Your shipyard requires class-approved materials, but generic "angle bars" fail inspections, causing project delays. The DNV certification is not just a stamp; it’s your guarantee of seaworthiness.

DNV certified marine L-shaped steel is a hot-rolled angle bar specifically approved by DNV GL for shipbuilding. It offers guaranteed mechanical properties (strength, toughness), strict dimensional tolerances, full traceability, and enhanced corrosion resistance suitable for harsh marine environments, ensuring regulatory compliance and structural integrity.

You see "L-shaped steel" everywhere. But marine-grade, class-certified L-shaped steel is a different product with defined features that bring real benefits. Understanding these details protects your project from risk. Let’s start by exploring the foundation: the grading system that defines its capabilities.

What are the grades of marine steel plates?

You order "marine steel," but the fabricator asks for the specific grade. Saying "the normal kind" isn’t enough. The grade dictates everything from strength to the coldest temperature it can survive.

Marine steel plates are graded primarily by yield strength and toughness. Common grades include A, B, D, E, and F (e.g., A36, DH36, EH40). The letter indicates toughness level (A is basic, F is for Arctic), and the number indicates the minimum yield strength in MPa (e.g., 36 for 355 MPa). These grades are standardized by classification societies like ABS, DNV, LR, and BV.

The Alphabet Code of Strength and Toughness

The grade is a material’s identity card. For marine L-shaped steel, it follows the same logic as plates. This system allows engineers to precisely match the material to the stress and environment of each ship part. Let’s decode it.

The grade name combines a letter and a number (e.g., AH36, DH36). Sometimes there is a prefix like ‘A’ for ‘as-rolled’.

The Letter (A, B, D, E, F): The Toughness Indicator

This is crucial for safety. It defines the steel’s ability to resist brittle fracture at low temperatures, measured by Charpy V-Notch impact tests.

- Grade A: Basic quality. No specific impact test requirement for ordinary thicknesses. Used for non-critical parts in temperate waters.

- Grade B: Improved toughness over A. Often required for thicker plates.

- Grade D: Delivered with guaranteed impact toughness at -20°C. This is a standard requirement for many hull structures in ocean-going vessels.

- Grade E: Guaranteed toughness at -40°C. Used for ships operating in colder waters or for critical zones.

- Grade F: Guaranteed toughness at -60°C. Used for ice-class vessels and Arctic operations.

The Number (32, 36, 40): The Strength Indicator

This number (approximately) indicates the minimum yield strength in kilograms-force per square millimeter (kgf/mm²). In modern SI units, it corresponds to MPa.

- 32: Minimum Yield Strength ~315 MPa

- 36: Minimum Yield Strength ~355 MPa

- 40: Minimum Yield Strength ~390 MPa

A higher number means stronger steel. Stronger steel can be used in thinner sections to save weight, which is vital for ship efficiency.

How This Applies to DNV Certified L-Shaped Steel

DNV has its own parallel system (e.g., NV A, NV D, NV E, NV F with strength levels). A DNV-certified mill produces L-shaped steel to these exact grades. The certification means DNV has surveyed the mill’s production process and regularly audits it to ensure every batch meets the published standard.

This table shows common applications based on grade:

| Grade (Example) | Key Property | Typical Charpy Test Temperature | Common Application in Shipbuilding |

|---|---|---|---|

| AH32 / DH32 | Yield Strength ~315 MPa | -20°C for D grade | Internal decks, secondary structures in smaller vessels. |

| AH36 / DH36 | Yield Strength ~355 MPa | -20°C for D grade | The most common grade. Hull plating, primary frames, deck structures. This is a standard for DNV L-shaped steel. |

| EH36 / FH36 | Yield Strength ~355 MPa | -40°C / -60°C | Critical zones of vessels in cold waters, ice-strengthened parts. |

| AH40 / DH40 | Yield Strength ~390 MPa | -20°C for D grade | High-stress areas like the keel, sheer strake, or large container ships. |

