The maritime industry is at a crossroads. For years, we’ve built ships with strength as the only goal. But now, the waves are changing. Rising fuel costs, new environmental rules, and a global push for greener operations are creating huge pressure. This pressure is reshaping everything, including the very steel that forms the hulls of our ships.

The future of the maritime industry is defined by a decisive shift towards sustainability. This means shipbuilders and steel producers must now prioritize materials that offer high strength, significant weight reduction, and superior corrosion resistance to meet strict emissions regulations and lower operational costs. The trend is moving from simply strong steel to smart, eco-friendly steel.

You might wonder how a traditional material like steel can adapt to such modern demands. The answer lies not just in chemistry, but in a complete change of mindset. From the mills where it’s made to the shipyards where it’s shaped, the journey of marine steel is undergoing a quiet revolution. This change affects everyone in the chain, from large-scale importers to project contractors. Let’s dive deeper into the currents driving this transformation and explore what it means for your next project.

Why is the marine industry on a decline?

Look at the headlines, and you might think the shipbuilding industry is slowing down. Orders are shifting, and some traditional shipyards face challenges. But is it a true decline, or is it a complex transformation? The reality is more about change than collapse. The industry is not disappearing; it is evolving under immense new pressures. For businesses that rely on marine steel, understanding this shift is critical for making smart decisions.

The marine industry is experiencing a transformation, not a simple decline, driven by three main factors: stricter environmental regulations1 (like IMO’s EEXI and CII), volatile fuel prices pushing for efficiency, and a market shift towards specialized, greener vessels2. This forces a fundamental rethink in design and materials.

The so-called "decline" is really a sign of the industry hitting a reset button. Let’s break down the core pressures forcing this reset.

The Three Anchors Weighing on Traditional Shipbuilding

The old way of building ships is becoming less viable. Three major forces are acting as anchors, slowing down the old models and demanding new approaches.

- Regulatory Pressure: Rules from the International Maritime Organization (IMO), like the Energy Efficiency Existing Ship Index3 (EEXI) and the Carbon Intensity Indicator4 (CII), are no longer future concepts. They are active rules today. Ships that do not comply face operational restrictions and financial penalties. This directly pushes owners to demand more efficient ships, which starts with lighter and stronger materials.

- Economic Pressure: Fuel oil remains one of the biggest costs in running a ship. With prices unstable, the economic incentive to reduce fuel consumption is enormous. A lighter ship uses less fuel. Even a 10% reduction in hull weight can lead to significant fuel savings over a vessel’s lifetime. This makes the choice of steel not just a construction decision, but a long-term financial one.

- Market Pressure: Global trade patterns are changing. There is less demand for very large, standardized container ships and more need for specialized vessels. These include LNG carriers, offshore wind installation ships, and more efficient bulk carriers. Each of these requires specific steel grades and properties, moving away from one-size-fits-all solutions.

For a steel supplier like us, these pressures translate into specific client demands. Our customer from Saudi Arabia, Gulf Metal Solutions, is a perfect example. They are a project-based distributor. Their clients, who are building or repairing ships in the Gulf region, are now asking for steel that can help new builds meet these IMO indices. Their pain point shifted from just finding "cheap plate" to finding "reliable, certified plate5 that contributes to vessel efficiency." Our solution involved not just supplying the steel, but providing full mill certification and supporting third-party inspection (like SGS) to prove the material’s properties. This gives their end-buyers the documentation needed for class approval. The industry isn’t declining; its requirements are ascending.

What are the future trends in the maritime industry?

If the old model is under pressure, what is replacing it? The future is being built on two parallel tracks: digitalization1 and decarbonization2. Imagine a ship that is not just a steel shell, but a connected, data-generating asset. Now, imagine that same ship powered by clean fuels. This dual reality is where the industry is heading. It creates exciting opportunities for those who prepare.

The maritime industry’s future is centered on decarbonization2 (using alternative fuels like LNG, methanol, and ammonia) and digitalization1 (using AI, IoT, and data analytics for smart shipping). This requires new ship designs and, consequently, new types of steel that can handle different stresses and environments.

These trends are not abstract ideas. They are already shaping new ship orders and retrofit projects around the world. Let’s explore how they directly impact marine steel specifications.

From Fuel Tanks to Data Tanks: How Trends Dictate Steel Specs

The choice of fuel and the integration of technology fundamentally change what we need from steel. It’s no longer just about thickness and yield strength. It’s about compatibility, safety, and new performance criteria.

| Trend | Impact on Ship Design & Structure | Implication for Marine Steel |

|---|---|---|

| Decarbonization (e.g., LNG/Methanol Fuel) | Requires special fuel containment systems (pressurized tanks, membrane tanks). Increases need for cryogenic applications. | Demand for low-temperature steel3 with high toughness at sub-zero temperatures. Need for steels with excellent weldability for safe tank construction. |

| Decarbonization (e.g., Ammonia/Hydrogen) | These fuels are highly corrosive and require extreme safety measures. New tank designs and piping systems are needed. | Surge in demand for corrosion-resistant steels4 and clad plates. Steel must resist hydrogen embrittlement or ammonia stress corrosion cracking. |

| Digitalization & Smart Shipping | Addition of numerous sensors, data conduits, and automated systems. Focus on structural health monitoring. | Steel must have consistent, verifiable properties for accurate sensor data. High-quality surface finish for sensor attachment. Integration may require cutting/forming precision. |

| Efficiency-Driven Design | Hull optimization (e.g., wider beams, new bow shapes) to reduce drag. Use of air lubrication systems. | Need for higher-strength steels5 (AH/EH grades) to build lighter yet strong structures. Steel must withstand new hydrodynamic stresses from novel designs. |

