Your marine steel costs are rising, deliveries are late, and quality issues are eating your profits. A broken supply chain turns a profitable project into a financial disaster. I’ve helped importers rebuild their supply chains from the ground up to regain control and reduce costs by over 15%.

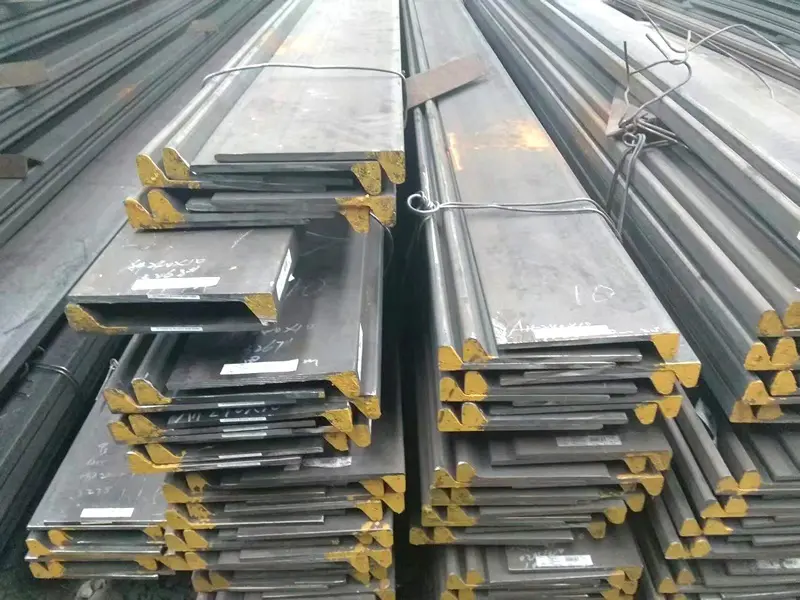

To build a cost-effective marine steel supply chain, establish direct partnerships with certified mills for best factory prices, consolidate shipments for freight savings, implement robust quality inspection protocols to avoid rejects, and use digital tools for transparent communication and logistics tracking. Efficiency at every stage—from sourcing to delivery—is what lowers the total landed cost.

For importers, distributors, and large project contractors, the supply chain is where real competitive advantage is built. It’s not just about buying cheap steel; it’s about buying smartly and managing risk. Let’s explore the principles and practical steps to achieve this, starting with a foundational framework.

What are the 7 C’s of supply chain management?

A strong supply chain doesn’t happen by accident. It’s built on core principles. The 7 C’s provide a checklist to evaluate and improve your own chain. A client in Saudi Arabia used this framework to audit their suppliers and identified "Coordination1" as their biggest weakness.

The 7 C’s of supply chain management are: Customer Focus2, Communication3, Collaboration4, Coordination1, Cooperation, Consistency5, and Cost-Effectiveness6. For a marine steel supply chain, this means aligning with your supplier on your project needs (Customer Focus2), maintaining clear updates (Communication3), working as partners to solve problems (Collaboration4), and ensuring reliable quality and delivery (Consistency5) to achieve the lowest total cost (Cost-Effectiveness6). These interconnected elements build resilience and value.

Applying the 7 C’s to Marine Steel Procurement

Let’s translate each "C" into a concrete action for buying marine steel like angles and plates.

