You ordered marine steel with perfect certificates, but the hull plates are already rusting in the shipyard. This costly mistake happens when buyers focus on the paper, not the actual material properties.

To avoid fake certificates, you must understand the steel itself. This means knowing the critical properties for marine use, the real disadvantages of steel, its inherent problems, and how to select the correct grade. Genuine certificates prove these factors; fakes ignore them.

A fake certificate often fails because it describes a perfect material that doesn’t exist. The best way to spot a fake is to know the truth about marine steel. Let’s move beyond the document and examine the metal it claims to represent. This knowledge is your most powerful verification tool.

What property is particularly important for shipbuilding steel to ensure it can withstand harsh marine environments?

Think of a ship battling North Atlantic waves in winter. The steel isn’t just strong; it must resist shattering in freezing impact. A certificate might list high strength, but if it’s fake, it likely misses this vital, life-saving property.

The single most important property is excellent low-temperature toughness1, specifically high impact resistance2 at sub-zero temperatures. This prevents brittle fracture in cold seas. Combined with this, high corrosion resistance3 and good weldability4 are equally critical for long-term structural integrity in saltwater environments.

The Critical Trio: Toughness, Corrosion, and Weldability

In shipbuilding, no single property works alone. But if I had to prioritize one based on catastrophic risk, it’s low-temperature toughness. A ship’s hull is a massive structure under constant, dynamic stress. In warm water, steel is ductile—it bends before breaking. But in freezing seawater, standard steel can transition from ductile to brittle behavior. A stress concentration at a weld or a notch can initiate a crack that propagates rapidly through the structure with little energy, leading to a brittle fracture. History shows us this risk is real.

However, toughness does not stand alone. It is part of a non-negotiable trio of properties that genuine marine steel certificates must validate:

1. Low-Temperature Toughness (Impact Resistance)

This is measured by a Charpy V-Notch (CVN) impact test. The test cools a small sample to a specified temperature (e.g., -20°C, -40°C, -60°C) and strikes it with a hammer. The energy absorbed before fracture is recorded in Joules.

- Standard Grades: ABS Grade A steel might require 27J at 0°C.

- Arctic Grades: Higher grades like ABS EH36 or FH40 require 34J or more at -40°C or -60°C for ice-class vessels.

A fake certificate5 might copy correct tensile strength numbers but often uses generic or incorrect CVN values because understanding this test requires specific knowledge.

2. Corrosion Resistance

Seawater is an electrolyte that aggressively attacks steel. Marine-grade steel uses two key strategies:

- Chemical Composition: Controlled levels of copper (Cu), chromium (Cr), and nickel (Ni) can improve atmospheric corrosion resistance. The real protection, however, comes from the coating system (paint, primers) and cathodic protection (zinc anodes). The steel’s role is to provide a good, clean surface for these systems to adhere to. A fake certificate5 might not detail the surface condition or chemistry that affects coating life.

- The Real Threat: Galvanic corrosion between different metals, and pitting corrosion6 under stagnant water. The steel’s homogeneity and cleanliness (freedom from inclusions) are vital here.

3. Weldability

A ship is a welded structure. Poor weldability leads to cracks, which become initiation points for fracture and corrosion.

- Key Metric: Carbon Equivalent Value (CEV)7. This formula (like IIW Ceq) calculates from the chemical composition8 (C, Mn, Cr, Mo, V, etc.). A lower CEV means the steel is easier to weld without pre-heat or post-heat treatment, reducing the risk of heat-affected zone (HAZ) cracking.

- The Fake Certificate Trap: A forger might list attractive strength numbers achieved by adding carbon (C) and manganese (Mn). But this raises the CEV, making the steel unweldable for standard shipyard procedures. A genuine mill certificate always shows the chemical analysis that allows CEV calculation.

