Your project manager just handed you the material list for a new series of container ships. The list includes over 5,000 tons of bulb flat steel. You feel the pressure. A mistake in procurement here doesn’t just affect cost; it can delay the entire construction schedule. A reactive, piecemeal buying approach will fail. You need a deliberate, end-to-end procurement strategy.

A successful bulb flat steel procurement strategy is proactive and technical. It starts with precise specification based on classification rules, involves strategic supplier selection for certified mill access, includes robust quality verification plans like SGS inspection, and manages logistics for just-in-time delivery. This approach mitigates risk and ensures a smooth material flow for the project lifecycle.

Procurement is more than sending out requests for quotes. It’s about building a reliable supply chain around a specialized product. To develop this strategy, you must first master the product itself. Ambiguity at the start leads to chaos later. Let’s define the core component clearly.

What is a bulb flat1?

You are discussing stiffener requirements with the design team. One person says "bulb flat1," another says "bulb bar." A new junior staff member writes "bulb plate" in the specification. This internal confusion is the first point of failure in any procurement strategy. A clear, shared definition is the non-negotiable foundation.

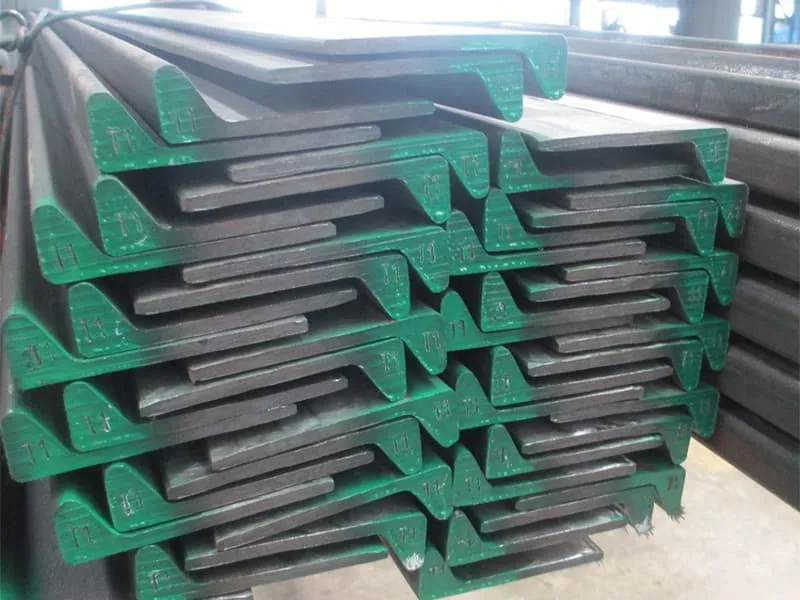

A bulb flat1 is a specialized, rolled steel profile2 with a flat web and a rounded bulb along one edge. Its unique cross-section is engineered to provide maximum bending stiffness with minimal weight. It is a standard product with defined dimensions (e.g., 250x11mm) and is a critical structural component in shipbuilding, used exclusively as a stiffener for hulls3, decks, and bulkheads.

Strategic Procurement Starts with Product Clarity

A vague understanding of the product opens the door to supplier errors, cost overruns, and project delays. A strategic procurement manager uses precise definitions as a tool.

1. The Strategic Implications of the Definition.

Knowing it’s a rolled section tells you something vital: not every steel mill can make it. It requires specific rolling mill equipment. This immediately narrows your potential supplier pool from "all steel suppliers" to "suppliers with access to section rolling mills that produce bulb flat1s." This is a key filter in your sourcing strategy.

