Offshore platforms face constant storms, waves, and saltwater. Their structure must be incredibly strong yet optimized for weight. Using the wrong stiffener can lead to buckling, fatigue cracks, and catastrophic failure in these harsh conditions.

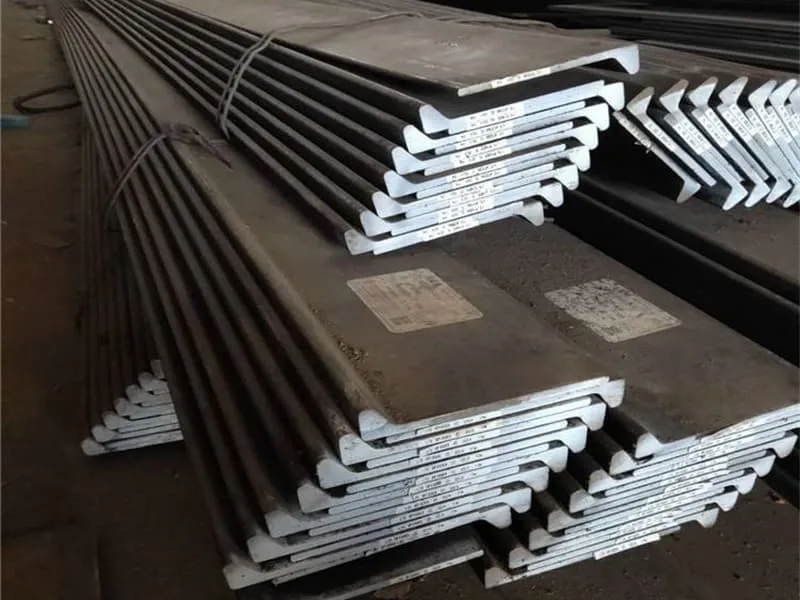

Bulb flat steel is extensively used in offshore platforms as primary and secondary stiffeners. Its unique shape provides high bending resistance with minimal weight, making it ideal for reinforcing the legs (jackets), decks, and wall plates of modules and living quarters. It withstands dynamic loads and corrosive environments when made from certified marine grades.

I supply bulb flats to fabricators who build offshore structures for the Middle East and Southeast Asia. The demands are even higher than for ships. There’s no room for error. Let’s explore why this specialized profile is the engineer’s choice for offshore construction and clarify some key technical points around its production and properties.

What are steel flats used for?

"Steel flats" is a broad term. It can refer to simple flat bars or the more complex bulb flats. In offshore construction, their use is highly specific and critical. They are not just filler material; they are integral to the platform’s skeletal strength.

Steel flats, particularly bulb flats, are used as stiffeners to reinforce large, flat steel plates against buckling and bending. In offshore platforms, they stiffen jacket legs, deck plates, module walls, and bulkheads. They transfer loads efficiently, allowing the overall structure to withstand wind, wave, and operational forces.

The Role of Stiffeners in Offshore Structural Design

An offshore platform is a giant three-dimensional frame. Thin steel plates cover this frame to form walls, decks, and submerged legs. These plates are wide and would buckle easily under pressure. Stiffeners solve this problem.

Specific Applications of Bulb Flats on an Offshore Platform

Each location has a specific loading condition that bulb flats are designed to handle.

| Platform Component | Application of Bulb Flat | Why Bulb Flats Are Preferred |

|---|---|---|

| Jacket Legs (Substructure) | Longitudinal stiffeners on the large-diameter tubular legs. They resist hydrostatic pressure and buckling from wave loads. | High section modulus in one direction (along the leg) is needed. Bulb flats provide this efficiently, reducing drag compared to heavier angles. |

| Deck Structure | Stiffeners underneath the main deck plating and on the walls of deck modules (topsides). | Supports heavy equipment loads (drilling rigs, cranes, living quarters). The bulb’s efficiency allows for lighter deck construction, which is crucial for weight management. |

| Module Walls & Bulkheads | Vertical and horizontal stiffeners on accommodation modules, equipment shelters, and watertight bulkheads. | Provides rigidity to wall panels against wind pressure and internal loads. Firewalls may require specific grades. |

| Boat Landings & Barge Bumpers | Used as reinforcing members on these impact-prone structures. | Provides localized strength to absorb berthing energy. |

The Engineering Advantage of the Bulb Profile

Compared to a simple flat bar or an angle, the bulb flat offers a superior strength-to-weight ratio.

