Your shipbuilding project budget is approved. Then, steel prices jump 15%. A delayed shipment costs you $10,000 a day in berth fees. These are not surprises; they are uncontrolled procurement costs. Managing them is the difference between profit and loss.

Controlling cost in shipbuilding procurement means moving beyond unit price. You must manage total cost through strategic sourcing, clear specifications, volume consolidation, logistical planning, and investing in quality to avoid expensive rework and delays.

I work with shipyards and fabricators from Mexico to the Philippines. The most successful ones do not just buy steel. They manage a complex supply chain. Their procurement strategy is their first line of defense against budget overruns. Let’s break down the real methods to control costs, starting with the core philosophy and moving to actionable calculations and material knowledge.

How to reduce costs in procurement?

A procurement manager pressures a supplier for a 5% lower price per ton. He gets it. Then, the steel arrives with surface defects, causing weeks of rework. The "savings" evaporate in delay costs. True cost reduction looks at the entire picture, not just the invoice.

To reduce costs in shipbuilding procurement, you must focus on total cost of ownership1. This includes strategies like standardizing specifications2, consolidating purchase volumes for better pricing, building long-term supplier partnerships3 for stability, and optimizing logistics to cut hidden freight and handling expenses.

Many people think cost reduction is only about negotiation. It is more about smart process design. We can categorize the strategies into four main areas: what you buy, who you buy from, how you buy it, and what happens after you buy it.

