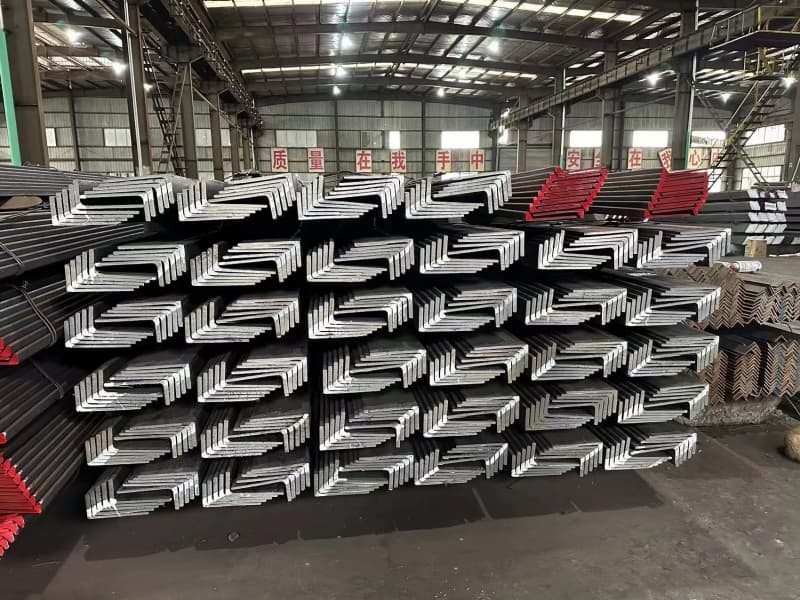

Shipyards face constant decisions about material certification standards. Both ABS and LR certified L-shaped steel meet maritime requirements, but subtle differences matter. Choosing wrong can affect project costs and timelines.

Both ABS and LR certified L-shaped steel provide excellent quality for shipbuilding, with ABS more common in American markets and LR preferred in European and Asian regions. The choice depends on project specifications, vessel flag state requirements, and shipyard preferences rather than significant quality differences between the certification systems.

Understanding the similarities and differences between ABS and LR certification helps shipyards make informed material selection decisions. Let’s examine the key questions that determine optimal choice.

What is the best steel for ship building?

Shipbuilding requires specific steel properties that ordinary structural steel cannot provide. The "best" steel depends on vessel type and operating conditions.

High-strength low-alloy (HSLA) steel grades like AH36 and DH36 are best for shipbuilding, offering excellent strength-to-weight ratios, good weldability, and impact resistance at low temperatures. These steels meet classification society requirements for hull structures, frames, and critical ship components in various marine environments.

Comprehensive Analysis of Optimal Shipbuilding Steel Selection

The selection of shipbuilding steel involves balancing multiple performance requirements against cost considerations and fabrication practicalities. Different vessel types and operating conditions demand specific material characteristics.

Strength and Weight Considerations

High-strength steels allow significant weight reduction in vessel structures. AH36 grade provides 355 MPa yield strength, approximately 50% higher than normal strength grades. The increased strength enables thinner sections and lighter structures. Weight savings translate directly to increased payload capacity or improved fuel efficiency. However, higher strength steels typically cost more and may require different fabrication techniques.

Toughness and Impact Resistance

Ship steels must withstand dynamic loading and potential impact events. Charpy V-notch testing verifies energy absorption capacity at service temperatures. Grade selection depends on operating environment temperature ranges. Normal strength Grade D steel tests at -20°C, while Grade E tests at -40°C. High-strength DH36 provides both strength and toughness for cold climate operations. This toughness prevents brittle fracture under shock loading conditions.

Corrosion Resistance Requirements

Marine environments create aggressive corrosion conditions. Ship steels incorporate copper, chromium, and nickel additions for improved corrosion resistance. The controlled chemical composition minimizes corrosion rates in seawater immersion. Proper coating systems provide additional protection. Material selection must consider both inherent corrosion resistance and compatibility with protection systems.

