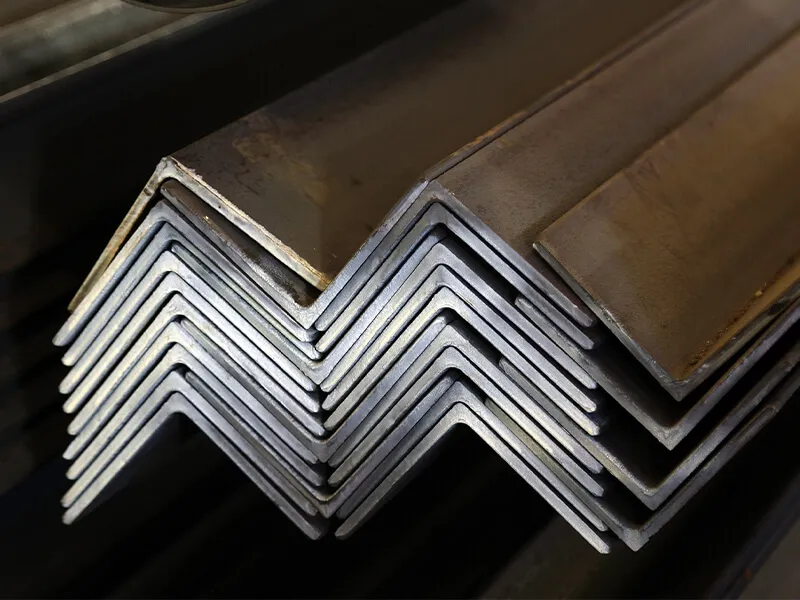

Your long-awaited shipment of marine angle steel finally arrives at the port. But signing the delivery papers without a proper inspection is a huge financial risk. I’ve seen clients discover critical flaws only after the steel was unloaded, turning a simple delivery into a costly dispute.

You must conduct a systematic inspection upon delivery by first verifying all documents (MTC, packing list), then checking the physical condition for damage, and finally measuring key dimensions (leg length, thickness) against the order specifications. This process protects your investment and ensures the steel is fit for its purpose in shipbuilding or marine construction.

For our clients—large importers and project contractors in places like Saudi Arabia and Qatar—this inspection is the final quality gate. It transforms trust into verified fact. Let’s break down this essential process into clear, actionable steps, starting with the foundational types of inspection you should know.

What are the 4 types of inspection?

Many buyers think inspection is just a quick look when the truck arrives. This is a mistake. A proper quality assurance system involves different inspection types at different stages. A fabricator in the Philippines once only checked for visible damage but missed a critical grade marking error that caused their entire fabrication to be rejected by a surveyor.

The four primary types of inspection are: Pre-Production Inspection (PPI) to check raw materials, During Production Inspection (DPI) to monitor the manufacturing process, Pre-Shipment Inspection (PSI) to verify finished goods before loading, and Container Loading Inspection (CLI) to ensure proper packing and loading. For marine angle steel, PSI and the final delivery inspection are the most critical for the buyer.

Understanding Each Inspection Stage for Marine Steel

Each type of inspection serves a distinct purpose and happens at a different point in the supply chain. Knowing them helps you decide where to focus your efforts and resources.

1. Pre-Production Inspection (PPI)

- When it happens: Before manufacturing begins. For steel, this is rarely done by the end buyer but is performed by the mill itself.

- What it checks: The mill verifies the chemical composition of the steel melt (the "heat") before it is cast into slabs. They check that the raw materials meet the required grade specification (e.g., ABS AH36).

- Your role as a buyer: You typically rely on the Mill Test Certificate (MTC) as the record of this stage. The MTC’s chemical analysis section is the result of PPI.

2. During Production Inspection (DPI)

- When it happens: While the steel is being rolled into angle shapes at the mill.

- What it checks: Mill operators monitor the rolling process for consistency in temperature and dimensions. They perform intermediate checks on the rolling stock.

- Your role as a buyer: This is internal to the mill. However, for very large or critical orders, a third-party inspector (like SGS) can be stationed at the mill to witness this process. This is common for major offshore projects.

3. Pre-Shipment Inspection (PSI)

- When it happens: After production is complete and the steel is packed, but before it is loaded into the container or onto the vessel.

