Requesting quotes from China can be frustrating. Vague prices, unclear terms, and slow replies waste your time and hide the true project cost until it’s too late.

To get the best quotation for L-shaped steel from China, provide a clear technical specification including dimensions, grade, standard, quantity, and required certifications. Also clarify packaging, delivery terms (FOB/CIF), and payment method. This allows suppliers to give an accurate, comparable, and all-inclusive price.

I receive hundreds of quote requests every month. The clear ones get my best price and fastest service immediately. The vague ones lead to endless emails and a price you can’t trust. Let me show you how to structure your request like a professional buyer.

What is L-shaped steel called?

Using the wrong name when you ask for a quote causes immediate confusion. Suppliers might assume you want the cheapest, non-standard product, not the marine-grade material you actually need.

L-shaped steel is formally called "Angle Bar1" or "Steel Angle." For precise quoting, you must specify if it’s an "Equal Leg Angle2" or "Unequal Leg Angle3," and reference the governing standard like EN 10056 or ASTM A364, along with the material grade (e.g., S355J2).

Think of the name as the first filter. It tells the supplier which department and which mill to contact. Getting this right saves days of back-and-forth clarification.

The Importance of Precise Terminology in Global Procurement

When you buy internationally, you are not just buying a product. You are buying a product that matches a technical description in a contract. The name is the key to that description.

Common Names and Their Pitfalls:

- "L-Bar" or "L-Steel": This is too vague. It could mean anything. A professional supplier will need to ask many follow-up questions.

- "Angle Iron": This is an outdated term. It often implies low-carbon, non-structural mild steel, possibly with poor dimensional tolerances. Never use "Angle Iron" when you need certified marine or structural steel. It signals a lack of technical knowledge and may attract lower-quality suppliers.

- "Steel Angle" or "Angle Bar1": These are the correct, professional terms understood worldwide.

How to Specify for a Quotation:

You must provide a complete description. Here is the formula:

"Equal/Unequal Leg Angle3e Bar](https://skind.com.sg/angle-bar-understanding-its-uses-and-benefits/)[^1] to [Standard], Grade [Material Grade], Size [AxBxt], Length [L]"

- Example 1 (Structural):

[Equal Leg Angle](https://www.coremarkmetals.com/hot-rolled-steel-equal-leg-angle?srsltid=AfmBOooRLaxPnZVE1bNm-tKyFyS9j1Dzk1X94ZadViKKL57E5bPDhkA9)[^2]e Bar](https://skind.com.sg/angle-bar-understanding-its-uses-and-benefits/)[^1] to EN 10056-1, Grade S275JR, Size 100x100x10mm, Length 12m - Example 2 (Marine):

[Unequal Leg Angle](https://alcobrametals.com/stainless-steel/unequal-leg-stainless-steel-angle/?srsltid=AfmBOopoIiM-IZNqW0Se7VChQJ4SoCojjQAsxbuCt_jbWBKzAQyaT26-)[^3]e Bar](https://skind.com.sg/angle-bar-understanding-its-uses-and-benefits/)[^1] (Marine Angle Steel) to [ASTM A36](https://www.azom.com/article.aspx?ArticleID=6117)[^4], Grade AH36, Size 150x90x12mm, Random Length 10-12m - Example 3 (With Treatment):

[Equal Leg Angle](https://www.coremarkmetals.com/hot-rolled-steel-equal-leg-angle?srsltid=AfmBOooRLaxPnZVE1bNm-tKyFyS9j1Dzk1X94ZadViKKL57E5bPDhkA9)[^2]e Bar](https://skind.com.sg/angle-bar-understanding-its-uses-and-benefits/)[^1] to JIS G3192, Size 75x75x6mm, Length 6m, Hot-Dip Galvanized after fabrication (if required)

The Role of Standards in the Quote:

The standard (EN, ASTM, JIS, GB) is not just a piece of paper. It defines:

- Dimensional Tolerances5: How much variation in leg width, thickness, and straightness is allowed. Tighter tolerances often cost more.

- Technical Delivery Conditions6: The rules for inspection, testing, and marking.