Weldability and Fabrication Characteristics

Modern ship construction relies heavily on welding for structural assembly. Ship steels feature controlled carbon equivalents below 0.40% for good weldability. Low sulfur and phosphorus levels minimize hot cracking susceptibility. The consistent chemical composition ensures predictable behavior during welding operations. Fabrication considerations include cutting, forming, and machining characteristics.

Classification Society Compliance

All shipbuilding steel requires certification from recognized classification societies. ABS, LR, DNV, and other societies set material standards. Certified materials undergo rigorous testing and quality assurance procedures. Classification society approval ensures international recognition and regulatory compliance. The certification provides assurance of material quality and performance.

Cost and Availability Factors

Material cost represents a significant portion of vessel construction expense. Higher strength steels command premium prices but may reduce total cost through weight savings. Availability varies by region and market conditions. Lead times affect project scheduling and material selection decisions. Total cost analysis should consider both material expense and fabrication implications.

Application-Specific Requirements

Different vessel areas demand specific steel properties. Hull plating requires excellent surface quality for coating adherence. Deck structures need good fatigue resistance for repeated loading. Tank boundaries demand specific corrosion resistance for various cargos. Understanding these application differences guides optimal material selection.

| Steel Grade | Yield Strength | Impact Test Temperature | Typical Applications |

|---|---|---|---|

| AH32 | 315 MPa | 0°C | General hull structures, warm waters |

| AH36 | 355 MPa | 0°C | Main hull plating, decks, frames |

| DH36 | 355 MPa | -20°C | Cold climate operations, ice-class vessels |

| EH36 | 355 MPa | -40°C | Arctic vessel construction |

| Normal Strength A-D | 235 MPa | 0°C to -20°C | Secondary structures, interior components |

We help shipyards like Gulf Metal Solutions select optimal steel grades based on their specific vessel types, operating routes, and budget considerations.

Which property of steel makes it suitable for shipbuilding?

Multiple steel properties contribute to suitability for shipbuilding applications. No single characteristic determines material performance alone.

Impact toughness at low temperatures is the most critical property making steel suitable for shipbuilding. This characteristic prevents brittle fracture in cold waters and during dynamic loading events. Combined with good weldability, corrosion resistance, and strength, it ensures structural integrity in harsh marine environments.

Essential Steel Properties for Marine Applications

Shipbuilding steel must possess a combination of mechanical, chemical, and physical properties that ensure performance under the unique conditions of marine service.

Fracture Toughness and Impact Resistance

The ability to absorb energy without brittle fracture represents the most critical property. Charpy V-notch testing measures energy absorption at specific temperatures. Ship steels must maintain adequate toughness at the lowest expected service temperatures. This property prevents catastrophic failure from wave impacts, collisions, or other shock loading events. The required toughness level depends on vessel type and operating environment.

Weldability and Fabrication Characteristics

Modern ship construction utilizes extensive welding for structural assembly. Steel must weld easily without special procedures or post-weld heat treatment. Carbon equivalent values below 0.40% ensure good weldability. Low sulfur and phosphorus contents minimize hot cracking susceptibility. The material must maintain properties in heat-affected zones after welding. Fabrication also involves cutting, forming, and machining operations.

Strength and Stiffness Properties

Tensile strength and yield strength determine load-bearing capacity. Higher strength allows lighter structures but may reduce toughness. Stiffness affects deflection under load and overall structural behavior. The strength-to-weight ratio influences vessel efficiency and payload capacity. Different structural areas may require different strength levels based on loading conditions.

Corrosion Resistance Performance

Marine environments create aggressive corrosion conditions. Steel composition affects corrosion rates in seawater and marine atmosphere. Alloying elements like copper, chromium, and nickel improve corrosion resistance. Surface quality influences coating adhesion and protection effectiveness. Corrosion allowance calculations determine required thickness for vessel design life.

Fatigue Resistance and Endurance

Ships experience cyclic loading from waves and operational stresses. Fatigue strength determines resistance to crack initiation under repeated stress. Stress concentrations at structural details affect fatigue performance. Material quality and internal soundness influence fatigue life. Proper design and material selection prevent fatigue failures during vessel service.

