Shipbuilders constantly reference dimension and weight charts for structural planning. Accurate data ensures proper design and material ordering. Many projects face delays from incorrect size specifications.

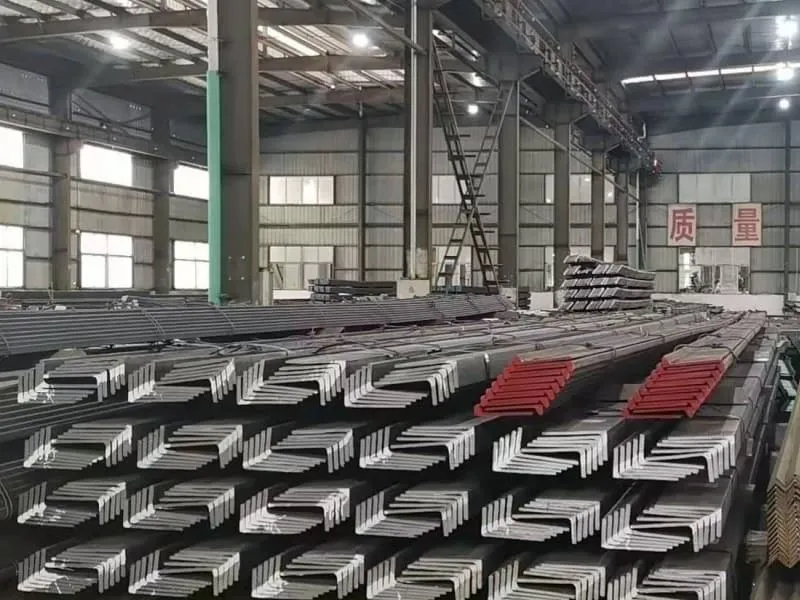

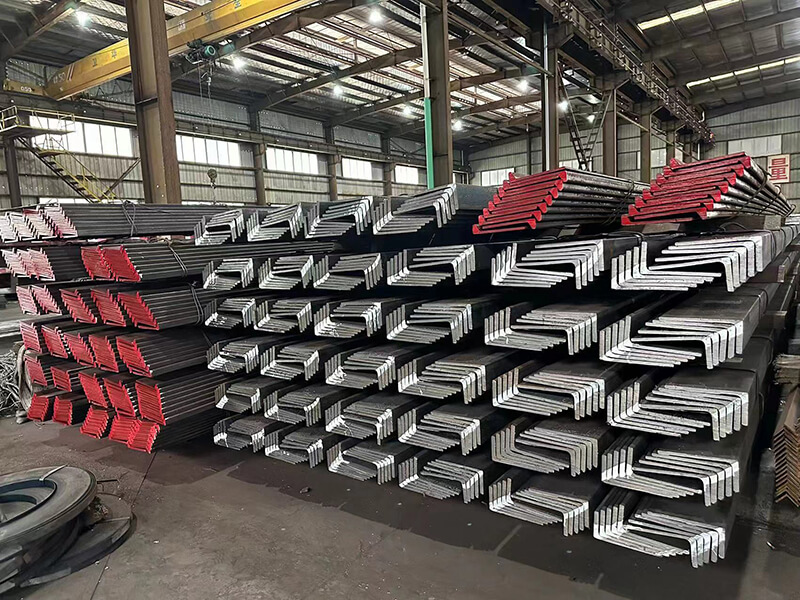

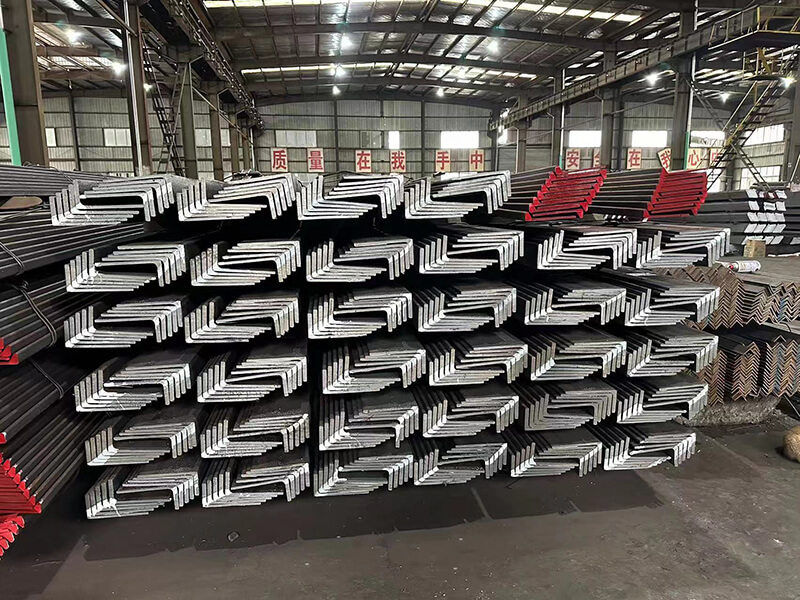

Marine L section steel comes in standard sizes from 20x20x3mm to 200x200x24mm, with weights ranging from 0.9 kg/m to 72.3 kg/m. The dimensions follow international standards like JIS G3192, ASTM A36, and EN 10056, with equal and unequal leg angles available for different structural applications in shipbuilding.

Understanding L section steel specifications requires detailed knowledge of sizing standards and application requirements. Let’s examine the fundamental questions about this essential shipbuilding material.

What is L grade steel?

Many people confuse L grade steel with general structural angles. The terminology has specific meaning in marine contexts.

L grade steel refers to normal strength shipbuilding steel with impact testing at 0°C, equivalent to ABS Grade A or LR Grade A specifications. This steel provides 235 MPa minimum yield strength and serves general structural applications in shipbuilding where high impact toughness is not required.

Comprehensive Understanding of L Grade Steel in Marine Applications

L grade steel represents a specific category within shipbuilding materials, with defined properties and application boundaries that distinguish it from higher-grade alternatives.

Chemical Composition Requirements

L grade steel maintains controlled chemical composition for consistent performance. Carbon content typically ranges between 0.18-0.21% maximum depending on product thickness. Manganese content varies from 0.70-1.60% to achieve required strength levels. Silicon content remains between 0.10-0.50% for deoxidation purposes. Phosphorus and sulfur have strict maximum limits of 0.035% each to ensure good weldability and toughness.