A Strategic Framework for Shipbuilding Procurement Cost Reduction

| Strategy Area | Specific Actions | How It Reduces Total Cost |

|---|---|---|

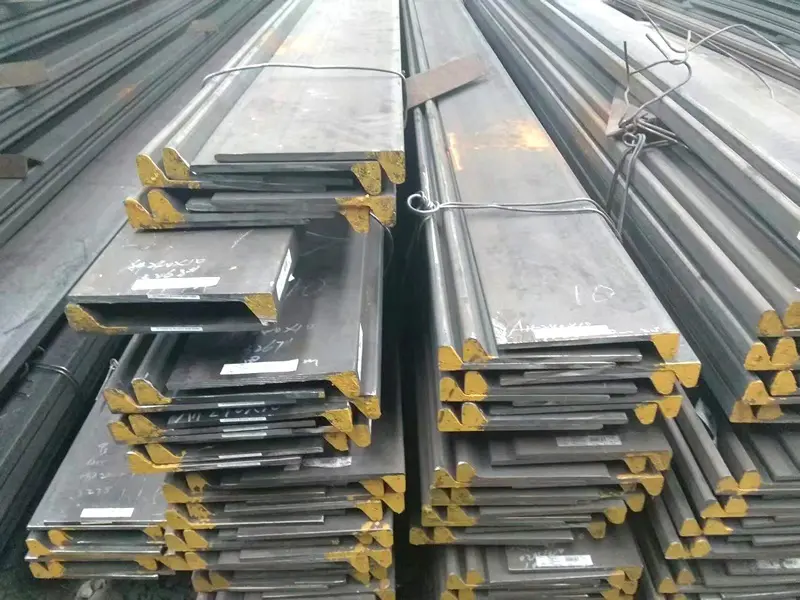

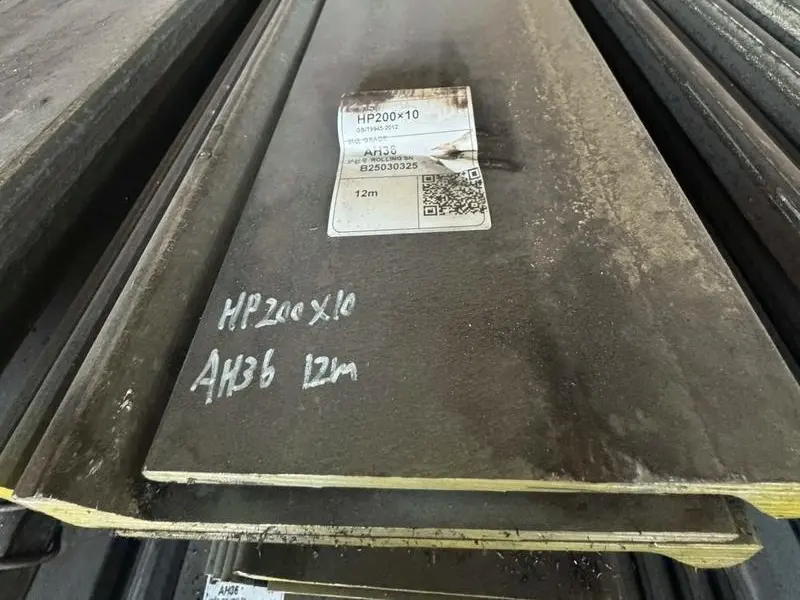

| Specification & Design | Standardize steel grades and dimensions across projects where possible. Involve procurement early in design to suggest material alternatives. | Reduces the need for special, expensive mill runs. Prevents over-specification (using AH36 where Grade A is sufficient). Minimizes cutting waste. |

| Supplier Relationship & Sourcing | Move from transactional buying to partnerships with 2-3 key suppliers. Prioritize suppliers with mill access, not just traders. Require certification (ABS, etc.) as a baseline. | Partners offer price stability and priority during shortages. Mill-direct suppliers reduce middleman markups. Certified quality prevents rejection and rework costs at the yard. |

| Purchasing Process | Consolidate requirements across projects for larger, quarterly or annual framework agreements. Use competitive bidding but with clear technical requirements. | Larger volumes command significant unit price discounts. Framework agreements lock in capacity and simplify re-ordering. |

| Logistics & After-Purchase | Optimize shipping Incoterms (e.g., FOB to control freight). Plan deliveries to match production schedules (JIT where feasible). Use suppliers who offer packaging that prevents damage. | Reduces demurrage and storage costs. Prevents production line stoppages. Eliminates costs from handling damaged materials. |

The most overlooked area is the cost of poor quality4. A cheaper, non-certified plate might cause it to fail the surveyor’s inspection. The cost then includes cutting it out, re-ordering, delayed production, and potential penalty clauses from the shipowner. This is why a rational, results-driven buyer like the one at Gulf Metal Solutions insists on stable quality and inspection support. They understand that paying a small premium for guaranteed, certified material with SGS inspection is actually a major cost reduction strategy.

From our side as a supplier, we enable these strategies. Our long-term cooperation with certified mills allows us to offer competitive factory prices for volume orders. Our flexible MOQ helps smaller yards or projects consolidate their needs. Our packaging is designed to protect the steel during long sea voyages to ports like Dammam or Hai Phong, ensuring it arrives in perfect, work-ready condition. This is not a service add-on; it is a direct contribution to our client’s cost control.

How to calculate cost savings in procurement?

Your finance department asks for proof of procurement’s value. Showing a lower unit price is easy. But how do you quantify the value of avoiding a two-week delay? You need a calculation method that captures real savings.

Calculate procurement cost savings by comparing total costs before and after a change. Use metrics like Price Variance1 (saved unit cost x volume), Cost Avoidance2 (value of prevented price increases or delays), and Total Cost of Ownership3 (TCO) analysis that includes quality, logistics, and operational impacts.

If you only track purchase price variance (PPV), you miss most of the story. Real savings come from avoiding costs, not just reducing them. We need to look at three types of calculations.

Key Methods to Calculate Real Procurement Savings

| Calculation Type | Formula / Method | Example in Shipbuilding | Why It Matters |

|---|---|---|---|

| Hard Cost Savings4 (Price Variance1) | (Old Price per unit – New Price per unit) x Quantity Purchased | You negotiated AH36 plate from $780/ton to $750/ton. You bought 1000 tons. Savings = ($30) x 1000 = $30,000. | This is the most direct and visible saving. It is easy to report. But it is only one part. |

| Soft Cost Savings5 / Cost Avoidance2 | Estimate the cost of a negative event that was prevented. This requires benchmarking and scenario planning. | Your new supplier’s fast response and perfect packaging prevented a 5-day production delay. A day of delay costs your yard $15,000. Cost Avoidance2 = 5 x $15,000 = $75,000. | This is where major value is created. It includes avoiding price hikes by locking in contracts, preventing quality rejects, and avoiding logistical delays. |