Ductility and Formability

Adequate ductility allows material deformation without fracture. This property supports fabrication operations like bending and forming. Elongation values indicate material ability to withstand plastic deformation. Reduction of area measurements provide additional ductility information. Sufficient ductility ensures structural redundancy and damage tolerance.

Through-Thickness Properties

Thick steel sections require good through-thickness characteristics. Z-direction testing verifies resistance to lamellar tearing. This property becomes critical in highly constrained joints and thick structural elements. Through-thickness strength ensures structural integrity in complex loading conditions.

Consistency and Homogeneity

Material consistency ensures predictable performance throughout the structure. Chemical composition must remain within specified limits. Mechanical properties should show minimal variation. Internal soundness prevents localized weaknesses. Homogeneous microstructure supports consistent behavior under load.

| Property | Importance Level | Testing Method | Acceptance Criteria |

|---|---|---|---|

| Impact Toughness | Critical | Charpy V-notch | Minimum energy at test temperature |

| Weldability | Critical | Carbon equivalent calculation | CE ≤ 0.40% |

| Tensile Strength | High | Tensile testing | Within specified range |

| Corrosion Resistance | High | Composition analysis | Meets specification limits |

| Fatigue Strength | Medium | Fatigue testing | Adequate life for service conditions |

| Through-thickness | Medium | Z-direction testing | Minimum reduction of area |

Our quality assurance processes verify all critical properties before shipping L-shaped steel to clients like Gulf Metal Solutions, ensuring materials meet their specific application requirements.

What grade of steel is used in shipbuilding?

Shipbuilding utilizes a range of steel grades tailored to specific applications and service conditions. Understanding grade selection ensures optimal material performance.

Normal strength grades A, B, D, E and high-strength grades AH32, AH36, DH32, DH36, EH36 are most commonly used in shipbuilding. Grade selection depends on structural importance, operating temperature, and strength requirements, with AH36 being the most widely used high-strength grade for main hull structures.

Comprehensive Guide to Shipbuilding Steel Grades

The shipbuilding industry employs a systematic grading system that indicates material properties and intended applications. Each grade serves specific purposes based on strength, toughness, and service conditions.

Normal Strength Steel Grades

Grade A represents the basic normal strength shipbuilding steel. It provides 235 MPa minimum yield strength with impact testing at 0°C. Grade B offers improved quality for important structures with similar mechanical properties. Grade D requires impact testing at -20°C for vessels operating in colder waters. Grade E demands testing at -40°C for severe environmental conditions. These grades serve secondary structures and less critical applications.

High Strength Steel Categories

High strength steels provide enhanced mechanical properties for weight-sensitive designs. AH32 and AH36 offer yield strengths of 315 MPa and 355 MPa respectively. Both require impact testing at 0°C. DH32 and DH36 provide the same strength levels with testing at -20°C. EH36 extends testing to -40°C for arctic service conditions. The higher strength allows reduced plate thickness and significant weight savings.

Chemical Composition Specifications

Each grade maintains specific chemical composition limits. Carbon content typically ranges from 0.18% to 0.21% maximum depending on grade and thickness. Manganese content varies from 0.70% to 1.60% based on strength requirements. Silicon, phosphorus, and sulfur have strict maximum limits. Micro-alloying elements like niobium, vanadium, or titanium may enhance properties in higher grades.

Application-Based Grade Selection

Hull plating typically uses AH32 or AH36 grades for main structures. Deck plating may utilize higher strength grades for weight reduction. Ice-class vessels require DH or EH grades for low-temperature toughness. Internal structures often use normal strength grades for cost efficiency. Each application gets matched with appropriate material specifications.