Mechanical Property Standards

L grade steel provides minimum yield strength of 235 MPa for structural applications. Tensile strength ranges from 400-510 MPa to ensure adequate load-bearing capacity. Elongation must exceed 22% in standard test specimens to guarantee sufficient ductility. The material undergoes bend testing to verify soundness and formability characteristics. These mechanical properties support reliable performance in marine environments.

Impact Toughness Characteristics

L grade steel requires Charpy V-notch impact testing at 0°C temperature. The minimum absorbed energy typically measures 27 joules for standard specimens. This toughness level prevents brittle fracture under normal service conditions. The material maintains adequate toughness for most temperate climate operations. Applications in colder environments require higher grades with improved low-temperature performance.

Manufacturing Process Controls

L grade steel production follows specific manufacturing protocols. Steelmaking processes must ensure chemical homogeneity and internal soundness. Rolling practices achieve specified mechanical properties and dimensional accuracy. Heat treatment may apply for certain product forms and thickness ranges. Quality control systems verify consistent compliance with specification requirements throughout production.

Application Scope and Limitations

L grade steel serves numerous shipbuilding applications where high impact toughness is not critical. It works well for internal structures and secondary framing members. The grade suits accommodation areas and superstructure components. It applies to non-critical bulkheads and partitions. However, L grade has limitations for hull plating in cold waters or highly stressed areas.