| Total Cost of Ownership3 (TCO) Analysis | Sum of all costs over the material’s life cycle: Purchase Price + Logistics + Handling + Storage + Quality Inspection/Reject Costs + Impact on Production Efficiency. | Supplier A: Plate cost $740/ton, but 3% rejection rate causes rework. Supplier B: Plate cost $760/ton, with SGS inspection and zero defects. TCO for Supplier B is lower when you add the cost of rework and delays. | TCO reveals the true cheapest option. It justifies paying more upfront for reliability, quality, and service. |

Implementing this requires data. You need to know your cost of delay per day. You need to track historical defect rates from different suppliers. You need to understand your logistics and handling expenses.

Let me give you a real example. A project contractor in Vietnam was comparing two offers for marine angle steel. Offer A was 3% cheaper per ton. Offer B was from us, slightly higher, but included pre-shipment SGS inspection and bundled logistics to their port. They did a simple TCO analysis6. They estimated that dealing with potential quality issues from Offer A would require 40 man-hours of their own inspection and risk a delay. They chose Offer B. The "savings" they reported were not on the invoice line. The savings were in the smooth, uninterrupted progress of their fabrication work. This is the calculation that matters to rational buyers. Our job is to provide the transparent data and reliable service that makes this TCO advantage clear and calculable.

What are the raw materials for shipbuilding industry?

You order "shipbuilding steel." But the mill needs specific raw materials to make it. Understanding this chain helps you predict price trends and assess a supplier’s true reliability. Your steel’s quality starts with these inputs.

The primary raw material for shipbuilding steel is iron ore. This is transformed into steel in a blast furnace using coking coal as fuel. Alloying elements like manganese, niobium, and vanadium are added to create specific marine grades with required strength and toughness.

When we talk about raw materials, we are talking about the recipe. The properties of ABS AH36 steel are not accidental. They are the result of carefully selected and processed inputs. Let’s look at the main ingredients and their roles.

The Raw Material Recipe for Quality Shipbuilding Steel

| Raw Material | Primary Role in Steelmaking | Impact on Final Shipbuilding Steel |

|---|---|---|

| Iron Ore1 | The source of iron (Fe). It is smelted to produce molten pig iron. | The base of all steel. The quality and purity of the ore affect the efficiency of refining and the level of impurities in the final steel. |

| Coking Coal2 | Heated in the absence of air to produce coke. Coke is the fuel and reducing agent in the blast furnace, removing oxygen from iron ore. | A major cost driver. Energy prices directly impact steel production costs. Mills with efficient energy use can better control costs. |

| Scrap Steel3 | Recycled steel melted in Electric Arc Furnaces (EAFs). Also used in Basic Oxygen Furnaces (BOFs) to adjust chemistry. | Using scrap is more energy-efficient. However, for the highest quality, thick marine plate, the integrated (BF-BOF) route using virgin iron ore is still dominant to control impurities. |

| Alloying Elements4 (Key for Marine Grades) | Manganese (Mn): Improves strength and hardenability. Niobium (Nb) / Vanadium (V): Tiny additions greatly increase strength and refine grain structure for toughness. Aluminum (Al): Used as a deoxidizer and for grain refinement. |

These are the "secret sauce." They allow mills to produce High-Strength Low-Alloy (HSLA) steels5 like AH36. The cost and availability of these ferroalloys influence the price premium of HSLA over normal strength steel. |

| Lime & Fluxes6 | Added to the furnace to remove impurities (like silicon, phosphorus, sulfur) by forming slag. | Critical for clean steel. Low sulfur and phosphorus are essential for good weldability and toughness in marine steels. This refining step is non-negotiable. |

Why does this matter for procurement? Because it ties directly to cost control and risk management. If you hear news about iron ore prices rising in Australia or coking coal supply issues in Mongolia, you can expect pressure on your steel costs in 2-3 months. A supplier with strong, long-term contracts with raw material suppliers is more resilient to these shocks.