- Metric vs. Imperial: EN standards are metric. ASTM standards are primarily imperial (inches, lbs/ft). Specifying the standard avoids unit confusion.

When Gulf Metal Solutions first contacted us, they asked for "L angle for marine project." Our sales rep immediately asked for the standard and grade. They provided "ASTM A364, 100x100x10." Because they used the correct terminology, we could immediately check mill stock and provide a valid price with the correct ASTM A364 MTC (Mill Test Certificate). Clear naming got them a firm quote in 2 hours, solving their "delayed responses" pain point from previous suppliers.

What is the price of L-angle 25x25x51?

This is the most common type of question I get, and it is impossible to answer correctly. Asking for the price of a single size without context is like asking the price of "a car"—the range is huge and meaningless.

The price of L-angle 25x25x51 depends on the material grade2 (S235 vs S3553), the standard (EN vs ASTM), the quantity (full truckload vs small bundle), the surface condition (black, primed), the current raw material cost, and the Incoterms4 (FOB China port or CIF your port). A single per-ton price without these details is unreliable.

Asking "how much for 25x25x5?" will get you a random number from a supplier, often the lowest possible price for the lowest quality. To get a real price, you need to build a complete commercial picture.

Deconstructing the Steel Price: More Than Just Dimensions

The price per ton you see is the final result of many variables. Let’s break them down so you know what you’re really paying for.

1. Base Material Cost (The Biggest Factor):

This is driven by the steel billet price, which changes daily based on iron ore, coke, and futures market prices. When you ask for a quote, the price is only valid for that day or maybe 24-48 hours.

2. Product Specifications:

- Grade: An angle in S235JR (basic structural steel) is cheaper than S355J2 (higher strength, guaranteed toughness). A marine grade like AH36 is more expensive due to stricter chemistry control and testing.

- Standard: Producing to a strict international standard (EN, ASTM) with full certification has a cost premium over producing to a generic local standard.

- Dimensional Tolerances: Standard tolerances are included. If you need tighter tolerances (e.g., for precision fabrication), it will cost extra.

3. Quantity and Packaging:

- MOQ (Minimum Order Quantity)5: Mills have minimum production runs, usually a "heat" (20-60 tons). For common sizes like 25x25x5, a supplier may have stock from a recent production run and offer a lower MOQ (e.g., 5 tons). We offer flexible MOQ to help smaller buyers.

