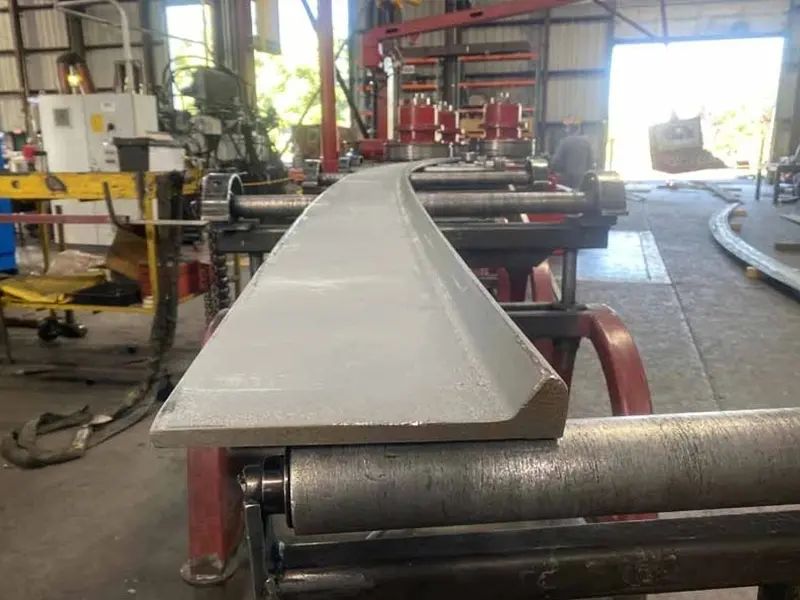

You’re designing a support structure or a ship’s frame, and you need to select a steel profile. The choice between a bulb flat, a standard angle, and an L-shaped section isn’t arbitrary—it directly impacts strength, weight, and cost. I’ve helped clients optimize designs by switching profiles, resulting in significant material savings.

Choose a bulb flat for maximum bending stiffness and weight efficiency as a longitudinal stiffener. Choose an L-shaped angle for versatility in bracing, framing, and connections where easy attachment in two directions is key. "L-shaped steel" is another name for angle steel. The decision hinges on the primary load direction, connection method, and the need for structural efficiency versus fabrication simplicity. Understanding their unique strengths leads to optimal design.

For structural engineers, fabricators, and procurement managers, this choice is fundamental. Each profile has its ideal role. This guide will clarify their differences, applications, and the material properties that influence their behavior, starting with a basic clarification about the "angle" in L sections.

What is the angle of L section steel?

This question often causes confusion. In geometry, an "angle" is a measure in degrees. In steel profiles, "angle" refers to the shape. For L-section steel1, the two legs form a specific, standardized angle. I’ve seen fabrication drawings misinterpret this, leading to ordering errors.

The angle of a standard L-section steel1 (angle iron) is 90 degrees2. The two legs, or "flanges," meet at a right angle to form the characteristic "L" shape. This 90-degree geometry provides inherent stiffness in two perpendicular directions and creates easy surfaces for bolting or welding to other members. There are also unequal angles where the legs are different lengths, but the included angle remains 90 degrees2.

The Significance of the 90-Degree Geometry

This right-angle design is not accidental. It is the result of practical engineering and manufacturing considerations.

1. Functional Advantages of the Right Angle:

- Biaxial Stiffness3: The profile resists bending forces applied along either leg. This makes it excellent for bracing in a frame, where loads can come from different directions.

- Ease of Connection: One leg can be easily fastened to a vertical surface (like a column flange), while the other leg extends horizontally to connect to a beam or another member. This simplifies construction.

- Efficient Use of Material: The shape places material away from the neutral axis (the center of the profile), increasing its moment of inertia and thus its resistance to bending, compared to a flat bar of the same weight.

2. Manufacturing and Standardization:

L-angles are produced by hot-rolling steel through shaped rolls. The 90-degree angle is the simplest and most efficient to produce consistently. This standardization means:

- Predictable mechanical properties.

- Wide availability in many sizes (e.g., L50x50x5, L150x90x12).

- Known and published dimension tolerances (per standards like ASTM A64, EN 10056).

3. Special Angles vs. Standard Angles:

While 90 degrees2 is the universal standard, steel can be custom-rolled or fabricated into other angles (e.g., 45 degrees, 60 degrees) for specific applications. However, this is rare, costly, and has long lead times. In 99% of structural applications, the 90-degree L-angle is specified.

Why This Matters for Your Choice:

When you choose an L-angle, you are selecting a profile designed for connections and bracing where loads are multi-directional. Its 90-degree shape is its key feature. In contrast, a bulb flat is optimized for a different primary function, which becomes clear when we look at flat steel’s role.

What is flat steel used for?

Flat steel bar is the simplest profile—just a rectangle. Its uses are vast, but in structural contexts, it’s often the baseline against which more efficient shapes like angles and bulb flats are compared. A fabricator in Thailand once used flat bars as stiffeners, but switching to angles reduced weight and improved rigidity.