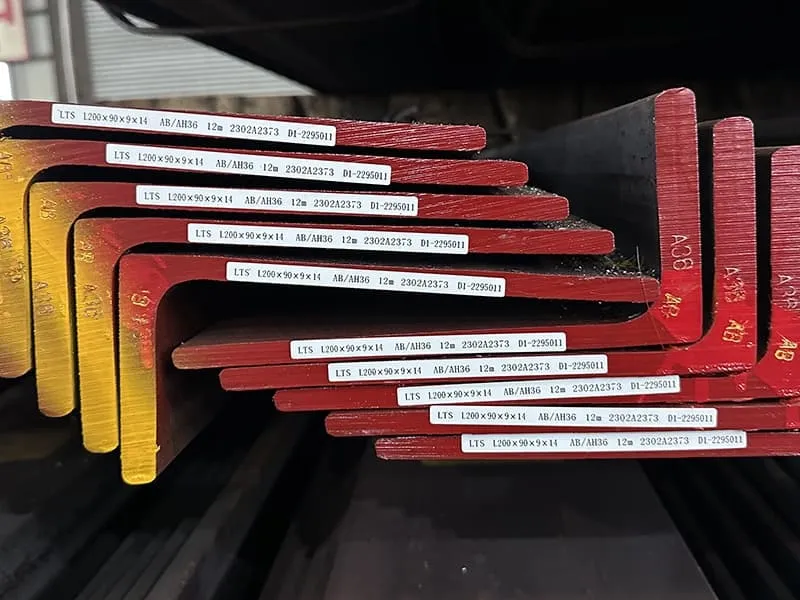

When you procure DNV L-shaped steel, you specify the grade (e.g., NV D36). This tells the mill exactly what chemical composition, mechanical properties, and impact toughness to deliver. The certificate that comes with the steel is your legal proof that it meets this grade. For a buyer like Gulf Metal Solutions, specifying the correct grade is the first step in ensuring the material is fit for their client’s specific vessel and its intended trading routes.

What size is L section steel?

You have a drawing that simply says "L 150x90x10". You need to order it, but you wonder if this covers all dimensions. The size notation is a code that reveals the key measurements.

L section steel size is denoted as L A x B x t (e.g., L 150x100x12). A and B are the leg lengths in millimeters, and t is the common thickness of both legs. For equal angles (A=B), it’s written as L 100x100x10. Standard lengths are usually 6m, 9m, or 12m, but can be cut to order.

Beyond the Basic Code: Tolerances and Availability

The size callout L A x B x t gives the nominal, or theoretical, dimensions. However, hot-rolled steel has permissible variations. For standard angle bars, these tolerances might be loose. For DNV-certified marine L-shaped steel, the tolerances are tighter and strictly controlled, which is a major benefit.

Decoding the Dimensions:

- Leg Lengths (A & B): Measured from the outer corner to the edge of each leg. For an

L 150x90x10, one leg extends 150mm from the corner, the other extends 90mm. - Thickness (t): The thickness of the steel. In a true hot-rolled angle, this thickness should be consistent across both legs. Some fabricated angles from plate may have differences.

- Root Radius (r): The inside curve of the corner. This is not usually in the callout but is defined by the rolling process. A generous radius reduces stress concentration, which is good for fatigue life.

The Importance of Tolerances:

Imagine ordering 100 pieces of L 200x100x12 for a frame. If the leg lengths vary by ±5mm, the pieces won’t align during assembly, requiring costly grinding or forcing.

- Standard Tolerances: Might allow several millimeters of deviation on leg length and thickness.

- DNV / Marine Tolerances: Are much stricter. DNV rules (or other class rules) specify tight limits for straightness, leg length, thickness deviation, and squareness. This ensures consistency for efficient shipyard assembly.

Common Size Ranges for Marine Use:

Marine L-shaped steel comes in a range of sizes suitable for different structural roles.

- Small Sizes (e.g., L 50x50x5 to L 80x80x8): Used for minor brackets, stiffeners on light bulkheads.

- Medium Sizes (e.g., L 100x100x10 to L 150x150x12): The workhorse range. Used for frame sections, primary brackets, and supports.

- Large Sizes (e.g., L 200x200x16 and above): Used for heavy foundation frames, strongbacks, and in larger vessels.

