The hidden skeleton of every large ship faces immense forces from waves, cargo, and its own weight. A weak frame can lead to catastrophic failure. I’ve seen how the right steel profile makes all the difference in a ship’s longevity.

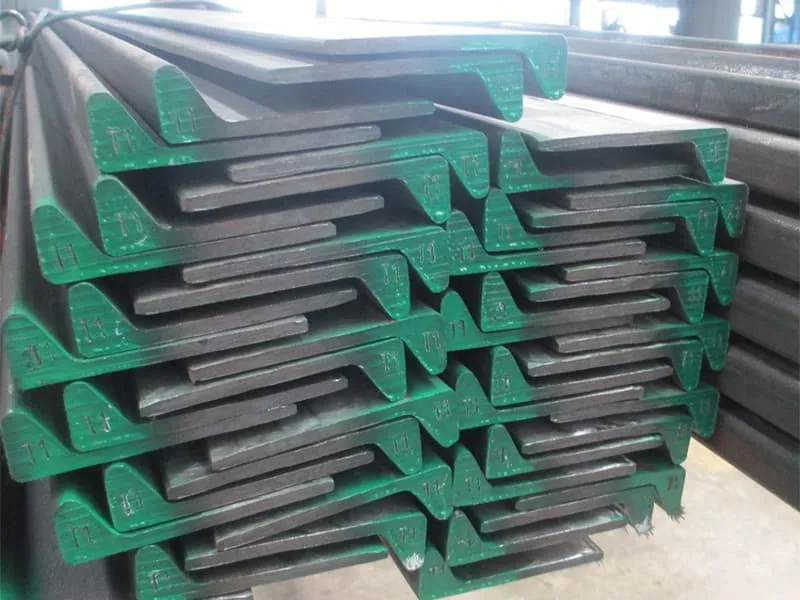

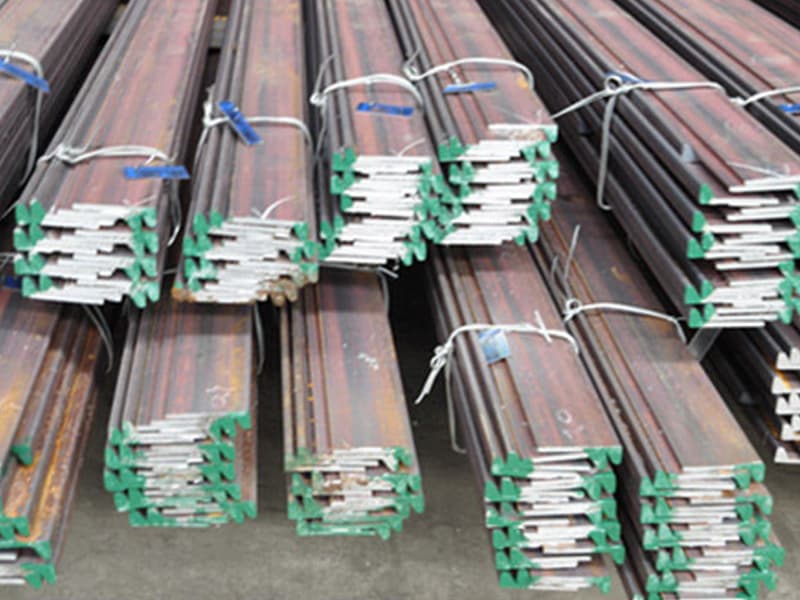

Bulb flat steel strengthens ship hull frames by providing exceptional strength-to-weight efficiency. Its unique "T" shape with a bulb at the tip increases the section modulus, allowing it to resist bending and buckling forces better than a standard flat bar of the same weight, making hulls lighter and stronger. This is why it’s a preferred choice for shipbuilders worldwide.

For our clients building oil tankers, bulk carriers, and container ships, understanding this component is key to selecting the right materials. The hull frame is the ship’s backbone. Let’s explore the critical role of bulb flats and the steel that makes modern ships possible.

What are bulb flats1 used for?

Many people see a ship’s hull and only see the smooth outer plating. They don’t see the complex internal skeleton that holds everything together. This skeleton relies on specific shapes, and bulb flats1 are one of the most important. A shipyard in Romania once tried to substitute a different profile, which led to increased weight and higher fuel costs for the shipowner.

Bulb flats are primarily used as stiffeners and framing members2 in ship hull3s and offshore structures. They are welded perpendicular to steel plates on decks, bulkheads, and the ship’s sides to prevent buckling under load. They are also used in construction, bridge building, and as edge reinforcements for large panels. Their design offers superior stiffness in one direction.

