You have the ship design ready. You have the budget approved. But your project gets stalled because the steel lacks the right certification. This delay costs money every single day.

DNV certified bulb flat steel is marine-grade steel approved by Det Norske Veritas, a leading classification society. This certification guarantees the steel meets strict standards for strength, toughness, and weldability, ensuring safety and regulatory compliance in shipbuilding and offshore construction.

I once worked with a shipyard in the Philippines. They ordered a large batch of bulb flats for a new bulk carrier. The steel arrived, and it looked good. But when they submitted the mill certificates to the classification surveyor, the certificates were not from a DNV-approved mill. The surveyor rejected the entire shipment. The yard faced massive delays and extra costs for replacement steel. That experience showed me that certification is not just a piece of paper. It is the foundation of trust in marine projects. In this article, I will explain why DNV certification matters and how it protects your investment.

What are bulb flats used for?

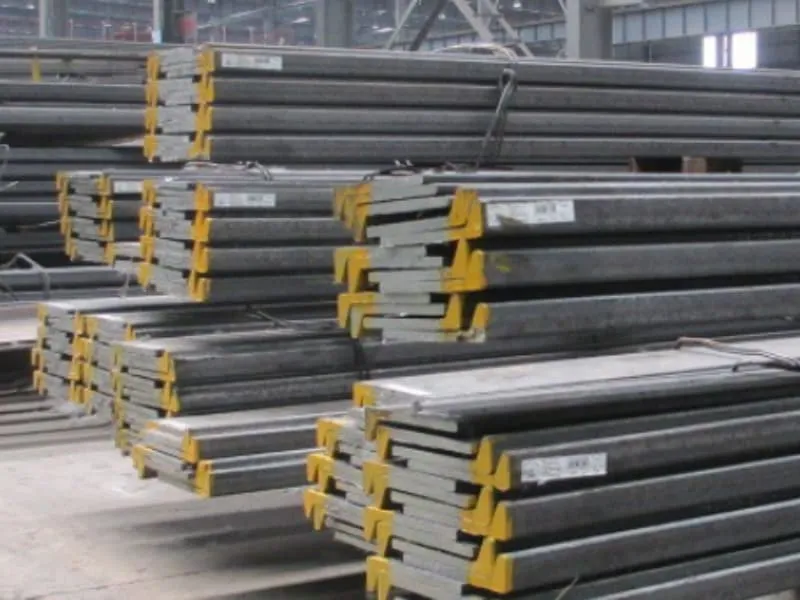

If you walk through any major shipyard, you will see thousands of these unique steel bars. They are the hidden skeleton that gives a ship its strength against the relentless power of the ocean.

Bulb flats are L-shaped steel bars with a rounded bulb at the edge. They are primarily used as stiffeners in ship hulls, decks, and bulkheads. Their design provides maximum bending resistance with minimal weight, making them essential for constructing oil tankers, container ships, and offshore platforms.

The Critical Role of Bulb Flats in Marine Structures

Bulb flats are not just another piece of steel. They are engineered components with a very specific job. Let’s break down their function.

Primary Function: Structural Stiffening

The main job of a bulb flat is to prevent large steel plates from buckling or bending. A ship’s hull is like a thin metal skin. Without support, it would collapse under water pressure or twist in heavy seas.

- Hull Frames: Bulb flats are welded vertically to the inner side of the hull plating. These vertical members are called frames. They act like the ribs of the ship, providing longitudinal strength.

- Deck Beams: On the decks, bulb flats run horizontally as beams. They support the deck plating from the weight of cargo, containers, or equipment.

- Bulkhead Stiffeners: Inside the ship, walls called bulkheads divide the space. Bulb flats are welded to these walls to keep them rigid, especially for watertight compartments that must hold pressure.

The Engineering Advantage: Why the Bulb?

You might ask, why not use a simple flat bar? The answer is efficiency. The bulb at the edge is a clever design feature.

The bulb puts extra steel mass far away from the center of the section. This greatly increases the section’s moment of inertia. Moment of inertia is a measure of how well a shape resists bending. A higher moment of inertia means a stiffer beam.

