Utilizing multiple channels of advanced high-pressure descaling technology, fully meeting the technical standards of PSPC in the international shipbuilding industry.

By applying precise rolling control with surplus cutting edges, the final rolling temperature is strictly managed under the recrystallization temperature of austenite, ensuring comprehensive optimization of product performance.

Achieving excellent straightening accuracy with double and strong straightening processes, ensuring the straightness tolerance of each shipbuilding section is less than 1‰, reaching the world’s advanced level.

Independently developed intelligent inspection system for shipbuilding sections, enabling full-process monitoring and quality control of steel section production.

| Grade | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cu (max) | Nb/V/Ti (max) |

|---|---|---|---|---|---|---|---|

| AH36 | 0.18 | 0.50 | 0.90–1.60 | 0.035 | 0.035 | 0.35 | 0.02–0.05 |

| DH36 | 0.18 | 0.50 | 0.90–1.60 | 0.035 | 0.035 | 0.35 | 0.02–0.05 |

| EH36 | 0.18 | 0.50 | 0.90–1.60 | 0.035 | 0.035 | 0.35 | 0.02–0.05 |

* Small amounts of Nb, V, Ti are permitted for strength improvement.

| Grade | Yield Strength (MPa, min) | Tensile Strength (MPa) | Elongation (%) | Impact Test* |

|---|---|---|---|---|

| AH36 | 355 | 490–620 | ≥21 | 0°C, longitudinal, min 34 J |

| DH36 | 355 | 490–620 | ≥21 | -20°C, longitudinal, min 34 J |

| EH36 | 355 | 490–620 | ≥21 | -40°C, longitudinal, min 34 J |

* Impact test temperatures: AH36 (0°C), DH36 (-20°C), EH36 (-40°C).