2. Standardization is Your Friend.

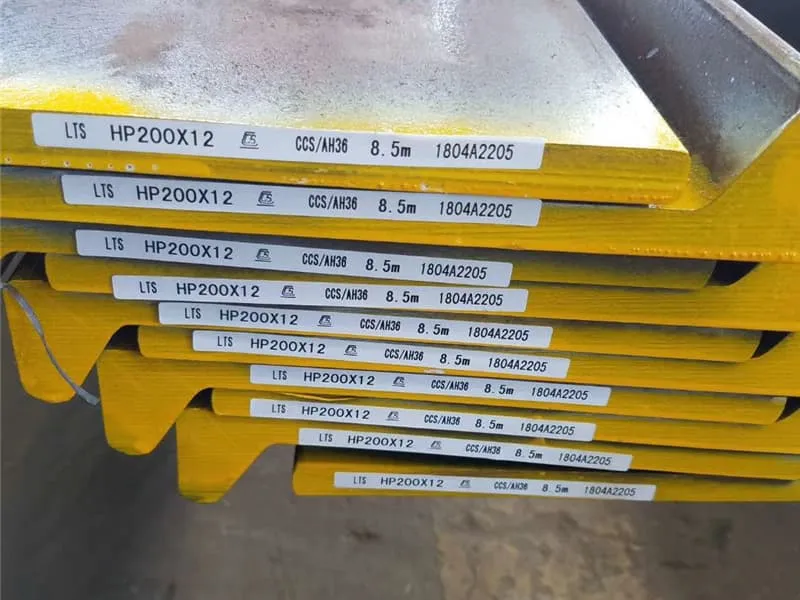

Bulb flats are produced to international standards4 like JIS G 3192, DIN 1027, or GB/T 9946. These standards define the exact dimensions for each size (e.g., for a "FB 250×11," the web height is 250mm, the thickness is 11mm, and the bulb has specific dimensions). Your strategy must mandate compliance with one of these standards in the purchase specification. This removes ambiguity and allows for accurate weight calculations and structural modeling.

3. The Cost of Misdefinition.

If your internal team or your supplier misunderstands the product, you risk:

- Procuring the Wrong Item: Buying a standard flat bar instead of a bulb flat1. The flat bar lacks the stiffness, so it will fail in service, or you’ll need to use a much heavier section, increasing weight and cost.

- Inaccurate Costing: The price per ton for a bulb flat1 is different from a plate or a flat bar. A budget based on the wrong product type will be incorrect.

- Fabrication Errors: The workshop may plan welding procedures and jigs for one profile but receive another.

My Insight from the Field

We were brought into a project in Thailand after the initial procurement failed. The shipyard’s purchase order simply said "Bulb Steel, 300mm wide, DH36 grade." The supplier, a general metal trader, delivered 300mm wide DH36 steel plate and cut it into strips. It was flat bar, not bulb flat1. The material was technically the right grade but the wrong shape, rendering it useless as a hull stiffener. The project was stalled. Our first action was to provide the yard’s procurement team with a one-page "Bulb Flat Definition Sheet5" including diagrams, standard references, and key terms. We then helped them re-specify and supply the correct product. This painful experience cost them months. Now, we advise all clients to make such a definition sheet the first page of their bulb flat1 procurement package. It aligns everyone internally and externally.

What is the use of bulb bar1?

You know it’s a stiffener2. But a strategic procurement plan requires deeper insight. You need to understand how and where it is used. This knowledge allows you to prioritize orders, plan deliveries in sync with the construction schedule3, and justify the investment in premium marine-grade material. You move from buying a commodity to supporting a construction process.

The bulb bar1 (bulb flat) is used as a unidirectional stiffener2. It is welded orthogonally to ship hull plates, deck plates, and bulkhead plates. Its sole function is to prevent these large, thin steel panels from buckling under operational loads like water pressure, deck cargo weight, or internal pressure. This application dictates its required strength, toughness, and weldability specifications.

Linking Application to Procurement Phasing and Logistics

Understanding the "use" transforms your procurement from a bulk purchase into a scheduled delivery plan aligned with the shipbuilding workflow.

1. Mapping Use to Construction Blocks.

A ship is built in blocks or sections. The procurement strategy4 should mirror this.

- Bottom Shell Blocks: These are often built first. They require the largest, thickest bulb bar1s due to high water pressure. Your first major purchase order and delivery should cover these blocks.

- Side Shell and Deck Blocks: These follow. They may use different sizes. Your procurement plan should have staggered delivery dates for these different profiles.

- Bulkhead Blocks: These can be fabricated in parallel. Their material can be included in later shipments.

2. The "Just-in-Time5" vs. "Just-in-Case" Dilemma.

A strategic procurement plan balances these two approaches.

- Just-in-Case (Stockpiling): You order all bulb flats for the entire project at once. This secures supply and price but ties up massive capital, requires huge storage space, and risks damage or corrosion during long storage.

- Just-in-Time5 (Scheduled Delivery): You order in phases, aligned with your 3-6 month construction schedule3. This improves cash flow and reduces storage but requires a highly reliable supplier and precise planning.

3. The Hybrid Strategy for Large Projects.

The most effective strategy is often a hybrid model:

- Step 1: Framework Agreement. At project start, sign a contract with a chosen supplier for the total estimated quantity at an agreed price formula. This secures your allocation at the mill.

