Your newly installed L-shaped steel brackets start to rust within months. The paint is peeling. The problem isn’t the steel quality; it’s the wrong surface treatment for the harsh marine environment. Choosing an inadequate treatment guarantees premature failure and costly repairs.

Surface treatment for marine L-shaped steel includes abrasive blasting to clean the surface, followed by applying protective coatings like zinc-rich primers, epoxy intermediates, and polyurethane topcoats. For long-term immersion, cathodic protection (sacrificial anodes) is also used. The goal is to create a durable, multi-layer barrier against saltwater, oxygen, and physical damage.

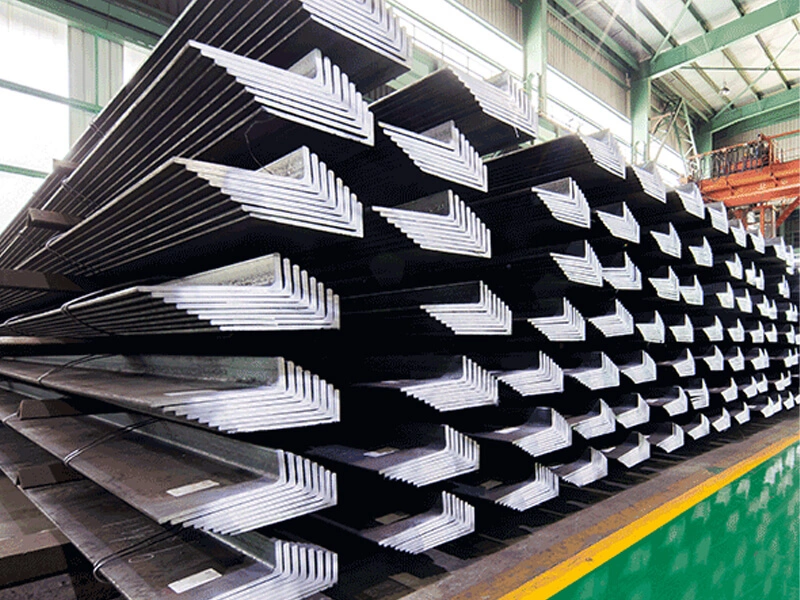

Treating steel is a science, not just a painting job. The L-shaped profile, with its sharp edges and corners, presents unique challenges. Let’s explore the complete treatment system, from initial cleaning to final protection, and how to specify it correctly for your project.

What is the surface treatment of steel?

You receive shiny new steel angles. They look ready to use. But that dark surface is mill scale, and it will cause your paint to fail. Surface treatment is the process you must do before the steel looks ready, to ensure it performs for decades.

Surface treatment of steel is the process of preparing and protecting the steel’s surface. It involves two main phases: 1) Surface Preparation1 (cleaning and profiling via blasting or grinding), and 2) Application of a Protective System (like paint, metal coating, or galvanizing). The preparation is often more critical than the coating itself for long-term adhesion and performance.

Many people think "surface treatment" means just painting. This is a dangerous oversimplification. Poor preparation guarantees coating failure, no matter how expensive the paint. Let’s break down the two-phase process in detail.

The Two Pillars of Success: Preparation and Protection

A successful surface treatment is 50% preparation and 50% coating. Skipping or rushing the first phase makes the second phase a waste of time and money.

Pillar 1: Surface Preparation1 – Creating the Foundation

The goal is to remove contaminants and create a surface profile for the coating to grip.

- Key Standards: The international standard is ISO 85012. It defines cleanliness grades (e.g., Sa 2, Sa 2½, Sa 3) and surface profile (roughness).

- Common Methods:

- Abrasive Blasting3 (Shot/Grit Blasting): The industry standard for marine work. It removes mill scale, rust, and old paint, and creates a uniform anchor profile. Sa 2½ (Near-White Metal) is the typical requirement for marine coatings. The surface should be uniformly gray-white with no visible contaminants.

- Power Tool Cleaning (Grinding, Sanding): Used for spot repair or where blasting is impossible. It is less effective at creating a profile.

- Chemical Cleaning4 (Pickling): Uses acid to remove mill scale. Common for some profiles before galvanizing.

- The Critical Detail for L-Shaped Steel: The edges and corners are the hardest areas to clean and coat properly. Blasting must be done at the right angle to hit the interior corner of the "L". A sharp, unfinished edge will hold coating poorly. This is why edge rounding or beveling before blasting is often recommended.

