You’re about to build a new vessel. The success of this multi-million dollar project starts with the steel. But it’s not just about buying "steel"—it’s about selecting the right products from a complete palette of certified materials. I’ve seen how a holistic approach to steel procurement streamlines construction and ensures quality.

This guide covers the complete range of marine steel products for new shipbuilding: primary structural plates, angle bars for framing, bulb flats for stiffening, and specialty stainless steel for fittings. It clarifies that 316 is the true marine-grade stainless, explains the product forms, and details the selection of optimal carbon steel grades (like AH36, DH36) based on hull location and strength requirements. A comprehensive understanding prevents costly specification errors.

For shipbuilders, naval architects, and procurement managers, this guide serves as a foundational reference. Knowing what products are available and their specific applications is the first step to efficient and safe construction. Let’s begin with a crucial distinction in corrosion-resistant materials.

Is 304 or 316 stainless steel1 marine grade?

This is one of the most common and critical questions in ship outfitting. Using the wrong stainless steel for deck hardware leads to rust, pitting, and premature failure. A shipyard in the Middle East learned this the hard way when their 304 fittings corroded within a year.

For marine environments, 316 stainless steel1 is considered the true marine-grade stainless steel. The key difference is molybdenum2 (2-3%), which 316 contains and 304 does not. Molybdenum provides vastly superior resistance to pitting and crevice corrosion from chloride ions in saltwater. Grade 304 may be acceptable for interior or sheltered applications, but for any exposed marine fitting, 316 is the standard and reliable choice. The small cost premium prevents major maintenance costs.

Why Molybdenum Makes All the Difference at Sea

Both 304 and 316 are austenitic stainless steels, but the marine environment aggressively tests their limits.

The Chemistry of Failure:

Saltwater is rich in chloride ions. These ions can locally break down the protective chromium oxide layer on stainless steel.

- On 304 stainless, this breakdown leads to pitting corrosion3—small, deep holes that penetrate the metal. Crevice corrosion under bolts or gaskets is also a major risk.

- The molybdenum2 in 316 stainless strengthens the passive layer, making it much more resistant to this chloride attack. It dramatically raises the threshold for pitting to occur.

Practical Application Guidelines for Shipbuilders:

Use 316 (or 316L for welding) for:

- Deck Hardware: Cleats, chocks, bollards, stanchions, railings, ladders.

- Marine Fasteners: Bolts, screws, nuts in exposed locations.

- Piping Systems: For seawater lines, ballast lines (though often lined or other materials), and exhaust uptakes.

- Splash Zone Components: Any item constantly wetted by salt spray.

304 might be considered for (with caution):

- Interior Cabinetry and Trim: Inside the superstructure, away from salt spray.

- Galley Surfaces and Sinks: Where frequent cleaning occurs.

- Decorative elements in fully climate-controlled interior spaces.

Consequences of Specifying 304 Where 316 is Needed:

You will see rust stains, visible pits, and loss of material. This compromises safety (e.g., weakened railings), increases lifecycle costs through replacement, and damages the vessel’s appearance and value.

Recommendation:

For new shipbuilding, make AISI 316/316L your default specification for all exterior stainless steel components. This applies to both the raw material (bar, plate, tube) and finished purchased fittings. This clarity on material grades is part of specifying the broader category of "finished products" made from steel.

What are the finished products of steel?

In shipbuilding, "finished products" refer to the semi-fabricated steel shapes that arrive at the shipyard, ready for cutting and assembly. They are the building blocks. A shipyard’s bill of materials is essentially a list of these finished steel products1. I work with clients to ensure their list matches what mills actually produce and supply.

In shipbuilding, the key finished steel products1 are plates (for hull, deck, bulkheads), sections (angles, bulb flats, channels), and bars. These are hot-rolled to specific dimensions and grades, then supplied to the shipyard for further fabrication (cutting, welding). "Finished" here means mill-finished, not a completed ship part. Understanding these product forms is essential for accurate ordering and nesting planning.