- Step 2: Phased Release Orders. Every quarter (or month), issue a release order against the framework contract for the quantity needed for the next block of work. The supplier then ships this quantity.

- Step 3: Buffer Stock. For the most critical size (e.g., the main bottom stiffener2), you might keep a 2-4 week buffer stock in your yard to guard against any shipping delays.

My Insight from the Field

We executed this hybrid strategy6 with a shipyard in Vietnam building a series of tankers. We signed a yearly framework agreement for all their bulb flat needs. Each month, their planning department gave us a 12-week rolling schedule of required sizes and quantities. We scheduled production and shipments to arrive at their yard just as each block entered the stiffener2 welding stage. This required excellent communication from our dedicated English-speaking sales rep. The result was that the yard reduced their on-site bulb flat inventory from 3 months’ worth to just 3 weeks’ worth. This freed up significant capital and yard space. The procurement manager told us we had become an extension of their planning department. This is the ultimate goal of a strategic procurement partnership.

What is a bulb plate?

You are reviewing historical project files or old specifications. You see the term "bulb plate." In a modern, strategic procurement process, this term is a dangerous anachronism. It represents ambiguity. Your strategy must actively eliminate such ambiguous terms from all documents, emails, and conversations to ensure flawless execution.

"Bulb plate" is an ambiguous and outdated term that should be systematically eliminated from procurement documents. In a modern context, it most likely refers to a bulb flat1 (the stiffener profile). To avoid costly errors, the procurement strategy2 must enforce the use of precise, standardized terminology: "bulb flat1" or "bulb bar" for the stiffener, and "steel plate3" for the hull material.

Terminology Standardization as a Risk Mitigation Tool

A proactive procurement strategy includes controlling the language used throughout the supply chain. This is a low-cost, high-impact form of risk management.

1. The Procurement Strategy Document: Your Rulebook.

Your strategy should include a "Glossary of Terms" section. This glossary becomes the reference for your entire team and all suppliers.

- Mandated Term: Bulb Flat (preferred) or Bulb Bar.

- Definition: As defined above, with reference to the governing standard (e.g., "as per DIN 1027").

- Forbidden Term: Bulb Plate. The document should state: "The term ‘Bulb Plate’ shall not be used. Any use of this term in inquiries or quotes shall be clarified before proceeding."

2. Enforcing Clarity in the RFQ Process.

Your Request for Quotation4 (RFQ) package is where you set the tone.

- Use Clear Titles: "Request for Quotation4: Bulb Flat Steel, AH36 Grade, for Hull Stiffening."

- Include Visual Aids: Embed the dimensional sketch and standard reference in the RFQ document.

- Require Acknowledgement: Ask suppliers to acknowledge they have read and understood the specification glossary. This formalizes their commitment to use the correct terms.

3. Supplier Qualification Based on Communication.

A supplier’s response to your precise terminology is a quick qualification test.

- Red Flag: A supplier’s quote uses "bulb plate" without question or provides a quote for plate instead of a section.

- Green Flag: A supplier asks for clarification if they see ambiguous terms, or their quote precisely mirrors your terminology and includes the correct standard. This indicates attention to detail and marine sector experience.

My Insight from the Field

A large European procurement agency was managing a newbuild project in the Middle East. Their tender document inherited the term "bulb plate" from an old template. We received the tender. Instead of just quoting, our first response was a formal request for clarification (RFI). We stated: "For the item described as ‘Bulb Plate, Grade DH36,’ please confirm the required product is a rolled bulb flat1 stiffener profile per a recognized standard, and not a steel plate3." The agency’s project manager was initially annoyed by the "delay." However, after reviewing, they realized the ambiguity. They issued a clarifying addendum to all bidders. Later, they told us that our RFI had prevented a major potential problem, as several other bidders had been preparing quotes for actual steel plate3s. Our insistence on precision demonstrated a strategic, risk-averse approach, which helped us win the contract. It showed we were partners in ensuring a successful outcome, not just vendors.

What type of steel is used in flat bars?

This is the most critical technical filter in your procurement strategy. You are not buying generic "flat bars." You are buying high-performance marine structural steel formed into a bulb flat profile. The steel type determines the safety, longevity, and class approval of the vessel. Your strategy must have unbreakable rules for material certification.