Our partnerships with large, certified mills in Shandong give us this stability. These mills have integrated operations or long-term agreements for raw materials. This allows them to plan production and offer more stable pricing to us, which we can then pass on as more predictable quotes to our clients. For a buyer planning a year-long shipbuilding project, this predictability is invaluable. It removes one major variable from their budget. When Gulf Metal Solutions plans their quarterly orders, they value this stability as much as the fast communication. They know that behind our responsive sales rep is a solid supply chain that reaches back to the raw materials.

What is the cost of procurement?

Your accounting shows the cost of steel purchased. But it does not show the salary of your procurement team, the cost of failed inspections, or the interest on capital tied up in inventory. The true cost of procurement is much larger than the purchase order.

The cost of procurement is the total sum of all resources spent to acquire materials. It includes direct costs like purchase price and freight, and hidden indirect costs like personnel salaries, quality control, inventory holding, transaction processing, and risks from delays or poor quality.

Most companies measure the visible 20% of the iceberg. The 80% below the waterline sinks budgets. To control cost, you must first make all these costs visible. We can categorize them into direct, indirect, and risk-based costs.

The Comprehensive Breakdown of Procurement Costs

| Cost Category | Specific Cost Elements | How It Impacts Your Shipbuilding Project |

|---|---|---|

| Direct / Visible Costs | 1. Material Purchase Price (per ton of steel). 2. Freight & Logistics: Ocean freight, insurance, port charges, inland transportation. 3. Import Duties & Taxes. |

These appear on invoices and are actively negotiated. They are the primary focus but not the whole story. |

| Indirect / Process Costs | 4. Procurement Labor: Salaries for buyers, managers, and quality inspectors. 5. Transaction Costs: Cost of tendering, contracting, order processing, and payment handling. 6. Inventory Holding Cost: Cost of capital tied up in stock, warehouse space, insurance, and management. 7. Quality Control Cost: Cost of in-house inspection, third-party inspection (like SGS), and material testing. |

These are overheads. They are often fixed or semi-variable. Efficient procurement reduces the time and effort per order. Good supplier quality reduces QC costs. |

| Risk & Failure Costs | 8. Cost of Poor Quality (COPQ): Rework, scrapped material, production delays due to defective supplies. 9. Delay Costs: Penalties from shipowners, idle labor and equipment costs (berth fees). 10. Supply Risk Cost: Premium paid for emergency orders during shortages, or costs of switching suppliers last minute. |

These are the most damaging and often unplanned. They are directly tied to supplier reliability and material certification. A single quality failure can wipe out years of negotiated price savings. |

The goal of strategic procurement is to minimize the total of all these costs, not just the purchase price. Sometimes, investing more in Category 1 (e.g., paying for certified steel with inspection) dramatically reduces costs in Categories 8 and 9.

This is the core of our value proposition. We help clients lower their total cost of procurement. Our fast, clear communication in English reduces their transaction and coordination costs. Our SGS inspection support reduces their internal QC costs and risk of COPQ. Our reliable delivery and protective packaging reduce their risk of delay costs. For a client, the "cost" of working with us is not just our factory price. It is a package that includes lower hidden costs. As one of our clients put it, the speed and stability we provide allow them to operate with more certainty and less administrative firefighting. That efficiency is a quantifiable cost saving on their bottom line.

Conclusion

Controlling shipbuilding procurement costs demands a total-cost view. Master strategic sourcing, quantify true savings, understand material origins, and relentlessly attack hidden expenses to secure your project’s profitability.

-

Understanding the significance of Iron Ore can help you grasp its impact on steel quality and pricing. ↩ ↩ ↩ ↩

-

Explore how Coking Coal influences energy costs and overall steel production efficiency. ↩ ↩ ↩ ↩ ↩

-

Learn about the benefits of using Scrap Steel for energy efficiency and its role in high-quality steel production. ↩ ↩ ↩ ↩

-

Discover how Alloying Elements enhance the strength and toughness of marine steel, crucial for shipbuilding. ↩ ↩ ↩

-

Explore the advantages of HSLA steels in shipbuilding, including their strength and cost implications. ↩ ↩

-

Understand how Lime & Fluxes contribute to producing clean steel, essential for weldability and toughness. ↩ ↩