1. Customer Focus2:

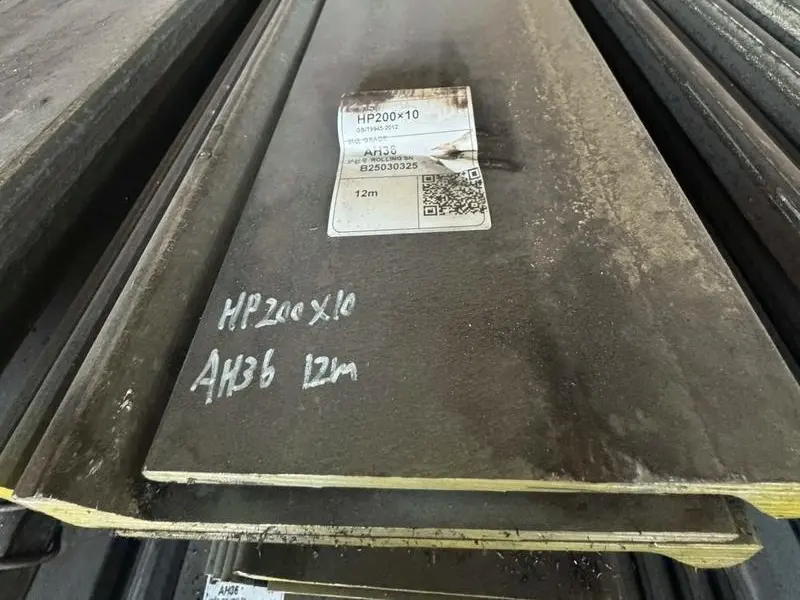

- Your Action: Clearly communicate your exact requirements: grade (ABS AH36), size, quantity, delivery schedule, and required certifications (MTC, SGS report).

- Supplier’s Role: A good supplier listens and advises. For example, they might suggest a more cost-effective standard size or explain lead times for special grades.

2. Communication3 & Collaboration4:

- Your Action: Establish a single point of contact (like our dedicated English-speaking sales rep). Share project forecasts.

- Supplier’s Role: Provide proactive updates on production status, MTCs, and shipping details. Collaborate on solutions if delays occur, like offering stock alternatives.

3. Coordination1 & Cooperation:

- Your Action: Coordinate your inland logistics to receive the container upon arrival to avoid demurrage charges.

- Supplier’s Role: Coordinate with the mill, forwarder, and inspection company (SGS) to ensure all steps happen smoothly and on time.

4. Consistency5:

- Your Action: Provide consistent order specifications and reasonable lead times.

- Supplier’s Role: Deliver material with stable quality (consistent chemistry, dimensions, surface finish) and reliable lead times every time. This was the key feedback from Gulf Metal Solutions.

5. Cost-Effectiveness6:

This is the result of mastering the first six C’s. It’s not about the lowest unit price, but the lowest total cost of ownership, which includes:

- Material cost.

- Freight and logistics cost.

- Cost of delays (project downtime).

- Cost of quality failures (rework, scrap, reputational damage).

Evaluation Table for Your Current Supplier:

| The "C" | Question to Ask | If the Answer is "No"… |

|---|---|---|

| Customer Focus2 | Do they understand my specific marine grade requirements? | You risk receiving incorrect or non-compliant material. |

| Communication3 | Do I get timely, clear updates without chasing? | You face uncertainty and project planning becomes difficult. |

| Consistency5 | Is the quality and packaging the same with every order? | You incur hidden costs of inspection and potential rejects. |

| Cost-Effectiveness6 | Am I considering total landed cost, not just FOB price? | You may be paying more in freight, delays, and quality issues. |

Building a chain based on these principles requires efficient partners, starting with the steel producer. Understanding their process helps you appreciate cost drivers and identify true efficiency.

What is a cheap and efficient process for making steel?

The cost of your marine steel1 starts at the mill. Knowing how it’s made helps you understand pricing and identify truly efficient suppliers. Not all mills are equal; their technology and scale directly impact your bottom line.

The most cost-effective and common process for making mass-produced steel, including marine grades, is the integrated Blast Furnace – Basic Oxygen Furnace (BF-BOF)2 route. It uses iron ore and coke, producing large volumes at high speed. For specialized or smaller batches, the Electric Arc Furnace (EAF) route using scrap steel is flexible and energy-efficient. Both processes are followed by continuous casting3 and hot rolling4 to form plates and sections. Efficiency comes from scale, modern equipment, and process control5.

How Production Efficiency Translates to Your Costs

The mill’s efficiency determines its ability to offer competitive, stable prices.

1. The Integrated BF-BOF Route (The Scale King):

- Process: Iron ore is reduced in a blast furnace to make molten iron. This iron is then refined in a BOF to make steel.

- Why it’s efficient for marine steel1: It produces very large volumes continuously. This is ideal for standard marine grades (AH36, DH36) that are ordered in thousands of tons. High volume means lower cost per ton.

- Your benefit: When you source from a large, integrated mill, you get the benefit of this scale, leading to a lower factory price. Our partner mills in Shandong use this route for bulk production.

2. The Electric Arc Furnace (EAF) Route (The Flexible Specialist):

- Process: Scrap steel is melted using powerful electric arcs.

- Why it’s efficient: It is highly flexible, can start and stop quickly, and uses recycled material. It excels at producing alloy steels, special grades, or smaller batches.