Here is a table showing how size relates to application and the value of tight tolerances:

| Nominal Size (L A x B x t) | Typical Marine Application | Why Tolerance Matters Here |

|---|---|---|

| L 75x75x8 | Stiffeners on accommodation decks, small platforms. | Less critical, but consistency speeds up assembly. |

| L 120x80x10 | Brackets connecting decks to hull frames (unequal angle). | Hole patterns on the bracket must align with pre-drilled holes on the frame and deck beam. Tight tolerances prevent mismatch. |

| L 150x150x12 | Main transverse frame sections in a mid-sized bulk carrier. | Many frames must be identical. Variation in leg length changes the ship’s form. |

| L 200x100x14 | Longitudinal stringer or a heavy foundation base. | The flat 200mm leg provides a wide mounting surface. Thickness tolerance affects welding procedure and strength calculation. |

When you order, you specify the nominal size and the applicable tolerance standard (e.g., "to DNV tolerances"). Our job is to source from mills whose rolling lines are capable of and approved for producing within these tighter marine limits. This dimensional reliability is a key feature that translates into the benefit of predictable, efficient fabrication at the shipyard.

What is L shape steel?

In a shipyard, you hear "angle bar," "angle iron," and "L-shaped steel." They look the same. So what makes marine L-shaped steel special? It’s all about the rules behind it.

L-shaped steel is the common name for a hot-rolled steel section with two legs forming a 90-degree angle. In marine contexts, it specifically refers to this profile produced to the stringent material and dimensional standards of a classification society (like DNV, ABS, LR) for use in ship and offshore structures.

From Generic Commodity to Engineered Component

Think of "angle bar" as a blank canvas. "DNV-certified L-shaped steel" is that canvas turned into a precise technical drawing. The difference lies in specification, control, and documentation.

The Base Product: The Hot-Rolled Angle

All L-shaped steel starts here. A billet of steel is heated and passed through a series of rolls that gradually shape it into the L-profile. This process determines its basic geometry and metallurgical state. However, this generic product is sold mainly by dimensions and basic strength (like S235, S355), with minimal guaranteed properties beyond that.

The Marine Transformation: Classification Society Approval

For use in a classed vessel, the steel must be "class-approved." This means:

- Mill Approval: The steel mill itself undergoes a rigorous audit by DNV (or other societies). Surveyors inspect the mill’s quality management system, production facilities, testing labs, and procedures. Only approved mills can produce classed steel.

- Grade-Specific Production: The steel is made to a specific marine grade (e.g., NV D36), which dictates its chemical composition, mechanical strength, and impact toughness.

- Batch Testing & Traceability: Each melt (heat) of steel is tested. Samples are taken and tested for chemistry, tensile strength, and impact toughness. The results are recorded on a Mill Test Certificate (MTC).

- Marking: Each length of classed L-shaped steel is marked with the mill’s logo, the grade, the heat number, and sometimes the class society symbol. This provides physical traceability.

The Role of the Supplier in the Chain

A company like ours doesn’t just trade metal. We partner with DNV-approved mills. We understand the specifications. We ensure the material you receive is accompanied by the correct, original certificates that match the heat numbers on the steel. We act as your quality and documentation filter.

This distinction is critical for procurement:

| Aspect | Generic Angle Bar / Angle Iron | DNV Certified Marine L-Shaped Steel |

|---|---|---|

| Primary Standard | Commercial standards (ASTM A36, EN 10025). | DNV Shipbuilding Rules, or other class rules. |

| Key Guarantee | Meets basic dimensional and tensile specs. | Guaranteed yield strength, tensile strength, and impact toughness at a specified low temperature. |

| Traceability | Usually by heat number, but certificate may be generic. | Full traceability. Each piece can be linked to a specific heat’s MTC with full test data. |

| Inspection | May not be required for non-critical use. | Often subject to review by the shipyard’s class surveyor. The certificate is mandatory. |

| Purpose | General construction, workshops, non-critical frames. | Load-bearing structures in classed ships and offshore units. |

| Cost Driver | Commodity price, dimensions, weight. | Grade, certification, testing, tighter tolerances, traceability. |

Therefore, when you buy "L-shaped steel" for a ship, you are not buying a shape. You are buying a package: the physical profile plus a guaranteed set of properties, plus a verifiable certificate, plus the assurance of a controlled production process. This package is what allows a ship to receive its class certificate.

Are L profiles rust-resistant?

You install shiny new L-profiles in a ship’s ballast tank. Six months later, you see rust. Is this normal, or did you get bad steel? All carbon steel rusts; the question is about the rate and how it’s managed.