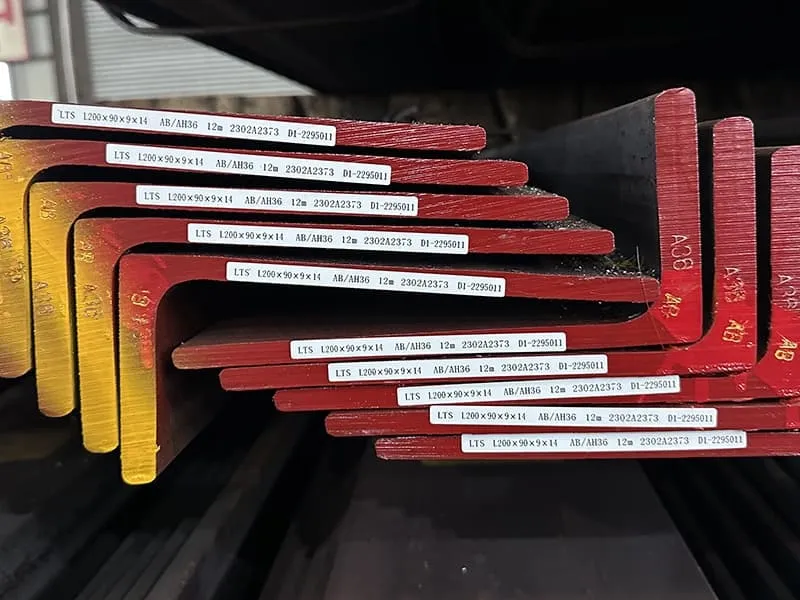

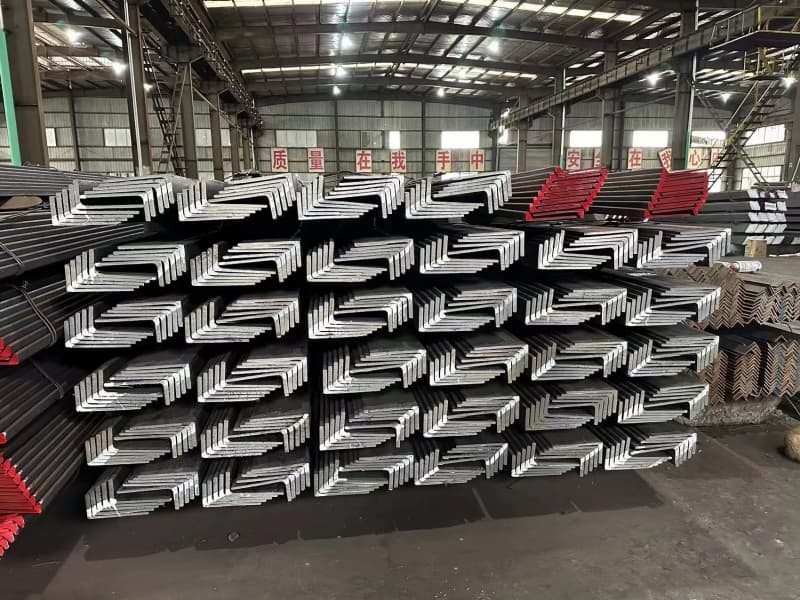

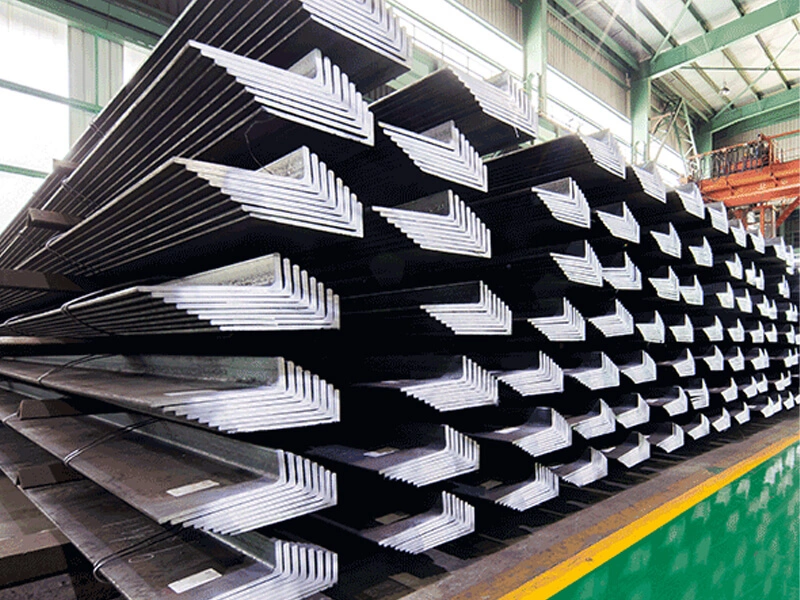

- Packaging: Standard packaging is in loose bundles with steel straps. If you need individual wrapping, waterproof packing, or special marking for traceability, this adds cost. Good packaging prevents damage during sea freight—this was a specific compliment from Gulf Metal Solutions.

4. Processing and Treatment:

- As-Rolled (Black): The standard, lowest-cost condition.

- Shot Blasted and Primed: Ready for painting. Adds $20-$50/ton or more.

- Hot-Dip Galvanized6: A significant additional process. You must specify if you need the angle galvanized before fabrication (easier) or after fabrication (for complete assembly protection).

5. Logistics and Incoterms4:

This is where prices become incomparable.

- EXW (Ex-Works): Price at the factory gate. You handle all trucking, port fees, shipping, and insurance. Hard to compare.

- FOB (Free On Board): Price includes everything to get the goods loaded on the ship at a Chinese port (e.g., Tianjin, Qingdao). You pay the sea freight and insurance. This is the most common and comparable term for international buyers.