The Engineering Advantage of the Bulb Flat Profile

The bulb flat is a specialized steel profile. It looks like a flat bar with a rounded bulb at one edge. This simple bulb creates a major engineering benefit.

Primary Function: Stiffening Platings

In shipbuilding, large areas of steel plate are under constant pressure. The hull plating faces water pressure. Deck plating supports cargo weight. Bulkhead plating resists flooding pressure. A flat plate by itself is weak and will buckle easily.

- Solution: Weld bulb flats1 vertically or horizontally to the back of the plate. They act like ribs, dividing the large plate into smaller, stronger panels. This dramatically increases the plate’s resistance to bending and deformation.

Why the Bulb? The Section Modulus Secret

The effectiveness of a beam or stiffener is measured by its section modulus4. A higher section modulus4 means greater bending resistance.

- A standard flat bar has its material evenly distributed.

- A bulb flat concentrates extra material at the furthest point from the plate (the tip of the bulb). This is a fundamental principle of engineering: material placed farther from the neutral axis contributes more to strength.

- Result: A bulb flat provides a much higher section modulus4—and thus more stiffness—than a flat bar of the same weight and height. This allows ship designers to use less steel to achieve the same strength, reducing the ship’s overall weight.

Key Applications in Marine and Offshore:

| Application Area | Specific Use of Bulb Flat | Benefit Provided |

|---|---|---|

| Ship Hull | Side shell longitudinals (running fore-and-aft), bottom longitudinals. | Stiffens the outer hull against water pressure and wave impacts, preventing oil-canning. |

| Decks | Deck longitudinals and transverses under cargo areas. | Supports heavy concentrated loads from containers or bulk cargo without excessive deflection. |

| Bulkheads | Vertical and horizontal stiffeners on watertight and structural bulkheads. | Prevents buckling from water pressure in case of flooding in an adjacent compartment. |

| Double Bottom | Floors and longitudinals in the double bottom structure. | Forms a rigid grid that absorbs grounding impacts and distributes hull bending stresses. |

| Offshore Platforms | Stiffeners on jacket legs, bracings, and deck panels. | Provides resistance against constant wave action and high wind loads in a corrosive environment. |

For our B2B clients—the fabricators and shipyards—this efficiency is crucial. It translates directly into material savings5, fuel efficiency for the vessel, and structural reliability. When Gulf Metal Solutions inquired about "spherical flat steel" for their next project, they were recognizing this exact benefit. The next logical question is: what specific steel is used to make these critical components?

What kind of steel is used for ship hulls?

You cannot use ordinary construction steel for a ship’s hull. The marine environment is one of the most punishing on Earth. The steel must withstand corrosion, impact, fatigue, and extreme loads. Using the wrong steel is an invitation to structural failure.

Ship hulls are built from marine-grade steel plates certified by classification societies like ABS, LR, DNV, or BV. Common grades include ABS Grade A, B, D, E and high-strength grades like ABS AH32, AH36, DH36, and EH36. These steels have controlled chemistry for weldability and undergo mandatory toughness (impact) testing at low temperatures. This ensures they won’t fracture in icy waters.

The Rigorous Specifications of Marine Hull Steel

Marine steel is not a single product. It is a family of materials, each with properties tailored for specific locations on the ship and specific service conditions.

Governance by Classification Societies

Every commercial ship is built under the rules of a classification society (e.g., American Bureau of Shipping, Lloyd’s Register). These societies approve the steel mills and the specific grades. The steel’s Mill Test Certificate (MTC) must show this approval.

The Two Main Categories: Ordinary Strength and High Strength

-

Ordinary Strength Hull Steel (Grades A, B, D, E):

- Grade A: Basic grade for less critical areas.

- Grade B: The most common grade for general hull plating.

- Grade D & E: Offer progressively better toughness at lower temperatures. Used in the forward parts of the hull (where impact from waves is high) and in ships operating in cold regions (Arctic, North Atlantic).

-

High Strength Hull Steel (Grades AH, DH, EH with numbers 32, 36, 40):

- The letter (A, D, E) still indicates the toughness level.

- The number indicates the minimum yield strength in kgf/mm² (e.g., 36 = 355 MPa).

- Example: AH36 has a yield strength of 355 MPa and Grade A toughness. DH36 has the same 355 MPa strength but with the improved toughness of Grade D.

- Benefit: Using higher strength steel (AH/DH36) allows for thinner plates, reducing hull weight and increasing cargo capacity. This is vital for modern, efficient vessel design.