This table shows how these properties are linked and verified:

| Critical Property | Why It Matters for Ships | How It’s Measured/Verified | Red Flag in a Fake Certificate |

|---|---|---|---|

| Low-Temp Toughness | Prevents sudden brittle fracture in cold seas. | Charpy V-Notch Impact Test at specified temperature (e.g., -40°C). | Missing CVN values, values that don’t match the claimed grade, or unrealistic temperatures for the grade. |

| Corrosion Resistance | Ensures long service life and structural soundness. | Chemical analysis (Cu, Ni, Cr), surface inspection for scale/rust. | No mention of corrosion-resistant elements; certificate shows a perfectly clean, theoretical composition. |

| Weldability | Enables safe, crack-free construction and repairs. | Carbon Equivalent Value (CEV)7 calculated from full chemical analysis. | High strength with low CEV that seems "too good to be true"; missing key elemental data needed for CEV calculation. |

| Strength (Yield/Tensile) | Provides the basic structural capacity to handle loads. | Tensile test on a sample. | Focus only on strength. A common trick: emphasize high tensile strength to distract from missing toughness or weldability data. |

For a buyer, the lesson is clear. When you review a certificate, don’t just look for the strength numbers. Immediately check for the impact test results at the correct temperature and the full chemical analysis. If these are missing, vague, or look copied from a template, the certificate is likely fake. The material it describes cannot perform its most critical job.

What is the disadvantage of using steel in ship building?

Steel is strong and affordable, making it the default choice. But if you ignore its inherent disadvantages, your project faces predictable failures. A fake certificate will never honestly list these downsides because its goal is to sell, not inform.

The primary disadvantage of steel in shipbuilding is its susceptibility to corrosion in seawater, requiring continuous and costly protection systems (painting, anodes). Other key drawbacks include its high density (weight), which impacts fuel efficiency, and the risk of brittle fracture at low temperatures if the wrong grade is used.

Managing the Trade-Offs: The True Cost of Steel

Choosing steel is always a decision to manage trade-offs. Understanding these disadvantages is not about rejecting steel, but about budgeting, planning, and specifying correctly. A supplier providing genuine material will discuss these points openly to find solutions.

Let’s break down the three core disadvantages and their practical implications:

1. Corrosion: The Never-Ending Battle

This is the single biggest operational cost over a vessel’s life. Saltwater attacks steel relentlessly.

- The Cost: A vessel requires a complete coating system—blast cleaning, primers, multiple paint layers. This adds millions to build cost. Then, dry-docking every 5 years for recoating costs millions more. Sacrificial zinc anodes must be replaced regularly.

- The Risk: If the coating fails or the anode system is inadequate, corrosion eats the plate thickness. This reduces structural strength (called "wastage") and can lead to leaks or catastrophic failure. Class surveys meticulously measure remaining plate thickness.

- The Certificate Link: A genuine certificate for marine steel often references the steel’s surface condition (e.g., "blast cleaned to Sa 2.5") and its suitability for coating. Fake certificates ignore this reality.

2. High Density and Weight

Steel is heavy. This impacts the ship’s design and economics.

- Less Deadweight: For a cargo ship, every ton of steel in the hull is one less ton of paying cargo it can carry.

- Higher Fuel Consumption: A heavier ship requires more engine power to move, increasing fuel costs and emissions over its lifetime.

- The Engineering Response: This is why ship design focuses on structural optimization—using the minimum amount of high-strength steel (like AH36 instead of Grade A) to achieve the required strength with less weight. The disadvantage creates demand for advanced, high-strength steel grades.

3. Risk of Brittle Fracture

As discussed earlier, this is a safety-critical disadvantage if the steel grade is not chosen for the operating environment.

- The Consequence: Can be catastrophic hull failure, as in the classic case of WWII Liberty ships.

- The Solution: This disadvantage is entirely mitigated by using the correct grade with certified low-temperature toughness. This is precisely why the certificate is so important. A fake certificate for a standard grade used in Arctic waters is not just a fraud; it is a direct threat to safety.