A bulb flat achieves high stiffness with less material weight compared to a flat bar. For a shipowner, less weight means more cargo capacity or better fuel efficiency. This is a direct economic benefit.

Common Applications Across Marine Vessels

Bulb flats are used in almost all types of large vessels:

- Bulk Carriers & Container Ships: Used extensively in the hull and cargo hold structures to handle heavy, shifting loads.

- Oil Tankers & Chemical Tankers: Critical for the complex inner hull structures that must contain liquids safely.

- Offshore Support Vessels & Platforms: Used in legs, jackets, and deck structures where strength-to-weight ratio is paramount.

- Naval Vessels: Employed for hull strength in frigates and other military ships.

Here is a table showing specific uses:

| Vessel Type | Primary Use of Bulb Flat | Key Requirement |

|---|---|---|

| Oil Tanker | Stiffeners on longitudinal bulkheads and hull. | High corrosion resistance, certified toughness. |

| Container Ship | Deck beams under container stacks, hull frames. | High strength to support heavy point loads. |

| Bulk Carrier | Hold frames and side shell stiffeners. | Good wear resistance for handling abrasive cargo. |

| Offshore Platform | Bracing members, stiffeners on tubular legs. | Excellent fatigue resistance and low-temperature toughness. |

From our experience: A client in Saudi Arabia, Gulf Metal Solutions, supplies steel to shipyards. They always specify bulb flats for hull stiffening projects. They told me that using the correct profile is non-negotiable. A substitute like an angle bar might fit, but it would not provide the same strength efficiency. This could compromise the ship’s design and fail classification approval. Knowing the exact use helps you appreciate why quality and certification are so important.

What is DNV steel?

When you hear "DNV steel," it does not mean a special type of metal. It refers to a system of quality assurance that is recognized and trusted by the entire maritime industry.

DNV steel is any steel material produced, tested, and certified according to the strict rules and standards set by DNV (Det Norske Veritas). It is a guarantee that the steel’s chemical composition, mechanical properties, and manufacturing process have been independently verified for marine use.

DNV: More Than Just an Acronym

DNV is one of the world’s leading classification societies. Their main role is to set technical standards for ships and offshore structures to ensure safety at sea. They do not make steel. Instead, they provide a framework that steel mills must follow.

The DNV Certification System for Materials

DNV has a detailed rulebook called the "DNV Rules for Classification of Ships" and "DNV Standards for Certification of Materials." These documents specify exactly what is required for steel to be called "DNV certified."

- Approved Mills: First, the steel manufacturing mill itself must be approved by DNV. DNV surveyors audit the mill’s entire process. They look at the melting furnaces, the casting process, the rolling mills, the heat treatment facilities, and the quality control labs. Only mills that pass this audit can produce DNV-certified steel.

- Material Grades: DNV defines its own grade system for steel. For example, normal strength shipbuilding steel is NV A, NV B, NV D, NV E. The letters indicate impact test temperature (similar to A, B, D, E). High-strength steel grades are NV AH32, NV DH36, NV EH40, etc. These grades align with but are specifically defined by DNV rules.

- Testing and Documentation: For each batch of steel, the mill must perform specific tests: chemical analysis, tensile tests, and Charpy V-notch impact tests. The results are recorded on an official DNV Type Approval Certificate or a Mill Certificate endorsed by a DNV surveyor. This certificate follows the steel from the mill to the end user.

Why DNV Standards Are Different

You might think all steel standards are similar. But DNV rules often have extra requirements.

- Traceability: DNV requires strict heat or melt number traceability. You can trace a single plate back to the specific cast it came from.

- Toughness Requirements: Their criteria for impact energy absorption can be more stringent in certain thickness ranges or for specific applications.

- Special Grades: DNV has rules for steels used in extreme conditions, like for Arctic service (ice class) or for very thick plates used in critical areas.

The bottom line: When you buy "DNV steel," you are buying more than metal. You are buying a product from an audited supply chain, backed by a third-party promise of quality. It removes guesswork and reduces risk for the shipbuilder, the owner, and the insurer.

What does DNV approved mean?