Take the trend towards LNG-fueled vessels. An LNG tank operates at -163°C. Ordinary steel becomes brittle and dangerous at that temperature. This is why we see a sharp increase in inquiries for ASTM A553 Type I or similar grades of low-temperature steel3 plate. We supplied such materials for a bunkering vessel project in Southeast Asia. The client wasn’t just buying steel; they were buying safety and regulatory compliance.

Similarly, digitalization1 means a ship’s steel structure is constantly monitored. If the steel quality is inconsistent, the sensor data becomes unreliable. This pushes mills and suppliers towards more controlled production processes and traceability. When Gulf Metal Solutions asked for SGS inspection support, it wasn’t just a formality. It was their way of building digital trust in the physical product for their end-users. The future trend is clear: steel will be a connected, certified, and specialized component of a smart, green vessel.

What are the trends in marine engineering?

Marine engineering is the field that turns these industry trends into real, floating structures. Engineers are the problem-solvers. Their trends are practical responses to the pressures we discussed. Today, marine engineers are focused on two main goals: making ships lighter and making them last longer with less maintenance. Both goals lead directly to innovations in how steel is used and what we ask it to do.

Current marine engineering trends focus on lightweight construction1 using high-strength steels2 and advanced composites3, and on extending asset life4 through superior corrosion protection systems5 and easier-to-maintain designs. The aim is to build vessels that are both economically and environmentally efficient over their entire lifecycle.

These engineering goals are changing standard practices in shipyards. The focus has shifted from just assembly to integrated design and material science. Let’s look at the key engineering strategies defining modern shipbuilding.

The Engineer’s Toolkit: Lightweighting and Longevity

To build the next generation of ships, engineers are adopting new tools and methods. These methods rely heavily on the availability of advanced materials and precise fabrication techniques.

Lightweighting Through Design and Material

The most effective way to reduce weight is to use less material without sacrificing strength. This is achieved through:

- Advanced Structural Design: Using computational tools to optimize every frame, bracket, and plate. This removes unnecessary steel, a process called "topology optimization6."

- Adoption of High-Strength Steel (HSS): Replacing ordinary mild steel (e.g., Grade A) with higher grades like AH32, AH36, EH40, and even EH47. A thinner plate of EH36 can carry the same load as a much thicker plate of Grade A, leading to significant weight savings. For example, using AH36 instead of Grade A in a bulk carrier’s upper deck can reduce the steel weight in that section by 20-30%. This directly translates to more cargo capacity or lower fuel consumption.

- Hybrid Structures: Integrating other lightweight materials like aluminum or composite panels for superstructures (the part of the ship above the main deck). This raises the ship’s center of gravity less than a full-steel superstructure, improving stability.

Longevity Through Corrosion Management

Corrosion is the enemy of a ship’s lifespan and its operational budget. Engineers are moving from simple painting to comprehensive "corrosion management systems."

- Improved Coatings: Using high-performance epoxy and silicone-based coatings that last longer between dry-docking.

- Cathodic Protection Enhancement: Designing more effective sacrificial anode or impressed current systems tailored to the new, lighter hull forms.

- Strategic Use of Corrosion-Resistant Steel: This is a key trend. Instead of coating the entire ship with thick paint, engineers specify corrosion-resistant steel7 (like ASTM A690 for marine atmospheres) for specific, high-risk areas. These include ballast tanks, waterline zones, and cargo holds for corrosive cargoes. This "right steel in the right place" philosophy reduces maintenance costs drastically.