- Your benefit: For non-standard sizes or smaller orders, an EAF mill might be more responsive. However, for large volumes of standard marine carbon steel, BF-BOF is typically more cost-competitive.

3. The Critical Steps After Melting: Continuous Casting and Rolling

- Continuous Casting: The molten steel is cast directly into slabs. This is faster and yields more product than the old ingot casting method.

- Hot Rolling: The slab is reheated and passed through rolling mills to become plate, angle, or bulb flat. Modern computer-controlled rolling ensures precise dimensions and properties.

How Inefficiency Costs You Money:

- Old Technology: Mills with outdated equipment have higher energy costs and lower yield (more waste), which they pass on as higher prices.

- Poor Process Control: Leads to inconsistent quality. You pay for this through increased inspection, sorting, and potential rejects.

- Lack of Certification: A mill not approved by ABS/DNV cannot produce certified marine steel1, forcing you to use a more expensive, approved source.

Choosing an Efficient Mill Partner:

| Mill Characteristic | Benefit to Your Supply Chain | Red Flag |

|---|---|---|

| Large, integrated BF-BOF mill with class approvals. | Competitive price for bulk orders, stable supply, certified quality. | A "mill" that is actually just a small re-roller with no melting capacity. |

| Modern continuous casting3 and rolling lines. | Consistent dimensions, good surface finish, high yield. | Manual or semi-automated rolling leading to size variations. |

| In-house quality lab with spectrometers. | Accurate MTCs, reliable chemistry control. | Reliance on external labs, causing delays in documentation. |

Partnering with an efficient mill is the first step. The next step is to make the entire chain from that mill to your workshop equally efficient.

How to make a supply chain more efficient?

Efficiency means removing waste: wasted time, wasted money, wasted movement. In a marine steel supply chain spanning countries, inefficiencies multiply quickly. I helped a fabricator in Mexico cut their order-to-delivery time by 30% by streamlining just a few steps.

To make a marine steel supply chain more efficient, consolidate orders to achieve Full Container Load (FCL) rates1, digitize documentation and tracking, establish clear Standard Operating Procedures (SOPs)2 for ordering and inspection, and build long-term partnerships with key suppliers to reduce negotiation time and gain priority treatment. Efficiency comes from simplification, visibility, and trust.

Actionable Strategies for Each Link in the Chain

Let’s break down the chain from order to delivery and apply efficiency levers.

1. Sourcing & Ordering Efficiency:

- Consolidate Demand: Work with your supplier to group multiple projects or plan quarterly purchases instead of monthly small orders. This achieves FCL shipping and often qualifies for better mill prices due to larger volume.

- Standardize Specifications: Where possible, design your projects around common steel grades (AH36) and sizes. This reduces the need for special mill runs and shortens lead times.

- Use Digital PO Systems3: Send clear, digital purchase orders. This reduces errors and speeds up processing.

2. Production & Logistics Efficiency:

- Supplier Coordination4: A good supplier acts as your agent at the mill. They coordinate production scheduling, quality inspection (like our SGS support), and booking shipping space in advance.

- Optimized Packaging: Proper, consistent packaging (like our noted high-standard packaging) prevents damage in transit. Damage is a huge inefficiency, causing claims, delays, and production stoppages.

- Track Shipments: Use container tracking numbers. Good suppliers provide this automatically.

3. Documentation & Customs Efficiency:

- Digital Documents: Ensure all documents (Proforma Invoice, Commercial Invoice, Packing List, MTC, Bill of Lading) are sent digitally in advance and are accurate. Errors here cause costly customs delays.

- Pre-Clearance5: Work with your customs broker to submit documents before the ship arrives.

4. Receiving & Inventory Efficiency:

- Schedule Receipts: Have your team and equipment ready when the container arrives. Avoid demurrage and storage fees.

- Efficient Inspection: Have a checklist (based on the MTC and order) for quick visual and dimensional checks. This fast validation gets the steel into production faster.

Efficiency Killers vs. Solutions:

| Inefficiency | Typical Cause | Efficient Solution |

|---|---|---|

| High Freight Cost per Ton | Shipping small, frequent LCL shipments. | Consolidate orders for FCL. Use supplier’s freight consolidation services. |

| Long Lead Times | Ordering special sizes, poor supplier communication. | Plan ahead, use standard sizes. Partner with a supplier offering fast delivery from stock or mill coordination. |

| Customs Delays | Incorrect or missing documents. | Use a supplier that provides complete, accurate docs. Implement a digital doc checklist. |

| Quality Disputes On-Site | No pre-shipment inspection, vague specs. | Mandate third-party pre-shipment inspection (PSI). Provide crystal clear specifications and approved samples. |

These efficiency drivers can be summarized into another powerful framework: the 5 C’s, which provide a more focused strategic lens.