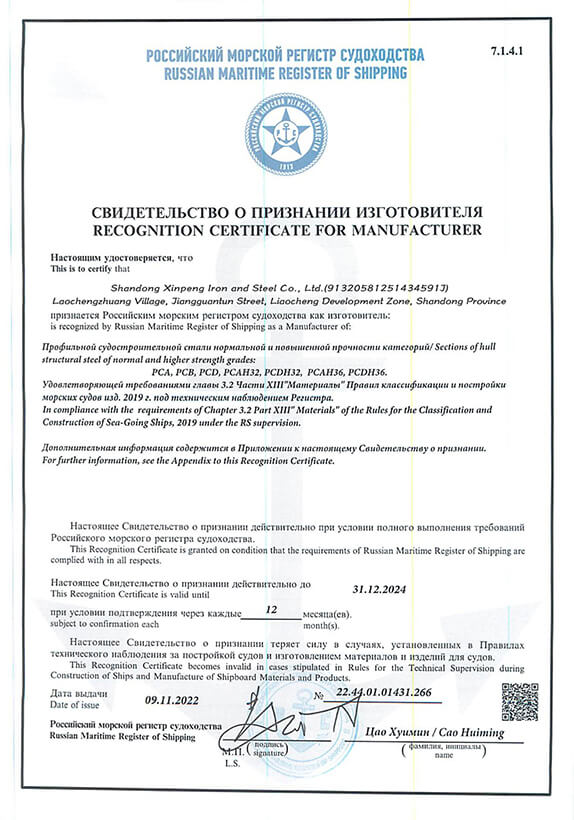

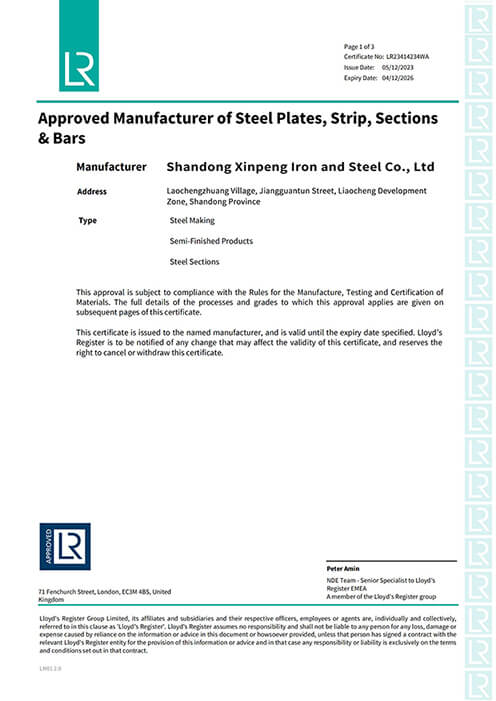

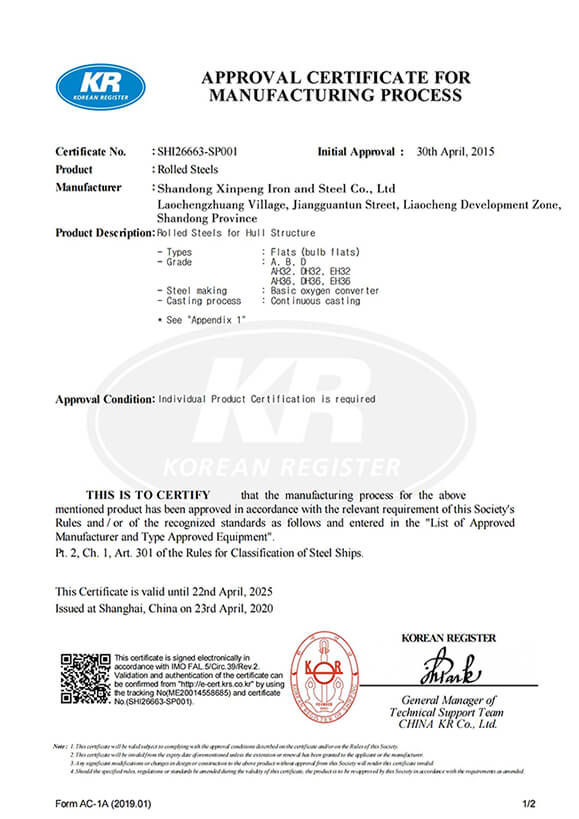

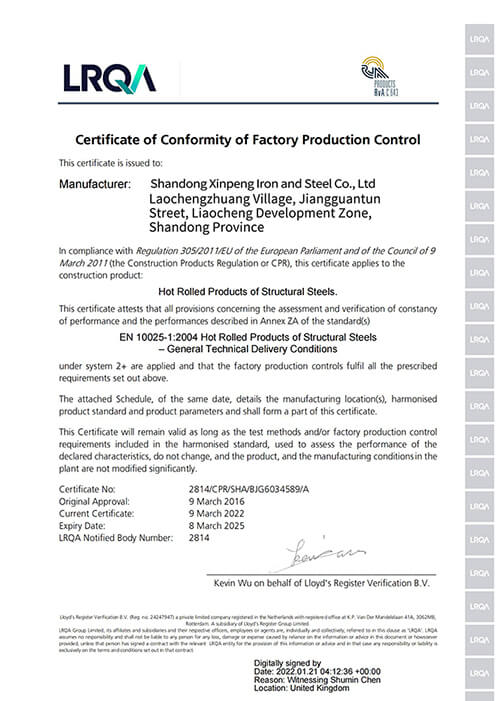

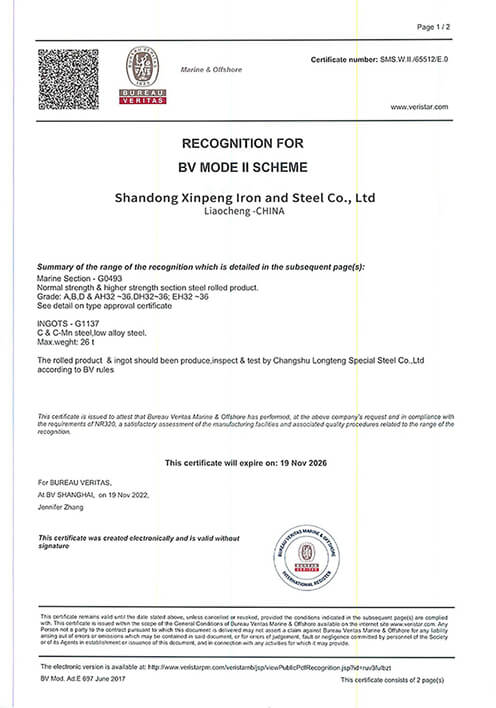

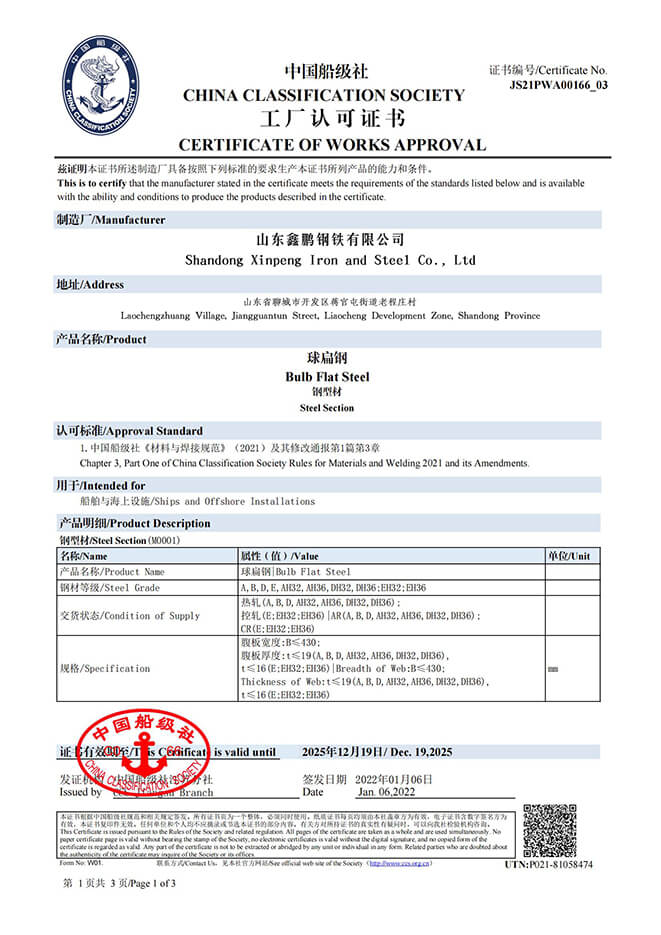

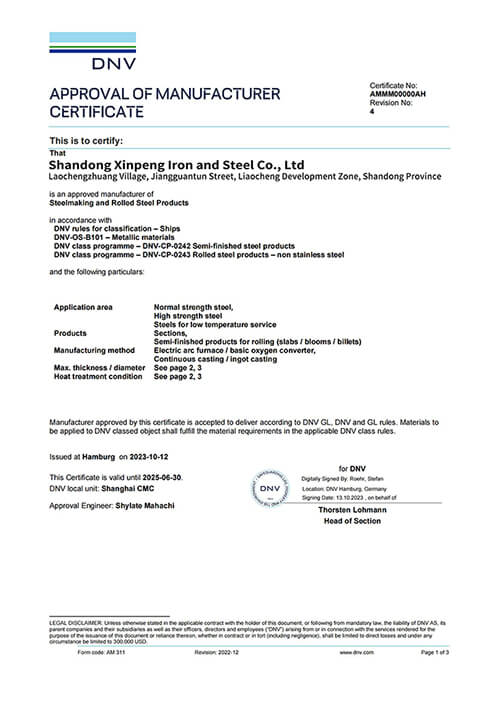

✅Classification societies: ABS, LR, BV, DNV, CCS

✅Inspection & testing: Mill Test Certificate (EN 10204 3.1/3.2), ultrasonic test, third-party inspections (SGS, BV, Intertek)

✅Standards: ASTM A131, EN, GB/T

We focus exclusively on shipbuilding and offshore steel solutions, not general steel trading.

Full approvals from ABS, LR, BV, DNV, CCS — ensuring global compliance and trust.

Wide availability of plates, bulb flats, L-sections, and angle steel with flexible stock options.

Quick shipment from stock or mill production, supported by major Chinese ports.

Full MTC (3.1/3.2) and third-party inspections by SGS, BV, or Intertek provided upon request.

Services include cutting, CNC processing, priming, shot-blasting, and galvanizing.

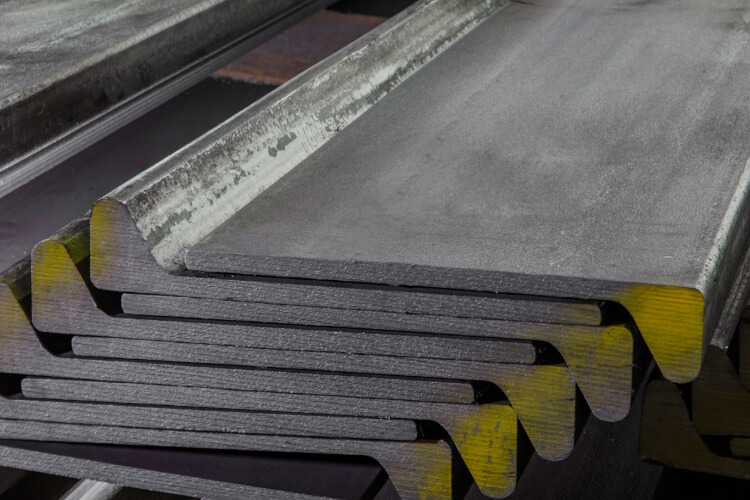

Marine angle steel is mainly used for ship hull structures, deck reinforcement, bulkheads, and frame construction. It provides strength, stability, and durability in harsh marine environments.

Our marine angle steels comply with major classification societies such as ABS, LR, BV, DNV, and CCS, ensuring full compliance with international shipbuilding standards.

We supply equal and unequal marine angle steels, with sizes ranging from 25×25 mm to 200×200 mm, and thicknesses from 3 mm to 20 mm. Customized dimensions can be provided upon request.

Yes, each batch comes with mill test certificates (MTC), mechanical properties reports, and classification society certification if required.

The steels are produced with precise chemical composition control and tested for impact toughness, weldability, and corrosion resistance. For additional protection, painting, galvanizing, or coating can be applied.

cnmarinesteel.com

Typically replies within minutes

Welcome to Xinpeng Steel! ✅ Certified marine steel supplier. Share your specs now — fast quotation guaranteed.”

WhatsApp Us

Online | Privacy policy

WhatsApp us

Have a project in mind or need a quotation? Fill out the form below and our sales team will contact you within 24 hours.