- CIF (Cost, Insurance, Freight)7: Price includes everything to a port in your country. This is easier for you but includes the supplier’s profit margin on freight. Always ask for a FOB breakdown to see the true material cost.

A Real Quote Example:

Instead of "Price for 25x25x5?", a good request is:

"Please quote for Equal Angle Bar:

- Standard: EN 10056-1

- Grade: S235JR

- Size: 25x25x5 mm

- Length: 6 meters

- Quantity: 20 Metric Tons

- Surface: As-rolled (black)

- Packaging: Standard export bundle, steel straps

- Certification: Mill Test Certificate EN 10204 3.1

- Delivery Term: FOB Qingdao Port, China

- Payment: 30% T/T deposit, 70% against copy of shipping documents"

This request will get you a firm, actionable price from a serious supplier.

Is US steel better than Chinese steel?

This is a deep-seated question for many buyers. The simple answer is "it depends," but that’s not helpful. The real question is: does the steel meet the specified standard and performance requirements for your project?

The quality of steel is defined by the mill’s production process and adherence to the specified standard (ASTM, EN, etc.), not its country of origin. Major Chinese mills produce steel to ASTM and EN standards that is physically and chemically identical to steel produced in the US or Europe for the same grade. The difference often lies in certification, traceability, and consistent quality control.

I supply Chinese steel to American-owned fabricators in Mexico and European contractors in the Middle East. They accept it because we provide the proof, not just the promise.

A Fact-Based Comparison: Standards, Mills, and Verification

The "better" debate usually masks concerns about consistency, reliability, and trust. Let’s address those concerns directly.

1. The Standard is the Rulebook:

If you specify ASTM A361, the chemical composition and mechanical properties are defined by the ASTM committee, regardless of where it’s made. A reputable Chinese mill producing ASTM A361 must make steel that passes the same tests as a US mill. The standard is the equalizer.

2. The Mill is the Key Differentiator:

Just like in the US, there is a range of mill quality in China.

- Large, State-Owned or Listed Mills (Baosteel2, Ansteel, Shougang, etc.): These are world-class facilities. They have modern technology (continuous casting, thermo-mechanical control process). They produce steel for global markets, including direct supply to US and EU companies. Their quality is consistently excellent.

- Smaller, Private Mills: Quality can be variable. They might focus on the domestic market with less strict standards.

As a supplier, our job is to source from the certified, reliable mills we have long-term agreements with. We do not buy from the spot market where quality is unknown.

3. The Critical Role of Certification and Inspection3:

This is where perceived quality differences are resolved.

- Mill Test Certificate (MTC)4: This is the birth certificate. A Type 3.1 Certificate5 is a statement of compliance from the mill. A Type 3.2 Certificate is more stringent, with validation by the mill’s independent inspection department.

- Third-Party Inspection6 (SGS, BV, Intertek): This is the independent verification. A third-party inspector witnesses the testing at the mill or warehouse, checks the MTC against the material, and issues their own report.

- Class Society Approval: For marine projects, mills can have approval from ABS, DNV, LR, etc. This means their quality system and specific grades are audited and approved.

The Verdict:

US steel is not inherently "better." Properly specified, certified, and inspected Chinese steel from a reputable mill is functionally identical for the vast majority of applications. The advantage of Chinese steel is often cost competitiveness7 due to scale and efficiencies.

The Real Risk and Our Solution:

The risk is not the country, but the supply chain8. A buyer who shops only for the lowest price per ton on Alibaba may end up with uncertified steel from a small mill, poor packaging, and no after-sales support. This was the exact experience of Gulf Metal Solutions before working with us.

We eliminate this risk by:

- Sourcing from Partner Mills: We use large, certified mills.

- Providing Full Documentation: We supply original MTCs.

- Offering Third-Party Inspection6: We organize and pay for SGS inspection before shipment, so the buyer sees the report before paying the balance.

- Providing Consistent Quality: Our long-term mill relationships ensure stable chemistry and mechanical properties batch after batch.

For your project, the question should not be "US or China?" It should be "Can you supply steel that meets this standard, with this certification, and can you prove it before shipment?"