Critical Material Properties Beyond Strength:

- Toughness (Impact Resistance): This is measured by a Charpy V-notch test at specified low temperatures (e.g., -20°C for Grade D). It ensures the steel will deform, not shatter, upon impact.

- Weldability: Hulls are welded, not riveted. The steel’s chemical composition, particularly the Carbon Equivalent (CE), is strictly controlled to prevent cracking during and after welding.

- Corrosion Resistance: While marine steels are still carbon steel and will rust, their cleaner composition (lower sulfur/phosphorus) and the use of coatings and cathodic protection systems manage corrosion.

Grade Selection Table for Different Hull Zones:

| Hull Structure Location | Typical Steel Grade Used | Primary Reason for Selection |

|---|---|---|

| Midship Bottom & Side Shell (main area) | ABS Grade B or AH32 | Balances good toughness, strength, and cost for the largest part of the hull. |

| Sheer Strake & Keel (high stress areas) | ABS Grade D or DH32/DH36 | Higher toughness to handle stress concentrations and potential impacts. |

| Fore Peak (bow area) | ABS Grade D, E, or DH/EH36 | Maximum toughness to resist brittle fracture from slamming waves and cold temperatures. |

| Inner Bottom, Decks (cargo areas) | ABS Grade A, B, or AH32/AH36 | Strength to support cargo; high-strength grades save weight. |

| Superstructure (above main deck) | Lower grades or even AH32 for weight saving. | Less severe loading environment; weight reduction high up improves stability. |

When we supply steel to shipyards in Vietnam or for projects in Qatar, we don’t just ship "ship plate." We supply ABS AH36 plates or LR Grade D plates with full traceability. This certification is non-negotiable and provides the foundation for why steel is the only logical choice for ship construction in the first place.

Why is steel used to build ships?

For centuries, shipbuilders used wood, then iron. Today, over 99% of large commercial vessels are made of steel. There is a very good reason for this dominance. No other commonly available material offers the same complete package of properties for marine construction.

Steel is used to build ships because it offers an unmatched combination of high strength, toughness, ease of fabrication (cutting, welding), recyclability, and relatively low cost. Its strength allows for large, robust hulls that can carry massive cargoes safely across oceans, while its ductility enables it to withstand impacts and flex without breaking. Alternatives like aluminum or composites lack this balance for primary hull structures.

The Unbeatable Economics and Physics of Steel

The choice of steel is not an accident. It is the result of physics, engineering, and economics aligning perfectly.

1. Strength and Weight (Strength-to-Weight Ratio)

- Steel has a very high strength, especially when alloyed and processed into modern marine grades. This strength allows ships to be built large enough to achieve economies of scale (like 24,000 TEU container ships).

- While steel is dense, the high strength means you don’t need thick, heavy sections everywhere. Intelligent design and the use of high-strength steels and efficient profiles (like bulb flats) optimize the weight.

2. Toughness and Ductility (Safety)

- This is critical. Steel is ductile. It can bend, stretch, and deform significantly before it fractures. In a collision or grounding, a steel hull will dent and tear, absorbing energy. A brittle material would shatter.

- The mandatory impact testing for marine steel ensures this ductility is present even in freezing conditions.

3. Fabricability and Weldability

- Steel plates and profiles can be cut precisely with plasma, laser, or water jets. They can be bent and formed into complex curves (like a ship’s bow).

- Most importantly, steel can be reliably and efficiently welded. Modern shipbuilding is an assembly line of welded modules. The entire hull is a welded structure. No other material of comparable strength is as easy to weld on a massive scale.

4. Cost and Availability

- Steel is produced in enormous quantities globally. This creates a competitive market and stable supply chains, which is essential for building structures that require thousands of tons of material.

- The raw material cost per ton of strength is lower than for advanced composites or aluminum alloys.

5. Recyclability

- At the end of a ship’s life (25-30 years), the steel is almost 100% recyclable. It is cut up and melted down to make new steel. This circular economy aspect is increasingly important.

Comparison with Potential Alternatives:

| Material | Advantages | Disadvantages for Primary Hull Construction |

|---|---|---|

| Steel | High strength, high toughness, excellent weldability, readily available, cost-effective, recyclable. | Susceptible to corrosion (requires protection systems). |

| Aluminum Alloys | Lighter weight, good corrosion resistance. | Much more expensive per ton. Lower strength and stiffness. Significantly more difficult and costly to weld on a large scale. Fire resistance is lower. |

| Fiber-Reinforced Polymers (Composites) | Lightweight, corrosion-free. | Extremely high material and fabrication cost for large structures. Difficult to repair. Poor fire resistance. Recycling is challenging. |

| Wood | Traditional, renewable. | Very low strength for large ships. Not fire-resistant. Requires skilled labor and is not suitable for modern mass production. |

For rational, results-driven business clients, the conclusion is clear. Steel provides the necessary performance at a viable cost. It is the backbone of global shipping. Within the steel family, milder grades play specific, vital roles, which leads to our final question.