The Shipbuilder’s Material Palette: From Mill to Yard

These products come directly from the steel mill in standardized forms. Each has a specific structural purpose.

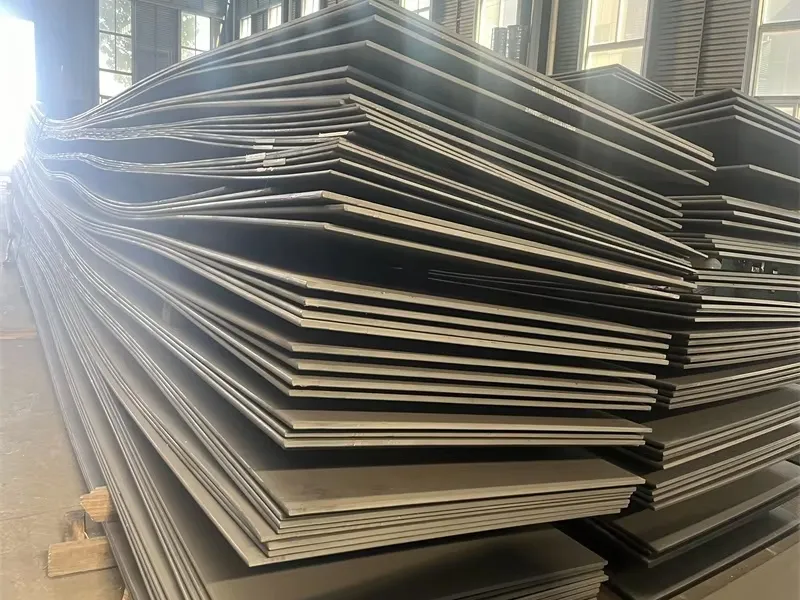

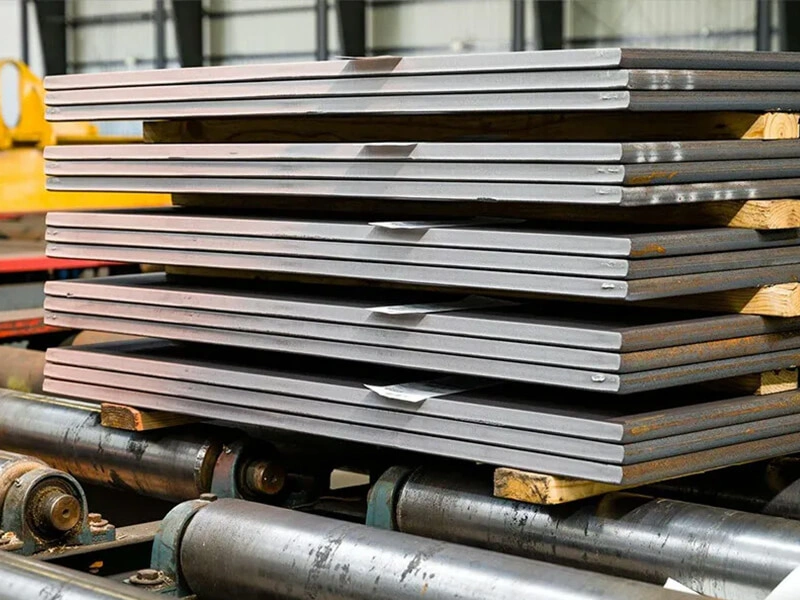

1. Steel Plates:

- Description: Flat, rectangular sheets of steel, the "skin" of the ship.

- Key Parameters: Thickness, width, length, grade (e.g., ABS AH36, 15mm thick).

- Shipyard Use: Cut into shapes for hull shell, decks, and bulkheads. The most voluminous product by weight.

2. Rolled Sections (Profiles):

These are long products with a constant cross-section.

- Angle Bars (L-Shaped): The workhorse for framing and stiffening.

- Equal Angles: Both legs same length (e.g., L150x150x12). Used for frames, braces.

- Unequal Angles: Legs different lengths (e.g., L200x90x10). Used for connections and brackets.

- Bulb Flats: A flat bar with a bulb at one edge.

