanding marine sector.

The primary advantages of steel are its high strength and stiffness, excellent durability and longevity, superior versatility in form and function, unmatched recyclability, and relative cost-effectiveness. For marine applications, its weldability, impact toughness, and the availability of specialized corrosion-resistant grades are additional critical benefits.

These advantages are interconnected. They create a virtuous cycle that makes steel difficult to displace. Let’s examine them in detail, with a focus on what matters for marine engineers and builders.

A Closer Look at Steel’s Winning Characteristics

Each advantage addresses a specific need in engineering and construction. Together, they form a compelling case.

1. Mechanical and Performance Advantages:

- High Strength & Stiffness1: Steel can carry heavy loads over long spans without excessive deflection. This allows for large, open spaces in ship interiors and on offshore decks.

- Ductility2: Steel can deform significantly before breaking. This gives warning before failure and allows it to absorb energy in collisions or groundings, a vital safety feature.

- Predictable Behavior: Engineers have extensive data on steel’s performance. Its behavior under load is well understood, allowing for precise and safe design.

2. Fabrication and Construction Advantages:

- Speed of Construction3: Pre-fabricated steel sections can be bolted or welded together quickly. This reduces on-site construction time, a major factor in project schedules and costs.

- Adaptability & Modifiability: Existing steel structures can be modified, extended, or strengthened with relative ease compared to concrete or composites.

3. Economic and Environmental Advantages:

- Life Cycle Cost4: While initial material cost is a factor, the long service life, low maintenance (with proper protection), and high residual (scrap) value make steel cost-effective over the full lifecycle of a structure.

- Sustainable Material5: Steel is the most recycled material on earth. The energy required to recycle scrap steel is a fraction of that needed for primary production. Modern mills also increasingly use recycled content.

Marine-Specific Advantages in Focus:

- Availability of Specialized Grades: The steel industry has developed entire families of grades for marine use: normal strength, high strength, extra-high toughness, weathering, and stainless steels. This allows for optimized, fit-for-purpose design.

- Compatibility with Protection Systems: Steel provides an ideal substrate for modern coating systems and works seamlessly with cathodic protection, creating a durable defense against corrosion.

Table: Advantage in Action for a Shipbuilder:

| Advantage | How it Benefits a Shipbuilding Project | Consequence of Using an Inferior Material |

|---|---|---|

| High Strength | Allows thinner hull plates, increasing cargo capacity. | Heavier vessel, less payload, higher fuel consumption. |

| Weldability6 | Enables efficient block construction in the yard. | Slower, more expensive joining methods; potential for weak joints. |

| Toughness7 | Prevents brittle fracture in cold North Atlantic waves. | Risk of catastrophic hull cracking in storm conditions. |

| Recyclability8 | At end of life, the ship’s value is not zero; scrap has value. | Disposal becomes a costly environmental problem. |

An integrated supplier enhances these inherent advantages. We ensure you get the full benefit of the right grade. We provide steel in forms (like pre-cut, beveled sections) that maximize fabrication speed. We support corrosion protection plans that maximize longevity. We don’t just sell the metal; we help you realize its full potential in your project.

What is the best marine grade stainless steel?

You need stainless for fittings, rails, or pumps. You know 316 is "marine grade," but is it the best? For some applications, a "better" grade exists, but it comes at a significantly higher cost. The "best" is a trade-off between performance and budget.

For most marine applications, 316/L (UNS S31600/S31603) stainless steel1 is considered the best practical choice. Its addition of 2-3% Molybdenum provides excellent resistance to chloride pitting and crevice corrosion, far superior to 304. For more severe conditions (warm, stagnant seawater, high chloride), Duplex Stainless Steels (e.g., 2205)2 or Super Austenitic grades (e.g., 904L)3 offer superior performance at a higher cost.

The search for the "best" must be guided by the specific service environment and the consequence of failure. Using an over-specified alloy wastes money. Using an under-specified alloy risks catastrophic failure. Let’s create a selection framework.

Selecting the Optimal Stainless Steel: A Guide Based on Severity

Stainless steel performance is measured by its Pitting Resistance Equivalent Number (PREN)4. Higher PREN generally means better corrosion resistance. But PREN is not the only factor.