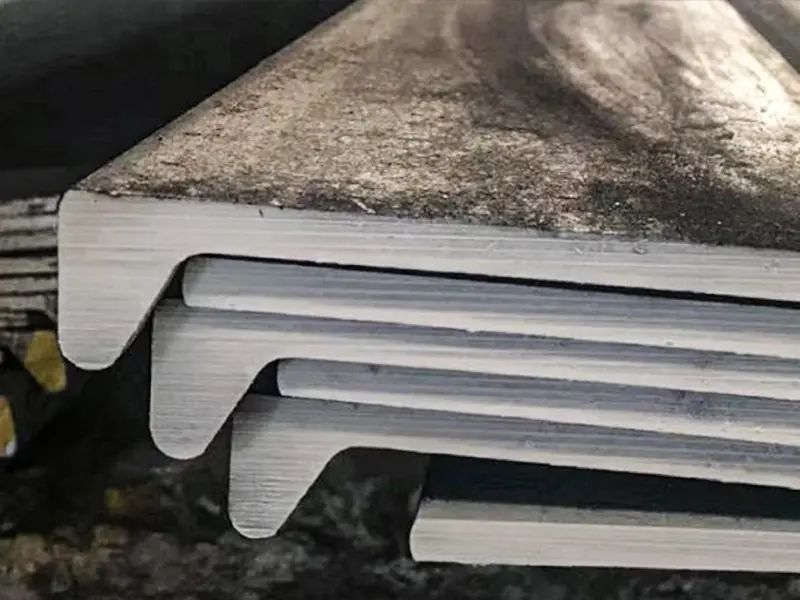

From our position as a supplier, we see this trend clearly. Orders for bulb flat steel (a key component for stiffening hulls) are increasingly for higher-strength grades. Clients want the "EH" series, not just the "AH" series. They tell us, "We need to save every ton we can." For longevity, we’ve supplied A690 steel plate for the splash zone areas of offshore service vessels. The engineer’s calculation was simple: the higher upfront cost of the special steel would be paid back in two years by avoiding one early dry-dock and repaint. Marine engineering is now a precise balance of physics, chemistry, and economics.

What is the trend in steel in 2025?

For the steel industry itself, 2025 is not just another year. It is a milestone where environmental accountability moves from the marketing department to the production floor. The trend is toward "green steel1." This term means steel produced with a significantly lower carbon footprint. Buyers are starting to ask for it, and regulations will soon require it. For marine applications, this green story combines with a continued push for performance: stronger, tougher, and more weldable steels that enable the engineering trends we just discussed.

The dominant steel trend for 2025 is the rise of "green steel1" produced via low-carbon routes (like hydrogen-based DRI), coupled with the development of "second-generation" high-strength steels that offer better weldability and toughness for safer, more efficient lightweight shipbuilding.

This dual focus creates both a challenge and an opportunity for suppliers. It’s not enough to have the right mechanical properties anymore; we must also prove the environmental credentials of our products. Let’s unpack what this means for procurement.

Green Credentials Meet Bluewater Demands

The steel of 2025 will be judged on two report cards: one from the classification society and one from the environmental auditor.

The Green Steel Revolution

Traditional steelmaking using blast furnaces is carbon-intensive. The industry is pivoting to cleaner methods. Two main paths are emerging:

- Electric Arc Furnace (EAF) Route2: This method recycles scrap steel using electricity. If the electricity comes from renewable sources (solar, wind, hydro), the carbon footprint plummets. Many mills we partner with in China are increasing their EAF capacity.

- Hydrogen-Based Direct Reduced Iron (H2-DRI)3: This is the frontier technology. Instead of using coal (coke) to remove oxygen from iron ore, it uses hydrogen. The only by-product is water. While large-scale production is still ramping up, pilot projects are underway. By 2025, the first commercial batches of this truly "green steel1" will be available for critical projects.

For buyers, this means requesting and verifying a Life Cycle Assessment (LCA)4 or an Environmental Product Declaration (EPD)5 for the steel. This document quantifies the CO2 emissions from cradle-to-gate (from mining to the mill gate). We are preparing to provide these for our key marine grades because we know our clients in Europe and the Middle East will need them for their own sustainability reporting.

Next-Generation Performance Steel

Alongside greener production, the steel itself is getting smarter. Research focuses on:

- Steels with Ultra-High Strength and Good Ductility: New compositions and thermo-mechanical control processes (TMCP) create steels that are both very strong and not brittle, improving safety.

- Enhanced Weldability: Reducing the carbon equivalent in high-strength steels makes them easier and faster to weld in shipyards, reducing construction time and risk of weld cracks.

- Functional Steels: Developing steels with built-in properties, such as better fatigue resistance for areas under constant stress.

For a wholesaler or project contractor, the 2025 trend means your sourcing criteria must expand. The checklist now includes: Grade (e.g., EH36), Standard (e.g., ABS, LR), Inspection (SGS/BV), and Carbon Footprint Data. It’s a more complex purchase, but it future-proofs your supply. When Gulf Metal Solutions plans their next order for L-shaped steel and bulb flats, the conversation will likely include these new parameters. The trend is clear: the best marine steel in 2025 will be strong, green, and fully documented.

Conclusion

The maritime world is not declining; it is evolving with purpose. Sustainability is the new compass, guiding trends in regulations, engineering, and material science. For anyone involved in supplying or using marine steel, understanding this shift—from simple strength to smart, green performance—is the key to navigating the future successfully.

-

Explore the significance of green steel in reducing carbon emissions and its impact on the future of steel production. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the EAF method and its role in recycling steel while minimizing environmental impact. ↩ ↩ ↩ ↩ ↩

-

Discover how H2-DRI technology is revolutionizing steel production with zero carbon emissions. ↩ ↩ ↩ ↩ ↩

-

Understand the importance of LCA in evaluating the environmental impact of steel products. ↩ ↩ ↩ ↩

-

Find out how EPDs help buyers assess the sustainability of steel products. ↩ ↩ ↩ ↩

-

Discover how topology optimization improves structural design in marine engineering, leading to lighter and stronger vessels. ↩

-

Learn about the importance of corrosion-resistant steel in marine engineering and its role in reducing maintenance and enhancing durability. ↩