- Primary Use: Longitudinal stiffeners on hull and decks. They offer the highest bending stiffness for their weight.

- Other Sections: Flat bars, channels, and beams are also used in smaller quantities for specific purposes.

3. Bars and Forgings:

- Rounds, Squares, Flats: Used for smaller components, shafts, and fasteners.

- Forgings: Shaped under pressure for high-strength, critical components like stern frames or rudder stocks.

The Supply Chain for These Products:

A shipyard doesn’t buy "steel." They buy:

- XX tons of AH36 plate, 12mm thick.

- YY tons of ABS Grade B L-angle, 200x200x16mm.

- ZZ tons of Bulb Flat, 300x12mm, JIS standard.

These are the finished mill products. A reliable supplier provides them all with consistent certification. The choice of which specific grade of plate or angle to use is dictated by the quest for the "best" steel for the job.

What is the best steel for marine use?

There is no single "best" steel. The best steel is the one that most precisely and economically meets the requirements of a specific location on the ship. Asking for the "best" steel without context is like asking for the best vehicle—it depends on the task. For a ship’s hull, strength and toughness are paramount; for a railing, corrosion resistance is key.

For primary hull structures, the best steels are high-strength, low-alloy carbon steels1 certified by classification societies, such as ABS AH362 or DNV NV A36 (355 MPa yield). For areas subject to impact and cold, grades like DH36 or EH36 with enhanced toughness are best. For corrosion resistance without structural load, 316 stainless steel is best. The "best" is always defined by the application: strength, toughness, weldability, and corrosion resistance balanced against cost. Selection is a zoned, performance-driven process.

A Zoned Approach to Material Selection

A ship is designed with different steel grades assigned to different zones based on stress, risk, and environment.

1. The Midship Hull (High Strength Zone):

- Challenge: Highest global bending stresses. Goal is to minimize weight for increased cargo capacity.

- Best Steel: High-strength steel. ABS AH362 (355 MPa yield) is the industry standard. It allows for thinner plates, reducing hull weight.

2. The Forward Hull and Bow (High Toughness Zone):

- Challenge: Wave slamming (impact), exposure to colder water. Risk of brittle fracture.

- Best Steel: High-toughness, high-strength steel. ABS DH36 (355 MPa yield, tested at -20°C) or EH36 (tested at -40°C). The ‘D’ and ‘E’ toughness grades are non-negotiable here for safety.

3. Internal Bulkheads and Secondary Structures:

- Challenge: Lower stresses, cost sensitivity.

- Best Steel: Ordinary strength steel. ABS Grade A or B. Provides adequate strength at a lower cost.

4. Superstructure:

- Challenge: Weight high up affects ship stability.

- Best Steel: Lower strength steels or thinner high-strength steels (AH32). The goal is to reduce top-side weight.

5. Deck Fittings and Hardware (Corrosion Zone):

- Challenge: Constant exposure to salt spray and weather.

- Best Steel: Stainless Steel AISI 3163. As discussed, its corrosion resistance is the primary requirement.

Decision Matrix for Common Ship Components:

| Ship Component | Primary Requirement | "Best" Steel Choice | Why |

|---|---|---|---|

| Midship Bottom Plate | High Strength, Fatigue Resistance | ABS AH362 Plate | Optimizes strength-to-weight for bending stresses. |

| Bow Plate | High Impact Toughness | ABS DH36 or EH36 Plate | Prevents brittle fracture from wave impact in cold water. |

| Transverse Frame | Strength, Ease of Fabrication | ABS Grade B or AH36 Angle Bar | Provides shape and strength; angles are easy to fit and weld. |

| Deck Longitudinal | High Bending Stiffness, Light Weight | Bulb Flat (AH36 grade) | Most efficient profile for supporting deck loads. |

| Deck Railing | Corrosion Resistance, Safety | Stainless Steel 316 Pipe/Bar | Withstands salt environment with minimal maintenance. |

This zoned selection4 relies on a clear understanding of the specific grades available within the marine steel plate family5, which is our final key topic.