The term "DNV approved" is often used, but its meaning is precise and powerful. It is your assurance that an independent expert has checked and validated the product at multiple stages.

"DNV approved" means that a product, material, or manufacturer has successfully undergone DNV’s certification process. This involves design review, factory assessment, production testing, and issuance of a certificate confirming compliance with DNV’s rigorous rules and standards for maritime safety.

The Layers of DNV Approval

Approval is not a single event. It is a process with several layers of verification. Understanding these layers helps you know what you are really getting.

Type Approval for Materials

This is the most common approval for steel products like bulb flats. The process works like this:

- The steel mill develops a product (e.g., bulb flat in grade NV AH36).

- They submit detailed technical documentation to DNV: the manufacturing process, chemical composition, mechanical property targets, and quality control procedures.

- DNV engineers review the documents. They check if everything meets the rules.

- DNV surveyors then visit the mill. They witness the production of a test batch. They observe the tests (tensile, impact) in the mill’s lab.

- If everything is correct, DNV grants a Type Approval Certificate for that specific product from that specific mill. This certificate has a validity period and needs renewal.

Factory Certification / Mill Approval

This is the foundation. Before a mill can get type approval for products, the mill itself must be certified. DNV assesses the mill’s Quality Management System (QMS). They check if the mill has the capability and consistency to produce quality steel every time. They look at equipment maintenance, personnel training, and calibration of testing machines.

Product Certification / Survey at Delivery

For important orders, the buyer can request a Survey at Delivery. A DNV surveyor goes to the mill or the supplier’s warehouse when the steel is ready for shipment. The surveyor randomly selects samples from the production batch. The surveyor sends these samples to an independent lab for testing, or witnesses testing at the mill’s DNV-witnessed lab. Only after the surveyor is satisfied does he or she release the material and stamp the certificates. This is the highest level of assurance.

What "DNV Approved" Means for You, the Buyer

When your supplier says the bulb flats are "DNV approved," you should expect these things:

- Traceable Documentation: You will receive official DNV certificates (Type Approval and/or Material Certificates) with unique numbers.

- Verified Properties: The steel’s strength, chemistry, and toughness are not just claims. They are verified data.

- Regulatory Acceptance: Shipyards and classification surveyors will accept this steel without question. It smooths the construction process.

- Risk Reduction: The risk of material failure, rejection, or project delay is significantly lower.

A cautionary note: Be precise with language. Some suppliers might say "steel meets DNV standards." This is not the same as "DNV approved." "Meets standards" could be a self-declaration. "DNV approved" means DNV was involved in the verification. Always ask to see the actual DNV certificate.

What are the 4 types of steel?

Understanding the four basic types of steel is like learning the alphabet before you write. It helps you understand where marine grades like DNV AH361 fit in the bigger picture.

The four main types of steel, categorized by their chemical composition2, are: Carbon Steel3, Alloy Steel4, Stainless Steel5, and Tool Steel6. Marine bulb flats are typically made from Carbon Steel3 or High-Strength Low-Alloy (HSLA) Steel7, which is a sub-category of Alloy Steel4.

A Guide to the Steel Family Tree

All steel is an alloy of iron and carbon. The difference between the four types comes from the other elements added and their primary purposes.

1. Carbon Steel3

This is the most common and widely used type. It is mostly iron with a small percentage of carbon (usually up to 2.1%) as the main alloying element. Manganese is also present in small amounts.

- Characteristics: It is strong, relatively inexpensive, but can be prone to corrosion (rust). Its properties are mainly controlled by the carbon content and heat treatment.

- Sub-Categories:

- Low Carbon (Mild Steel): 0.6% Carbon. Very hard and strong, but brittle. Used for springs, blades, and tools.

- Relevance to Bulb Flats: Most general-grade structural steel (like S235, S355) is carbon steel. However, for marine applications, even carbon steels have controlled chemistry and added micro-alloys for better performance.

2. Alloy Steel4

This is carbon steel with additional alloying elements (like Chromium, Nickel, Molybdenum, Vanadium) added deliberately to change its properties.