The Contenders:

- 316 / 316L: The workhorse. PREN ~25. "L" denotes low carbon for better weldability. This is the default, correct choice for >90% of marine stainless needs: deck fittings, handrails, fasteners, pump components in regular seawater.

- Duplex Stainless Steels (e.g., 2205)2: PREN ~35-40. A mix of austenitic and ferritic structures. They offer roughly double the yield strength of 316 and better resistance to stress corrosion cracking. They are more expensive and require careful welding procedures.

- Super Austenitic & High-Alloy Stainless (e.g., 254 SMO, 904L): PREN >40. Exceptional corrosion resistance for the most aggressive environments, like hot, chlorinated seawater or fine gas scrubbers.

- Nickel Alloys (e.g., Inconel 625, Hastelloy C-276)5: PREN often >50. These are beyond stainless steels. They are used for extreme services like seawater piping on high-performance vessels or components in offshore oil & gas with H2S.

A Practical Selection Matrix:

| Application & Service Environment | Recommended "Best" Grade | Rationale |

|---|---|---|

| Deck handrails, ladders, door fittings (Atmospheric/splash zone) | 316/L | Excellent resistance to salt spray. Cost-effective. Readily available. |

| Boat cleats, shafts, propeller fittings (Full immersion, moving seawater) | 316/L (for smaller craft), Duplex 2205 (for high-load or critical applications). | 316L is often sufficient with good water flow. Duplex offers higher strength and margin. |

| Seawater pump casings, valve bodies (Stagnant/flowing seawater) | Duplex 2205 or Cast CF8M/CF3M (316 equivalent). | More resistant to crevice corrosion under gaskets and in stagnant areas. |

| Heat exchanger tubes (Warm seawater ~30-40°C) | Titanium or High-grade CuNi alloy are often better. Among stainless, Super Austenitic (254 SMO). | Chloride stress corrosion cracking risk increases with temperature. Standard 316 may fail. |

| Offshore platform splash zone cladding | Duplex 2205 or Nickel Alloy weld overlay. | The most corrosive marine zone demands the highest performance. |

The Integrated Supplier’s Role in Stainless Selection:

A supplier who only sells carbon steel might push 304 because it’s cheaper, or might not offer guidance at all. An integrated marine supplier6 understands the full material landscape.

- We provide the right guidance: We will recommend 316/L for standard marine use and explain why 304 is risky.

- We offer the right products: Our network includes sources for 316/L bars, plates, and sections suitable for marine fabrication.

- We ensure quality: We can provide PMI (Positive Material Identification) test reports to verify the molybdenum content, ensuring you get genuine 316, not mislabeled 304.

For a client building a new port facility in the Middle East, we supplied 316L stainless steel angles for the bollards and cleats. We provided the MTCs showing the Mo content and recommended a passivation treatment7 after fabrication. This holistic approach—right material, right documentation, right advice—is the essence of an integrated solution. It ensures that the "best" steel for the job is not just specified, but actually delivered and implemented correctly.

Conclusion

Integrated marine steel solutions offer efficiency, consistency, and expert support by combining product supply with logistical and technical services, turning fragmented procurement into a strategic advantage for shipbuilders and fabricators.

-

Explore the advantages of 316/L stainless steel, known for its excellent resistance to corrosion, making it ideal for marine environments. ↩ ↩ ↩ ↩ ↩

-

Learn about Duplex Stainless Steels like 2205, which offer superior strength and corrosion resistance for demanding marine applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the exceptional properties of Super Austenitic grades like 904L, perfect for aggressive marine conditions. ↩ ↩ ↩ ↩

-

Understand the importance of PREN in assessing stainless steel’s corrosion resistance, crucial for marine applications. ↩ ↩ ↩

-

Explore the high-performance capabilities of Nickel Alloys, essential for extreme marine environments. ↩ ↩ ↩

-

Find out how to choose a reliable marine supplier who can provide the right materials and guidance for your projects. ↩ ↩ ↩

-

Discover how passivation treatment enhances the corrosion resistance of stainless steel, crucial for marine durability. ↩ ↩ ↩

-

Learn how steel’s recyclability can reduce waste and provide economic benefits. ↩ ↩