What are the grades of marine steel plates1?

Marine steel plates are not a single product. They are a system of grades, each with a defined role. The grade stamped on the plate tells you its guaranteed properties. Using the wrong grade in a critical area violates classification rules and compromises safety. We ensure every plate we ship has the correct, verifiable grade marking2.

Marine steel plates are graded by classification societies (ABS, DNV, LR, etc.) into ordinary strength (Grades A, B, D, E) and high-strength (Grades AH32, AH36, DH36, EH36, FH40) categories. The letter indicates toughness level (A=basic, E=highest at -40°C), and the number indicates minimum yield strength in kgf/mm² (e.g., 36 = 355 MPa). Plates are selected based on their hull location, required strength, and operating temperature environment.

Decoding the Grade System for Precise Procurement

This logical naming convention allows for precise specification and traceability.

1. Ordinary Strength Steel Grades (A, B, D, E):

These are defined primarily by their notch toughness.

- Grade A: Basic grade for non-critical applications. May have minimal impact test requirements.

- Grade B: The standard grade for general hull plating in temperate zones. Requires impact testing at 0°C.

- Grade D: Improved toughness. Mandatory impact testing at -20°C. Used in forward hulls and for cooler climates.

- Grade E: High toughness. Mandatory impact testing at -40°C. For Arctic service.

2. High Strength Steel Grades (H-grades):

These combine increased strength with a designated toughness level.

- Naming Convention: The letter (A, D, E) denotes the toughness level. The number (32, 36, 40) denotes the minimum yield strength.

- Example – AH36: ‘A’ toughness (tested at 0°C), ‘H’ for High Strength, ’36’ for 355 MPa yield.

- Example – DH36: ‘D’ toughness (tested at -20°C), High Strength, 355 MPa yield.

3. Application-Based Grade Selection for Plates:

The hull structural drawings3 will specify the grade for each plate location.

| Hull Zone / Plate Application | Typical Plate Grade | Reason for Selection |

|---|---|---|

| Midship Bottom & Side Shell | AH36 or DH36 | High strength for global bending. DH36 used if enhanced toughness is specified. |

| Bottom & Side Shell in Forward 1/4 Length | DH36 or EH36 | Subject to wave impact; high toughness is mandatory. |

| Deck Plating (Cargo Area) | AH36 | High strength to support heavy cargo with minimal structural weight. |

| Inner Bottom Plating | Grade B or AH32 | Lower stress area; cost-effective strength. |

| Superstructure Plating | Grade A or lower strength grades | Non-primary structure; reducing weight high up improves stability. |

The Complete Product Picture for a Newbuild:

When a shipyard orders steel for a new vessel, they provide a material list that translates into:

- Plates: Of various grades (AH36, DH36, Grade B) and thicknesses.

- Sections: Angles (of corresponding grades) for frames, Bulb Flats (AH36/DH36) for longitudinals.

- Special Materials: Stainless steel 316 for specified fittings.

A supplier providing a "complete guide" service doesn’t just sell these items. They help navigate this list, ensure grade compatibility, provide all necessary certifications (MTC, inspection reports), and manage the logistics to deliver this complete product portfolio as a synchronized, build-ready package. This turns a complex procurement task into a streamlined process.

Conclusion

Successful new shipbuilding requires a complete marine steel product portfolio: correctly zoned AH36/DH36 plates for the hull, corresponding angles and bulb flats for the frame, and 316 stainless for corrosion-prone fittings. Understanding these products and their specific grades is the foundation of efficient, compliant, and safe vessel construction.

-

Explore this link to understand the different grades of marine steel plates and their specific applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Find out why grade marking is crucial for marine steel plates and how it ensures safety and compliance. ↩ ↩ ↩ ↩ ↩ ↩

-

Understand how hull structural drawings dictate the selection of steel grades for marine vessels. ↩ ↩ ↩

-

Understand how zoned selection optimizes material use for different ship components. ↩

-

Explore the various grades of marine steel plates and their specific applications. ↩