What are the 5 C’s of supply chain management?

The 5 C’s offer a more strategic, high-level view of supply chain health1. They help you assess not just operations, but the fundamental capability of your supply partners. When evaluating a new steel supplier, we implicitly use these criteria.

The 5 C’s of supply chain management are: Connect2, Communicate3, Collaborate4, Coordinate5, and Consolidate6. For marine steel, this means digitally connecting systems for orders, maintaining transparent communication on status, collaborating on problem-solving, coordinating all parties (mill, forwarder, inspector), and consolidating shipments and suppliers to gain economies of scale. Mastering these five areas creates a lean, responsive, and low-cost chain.

A Strategic Blueprint for Your Marine Steel Supply Chain

The 5 C’s move from tactical fixes to building a superior supply network.

1. Connect2 (Systems Integration):

- Goal: Seamless data flow.

- In Practice: This might start simply with using email and shared cloud folders for documents. Advanced integration involves linking your ERP system with a supplier’s portal for real-time inventory and order status. The key is reliable information exchange.

2. Communicate3 (Information Transparency):

- Goal: No surprises.

- In Practice: This goes beyond basic updates. It means your supplier communicates potential issues early (e.g., "Mill delay of 3 days on the AH36 heat") and provides clear reasons. Our fast response and maintained communication speed, as noted by our client, is a core part of this.

3. Collaborate4 (Joint Problem-Solving):

- Goal: Mutual success.

- In Practice: When a design change requires a new steel grade, a collaborative supplier works with you and the mill to find a solution, perhaps suggesting a technically equivalent but more available grade. They don’t just say "can’t do it."

4. Coordinate5 (Orchestration of Activities):

- Goal: Synchronized movement.

- In Practice: The supplier coordinates the mill production, the SGS inspection date, the trucking to port, and the vessel booking. You coordinate the customs clearance and inland haulage. When both sides coordinate effectively, the handoffs are smooth.

5. Consolidate6 (Leveraging Scale):

- Goal: Reduce complexity and cost.

- In Practice: This has two parts:

- Consolidate6 Suppliers: Reduce your number of steel suppliers to 1-2 key strategic partners. This gives you more volume leverage, simpler management, and consistent quality.

- Consolidate6 Shipments: As before, group purchases into FCL containers. A good supplier will actively help you plan this.

Building Your Chain with the 5 C’s: A Phased Approach

| Phase | Focus "C" | Action Item for Marine Steel |

|---|---|---|

| Foundation | Communicate3 & Coordinate5 | Select a supplier known for clear communication. Establish SOPs for orders and documentation. |

| Optimization | Consolidate6 | Work with that supplier to bundle orders for FCL. Negotiate annual volume-based pricing. |

| Partnership | Collaborate4 | Share your annual forecast. Jointly develop contingency plans for market disruptions. |

| Advanced | Connect2 | Explore electronic data interchange (EDI) for automated PO and status updates. |

For a results-driven business, the ultimate goal is a supply chain that is not just a cost center, but a reliable, predictable, and value-adding asset. By applying the principles of the 7 C’s, understanding production efficiency, implementing practical improvements, and strategically employing the 5 C’s, you transform a fragile string of transactions into a robust, cost-effective pipeline for marine steel.

Conclusion

A cost-effective marine steel supply chain is built on strategic partnerships with efficient mills, consolidated logistics, digitized processes, and principles of clear communication and collaboration. This integrated approach minimizes waste, manages risk, and delivers reliable, certified material at the optimal total landed cost.

-

Exploring supply chain health metrics can provide insights into optimizing your supply chain performance. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding the role of Connect can enhance your supply chain’s efficiency through better systems integration. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring this topic can reveal strategies to improve transparency and reduce surprises in your supply chain. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learning about collaboration can help you foster mutual success with suppliers and improve problem-solving. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discovering the importance of coordination can lead to smoother operations and better synchronization in your supply chain. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding consolidation strategies can help you leverage scale and simplify supplier management. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