Here is how these disadvantages translate into real-world considerations and how a legitimate supplier addresses them:

| Disadvantage | Impact on Ship Design & Operation | How a Knowledgeable Supplier Helps Mitigate It |

|---|---|---|

| Corrosion | High lifetime cost for coating maintenance and repairs. Risk of structural weakening. | Recommends steel with good surface quality for coating adhesion. Can provide steel pre-blasted and primed. Discusses anode compatibility. |

| High Weight | Reduced cargo capacity (deadweight). Higher fuel consumption and emissions. | Recommends high-strength steels (e.g., AH36/DH36/EH36) to reduce plate thickness and total weight for the same strength. |

| Brittle Fracture Risk | Catastrophic safety risk in cold environments. | This is the core of certification. Ensures the supplied steel has the certified impact toughness (CVN) for the vessel’s operational zone (e.g., standard, temperate, or ice class). |

A fake certificate pretends steel is a perfect material. A real supplier talks about these disadvantages to build a realistic plan with you. When a buyer like Gulf Metal Solutions asks about corrosion resistance, they aren’t just asking for a feature; they are asking us to partner in managing this fundamental disadvantage over the lifecycle of their client’s asset.

What are two problems with steel?

Steel isn’t magic. It has inherent flaws that engineers must work around. A certificate for perfect, flawless steel is an immediate warning sign. Real steel has real problems.

Two fundamental problems with steel are its tendency to corrode (rust) when exposed to oxygen and moisture, and its behavior change from ductile to brittle at low temperatures. These are not defects, but intrinsic material characteristics that must be managed through proper grade selection, protection systems, and certified verification.

The Inherent Duality: Managing Contradictions

The phrase "problems with steel" is interesting. From a pure materials science view, these aren’t problems—they are inherent behaviors. From an engineering and procurement view, they are the central problems we solve every day. Let’s analyze this duality.

Problem 1: The Thermodynamic Drive to Corrode

Pure iron is unstable in Earth’s atmosphere. It wants to return to its more stable oxidized state—rust. The steelmaking process creates a meta-stable material.

- The Science: The corrosion process is an electrochemical reaction. It requires an anode, a cathode, an electrolyte (water), and a metallic path. Seawater is a perfect electrolyte.

- The "Problem": This reaction is spontaneous and continuous. You cannot stop it; you can only slow it down or control it.

- The Procurement Impact: This means you are never just buying steel. You are buying a steel-plus-protection-system. The certificate must assure the steel is fit for that system (clean surface, suitable chemistry). A fake certificate ignores this systemic need, treating steel as a finished product.

Problem 2: The Ductile-to-Brittle Transition

This is a profound characteristic of ferritic steels (the kind used for most ship hulls). The same piece of steel can behave in two completely different ways.

- The Science: At high temperatures, dislocations in the steel’s crystal structure can move easily, allowing the material to deform plastically (ductile). At low temperatures, these movements are hindered, and the material fails by cleavage (brittle fracture) with little deformation.

- The "Problem": There is a specific temperature range where this transition happens—the Ductile-to-Brittle Transition Temperature (DBTT). If a ship operates below the DBTT of its hull steel, it is at risk.

- The Procurement Impact: You must select steel with a DBTT well below the vessel’s minimum operating temperature. This is achieved through alloying (Ni, fine-grain practice) and thermo-mechanical processing. The certificate’s Charpy impact test is the practical, contractual proof of where this transition lies.