What is mild steel used in ship construction?

The term "mild steel" is common, but in modern shipbuilding, its use is specific. Not every part of a ship needs the enhanced properties of AH36 or DH36. Using a more expensive grade where it’s not needed wastes money. A shipyard in Thailand optimized their costs by correctly specifying different grades for different applications.

In ship construction, mild steel (typically equivalent to ABS Grade A or ASTM A36) is used for non-critical secondary structures where high strength or exceptional toughness is not required. This includes non-watertight bulkheads, minor brackets, platforms, ladders, foundations for non-essential equipment, and some interior outfitting. It provides adequate strength at a lower cost.

Defining the Role of "Mild Steel" in a High-Tech Hull

It’s important to define "mild steel." In a marine context, it usually refers to ordinary strength carbon steel that meets basic structural standards but may not have the stringent toughness or chemistry controls of primary hull grades.

Typical Properties of Marine "Mild Steel":

- Grade Examples: ABS Grade A, ASTM A36, EN S235JR.

- Yield Strength: Around 235-250 MPa.

- Toughness: May not require mandatory Charpy impact testing, or testing is at a higher temperature (like +20°C).

- Cost: It is generally less expensive than higher-grade, specially processed steels.

Where and Why It’s Used: The Cost-Performance Balance

A ship is a complex city at sea. Not every wall or floor is critical to surviving a storm. Engineers allocate material properties based on risk and function.

1. Non-Structural / Secondary Structures:

- Example: Interior cabin partitions, office walls, non-load-bearing platforms inside the superstructure.

- Reason: These components only need to support their own weight and minor live loads (people, furniture). Using high-grade steel here is unnecessary.

2. Tertiary Structural Elements:

- Example: Small brackets, gussets, supports for piping, cable trays, and ventilation ducts.

- Reason: These parts transfer small loads. They are important for functionality but not for the global strength of the hull. Mild steel is easy to cut and weld for these small, numerous items.

3. Temporary Construction Aids:

- Example: Strongbacks, alignment jigs, and temporary supports used during the building process.

- Reason: These are removed before the ship sails. They just need to be strong enough for construction purposes.

Important Distinction: It’s Still "Marine" if Exposed

Even "mild steel" used on a ship, if it is exposed to the weather or exterior, will often have a specified quality. It might still need to be from a certified mill and have a controlled chemistry to ensure proper welding and painting compatibility. The key difference is the lack of mandatory low-temperature toughness testing.

Application Guide: Mild vs. Higher Grade Steel

| Ship Component | Typical Steel Grade Required | Why This Grade is Sufficient |

|---|---|---|

| Outer Hull Plating (Bottom) | ABS Grade B, D, or AH/DH36 | Must resist water pressure, slamming, and have good low-temperature toughness. |

| Main Load-Bearing Bulkhead | ABS Grade B or AH32 | Must maintain watertight integrity and handle flood pressure. |

| Interior Non-watertight Bulkhead | ABS Grade A or Mild Steel (S235) | Only needs to divide space; no significant structural or pressure load. |

| Engine Foundation | High-strength steel (AH36 or higher) | Must resist massive dynamic loads and vibrations from the main engine. |

| Ladder and Platform inside superstructure | Mild Steel (A36/S235) | Only supports human traffic; lower weight and cost are priorities. |

For our clients who are distributors and fabricators, understanding this hierarchy is key to smart procurement. They can stock different grades for different customer projects. It also explains why our product range includes both standard and high-grade materials—to meet the full spectrum of shipbuilding needs, from the critical hull frame made of bulb flats to the interior platforms.

Conclusion

Bulb flat steel is a key engineering solution for strong, lightweight ship frames. When made from certified marine-grade steel, it forms a durable backbone that withstands ocean forces, demonstrating why steel remains the essential material for safe and efficient shipbuilding.

-

Explore the significance of bulb flats in shipbuilding and their role in enhancing structural integrity. ↩ ↩ ↩

-

Learn how stiffeners and framing members contribute to the strength and durability of ship hulls. ↩

-

Discover the essential elements of a ship hull and how they work together for stability and safety. ↩

-

Understand the concept of section modulus and its impact on structural design and strength. ↩ ↩ ↩

-

Explore how the use of bulb flats leads to significant material savings and efficiency in ship construction. ↩