Flat steel bar is used for low-stress applications like spacers, braces, trim, edge reinforcement, and small brackets. In construction, it serves as ledger plates, base plates, and straps. However, for primary stiffening or load-bearing members, profiles like angles or bulb flats are more efficient because they provide greater stiffness for the same weight of material. Flat bar is cost-effective but structurally inefficient for bending loads.

The Role and Limitations of Flat Bar in Structural Design

Understanding where flat bar works—and where it doesn’t—prevents under-engineering.

1. Appropriate Applications of Flat Bar:

- Non-Structural or Light-Duty Uses:

- Spacers and Shim Stock: For adjusting gaps between parts.

- Trim and Edging: To cover raw edges on panels or steps.

- Machine Guards: Lightweight panels and frames.

- Decorative Elements: Where load is negligible.

- Structural but Low-Stress Applications:

- Gusset Plates: Small, flat plates used to reinforce connections between beams and columns.

- Base Plates: To distribute the load from a column to a concrete foundation.

- Tie Straps: To hold members together laterally.

2. The Structural Inefficiency Problem:

For a member subject to bending (like a stiffener on a plate), the measure of effectiveness is the section modulus. A flat bar has its material distributed evenly. If you bend it, most of the material is near the neutral axis and doesn’t contribute much to resistance.

- Compare to an Angle: The L-shape pushes material to the outer edges of the legs, increasing the section modulus.

- Compare to a Bulb Flat: The bulb concentrates extra material at the farthest point from the plate, maximizing the section modulus for its weight.

- Result: To achieve the same stiffness as an angle or bulb flat, a flat bar would need to be much thicker and heavier, which is wasteful.

3. When to Choose Flat Bar Over an Angle:

- When the load is purely in tension or compression (not bending).

- When you need a simple, wide surface for welding or bolting.

- When cost is the absolute primary driver and the load is very small.

Comparison for a Stiffener Application:

| Profile Used as Stiffener | Relative Stiffness (Section Modulus) | Relative Weight | Best Use Case |

|---|---|---|---|

| Flat Bar | Low (Baseline) | High (for same stiffness) | Very light-duty applications, edge trim. |

| L-Angle | High (3-5x a flat bar of same weight) | Medium | General stiffening, bracing, frames. Versatile. |

| Bulb Flat | Very High (Highest for weight) | Low | Primary longitudinal stiffeners on ship hulls/decks for max efficiency. |

The choice of profile often goes hand-in-hand with the choice of material grade. For formability and welding, low-carbon steel is common, which leads to the next important comparison.

Is low carbon steel more easily shaped than high carbon steel?

Yes, absolutely. This is a fundamental principle of metallurgy that directly impacts fabrication. A workshop in Vietnam struggled to bend high-carbon steel for a tool, not realizing its inherent lack of ductility compared to the low-carbon steel they used for structures.

Low carbon steel (e.g., 0.6% carbon). The lower carbon content makes low carbon steel more ductile and malleable, allowing it to be cold-worked without cracking. High carbon steel is harder and stronger but also much more brittle, making it prone to cracking during forming operations and requiring heat treatment for shaping. For structural profiles like angles and bulb flats, low-carbon or mild steel is standard.

The Trade-Off: Ductility vs. Strength

Carbon content is the primary controller of a steel’s balance between hardness/strength and ductility/toughness.

1. Low Carbon Steel (Mild Steel – ~0.05% to 0.25% C):

- Properties: Ductile, tough, malleable, easily welded. It has a relatively low yield strength.

- Ease of Shaping:

- Can be easily cold-formed (bent, rolled, punched) without risk of cracking.

- Excellent weldability without pre- or post-heat treatment under normal conditions.

- This is why most structural shapes (A36, S235) and marine steels (AH36 max C~0.18%) are low-carbon. They must be roll-formed into complex shapes and extensively welded.

2. High Carbon Steel (Tool Steel – >0.6% C):

- Properties: Very hard, strong, wear-resistant, but brittle.

- Difficulty in Shaping:

- Poor ductility. Attempting to bend it cold will likely cause it to fracture.

- Often requires hot-working (shaping at high temperatures) or machining instead of forming.

- Poor weldability. Welding creates a hard, crack-prone heat-affected zone (HAZ). Special procedures are needed.

3. Medium Carbon Steel (0.3% – 0.6% C):

Falls in between. Can be formed with more difficulty than low carbon steel and may require heating for certain operations.

Impact on Profile Manufacturing and Fabrication:

- Rolling Profiles: Angles and bulb flats are hot-rolled from billets. Low-carbon steel is ideal for this process, allowing the steel to flow into the complex mold shapes without cracking.

- Site Fabrication: When a shipyard needs to adjust an angle on-site, they can cold-bend mild steel slightly. They could not do this with a high-carbon steel angle.