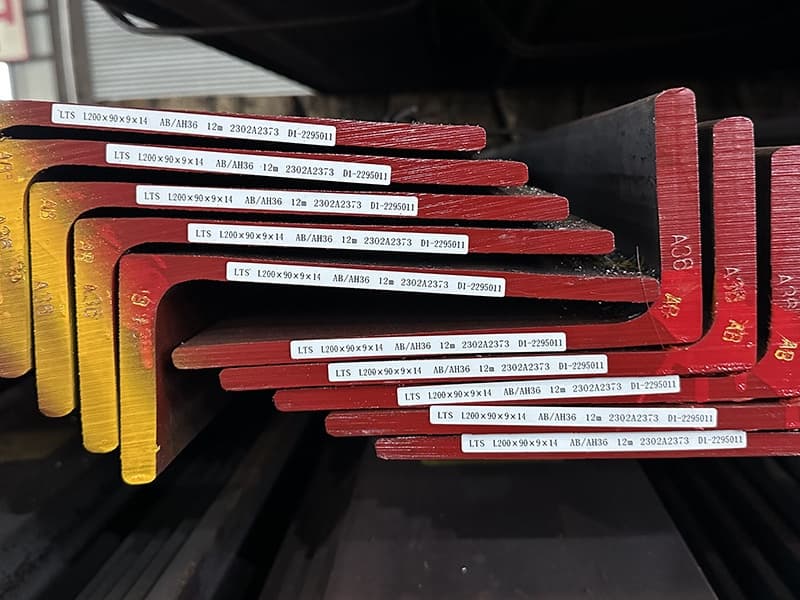

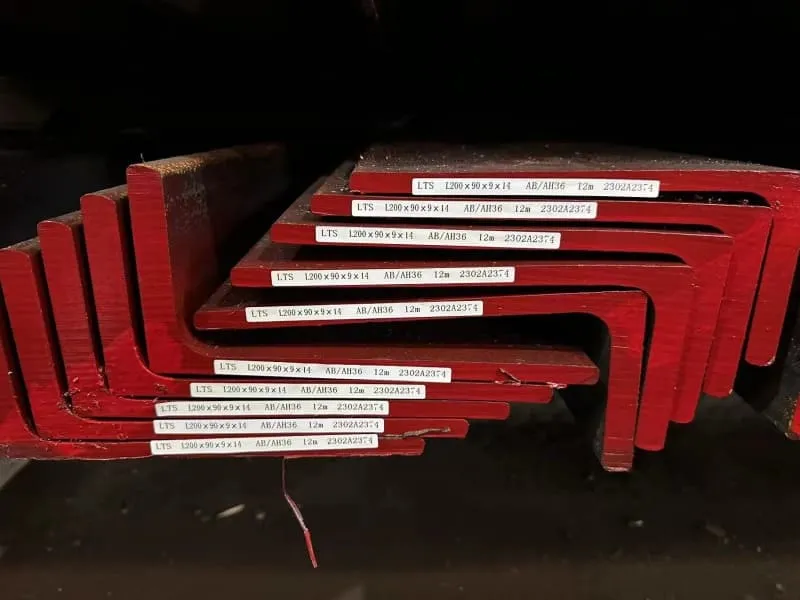

Quality and Certification Requirements

All shipbuilding grades require certification from classification societies. ABS, LR, DNV, and other societies set material standards. Manufacturers must demonstrate consistent compliance through testing and documentation. Regular audits ensure ongoing quality maintenance. Certified materials provide assurance of performance and safety compliance.

Regional and Project Variations

Different regions may show preferences for specific grades based on historical practices. European shipyards often specify LR or DNV grades. Asian shipyards commonly use ABS or Class NK grades. Project specifications determine the required classification society approval. Understanding these variations helps material selection for international projects.

Future Grade Developments

New steel grades continue emerging to address specific challenges. Extra-high-strength grades enable further weight reduction. Improved toughness grades enhance safety in extreme conditions. Environmental considerations drive development of more sustainable production methods. Technological advancements support continued grade evolution.

| Steel Grade | Yield Strength | Impact Test Temperature | Common Applications |

|---|---|---|---|

| Grade A | 235 MPa | 0°C | Secondary structures, non-critical areas |

| Grade D | 235 MPa | -20°C | Cold climate vessels, important structures |

| AH36 | 355 MPa | 0°C | Main hull plating, warm water operations |

| DH36 | 355 MPa | -20°C | Deck structures, cold climate vessels |

| EH36 | 355 MPa | -40°C | Arctic vessels, special applications |

We supply all common shipbuilding grades to clients like Gulf Metal Solutions, helping them select materials based on their specific project requirements and classification society approvals.