Standard carbon steel L profiles are not inherently rust-resistant and will corrode in marine environments. However, marine-grade L-shaped steel can be supplied with enhanced corrosion resistance through controlled chemistry (e.g., added Copper, Chromium) and is always used with a protective system: high-quality coatings (paint) and/or cathodic protection (zinc anodes).

The Reality of Rust and the Marine Defense Strategy

In seawater, corrosion is a certainty, not a possibility. The benefit of DNV-certified L-shaped steel is not that it doesn’t rust, but that it is designed and documented to work effectively within the ship’s overall corrosion protection system. Let’s separate myth from practical engineering.

Why Steel Corrodes: The Electrochemical Reaction

Rust is iron oxide. It forms when iron, water, and oxygen interact. Seawater, with its salt content, is a highly conductive electrolyte that dramatically accelerates this process. The sharp inside corner (root) of an L-profile can trap water and debris, creating a perfect spot for localized "crevice corrosion."

Material-Level Enhancements: "Weathering" and "Corrosion-Resistant" Steels

Some steels are formulated for better atmospheric corrosion resistance.

- Chemistry: Adding small amounts of copper (Cu), chromium (Cr), nickel (Ni), and phosphorus (P) promotes the formation of a tight, protective patina of rust that slows further corrosion. These are often called "weathering steels" (e.g., ASTM A588).

- Marine Grades: Standard marine grades like AH36/DH36 are not primarily optimized for corrosion resistance through chemistry. Their focus is on strength and toughness. However, some specialized marine steels may include corrosion-resistant elements, especially for tanks or topsides.

The Primary Defense: The Protection System

No structural carbon steel is placed in a ship unprotected. The corrosion resistance is a system property, not just a material property.

- Surface Preparation: The steel must be properly cleaned. For marine use, this typically means abrasive blast cleaning to a standard like Sa 2.5 (Near-White Metal) to remove all mill scale and rust, providing a perfect surface for coating adhesion.

- Coating (Paint) System: A multi-layer system is applied: an epoxy primer, intermediate coats, and a topcoat. This barrier physically separates the steel from water and oxygen. The sharp root of the L-profile requires special attention during application to ensure adequate paint thickness.

- Cathodic Protection (CP): For underwater hull areas and ballast tanks, sacrificial zinc anodes are attached. These anodes corrode instead of the steel, "sacrificing" themselves to protect the structure.

How DNV Certification Adds Value Here:

- Surface Condition: The certification process may involve rules about surface quality (freedom from excessive scale, pits, etc.) to ensure it is suitable for high-performance coating.

- Weldability: The controlled chemistry (Carbon Equivalent Value) ensures good weldability. Poor welds are prime sites for coating failure and accelerated corrosion.

- Predictability: Because the steel’s properties are consistent, the coating and CP system can be designed with reliable assumptions. Variable steel quality leads to unpredictable coating performance.

This comparison shows the holistic approach:

| Factor | Contribution to Corrosion Resistance | Role of DNV L-Shaped Steel |

|---|---|---|

| Steel Chemistry | Minor. Can slow atmospheric rust in some grades. | Provides consistent, documented chemistry. Ensures weldability to maintain coating integrity at joints. |

| Surface Preparation | Critical. Determines coating adhesion and lifespan. | Supplied with a surface condition suitable for high-grade blast cleaning (e.g., minimal deep pitting). |

| Coating System | The Main Barrier. | N/A (applied by shipyard). The steel’s consistent dimensions and clean surface enable optimal coating application. |

| Cathodic Protection | Essential for immersed areas. | N/A (designed by naval architect). The steel’s electrical properties are consistent for CP system design. |

| Design & Detailing | Important. Avoids water traps. | The predictable dimensions and tolerances allow for accurate detailing to minimize crevices. |

So, are L-profiles rust-resistant? No, they are rust-manageable. The feature of DNV-certified L-shaped steel is its reliability and compatibility within the managed corrosion control system. It gives the shipyard a known, high-quality substrate to apply their protective systems to, maximizing their effectiveness and the vessel’s service life.

Conclusion

DNV certified L-shaped steel provides guaranteed strength, toughness, tight tolerances, and traceability. It’s not just an angle bar; it’s a specified component for safe, compliant, and efficient ship construction.