Material Selection for Common Profiles:

| Steel Profile | Typical Carbon Content | Reason for This Choice |

|---|---|---|

| Structural Angle (A36) | Low (~0.25% max) | Must be roll-formed and welded easily on construction sites. |

| Marine Bulb Flat (AH36) | Low (~0.18% max) | Must be roll-formed, and the entire ship hull is welded. Weldability is critical. |

| Spring Steel | High (0.6%-1.0%) | Needs high elastic limit and hardness, not formability after manufacture. |

| Chisel or Blade | Very High (0.8%-1.2%) | Needs extreme hardness and edge retention; shaped by forging (hot) and grinding. |

Choosing low-carbon steel for structural profiles is standard, but this choice comes with its own set of compromises, which are important to acknowledge.

What are the disadvantages of using low-carbon steel1?

Low-carbon steel is the default for most structures for good reasons, but it’s not perfect. Understanding its limitations informs design choices and protection strategies. A coastal railing made from mild steel rusted quickly because its low corrosion resistance2 wasn’t adequately addressed.

The main disadvantages of low-carbon steel1 are its relatively low strength compared to alloy or high-carbon steels, poor corrosion resistance2 requiring protective coatings3, and lower hardness leading to poor wear and abrasion resistance. It is also susceptible to creep at elevated temperatures. For many applications, these drawbacks are managed through design (using larger sections), protective systems (painting, galvanizing4), and material selection5 for specific wear parts.

Managing the Limitations in Practical Applications

Acknowledging these disadvantages is the first step to mitigating them effectively.

1. Lower Strength:

- The Issue: Mild steel like A36 has a yield strength of 250 MPa. High-strength low-alloy (HSLA) steels like AH36 offer 355 MPa, and quenched & tempered alloys can exceed 690 MPa.

- The Impact: To carry the same load, a mild steel member must be larger (thicker, deeper) than a high-strength steel6 member. This increases weight and material usage.

- The Solution: Where weight or space is critical (ships, mobile equipment), specify HSLA grades (like AH36) which retain good weldability while offering higher strength.

2. Poor Corrosion Resistance:

- The Issue: Low-carbon steel rusts readily when exposed to moisture and oxygen, especially in marine or industrial atmospheres.

- The Impact: Unprotected steel loses cross-section and strength over time. Maintenance costs for repainting are high.

- The Solution: Implement protective systems. This includes:

- Coatings: Paint, powder coating.

- Metallic Coatings: Hot-dip galvanizing4 (zinc).

- Cathodic Protection: Used for submerged structures like ship hulls or pipelines.

- Material Upgrade: For highly corrosive areas, use stainless steel (316) or weathering steel (A588) instead.

3. Low Hardness and Wear Resistance:

- The Issue: Soft surfaces wear down quickly under friction or abrasion.

- The Impact: Not suitable for parts like gears, cutting edges, or liners in high-wear areas.

- The Solution: Use low-carbon steel1 for the main structure but attach hardened wear plates (made of high-carbon or alloy steel) at points of contact. Or, select a different material entirely for the wear component.

4. Creep at High Temperature:

- The Issue: At temperatures above ~425°C, mild steel can slowly deform under constant stress.

- The Impact: Not suitable for high-temperature service like boiler tubes.

- The Solution: Use alloy steels designed for high-temperature service.

Applying This Knowledge to Profile Selection:

When choosing between a bulb flat, angle, or flat bar made from low-carbon steel1, you are generally accepting these disadvantages in exchange for excellent fabricability and cost. Your design must account for them.

- For a ship’s hull frame (Angle/AH36): You accept the need for coatings and anodes to manage corrosion. You choose AH36 over plain A36 to gain higher strength and reduce weight.

- For a conveyor support frame (Angle/A36): You might specify hot-dip galvanizing4 for corrosion protection in a dusty, humid plant environment.

- For a machine base (Flat bar/A36): You accept its lower stiffness and size it accordingly, but benefit from its low cost and easy welding.

A rational selection process weighs these material disadvantages against the functional advantages of each profile, leading to an optimized, durable, and cost-effective design.

Conclusion

Choose bulb flats for high-efficiency longitudinal stiffening, angles (L-sections) for versatile bracing and framing, and understand that flat bar is for light-duty use. Base your choice on the required stiffness, connection needs, and the inherent properties of the low-carbon steel typically used, managing its disadvantages through design and protection.

-

Explore the properties and applications of low-carbon steel to understand its advantages and limitations in various industries. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about effective methods to enhance corrosion resistance in low-carbon steel, ensuring longevity and durability. ↩ ↩ ↩ ↩ ↩

-

Find out which protective coatings are most effective for low-carbon steel to prevent rust and extend its lifespan. ↩ ↩

-

Learn about the galvanizing process and its benefits for protecting low-carbon steel from corrosion. ↩ ↩ ↩ ↩

-

Discover best practices for material selection in structural applications, balancing performance and cost. ↩

-

Discover how high-strength steel enhances ship hull design and performance. ↩