Pillar 2: Protective System Application – Building the Barrier

Once the steel is clean and profiled, the protective system is applied. Systems are multi-layered, with each layer having a specific function.

- Primer: The first layer. It must have excellent adhesion to the steel and provide either a barrier or sacrificial protection. Zinc-rich primers5 are common.

- Intermediate/Build Coat: This layer provides the main film thickness for barrier resistance. It is often a high-build epoxy.

- Topcoat/Finish Coat6: The final layer. It provides resistance to UV degradation, abrasion, chemicals, and gives color.

Consequences of Poor Treatment on L-Shaped Steel:

| Poor Practice | What Happens on the L-Angle | Result |

|---|---|---|

| Incomplete blasting in the interior corner. | Mill scale remains. Primer cannot adhere. | Coating delaminates from the inside of the angle, hidden from view until rust bleeds out. |

| Leaving sharp edges. | Coating pulls thin at the edge due to surface tension. The thin coating chips easily. | The edge rusts first, undermining the coating on the flat surfaces. |

| Applying coating too thick in one pass. | The coating sags or runs on vertical legs, especially at the corner. | Uneven protection, weak spots, poor appearance. |

When sourcing marine L-shaped steel, you can order it "blast cleaned and primed7" from the supplier. This ensures professional preparation is done in a controlled environment before the steel even reaches your yard, protecting it during storage and fabrication.

Which material is often used to coat steel structures to protect them from corrosion in marine environments?

You need a coating that can survive years of sun, salt, and waves. Standard industrial paint will fail quickly. The marine coating industry has developed specific material systems for this battle.

The most common materials used to coat steel in marine environments are epoxy-based paints1 and polyurethane topcoats2. Epoxy provides excellent adhesion, chemical resistance3, and barrier properties. Polyurethane provides superior UV resistance, gloss retention, and abrasion resistance4. These are applied in a multi-coat system over a zinc-rich primer for comprehensive protection.

These are not simple paints. They are chemically engineered products that cure into tough, resilient films. The choice of specific product within these families depends on the exact service location (atmospheric, splash, immersed). Let’s examine the material science behind them.

The Chemistry of Defense: Epoxy, Polyurethane, and Zinc

A marine coating system5 is a tailored combination of resins, pigments, and additives. Each component has a job.

1. Zinc-Rich Primers6 (The Sacrificial Layer)

- Material: High load of zinc dust (80-90% by weight) in an organic (epoxy) or inorganic (silicate) binder.

- How it Works: Zinc is more electrochemically active than steel. If the coating is scratched, the zinc corrodes preferentially, protecting the underlying steel (sacrificial cathodic protection). It is an essential first line of defense.

- Application: Applied directly onto blast-cleaned steel. A thin layer (50-80 microns) is sufficient.

2. Epoxy Intermediate/Barrier Coats7 (The Workhorse)

- Material: Two-component (2K) epoxy resin. It cures by chemical reaction, not just drying.

- Key Properties:

- Excellent Adhesion: Bonds strongly to the primer and steel.

- Low Permeability: Creates an exceptional barrier against water, oxygen, and chloride ions.

- High Build: Can be applied in thick coats (150-300 microns per coat) to build total film thickness quickly.

- Chemical Resistance: Resists oils, solvents, and many chemicals.

- Weakness: Poor resistance to UV light. It will chalk and degrade if left untopcoated. Therefore, it is always used as a mid-coat.

3. Polyurethane (PU) or Polysiloxane Topcoats (The Shield)

- Material: 2K polyurethane or advanced polysiloxane resins.

- Key Properties:

- Superior UV Resistance: Does not chalk or degrade quickly in sunlight.

- Abrasion and Impact Resistance: Withstands physical knocks and wear.

- Gloss and Color Retention: Maintains appearance for years.

- Flexibility: Can accommodate thermal expansion and contraction of the steel.

Selection Guide Based on Marine Zone:

| Marine Zone | Coating System Example | Material Function |

|---|---|---|

| Atmospheric Zone (Deck, Superstructure) | Zinc Epoxy Primer (75μm) + Epoxy MIO (Micaceous Iron Oxide) Intermediate (150μm) + Polyurethane Topcoat (50μm). | Zinc protects. Epoxy MIO adds barrier & UV resistance. PU provides final weather shield. |

| Splash & Tidal Zone (Most severe) | Zinc Epoxy Primer + High-build Epoxy (250-500μm) or Glass Flake Reinforced Epoxy. | Extra thickness and/or glass flakes for enhanced barrier and abrasion resistance4. May omit PU if abrasion is extreme. |

| Immersed Zone (Ballast Tanks, Hull) | Pure epoxy or modified epoxy systems, often tank-lining grades. No topcoat needed (no UV). | Maximum barrier and resistance to constant water immersion, possibly with anti-fouling properties. |

| Internal Dry Spaces | May use simpler epoxy or alkyd systems. | Basic corrosion protection where environment is less aggressive. |

For L-shaped steel, the choice also depends on its use. A bracket inside a ballast tank needs an immersion-grade epoxy. A handrail on deck needs the full epoxy+PU system. When you procure, you should know the intended environment so you or your supplier can recommend the appropriate pre-treatment or coating specification.