The table below contrasts how these "problems" manifest versus how they are managed:

| Inherent "Problem" | What It Looks Like in Practice | The Engineering/Procurement Solution | What the Certificate Must Prove |

|---|---|---|---|

| Corrosion | Red/brown rust, pitting, loss of thickness, weakened structures. | Coatings (paint), Cathodic Protection (anodes), Use of more noble materials (stainless for fittings). | Steel cleanliness (low S, P), surface condition, compatibility with standard protection systems. |

| Brittle Behavior | Sudden, catastrophic crack propagation with little warning, often from a notch or weld defect. | Selecting steel grades with high toughness at the design temperature. Strict welding procedures. | Charpy Impact Energy (Joules) at the specified Design Temperature is above the required minimum. |

| Additional Consideration: Fatigue | Cracks initiating and growing under repeated cyclic stress (waves). | Good design (smooth transitions), high-quality welding, regular inspection. | Tensile strength and toughness properties that contribute to good fatigue resistance. |

Understanding these problems is key to detecting certificate fraud. A forger creates a document for an ideal, theoretical material. They list strength but often neglect the nuanced data that proves the steel can handle its inherent problems—like a full traceable chemical analysis for corrosion prediction or legitimate, batch-specific impact test results for fracture safety. When you know the problems, you know what questions to ask, and a fake certificate has no good answers.

What is the best steel for boat building?

Searching for the "best" steel is like asking for the best tool without describing the job. The wrong choice, even with a "real" certificate, is a disaster. The best steel is the one whose certified properties exactly match your specific vessel’s demands.

There is no single "best" steel. The optimal choice depends on the vessel’s size, type, operating environment, and construction budget. For most ocean-going commercial vessels, normalized high-strength low-alloy (HSLA) steels like AH36/DH36/EH36 offer the best balance of strength, toughness, weldability, and cost for hull construction.

Matching the Metal to the Mission: A Decision Framework

The question "what is the best?" is the wrong question. The right question is: "What is the most suitable and cost-effective steel grade for my specific project?" Let’s build a framework to answer that, which will also show you why generic or fake certificates are useless.

The choice revolves around four pillars: Application, Environment, Regulation, and Cost. A certificate is the legal proof that your chosen steel meets the needs of all four pillars.

1. Application: What is the vessel’s type and criticality?

- Small Boats/Yachts: Often use stainless steel (316L) for fittings and small structures, or milder steels for hulls. The "best" steel here might prioritize corrosion resistance and aesthetics over ultimate strength.

- Commercial Workboats, Tugs: Require good durability and moderate strength. ABS Grade A or B is common.

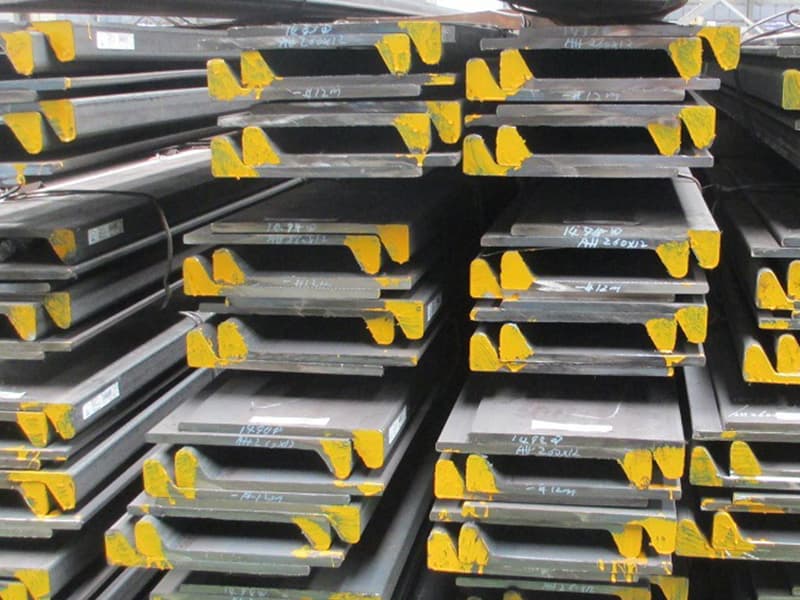

- Large Commercial Vessels (Bulk Carriers, Tankers, Containers): This is our core business. Here, high-strength steel is used to reduce weight. Grades like AH32/36 (for ambient temperatures) or DH32/36 (for lower temperatures) are the industry standard for most hull areas. They offer an excellent balance.