What is the angle of L section steel?

This sounds like a trick question, but it highlights a crucial point about geometry and tolerances. The nominal angle is 90 degrees, but in real-world manufacturing and construction, perfection does not exist. The allowed deviation matters.

The nominal angle of L-section steel is 90 degrees. However, manufacturing standards allow a small angular deviation (typically ±1 to ±2 degrees). For most construction, this is fine, but for precision fabrication or tight fit-up, specifying the tolerance or checking the mill’s capability is important.

If you assume every L-angle is a perfect right angle, you will have fit-up problems during fabrication. Understanding the tolerance is part of getting a quality product.

Why Tolerances Matter More Than the Perfect Angle

The 90-degree angle is the design ideal. The allowed variation is the engineering reality that affects cost and assembly.

The Standard Allowances:

International standards define how much an angle can deviate from 90 degrees. This is called the angularity tolerance1.

- EN 10056-12: For leg lengths up to 90mm, the tolerance is ±1.5 degrees. For leg lengths over 90mm, it is ±1.0 degree.

- ASTM A6/A6M3: The tolerance is typically ±2 degrees for hot-rolled angles.

- JIS G3192: Specifies a tolerance on the "squareness" which translates to a similar angular deviation.

Why Does This Deviation Happen?

During the hot-rolling process, the steel is shaped at high temperatures. As it cools, internal stresses can cause slight twisting or bending. Modern mills with straightening machines control this very well, but a perfect 90.00 degrees on every piece is not commercially viable.

When Does it Become a Problem?

For 99% of applications—standard stiffeners, brackets, framing—the standard tolerance is perfectly acceptable. Problems arise in:

- Precision Jigs and Fixtures: Where angles are used as datums or guides for machining.

- Modular Construction: When many angles must fit together perfectly for bolt-up assembly without force.

- Cladding and Curtain Wall Systems: Where visual lines must be perfectly straight and square.

How to Ensure You Get What You Need:

- Specify the Standard: By ordering to EN 10056 or ASTM A6, you automatically get the standard tolerance.

- Request a Tighter Tolerance (If Needed): This is a special requirement and will cost more. You must state it clearly in your quote request: "Angular deviation must not exceed ±0.5 degrees." The mill may need to perform extra straightening or sorting.

- Review the Mill’s Certificate and Capability: Reputable mills have process controls to keep angles within the middle of the tolerance band. Our partner mills consistently produce angles well within the ±1 degree range.

- Consider Machining: For ultra-critical applications, it is sometimes more economical to buy standard angle and have the fabricator machine one leg to a perfect 90 degrees.

The Bigger Picture:

Focusing only on the perfect 90-degree angle misses other critical geometric factors that affect fit-up:

- Leg Straightness: How flat each leg is.

- Twist: The entire angle should not be twisted like a propeller.

- Leg Length and Thickness Tolerances: These also impact how parts mate together.

A professional supplier like us understands these tolerances. When we pack angles for shipment, we ensure they are bundled straight and protected to prevent distortion during transit. This attention to geometric integrity4 is part of the "stable quality" our clients value.

Conclusion

To get the best quote from China, provide complete specs, understand all price factors, focus on certification over origin, and know the geometric tolerances. This turns a price request into a professional procurement exercise.

-

Understanding angularity tolerance is crucial for ensuring the quality and fit of steel components in construction. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring EN 10056-1 will provide insights into international standards for angular tolerances in steel fabrication. ↩ ↩ ↩ ↩

-

ASTM A6/A6M outlines important tolerances for hot-rolled angles, essential for quality assurance in steel construction. ↩ ↩ ↩ ↩ ↩

-

Exploring geometric integrity will reveal how it affects the overall quality and performance of steel structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about Type 3.1 Certificates and their significance in verifying steel compliance. ↩ ↩ ↩

-

Explore how third-party inspections ensure the integrity and quality of steel products. ↩ ↩ ↩ ↩

-

Understanding cost competitiveness can help you evaluate the best options for your steel needs. ↩ ↩

-

Explore the critical role of the supply chain in ensuring the quality and reliability of steel. ↩