Certification and Documentation

Genuine L grade steel requires proper certification from classification societies. Material test certificates provide complete chemical and mechanical property data. Mill certificates confirm production details and compliance with specifications. Classification society approval ensures international recognition and regulatory acceptance. Proper documentation supports material traceability throughout vessel life.

Comparison with Higher Grades

L grade offers cost advantages over higher-grade alternatives. It provides adequate performance for many applications at lower material cost. However, higher grades like D and E offer improved toughness for demanding conditions. The selection between grades involves balancing performance requirements against budget considerations.

| Property | L Grade Steel | D Grade Steel | E Grade Steel |

|---|---|---|---|

| Yield Strength | 235 MPa | 235 MPa | 235 MPa |

| Impact Test Temperature | 0°C | -20°C | -40°C |

| Minimum Impact Energy | 27J | 27J | 27J |

| Typical Cost Factor | 1.0x | 1.1x | 1.2x |

| Primary Applications | Internal structures, warm waters | Cold climate vessels | Arctic operations |

We help clients like Gulf Metal Solutions select appropriate grades based on their specific vessel types and operating environments, ensuring optimal performance without unnecessary cost.

What is L-shaped steel called?

L-shaped steel goes by multiple names in different industries and regions. Understanding these terms prevents confusion in international projects.

L-shaped steel is commonly called angle steel, angle iron, or steel angle in construction and shipbuilding industries. The technical term is "equal leg angle" or "unequal leg angle" based on dimension proportions. Marine applications specifically refer to it as ship angle or marine angle steel.

Comprehensive Terminology Guide for L-Shaped Steel Products

The naming conventions for L-shaped steel reflect both technical specifications and industry traditions, with variations across different regions and application sectors.

Technical Standard Nomenclature

International standards use precise terminology for L-shaped steel products. Equal angles have legs of identical dimensions with uniform thickness. Unequal angles feature different leg lengths with consistent or varying thickness. The standard designation includes leg dimensions and thickness, such as 100x100x10mm for equal angle or 150x75x10mm for unequal angle. This systematic naming ensures clear communication across global projects.

Regional Terminology Variations

Different countries and regions employ distinct terminology for L-shaped steel. United States commonly uses "angle iron" for smaller sections and "structural angle" for larger sizes. United Kingdom refers to "steel angle" or "L-section" in technical contexts. European countries may use "L-profile" or "corner section" in translations. Asian markets often use "angle bar" in commercial discussions. Understanding these variations facilitates international trade.

Industry-Specific Terminology

Various industries developed specific terminology for L-shaped steel applications. Shipbuilding industry uses "ship angle" or "marine angle" for certified materials. Construction sector employs "structural angle" for building frameworks. Manufacturing industry may use "frame angle" for machinery structures. Infrastructure projects refer to "bridge angle" for specific applications. These terms reflect specialized requirements and standards.

Historical Terminology Evolution

The terminology for L-shaped steel evolved with industrial development. "Angle iron" originated when these products were primarily produced as wrought iron. The term persisted even after transition to steel production. "L-shaped steel" became common with standardization of rolled sections. Modern terminology emphasizes precise dimensional specifications rather than historical names. Understanding this evolution helps interpret older documentation.

Classification Society Terminology

Marine classification societies use specific terminology for certified materials. ABS refers to "rolled angles" in their rule requirements. LR uses "steel angles" in material specifications. DNV employs "L-profiles" in technical standards. These societies maintain consistent terminology within their documentation systems. Proper terminology ensures compliance with classification requirements.

Commercial and Catalog Terminology

Suppliers and distributors use commercial terminology for L-shaped steel products. Catalogs typically list "steel angles" with complete dimension tables. Quotations may use abbreviated terms like "L-bar" or "angle section". Export documentation requires precise descriptions for customs classification. Understanding commercial terminology facilitates procurement and logistics.

