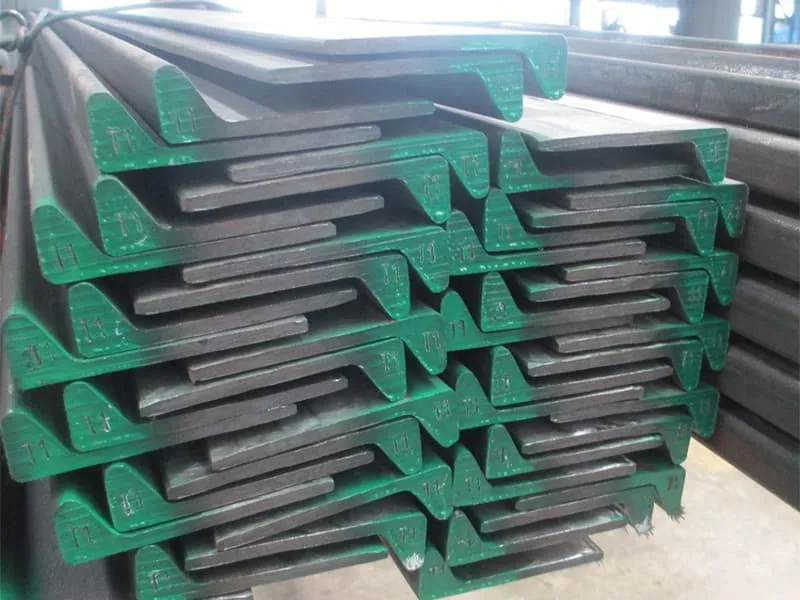

You are installing bulb flat steel for a ship’s frame. You find a slight curve in a 6-meter length. Is this acceptable, or will it cause fitting problems and weaken the structure? Guessing is not an option in shipbuilding.

To check the straightness tolerance of bulb flat steel, place it on a flat surface and use a precision straightedge or a taut wire along its length. Measure the maximum gap between the steel and the straightedge. Compare this deviation to the allowable tolerance, which is typically 0.1% to 0.2% of the length (e.g., 2mm per meter) as per standards like EN 10067 or customer specification.

Knowing the theory is one thing. Applying it correctly on the workshop floor is another. A small error in measurement can lead to a big rejection of a whole batch. I want to guide you through the practical methods, the exact tolerances, and how to adapt these checks for different profiles. This knowledge will help you ensure every piece meets the strict demands of marine construction. Let’s start with the foundation: understanding flatness.

How to measure flatness tolerance1?

The flat surface of the bulb flat’s web must be truly flat. A warped or twisted web will not make proper contact during welding, creating stress points. Measuring flatness tells you if the surface is within the required plane.

To measure flatness tolerance1, place the bulb flat steel2 on a surface plate3 or three stable supports. Use a height gauge4 or a dial indicator to take multiple height readings across the surface. The flatness tolerance1 is the difference between the highest and lowest measured points, and it must not exceed the specified limit, often 1-2mm over the entire surface.

Flatness is about an entire surface, not just a line. It is a more complex measurement than straightness. We need a systematic approach to capture the true shape of the web.

Understanding the Goal of Flatness Measurement

Flatness answers one question: "How much does this surface deviate from a perfect plane?" In shipbuilding, a flat web ensures uniform welding and load distribution. We are not looking for a single bend, but for any hills or valleys across the area.

A Step-by-Step Practical Method

You can achieve accurate results with standard workshop tools. Here is a reliable method:

- Prepare the Setup: Place the bulb flat steel2 on a certified surface plate3. If the piece is very long, use three adjustable supports placed under the ends and the middle to avoid sagging. The goal is to simulate a stable, neutral state.

- Establish a Reference Plane: We cannot compare to a perfect plane directly. Instead, we create a practical reference. Imagine a flat sheet of glass just touching the highest points of the steel surface. All other points should be at or below this "glass."

- Take Measurement Points: Use a height gauge4 or a dial indicator mounted on a stand. Take readings at many points in a grid pattern across the web surface. Mark these points with chalk first.

- Calculate the Result: Find the highest measurement value and the lowest measurement value. The flatness error5 is the difference between these two numbers.

Flatness vs. Straightness: A Critical Distinction

People often confuse these two. It is important to separate them.

| Feature | What It Measures | Analogy | Primary Tool |

|---|---|---|---|

| Straightness | Deviation of a line (e.g., the edge). | Checking if a drawn line is wavy. | Straightedge, taut wire, laser. |

| Flatness | Deviation of a surface (e.g., the web face). | Checking if a tabletop is warped. | Surface plate, height gauge4, dial indicator. |

A piece can be straight along all its edges but still not be flat (like a twisted piece). Conversely, a surface could be flat locally but the edge could be curved. For bulb flats, we check both. The standard tolerance for flatness is usually given as a maximum deviation over a specified area, like "1.5mm over any 1m x 1m area" or "3mm over the entire length." When we prepare shipments for clients who value precision, like Gulf Metal Solutions, we often include a flatness check report from our mill’s quality department. This gives them confidence before the steel even leaves our factory.