Which coating is used to protect steel?

You see "marine coating" on a product label, but is it the right type? There are barrier coatings, sacrificial coatings, and inhibitive coatings. Using the wrong type for your L-shaped steel’s application is a fundamental error.

Many coatings protect steel, but for marine environments, the primary types are: Barrier Coatings1 (like epoxies and polyurethanes that block water/oxygen), Sacrificial Coatings2 (like zinc-rich primers that corrode instead of the steel), and Inhibitive Coatings3 (primers containing corrosion-inhibiting pigments). A complete marine system typically uses a sacrificial or inhibitive primer topped with multiple barrier coats.

Understanding the protection mechanism helps you choose and inspect the coating correctly. A barrier coating can look perfect but fail if it has a pinhole. A sacrificial coating can look like it’s rusting (zinc corrosion) but still be actively protecting. Let’s decode these mechanisms.

The Protection Mechanisms: How Coatings Actually Work

Coatings don’t just "cover" steel. They interact with the environment and the steel surface in specific ways to stop the corrosion reaction.

1. Sacrificial (Galvanic) Coatings

- Mechanism: The coating material (zinc) is more "active" than steel. It acts as a sacrificial anode, corroding preferentially. Even at a scratch, the zinc protects the exposed steel.

- Common Form: Zinc-Rich Primers4 (ZRP). Can be epoxy-zinc or inorganic silicate-zinc.

- Best For: Excellent for edges, welds, and areas prone to damage. The backbone of marine primer systems.

- Visual Cue: The coating may develop a white, powdery deposit (zinc corrosion products). This is normal and indicates it is working.

- Mechanism: They create a physical, impermeable barrier between the steel and the corrosive agents (water, oxygen, salts). They rely on having high film integrity—no pores, no scratches.

- Common Forms: Epoxies5, Polyurethanes6, Vinyl Esters, Glass Flake Coatings. Thicker films are better barriers.

- Best For: The main body of protection over the primer. Used in immersion and severe atmospheric service.

- Weakness: If the barrier is breached, corrosion starts at the breach with no cathodic protection. This is why they are used over a sacrificial primer.

- Mechanism: The primer contains soluble pigments (like zinc phosphate, chromates) that leach out and "passivate" the steel surface, making it less chemically active.

- Common Forms: Some epoxy primers and alkyd primers.

- Best For: General industrial use. Less common as the primary defense in modern high-performance marine systems, but still used in some formulations.

Application Strategy for L-Shaped Steel:

The geometry demands a strategy that addresses weak points.

| Coating Mechanism | How to Apply on L-Shaped Steel | Purpose |

|---|---|---|

| Sacrificial (Zinc Primer) | Ensure complete coverage, especially on edges and corners. Use a brush to "work" the primer into the interior corner. | Provides active protection at vulnerable areas likely to have thin coating or damage. |

| Barrier (Epoxy/PU) | Apply multiple thin coats. Pay attention to runs and sags on vertical legs. Use a wet film thickness gauge. | Builds a continuous, thick barrier over the entire profile. |

| Combined System7 (Standard Practice) | Zinc Epoxy Primer (75μm) + Epoxy Barrier Coat (150-200μm) + Polyurethane Topcoat (50μm). | Sacrificial protection at the base, robust barrier in the middle, weather resistance on top. |

Specifying "shop primer" when ordering your L-shaped steel means the supplier applies a thin coat of zinc-rich or inhibitive primer after blasting. This protects the steel during transit and storage, and it is compatible with the full coating system you will apply later in the yard. It is a smart first step in the coating process.

How is corrosion protection of steel in marine environment?

You have a coating system1. Is that enough for a pier piling or a ship’s hull below the waterline? For fully immersed steel, coatings alone are not sufficient. You need a second, independent layer of defense.