The type of steel used in flat bars for general purposes is typically low-carbon steel (e.g., ASTM A36). For marine bulb flats, the steel must be a marine-grade structural steel1 produced under classification society rules. Grades like ABS AH362, DH36, or EH36 are common. These are High-Strength Low-Alloy (HSLA) steels3 with guaranteed toughness, weldability, and corrosion resistance for harsh sea environments.

The Certification-Centric Procurement Strategy

Your strategy must be designed to guarantee and verify the material’s pedigree. This goes far beyond checking a box on a quote.

1. The Non-Negotiable: Classification Society Certification4.

Your procurement policy must state: "All bulb flat steel shall be supplied with a valid, original Mill Test Certificate (MTC)5 that is traceable to a Classification Society Certificate of Approval for the specified grade." This is not a preference; it is a mandatory pass/fail criterion for supplier selection and material acceptance.

2. Building Verification into the Process.

Trust, but verify. A robust strategy includes planned verification steps.

- Pre-Shipment Inspection: Your strategy should budget for and mandate third-party inspection6 (e.g., SGS, BV, ABS survey) at the mill or before loading. This inspection verifies dimensions, visual quality, and checks the certificates against the material markings (heat numbers). The cost is minor compared to the risk of rejecting a shipload of material at your yard.

- Incoming Inspection at Yard: Upon arrival, your quality team should perform a sampling check to verify dimensions, grade markings, and the condition of the protective packaging.

3. Strategic Supplier Selection Based on Mill Access.

Your choice of supplier is essentially a choice of mill. Your strategy should evaluate suppliers on their mill partnerships.

- Question to Ask Potential Suppliers: "Which specific mill will produce this bulb flat? Can you provide their current valid approval certificates from ABS/LR/DNV for the grade we need?"

- Preferred Supplier Profile: A supplier with long-term cooperation with certified mills (like our status) is lower risk. They have stable allocation and a proven quality track record. A trader who shops around different mills for the lowest price each time introduces variability and risk.

4. Table: Procurement Strategy Checklist for Steel Type & Certification.

| Strategy Phase | Action Item | Documentation/Proof Required |

|---|---|---|

| Supplier Pre-Qualification | Verify mill approvals. | Copies of the mill’s Classification Society approval certificates for the relevant grades. |

| Request for Quotation (RFQ) | Specify exact grade and certification. | "Material: Bulb Flat per DIN 1027, Steel Grade: ABS DH36. Must supply valid ABS Certificate and MTC." |

| Contract Award | Include certification as a contract condition. | Contract clause stating material rejection and cost liability if certificates are invalid or missing. |

| Order Execution | Confirm production from approved mill. | Supplier to provide mill’s production schedule and heat numbers prior to rolling. |

| Pre-Shipment | Third-party inspection. | SGS or equivalent report confirming compliance with order spec and certificates. |

| Payment Terms | Link payment to documentation. | e.g., 90% payment against shipping documents, 10% retention upon receipt and verification of original certificates at destination. |

My Insight from the Field

A client in Saudi Arabia (Gulf Metal Solutions) specifically included SGS inspection support in their purchasing preferences because of past quality issues. Our standard process already included this option. For their first order, we arranged for an SGS inspector to visit our partner mill. The inspector witnessed the marking, measured random samples, and cross-checked the heat numbers against the mill certificates. The SGS report was sent directly to the client. This independent verification gave them absolute confidence. They later said this step was the key reason they switched from their previous supplier. It de-risked their procurement completely. This experience is now a core part of our recommended procurement strategy for all large projects: always budget for and require independent pre-shipment inspection7. It turns a subjective quality worry into an objective, documented fact.

Conclusion

A winning procurement strategy for bulb flat steel is a disciplined framework. It combines precise technical definition, schedule-aligned logistics, unambiguous communication, and an uncompromising focus on certified marine-grade material from a vetted supplier partnership.

-

Understanding marine-grade structural steel is crucial for ensuring safety and durability in marine applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out about ABS AH36 steel and its applications in marine structural projects for enhanced safety. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the benefits of HSLA steels, including their toughness and corrosion resistance for marine environments. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the importance of Classification Society Certification in ensuring material quality and compliance. ↩ ↩ ↩ ↩ ↩

-

Discover how a Mill Test Certificate (MTC) guarantees the quality and traceability of steel materials. ↩ ↩ ↩ ↩

-

Understand the role of third-party inspection in verifying material quality and compliance before shipment. ↩ ↩

-

Discover the significance of pre-shipment inspection in ensuring the quality and compliance of steel products. ↩