How to check straightness?

You have a 12-meter bulb flat. Visually, it looks good. But your eye cannot detect a 5mm bend over that distance. You need a reliable, physical method to be certain.

To check the straightness of bulb flat steel, use a precision straightedge or a tightly stretched wire along its length. For the straightedge method, place it on the web or against the edge and measure any gap with feeler gauges. For the wire method, measure the distance from the wire to the steel at multiple points; the maximum deviation is the straightness error.

There are two main methods, each suited for different situations. Choosing the right one depends on length, accuracy needs, and available tools.

Method 1: The Precision Straightedge (For Shorter Lengths and Edges)

This is the most common workshop method. It is simple and direct.

- Tools Needed: A precision straightedge (hardened steel), a set of feeler gauges, a clean cloth.

- Procedure: Clean the straightedge and the steel edge. Place the straightedge firmly along the length of the bulb flat’s web or against its side (the flange edge). Shine a light from behind. If you see light under the straightedge, use feeler gauges to measure the thickness of the gap. Slide the feeler gauge through the gap. The largest gauge that fits is the local deviation. Move the straightedge along the entire length to check for consistent straightness.

- Best For: Checking shorter lengths (up to 2-3 meters), verifying edge straightness after cutting, and quick incoming inspections.

Method 2: The Taut Wire or String Line Method (For Long Lengths)

For long bulb flats used in ship frames, a straightedge is too short. The taut wire method is the traditional and effective solution.

- Tools Needed: A strong, thin wire (piano wire is ideal), two stands with adjustable height, a measuring device (ruler, caliper, or micrometer).

- Procedure: Set up two stands at each end of the bulb flat. Stretch the wire tightly between them, positioning it parallel to the steel’s edge. The wire should just clear the steel along its entire length. Use a ruler or a depth micrometer to measure the distance from the wire to the steel at regular intervals (e.g., every meter). Record all measurements.

- Calculating Straightness: The wire represents the ideal straight line. The difference between the smallest and largest measurement is the total straightness error. For example, if measurements are 5mm, 7mm, 4mm, and 8mm, the error is 8mm – 4mm = 4mm.

- Best For: Checking straightness of very long sections (6 meters and above) in the workshop or on the fabrication floor.

Modern Method: Laser Alignment

Many modern shipyards use laser alignment systems. A laser emitter projects a perfectly straight beam of light. A digital detector is moved along the steel, and it displays the deviation in real time on a screen. This method is very fast and accurate but requires a significant investment in equipment. For most manufacturers and fabricators, the straightedge and wire methods are perfectly adequate when done correctly. The key is consistency. Always measure from the same reference surface (usually the web) and take enough measurement points to catch any localized bow or sweep.

What is the tolerance of straightness?

You measure a 2mm gap under your straightedge on an 8-meter bulb flat. Is this acceptable? The answer lies in the straightness tolerance, a defined limit that separates acceptable product from reject.

The straightness tolerance for bulb flat steel is typically defined as a maximum allowable deviation over a given length. Common standards like EN 10067 specify a tolerance of 0.1% to 0.2% of the length. This means for a 10-meter piece, the allowable bend is 10mm to 20mm. Tighter tolerances, like 0.05%, can be specified for critical applications.

Tolerance is not a single number. It is a rule that scales with the size of the product. Understanding this rule and its sources is crucial for quality control.

The Source of Tolerances: Standards and Specifications

Tolerances do not come from the supplier. They come from international standards or project specifications.

- International Standards: The most common standard for bulb flats in Europe is EN 10067. This standard provides tables for straightness tolerance based on the height (h) of the bulb flat and its length. Other standards include JIS (Japanese) and ASTM (American). These standards ensure a common language between mills and shipyards worldwide.

- Project Specifications: Often, a shipyard or naval architect will define even tighter tolerances in their project technical specification. These custom tolerances override the general standard. As a supplier, we must meet these specific requirements.

Interpreting Tolerance Values

The tolerance is usually expressed in one of two ways:

- As a Percentage of Length: "Straightness tolerance: 0.15% of length (L)." To calculate: Allowable Deviation = Length (in mm) × (Tolerance % / 100). For a 6000mm length at 0.15%: 6000 × 0.0015 = 9mm.

- As a Fixed Value per Unit Length: "Straightness shall not exceed 2mm in any 1m length, nor 8mm in total length." This is a stricter, two-part check. You must check every meter segment and the overall length.