Corrosion protection in marine environments uses a dual-defense strategy2: 1) Coatings as the primary, physical barrier, and 2) Cathodic Protection (CP)3 as a secondary, electrochemical backup system. CP works by making the steel the cathode of an electrochemical cell, stopping the corrosion reaction. It protects areas where the coating is damaged or incomplete.

Think of it like a castle. The coating is the strong wall. Cathodic protection is the moat and the guards that stop attackers who breach the wall. For L-shaped steel4 used in submerged or buried applications (like pile bracings), CP is not optional; it’s mandatory. Let’s explore this complete system.

The Complete Defense: Integrating Coatings and Cathodic Protection

This is a systems-engineering approach. The two methods are designed to work together for the design life of the structure (often 20+ years).

Part A: The Coating System (First Line of Defense)

As detailed above, its job is to isolate the steel. A good coating drastically reduces the amount of current needed for cathodic protection, making CP more efficient and longer-lasting.

Part B: Cathodic Protection (Second Line of Defense)

CP addresses the reality that no coating is perfect. It prevents corrosion at coating defects (holidays).

- How it Works: It forces the entire steel structure to become a cathode. At a cathode, the corrosion reaction (metal dissolving) is suppressed.

- Two Main Types:

- Sacrificial Anode Cathodic Protection (SACP)5: Uses blocks of a more active metal (like aluminum, zinc, or magnesium alloy) connected directly to the steel. These "anodes" corrode sacrificially, sending a protective current to the steel. They are simple, reliable, and need no external power.

- Impressed Current Cathodic Protection (ICCP)6: Uses an external DC power source and durable, inert anodes (like mixed metal oxide) to drive a protective current onto the steel. ICCP systems are used for large structures (ships, offshore platforms) as they can be adjusted and have long life.

Implications for L-Shaped Steel Components:

The need for CP depends entirely on where the L-angle is used.

- L-Angle as a Deck Bracket (Atmospheric): Coating only. CP is not applicable.

- L-Angle as a Stiffener in a Ballast Tank (Immersed): Coating + CP. The tank will have sacrificial anodes mounted on the tank walls.

- L-Angle as a Brace on a Submerged Jetty Pile (Immersed): Coating + CP. The entire jetty structure will have an ICCP or SACP system.

- L-Angle in the Splash Zone: Specialized thick coating/ cladding is primary. CP is less effective here due to intermittent wetting, but the submerged parts below will be protected.

Critical Coordination for Fabricators:

When you fabricate and install L-shaped steel4 that will be cathodically protected, you must avoid creating electrical shorts7.

- Example: If an L-angle bracket is welded to a steel pile that is CP-protected, it automatically becomes part of the protected system. That’s good.

- Problem: If that same L-angle is also accidentally touching a different, unconnected steel structure (like a conduit), it can create a "short circuit," draining the CP current and causing corrosion elsewhere.

- Solution: Ensure electrical isolation where design requires it, and inspect for accidental contacts.

Procurement and Specification Checklist:

When ordering L-shaped steel4 for a CP-protected zone, your specification should include:

- Coating Specification: Full system (primer, intermediate, topcoat) compatible with CP. Some coatings can be disbonded by the alkaline environment created at the cathode.

- Material Compatibility: The steel itself must be suitable. This is standard for marine grades.

- Welding Requirements: Weld areas must be coated to the same standard. The weld metal and HAZ become part of the protected structure.

An integrated supplier understands these requirements. We can provide L-shaped steel4 that is pre-blasted and primed with a CP-compatible coating, ready for fabrication and final coating before installation into a protected system. This ensures the material is prepared for the complete marine defense strategy from the start.

Conclusion

Effective surface treatment for marine L-shaped steel requires proper preparation, a multi-layer coating system tailored to the service environment, and integration with cathodic protection for submerged applications.

-

Explore how a robust coating system serves as the first line of defense against corrosion. ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding this strategy is crucial for effective corrosion management in marine applications. ↩ ↩ ↩ ↩

-

Explore how CP acts as a vital secondary defense against corrosion, enhancing the longevity of marine structures. ↩ ↩ ↩ ↩ ↩

-

Understanding the use of L-shaped steel can help in selecting the right materials for marine construction. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about SACP’s role in corrosion protection and its practical applications in marine environments. ↩ ↩ ↩ ↩

-

Discover how ICCP systems provide adjustable and long-lasting protection for large marine structures. ↩ ↩ ↩ ↩

-

Learn about the risks of electrical shorts and how to prevent them in corrosion protection systems. ↩ ↩ ↩ ↩