Technical Drawing Terminology

Engineering drawings employ specific symbols and notations for L-shaped steel. The ∠ symbol represents angles in many drawing standards. Dimension callouts specify leg sizes and thickness. Material specifications indicate grade and certification requirements. Understanding drawing terminology ensures accurate fabrication and construction.

| Terminology | Common Usage | Typical Context | Key Characteristics |

|---|---|---|---|

| Angle Steel | General industrial | Manufacturing, construction | Broad term for all L-shaped sections |

| Steel Angle | Technical specifications | Engineering drawings | Precise dimensional reference |

| Angle Iron | Traditional, informal | Construction sites | Often refers to smaller sections |

| L-Section | European technical | Structural engineering | Emphasizes cross-section shape |

| Ship Angle | Marine industry | Shipbuilding specifications | Certified for marine applications |

| Structural Angle | Building construction | Framing systems | Emphasis on load-bearing function |

We ensure clear communication with international clients like Gulf Metal Solutions by using standardized terminology in all technical documentation and commercial communications.

What does L stand for in structural steel?

The "L" designation in structural steel has specific technical meaning that relates to both shape and application characteristics.

In structural steel, "L" stands for "angle" shape, representing steel sections with two legs forming a 90-degree angle. The L designation distinguishes these products from other shapes like I-beams (I), channels (C), tees (T), and wide-flange sections (W) in structural engineering and construction applications.

Comprehensive Explanation of L Designation in Structural Steel

The L designation serves multiple purposes in structural steel classification, providing immediate recognition of product shape, dimensional characteristics, and typical applications.

Shape Identification and Classification

The L designation primarily identifies the angular cross-section shape. The two legs meet at 90 degrees to form the characteristic L profile. This shape provides unique structural properties different from other section types. The designation allows quick identification in material lists and drawings. The L shape offers excellent resistance to bending in multiple directions. The symmetrical design provides balanced strength characteristics.

Dimensional Notation System

Structural steel angles use standardized dimension notation. Equal angles show as L A×A×T where A represents leg length and T indicates thickness. Unequal angles notation is L A×B×T with A and B indicating different leg lengths. The dimension notation follows international standards for consistency. This system allows precise specification and ordering. The notation appears in catalogs, drawings, and material takeoffs.

Structural Properties and Applications

The L shape provides specific structural advantages. The geometry offers good torsional resistance compared to flat sections. The shape provides excellent connection possibilities with bolting or welding. L sections work well as edge stiffeners and reinforcement members. They serve as bracing elements in frameworks and trusses. The shape facilitates fabrication of complex structural assemblies.

Manufacturing Process Indication

The L designation often implies specific manufacturing methods. Most structural angles undergo hot rolling production. The process creates the characteristic rounded inner corner radius. Some specialized angles may form through other methods like bending or welding. The manufacturing process affects material properties and available sizes. Understanding manufacturing implications helps proper application.

International Standard Variations

Different countries employ variations of the L designation system. American standards typically use L for both equal and unequal angles. European standards may use L for equal angles and VL for unequal angles. Asian standards often follow American or European conventions. International projects require awareness of these variations. Standard conversion tables facilitate cross-border projects.

Relationship to Other Designations

The L designation relates systematically to other structural shape designations. I-beams provide efficient bending resistance in one direction. Channels offer good strength-to-weight ratios for certain applications. Tees serve specific connection and framing purposes. Understanding these relationships helps optimal shape selection for structural designs.

Historical Development Context

The L designation evolved with structural steel standardization. Early iron construction used similar shapes with different terminology. Standardization efforts created systematic designation systems. The L designation gained international acceptance through trade and engineering practice. Historical context helps interpret older drawings and specifications.

| Designation | Shape Description | Typical Applications | Key Features |

|---|---|---|---|

| L | Equal or unequal angle | Framing, bracing, reinforcement | 90-degree legs, versatile connections |

| I | I-beam shape | Beams, columns, primary framing | Efficient bending resistance |

| C | Channel section | Purlins, framing, edge members | Good strength-to-weight ratio |

| T | Tee section | Connections, special framing | Symmetrical or asymmetrical legs |

| W | Wide flange | Heavy construction, columns | Enhanced stability characteristics |

Our technical documentation for clients like Gulf Metal Solutions uses standardized L designations to ensure clear communication and accurate material specification.