A Practical Tolerance Reference Table

Here is a simplified guide based on common practice for marine-grade bulb flats:

| Bulb Flat Length (L) | Typical Standard Tolerance (0.15% of L) | Tight Tolerance (0.08% of L) | Application Context |

|---|---|---|---|

| 3 meters | 4.5 mm | 2.4 mm | General hull framing, non-critical structures. |

| 6 meters | 9 mm | 4.8 mm | Standard ship frames, longitudinal stiffeners. |

| 10 meters | 15 mm | 8 mm | Longitudinals for large bulk carriers or tankers. |

| 12 meters | 18 mm | 9.6 mm | Keel components, major girders (often with tighter spec). |

It is vital to know which tolerance applies to your order. When a client like a project contractor in the Philippines places an order, the first thing we confirm is the applicable standard and any special tolerance requirements. We then instruct our mill accordingly. The mill’s quality control report, which we provide, will show the measured straightness against the agreed tolerance. This transparency builds trust and prevents disputes upon delivery. Remember, a tolerance is a permission to vary, not a target. Good mills aim for results well within the limit.

How to measure the straightness of a tube?

You are working with both bulb flats and tubular sections for a ship’s railing or piping system. The principle of checking straightness is similar, but the round shape of a tube presents a unique challenge.

To measure the straightness of a tube, roll it on a flat surface plate; a straight tube will roll smoothly without wobbling. For precise measurement, use a laser alignment tool that projects a line along the length, or set up V-blocks at each end and use a dial indicator to measure runout as the tube is rotated.

Tubes and pipes are hollow and cylindrical. You cannot place a straightedge on their curved surface. We need methods adapted to their geometry.

Why Tube Straightness Matters in Marine Contexts

In shipbuilding, straight tubes are used for handrails, fluid pipelines, hydraulic systems, and structural members. A bent tube can cause assembly issues, restrict fluid flow, or create weak points under pressure. The checking methods must account for the entire cylindrical form.

Three Effective Methods for Tubes

From simple to precise, here are the ways to check a tube’s straightness.

-

The Surface Plate Roll Test (Quick Check)

This is a fast, visual method for initial inspection. Place the tube on a clean, flat surface plate. Gently roll it. A perfectly straight tube will roll evenly, with its entire length in contact with the plate. A bent tube will exhibit a "wobble" or a rising and falling motion as it rolls. You can see or hear an irregular rhythm. This method is good for spotting obvious bends but does not give a numerical measurement. -

The V-Block and Dial Indicator Method (Precision Measurement)

This is the standard workshop method for quantitative measurement.- Setup: Place two V-blocks on a surface plate, one near each end of the tube. Place the tube in the V-blocks. Mount a dial indicator on a stand so its tip touches the top of the tube’s surface, roughly in the middle of the length.

- Procedure: Rotate the tube slowly by hand one full revolution while watching the dial indicator. The needle will move as the tube rotates. The total movement (the difference between the highest and lowest reading) is called the Total Indicated Runout (TIR). This TIR value is twice the amount of bend (the deviation from the centerline). For straightness over the full length, you would move the dial indicator along the tube and take readings at several points.

-

The Laser Alignment Method (High-Tech and Accurate)

Modern laser tools are excellent for long tubes. A laser beam is shot through the center of the tube (if it’s hollow and open) or along its outside. A target or detector at the far end shows the beam’s position. Any bend in the tube will cause the beam to hit off-center. More advanced systems use a laser line projected along the outside to check for straightness along a generating line.

Applying the Lessons to Bulb Flats

While the tools differ, the core concept is the same for tubes and bulb flats: compare the object to an ideal straight reference and measure the maximum deviation. For a bulb flat, the reference is a straightedge or a wire along a flat surface. For a tube, the reference is the axis of rotation (in the V-block method) or a laser line.

Understanding these different methods makes you a more knowledgeable buyer. When you source various steel profiles, you can ask your supplier about their quality control procedures. For instance, you can ask, "What method do you use to check straightness on bulb flats over 8 meters?" or "Can you provide a straightness report for this batch of tubes?" A competent supplier, like us, will have clear answers and documented processes. This level of detail is what separates a commodity seller from a technical partner in the marine industry.

Conclusion

Checking straightness and flatness is a fundamental quality step. Using the right method—straightedge, wire, or V-blocks—and knowing the applicable tolerance ensures your bulb flat steel is fit for purpose and avoids costly rework.

-

Understanding flatness tolerance is crucial for ensuring quality in manufacturing processes, especially in welding and structural applications. ↩ ↩ ↩

-

Gain insights into bulb flat steel, its properties, and its critical role in construction and manufacturing. ↩ ↩

-

Explore the importance of surface plates in achieving accurate measurements and maintaining quality standards in engineering. ↩ ↩

-

Learn how to effectively use a height gauge for precise flatness measurements, enhancing your quality control processes. ↩ ↩ ↩

-

Understanding how to calculate flatness error is vital for quality assurance in engineering and manufacturing. ↩