- Ice-Class Vessels & Arctic Operations: Require exceptional low-temperature toughness. Grades like EH36/FH40, and even special Arctic grades with extra nickel, are "best." Their certificates will show very high impact values at -50°C or -60°C.

- Naval/Military Vessels: Use specially developed high-strength steels (like HY-80/100) with stringent toughness requirements and often secret chemical compositions.

2. Environment: Where will it sail?

- Tropical vs. Arctic: This directly dictates the required impact toughness and thus the steel grade (A, D, E, F grades).

- Route Specifics: A vessel on the North Atlantic run needs different steel than one in the Mediterranean.

3. Regulation: What rules must it follow?

- Classification Society Rules: ABS, DNV, Lloyd’s, etc., have strict, published requirements for each grade. The "best" steel is the one with a certificate fully compliant with the chosen class rules.

- International Standards: ISO, ASTM, EN standards provide alternative specifications.

4. Cost: What is the budget reality?

Higher grades (E, F) and special treatments (normalizing, thermo-mechanical rolling) cost more. The "best" steel achieves the required performance at the lowest total lifecycle cost, considering build cost and maintenance.

This decision matrix can guide the conversation:

| Vessel Profile | Primary Consideration | Typical "Best Fit" Grade(s) | Critical Certificate Data Point |

|---|---|---|---|

| Coastal Barge, Inland Waterway | Cost, basic strength. | Mild Steel (e.g., ASTM A36), ABS Grade A. | Tensile strength, yield strength. |

| General Cargo Ship (Global) | Balance of strength & weight, global routes. | AH32 / AH36 (higher strength for weight saving). | Yield strength (355 MPa min for AH36), CVN at 0°C. |

| Container Ship / Oil Tanker | Maximize cargo space (lightweight), long lifespan. | AH36/DH36 extensively used. | Full chemical analysis for CEV, CVN at -20°C for DH grade. |

| Icebreaker / Arctic Supply Vessel | Survival in extreme cold, impact resistance. | EH36, FH40, special Arctic grades. | CVN impact values at -40°C, -50°C, or -60°C. This is the certificate’s most important line. |

| High-Speed Ferry | Light weight for speed, fatigue resistance. | Special high-strength, low-alloy steels, sometimes aluminum. | High strength-to-weight ratio, detailed fatigue data. |

For our clients building standard commercial vessels, AH36 and DH36 are the workhorses. They are proven, widely available, and their properties are well understood. When Gulf Metal Solutions orders these grades, they aren’t looking for a mystery "best" steel. They are looking for a guarantee that the steel they receive is true, certified AH36 or DH36. The certificate is that guarantee.

Therefore, the "best" steel is the one with the most reliable, verifiable certificate that matches your project’s specific technical profile. A fake certificate for a high-grade steel is worse than a genuine certificate for a standard grade, because it leads to misinformed, dangerous decisions. Your job is to match the mission to the metal, and then demand proof.

Conclusion

Avoiding fake certificates requires deep material knowledge. Understand steel’s critical properties, acknowledge its disadvantages, know its inherent problems, and select the right grade for the job. Then, demand proof that matches reality.

-

Understanding this property is crucial for ensuring safety and performance in harsh marine environments. ↩

-

High impact resistance prevents brittle fractures, ensuring the ship’s integrity in freezing conditions. ↩

-

Corrosion resistance is vital for the longevity and structural integrity of ships in saltwater. ↩

-

Good weldability ensures safe construction and repairs, reducing the risk of cracks in the hull. ↩

-

Recognizing signs of a fake certificate is crucial for ensuring the quality and safety of shipbuilding materials. ↩ ↩

-

Pitting corrosion poses a significant threat to steel structures; knowing it helps in material selection. ↩

-

CEV is a key metric for weldability, influencing how easily steel can be welded without issues. ↩ ↩

-

The right chemical composition enhances corrosion resistance and overall performance in harsh conditions. ↩