What grade of steel is used in ships?

Modern ships utilize multiple steel grades throughout their structures, with selection based on structural importance and service conditions. Different vessel areas require specific material properties.

Ships primarily use AH36 grade steel for hull structures, with DH36 for colder operations and EH36 for arctic service. Normal strength grades A, B, D serve secondary structures, while special grades like FH36 apply to extreme low-temperature applications. Grade selection varies by vessel area and operating environment.

Detailed Analysis of Steel Grade Applications in Ship Structures

Different ship areas demand specific steel grades based on loading conditions, environmental exposure, and structural importance. Understanding these applications ensures proper material selection throughout vessel construction.

Hull Plating and Shell Construction

The outer hull represents the most critical structural area. Bottom plating typically uses AH36 grade for main strength members. Side shell plating may use AH32 or AH36 depending on vessel size and design. Ice belt strengthening in ice-class vessels requires DH36 or EH36 grades. The hull plating must withstand water pressure, wave impacts, and potential grounding events.

Deck Structures and Plating

Main deck plating carries significant loads from equipment and cargo. Strength deck typically uses AH36 grade for optimal strength-to-weight ratio. Weather deck areas may require higher toughness grades for exposed locations. Deck plating must provide torsional rigidity to the entire hull structure. Fatigue considerations influence grade selection in high-stress areas.

Bulkheads and Internal Structures

Watertight bulkheads use steel grades matching their importance and location. Collision bulkheads typically require AH36 grade for impact resistance. Tank bulkheads may use normal strength grades with adequate corrosion properties. Non-watertight partitions often use Grade A or B steel for cost efficiency. Internal structures balance strength requirements with weight considerations.

Framing and Support Systems

Primary framing members like web frames and stringers use AH36 grade. Secondary framing may utilize AH32 or normal strength grades. Bracket connections and reinforcements require good weldability and toughness. Support structures for equipment and systems match grade to loading conditions. The framing system provides the structural skeleton for the entire vessel.

Superstructure and Accommodation Blocks

Navigation bridges and crew accommodations often use lighter gauge materials. Superstructure plating may utilize normal strength grades with adequate toughness. Weight savings in upper structures improve vessel stability. Fire protection considerations influence material selection for accommodation areas. These structures require good fabrication characteristics for complex shapes.

Special Applications and Components

Rudder stocks and stern frames require high-strength materials with good through-thickness properties. Machinery foundations need grades with adequate fatigue resistance. Hatch coamings and opening reinforcements require toughness for stress concentrations. Each special application demands specific material characteristics.

Tank Construction and Boundaries

Cargo tanks utilize steels compatible with specific cargos. Oil tanks require grades with good corrosion resistance for various petroleum products. Chemical carriers need specialized alloys for aggressive substances. Ballast tanks use grades with enhanced corrosion protection due to constant water exposure. Tank materials must withstand both structural loads and chemical exposure.

| Ship Area | Primary Grade | Alternative Grades | Key Requirements |

|---|---|---|---|

| Bottom Plating | AH36 | AH32, DH36 | Strength, impact resistance |

| Side Shell | AH36 | AH32, DH36 | Corrosion resistance, toughness |

| Strength Deck | AH36 | AH32, DH36 | Fatigue strength, stiffness |

| Bulkheads | Grade D | AH32, Grade A | Watertight integrity, stiffness |

| Framing | AH36 | AH32, Grade D | Strength, weldability |

| Superstructure | Grade A | Grade B, AH32 | Weight savings, fabrication |

We provide detailed guidance to shipyards like Gulf Metal Solutions on grade selection for different vessel areas, ensuring optimal performance while controlling costs.

Conclusion

Both ABS and LR certified L-shaped steel provide excellent quality for shipbuilding, with selection depending on project requirements rather than significant quality differences between certification systems.