- Section Modulus: This is a key geometric property that measures a beam’s resistance to bending. By concentrating material away from the neutral axis (in the bulb), the bulb flat achieves a high section modulus with less material than a flat bar of the same weight. This means less steel, less weight, and lower cost for the same strength.

- Connection Efficiency: The flat flange of the bulb flat provides a clean, wide surface for welding to the primary plate. This creates a strong, reliable connection. The smooth transition from bulb to flange also reduces stress concentrations.

- Corrosion and Coating: The shape, while efficient, has fewer sharp crevices than a complex angle connection, which can be beneficial for coating application and corrosion protection.

For a project contractor in Qatar building a gas platform, the choice of stiffener is not arbitrary. It is specified by the structural design software to meet exact load cases. Our role as a supplier is to provide bulb flats that match those specifications precisely—in grade (often DH36 or higher for offshore), dimensions, and with full certification (e.g., DNV, ABS Offshore). This ensures the fabricated component performs as the engineer intended.

Which is better, CR or HR?

This is a fundamental question in steel selection, but for offshore structural components like bulb flats, the answer is absolute. There is no "better"—there is only "correct." For primary load-bearing sections, Hot-Rolled (HR) is the mandatory process.

For structural shapes like bulb flats, beams, and angles used in offshore platforms, Hot-Rolled (HR) steel is definitively better. HR processing preserves the steel’s toughness and ductility, which are critical for withstanding dynamic ocean loads and low-temperature service. Cold-Rolled (CR) steel is unsuitable due to its brittleness and residual stresses.

Why Hot-Rolling is Non-Negotiable for Offshore Bulb Flats

The manufacturing process defines the steel’s internal microstructure and, therefore, its mechanical properties. Offshore environments are unforgiving of material flaws.

A Comparative Analysis of HR vs. CR for Structural Use

The differences are not minor; they are foundational to material performance.

| Property | Hot-Rolled (HR) Steel | Cold-Rolled (CR) Steel | Impact on Offshore Bulb Flat Performance |

|---|---|---|---|

| Production Method | Shaped at high temperature (>1000°C), above the recrystallization point. | Shaped at room temperature from a hot-rolled starting product. | The complex bulb shape can only be formed practically and economically by hot-rolling. |

| Microstructure & Grain | Results in a normalized, equiaxed grain structure with low internal stress. | Creates elongated, stressed grains with high dislocation density (work hardening). | HR’s uniform grain structure provides good toughness. CR’s stressed structure is prone to brittle fracture. |

| Yield Strength | Lower as-rolled yield strength, but can be increased via alloying and TMCP. | Higher yield strength due to work hardening. | Offshore grades get strength from chemistry and TMCP, not cold work. They need the underlying toughness HR provides. |

| Ductility & Toughness | Excellent. High elongation and impact resistance. | Poor. Lower elongation and significantly reduced impact toughness. | Offshore structures face impact from waves, ice, and objects. Toughness is a safety-critical requirement. CR fails here. |

| Residual Stress | Generally low. | Very high internally, leading to potential distortion during welding. | High residual stresses can combine with operational stresses, promoting fatigue cracks and stress corrosion cracking in the salty environment. |

The Specification Reality

You will never find a reputable offshore engineering standard (API, DNV, ISO) that permits the use of cold-rolled sections for primary structural members. The Mill Test Certificate for offshore-grade bulb flats will always state the delivery condition as "Hot Rolled," "As Rolled," or "Normalized."