What is marine grade stainless steel 316L?

Marine grade stainless steel 316L serves critical applications where corrosion resistance matters most. Understanding its properties ensures proper material selection.

Marine grade stainless steel 316L is a low-carbon austenitic stainless steel containing 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The "L" indicates low carbon content (0.03% max) for improved weldability and corrosion resistance in marine environments, particularly against chloride-induced pitting and crevice corrosion.

Comprehensive Analysis of 316L Stainless Steel in Marine Applications

316L stainless steel represents the premium choice for marine applications requiring superior corrosion resistance, with specific properties that make it ideal for harsh seawater environments.

Chemical Composition Advantages

The chemical composition of 316L provides exceptional corrosion resistance. Chromium content (16-18%) enables formation of protective passive layers. Nickel content (10-14%) stabilizes the austenitic structure for toughness. Molybdenum addition (2-3%) significantly enhances chloride resistance. Low carbon content (0.03% max) minimizes carbide precipitation during welding. This balanced composition ensures performance in aggressive marine conditions.

Corrosion Resistance Mechanisms

316L resists multiple corrosion types common in marine environments. The molybdenum content provides excellent resistance to pitting corrosion from chlorides. Crevice corrosion resistance benefits from stable passive layer formation. General corrosion rates remain low in seawater and marine atmospheres. Stress corrosion cracking resistance exceeds standard austenitic grades. These properties ensure long-term performance in marine service.

Mechanical Properties Profile

316L offers good mechanical properties for structural applications. Yield strength typically measures 170 MPa minimum in annealed condition. Tensile strength reaches 485 MPa minimum with good elongation. The material maintains strength at elevated temperatures better than carbon steels. Impact toughness remains excellent down to cryogenic temperatures. These properties support diverse marine applications.

Fabrication and Welding Characteristics

The low carbon content significantly improves weldability compared to standard 316. Welding operations minimize sensitization and subsequent intergranular corrosion. Post-weld heat treatment is generally not required for most applications. The material forms well using standard techniques and equipment. Machining requires appropriate techniques due to work hardening tendency.

Marine Application Examples

316L serves numerous critical marine applications. It works well for hardware, fasteners, and deck fittings exposed to seawater. The grade suits pumps, valves, and piping systems handling seawater. Marine exhaust systems benefit from its corrosion and temperature resistance. Architectural elements on vessels use 316L for aesthetic durability. These applications leverage the material’s marine performance characteristics.

Comparison with Alternative Grades

316L offers advantages over other stainless grades for marine use. It provides better corrosion resistance than 304/L grades in chloride environments. It costs less than super austenitic or duplex grades for many applications. The balance of properties makes it the standard for marine stainless applications. Understanding these comparisons guides optimal material selection.

Maintenance and Service Considerations

Proper maintenance ensures long-term performance of 316L components. Regular cleaning prevents buildup of contaminants that could initiate corrosion. Design should avoid crevices where corrosion could initiate. Compatibility with other materials prevents galvanic corrosion issues. These considerations maximize service life in marine environments.

| Property | 316L Stainless Steel | 304L Stainless Steel | Carbon Steel |

|---|---|---|---|

| Chromium Content | 16-18% | 18-20% | None |

| Molybdenum Content | 2-3% | None | None |

| Pitting Resistance | Excellent | Good | Poor |

| Typical Marine Life | 20+ years | 5-10 years | 2-5 years |

| Relative Cost | 1.0x | 0.7x | 0.3x |

We recommend 316L stainless steel to clients like Gulf Metal Solutions for applications requiring maximum corrosion resistance in marine environments, particularly for critical components and visible architectural elements.

Conclusion

Understanding marine L section steel dimensions, terminology, and material grades ensures proper specification and successful shipbuilding projects. Accurate data supports efficient design and construction.