- Characteristics: Alloying elements can increase strength, toughness, wear resistance, or hardenability. The most relevant sub-category for us is High-Strength Low-Alloy (HSLA) Steel7.

- HSLA Steel: This is the workhorse of modern shipbuilding. It contains very small amounts of elements like Niobium, Vanadium, Titanium, or Copper. These elements give it much higher yield strength (e.g., 355 MPa, 420 MPa) and better toughness than plain carbon steel, while still maintaining good weldability. DNV grades like AH36, DH36, EH40 are classic examples of HSLA steels.

3. Stainless Steel5

This is steel with a high chromium content (at least 10.5%). Chromium forms a passive, protective layer of chromium oxide on the surface that prevents rust.

- Characteristics: Excellent corrosion resistance8, can be very strong, and often has a bright appearance. It is more expensive than carbon steel.

- Relevance to Bulb Flats: Stainless steel bulb flats are rare. They might be used in special chemical tankers or in specific areas of a ship where corrosion is a severe problem. They are not for general hull construction due to cost.

4. Tool Steel6

This is a type of alloy or carbon steel specifically designed for making tools. It has very high hardness, wear resistance, and ability to hold an edge.

- Characteristics: Contains elements like Tungsten, Cobalt, and high levels of Carbon. It is very hard and often brittle.

- Relevance to Bulb Flats: None. Tool steel is not a structural material.

Where DNV Marine Bulb Flats Fit In

DNV-certified bulb flats are almost exclusively made from High-Strength Low-Alloy (HSLA) Steel7. They fall under the broad "Alloy Steel4" category but are a specialized group for structural applications9.

Here is a simple comparison table:

| Steel Type | Key Alloying Elements | Main Properties | Common Uses | Use in Marine Bulb Flats? |

|---|---|---|---|---|

| Carbon Steel3 | Iron, Carbon (C), Manganese (Mn) | Strong, cheap, weldable (low C), can rust. | Buildings, bridges, pipes, cars. | Low-grade, non-critical structures only. |

| Alloy Steel4 (HSLA) | Iron, C, Mn + Niobium (Nb), Vanadium (V), etc. | High strength, good toughness, good weldability. | Ships, offshore platforms, pressure vessels. | YES – This is the primary material (AH36, DH36, etc.). |

| Stainless Steel5 | Iron, C, High Chromium (Cr), Nickel (Ni) | Excellent corrosion resistance8, higher cost. | Kitchenware, chemical plants, medical equipment. | Rare, only for special corrosive environments. |

| Tool Steel6 | Iron, High C, Tungsten (W), Cobalt (Co) | Extreme hardness, wear resistance. | Drills, dies, cutting tools. | No. |

Why this matters: When you order DNV AH361 bulb flats, you are not ordering generic "steel." You are ordering a specific HSLA alloy steel designed and certified for a harsh, demanding environment. Knowing this helps you understand the value behind the certification and why it costs more than ordinary steel.

Conclusion

DNV certified bulb flat steel is the industry standard for a reason. It provides verified quality, ensures regulatory compliance, and ultimately protects lives and assets at sea by guaranteeing the material’s performance.

-

Learn about DNV AH36’s certification and its importance in ensuring safety and performance in marine structures. ↩ ↩

-

Delve into how the chemical composition of steel influences its properties and suitability for various applications. ↩

-

Explore the unique characteristics and applications of Carbon Steel, the most common type of steel used in various industries. ↩ ↩ ↩ ↩

-

Learn about Alloy Steel, its composition, and how it enhances strength and durability in construction and manufacturing. ↩ ↩ ↩ ↩ ↩

-

Find out why Stainless Steel is favored for its corrosion resistance and strength in various environments. ↩ ↩ ↩

-

Understand the unique properties of Tool Steel and its critical role in manufacturing tools and machinery. ↩ ↩ ↩

-

Discover the advantages of HSLA Steel in shipbuilding and other demanding applications, making it a preferred choice. ↩ ↩ ↩

-

Understand the concept of corrosion resistance and its importance in selecting materials for construction and manufacturing. ↩ ↩

-

Discover the various structural applications of different steel types and their significance in engineering and construction. ↩