When sourcing, a supplier who even mentions "CR" in the context of bulb flats displays a fundamental lack of understanding of offshore material requirements. For a rational buyer like the manager at Gulf Metal Solutions, this is an immediate red flag. They prefer suppliers who speak the correct technical language because it indicates a deeper understanding of the product’s end use and the associated risks.

What are the disadvantages of cold rolled steel?

Understanding the disadvantages of Cold-Rolled steel reinforces why it’s wrong for offshore applications. These disadvantages are not just minor trade-offs; they are disqualifying flaws for a structure that must survive decades at sea.

The key disadvantages of cold-rolled steel for structural applications are its poor toughness and impact resistance, high internal residual stresses, limited thickness and section availability, and unsuitability for welding in thick sections. These flaws make it vulnerable to brittle fracture, distortion, and cracking in the demanding offshore environment.

Why Cold-Rolled Steel Fails the Offshore Test

Let’s examine each disadvantage in the context of an offshore platform’s life cycle—from fabrication to operation in a storm.

A Breakdown of Critical Disadvantages

| Disadvantage | Technical Explanation | Consequence for Offshore Use |

|---|---|---|

| Low Toughness & Brittle Fracture Risk | The cold-working process hardens the steel but makes it less able to absorb energy (low Charpy impact values). It shifts the ductile-to-brittle transition temperature upward. | In cold North Sea or Arctic waters, a CR component could shatter like glass upon impact from a wave-slam or floating ice, instead of deforming. This is catastrophic. |

| High Residual Stresses | Plastic deformation at room temperature locks in high internal stresses. | During welding—a universal process in offshore fabrication—these stresses are released unevenly, causing severe distortion. This makes fit-up and alignment of large structures incredibly difficult and costly to correct. |

| Poor Weldability | High carbon equivalent (from work hardening) and residual stresses increase the risk of hydrogen-induced cracking (HIC) and cold cracking in welds, especially in thicker sections. | Offshore structures are massively welded. Weld failures are a primary cause of in-service structural problems. CR steel dramatically increases this risk. |

| Limited Product Range | CR is economically viable only for relatively thin sheets and strips (typically < 3-6mm). | Bulb flats for offshore use have flanges that are often 10-25mm thick. They cannot be produced by cold-rolling. |

| Surface Condition Dependency | The smooth, clean surface is an advantage for some applications but offers no benefit here. The surface will be blast-cleaned and coated anyway. | No advantage, while the core material properties are wrong. |

The Real-World Cost of Choosing Wrong

Imagine a fabrication yard trying to build a jacket section using cold-rolled stiffeners.

- Fabrication Nightmare: As soon as welding starts, the panels would warp and twist uncontrollably. The rework required to make sections fit for assembly would be enormous, blowing the project schedule and budget.

- Quality Control Failure: Non-destructive testing (NDT) like ultrasonic testing would likely reveal a high number of weld defects (cracks). Repairing these would add further cost and delay.

- Class Society Rejection: The classification society surveyor (e.g., DNV) reviewing the material certificates and fabrication would reject the use of CR material outright. The work would have to be scrapped.

Our supply chain is built to avoid these scenarios. We source from mills that produce hot-rolled, TMCP offshore grades. We provide the certified paperwork that proves it. For an offshore project, the cost of material is small compared to the cost of fabrication and the risk of failure. Using the correct HR material is the only rational, results-driven choice.

Do magnets stick to cold rolled steel?

This is a simple test people know from spotting stainless steel. But for carbon and high-strength low-alloy steels like those used in bulb flats, the answer is always yes. However, this question opens a door to a more important discussion: material verification beyond a simple magnet test.

Yes, magnets stick strongly to both cold-rolled (CR) and hot-rolled (HR) carbon and alloy steels, including all marine and offshore grades like AH36 or DH36. The magnet test is useless for distinguishing between HR and CR steel or for verifying grade authenticity. Proper verification requires checking Mill Test Certificates1, chemical analysis2, and mechanical test reports3.

%[magnet sticking to a hot-rolled bulb flat steel section](https://cnmarinesteel.com/wp-content/uploads/2025/11/Flat-steel-ball-70.webp "Magnet Test on Steel")

Moving Beyond the Magnet: Professional Material Verification

A magnet tells you only that the material is ferromagnetic (iron-based). It tells you nothing about the grade, strength, toughness, or production process. For offshore procurement, you need forensic-level verification.

Why the Magnet Test is Insufficient (and What to Do Instead)

Relying on a magnet gives a false sense of security. Here is what a magnet cannot detect:

| What a Magnet Can't Detect | What a Fraudulent Supplier Might Do | The Professional Verification Method |

|---|---|---|

| Material Grade (e.g., AH36 vs. Q235) | Substitute cheaper mild steel (Q235) for marine-grade steel (AH36). Both are magnetic. | Spectroscopic Analysis4: Use a portable XRF (X-Ray Fluorescence) gun to check the chemical composition on-site. AH36 will have specific levels of Niobium, Vanadium, etc., while Q235 will not. |

| Heat Treatment/Process (HR vs. CR) | As discussed, this is less likely for sections, but a magnet won't help. | Check the MTC: The certificate will state the delivery condition. For offshore, it must be Hot Rolled, Normalized, or TMCP. Microstructure Analysis: A lab can examine the grain structure, but this is destructive. |

| Impact Toughness | Sell steel that meets strength on paper but has poor toughness due to improper production. | Review the MTC: The Charpy V-Notch impact test results at the specified temperature (e.g., -20°C for DH36) must be reported and meet minimums. For high-risk applications, order additional testing. |

| Certificate Authenticity | Provide a completely forged Mill Test Certificate for fake or non-conforming material. | Certificate Authentication: Verify the certificate number, heat number, and mill details directly with the classification society (DNV, ABS) via their online portal or by contacting their office. |

The Offshore Procurement Verification Protocol

For a critical component like offshore bulb flats, a systematic approach is mandatory.

- Source Qualification: Before ordering, qualify your supplier. Do they have a track record of supplying to offshore projects? Can they provide references? Do they have long-term cooperation with certified mills, as we do?

- Pre-Shipment Inspection5 (PSI): Engage a third-party inspection company like SGS, Bureau Veritas, or Lloyd's Register to inspect the material before it leaves the mill or the supplier's warehouse. Their inspection should include:

- Witnessing dimensional checks.

- Verifying marking (heat number stamping).

- Checking the MTC against the material.

- Possibly witnessing sample cutting for independent testing.

- Receipt Inspection: When the material arrives, perform a visual and dimensional check. Verify the heat numbers on the material match those on the provided certificates.

The magnet test is a party trick. The professional verification protocol is insurance. Our clients in the offshore sector expect and require this level of diligence. By offering SGS inspection support and transparent mill certifications, we align our process with their need for absolute certainty in material quality. In an industry where failure is not an option, there is no substitute for proven, documented quality.

Conclusion

Bulb flat steel is a critical, optimized component for offshore platforms, chosen for its strength and efficiency. Always specify hot-rolled, certified marine grades and employ rigorous verification to ensure structural integrity and safety.

-

Learn about Mill Test Certificates to ensure material authenticity and compliance in procurement. ↩

-

Explore the methods of chemical analysis to verify the composition and quality of steel materials. ↩

-

Mechanical test reports provide essential data on material strength and performance, vital for safety. ↩

-

Discover how Spectroscopic Analysis can accurately determine the chemical composition of materials. ↩

-

Pre-Shipment Inspection ensures that materials meet specifications before they are shipped, reducing risks. ↩