- What it checks: This is the most important inspection for importers. It verifies:

- Quantity: Number of bundles, pieces, and total weight.

- Quality: Visual surface condition (rust, pitting, deep scratches), straightness.

- Dimensions: Random sampling to check leg length, thickness, and length against tolerances.

- Marking & Documentation: Checking heat numbers and grade markings against the MTC.

- Your role as a buyer: You should always require a PSI. We offer this as a core service. Our sales rep coordinates with an inspector at our warehouse in Liaocheng. The inspector sends a report with photos and videos before the steel ever leaves China. This solved the "quality inconsistency" pain point for Gulf Metal Solutions.

4. Container Loading Inspection (CLI)

- When it happens: During the physical loading of inspected goods into the shipping container.

- What it checks: It ensures the correct, inspected goods are loaded. It verifies the container’s interior condition is clean and dry. It monitors the loading method to prevent damage during transit (e.g., proper blocking and bracing).

- Your role as a buyer: This is often part of a full PSI service. It provides a final safeguard against shipping errors and secures your cargo for the ocean journey.

This table shows how these inspections align with your buying process:

| Inspection Type | Who Typically Does It? | Key Benefit for the Importer/Buyer |

|---|---|---|

| Pre-Production (PPI) | Steel Mill (Internal) | Assurance that the chemistry is correct from the start. Evidence is in the MTC. |

| During Production (DPI) | Steel Mill (Internal) or Third-Party | Catches process-related issues early before all steel is rolled. |

| Pre-Shipment (PSI) | Third-Party (e.g., SGS) or Supplier’s QC | Most critical. Provides independent verification that what is about to be shipped matches your order. |

| Container Loading (CLI) | Third-Party or Supplier’s Logistics Team | Prevents loading mistakes and ensures proper packing for safe ocean transport. |

For rational, results-driven buyers, the PSI is the non-negotiable checkpoint. It provides the evidence needed to approve shipment and gives peace of mind. The next step is understanding what to look for during the final inspection of the steel structure itself.

How to inspect steel structure?

The term "steel structure" can refer to a completed building frame or, in your case as a buyer, the raw structural steel components—like angle bars—that will become part of a structure. Inspecting these components upon delivery is a focused technical task. A project contractor in Qatar once accepted angled beams that were slightly twisted, causing major fit-up issues that delayed their entire port crane project.

To inspect structural steel components like angle bars, follow a three-step approach: First, perform a visual inspection for physical damage, corrosion, and straightness. Second, conduct a dimensional inspection using calipers and tape measures to verify sizes. Third, verify all material markings and certifications against the provided Mill Test Certificates (MTC). This method ensures the material is sound before fabrication begins.

A Detailed Protocol for Inspecting Structural Steel Components

This inspection happens at your yard after delivery. You should have your own team or a local third-party inspector ready to perform it as soon as the truck arrives.

Step 1: Visual Inspection (The First Look)

Do this before unloading if possible. Your eyes are your first tool.

- Packaging & Damage: Check the bundles for broken straps or damaged wrapping. Look for signs of impact during transit (dents, deep scratches, bent ends). Marine steel should be well-protected; poor packaging was a specific complaint from our clients before they worked with us.

- Surface Condition: Look for excessive or abnormal rust. Mill scale (a dark blue-grey oxide layer) is normal and protective on hot-rolled steel. However, you must distinguish this from active red rust (which is flaky and porous) or pitting corrosion. Reject any material with deep pitting.

- Straightness: Sight down the length of several angle bars from each bundle. Look for obvious bowing (curvature along the length) or camber (curvature across the leg). A slight natural camber is allowed per standards like ASTM A6, but severe twisting is not acceptable.

Step 2: Dimensional Inspection (The Precision Check)

Use simple, calibrated tools. You don’t need a full lab.

- Tools Needed: Digital caliper, steel tape measure, straight edge.

- What to Measure (for angles):

- Leg Length (A & B): Measure from the outer heel to the outer edge of each leg. Check multiple points.

- Thickness (t): Crucially, measure away from the rounded toe. Place caliper jaws about 20mm in from the edge. Measure at several points along the leg.

- Length: Verify the random or ordered length of sample pieces.

- Sampling Plan: You cannot measure every piece. For a shipment of 100 bundles, inspect 3-5 bundles at random. From each inspected bundle, measure 2-3 pieces. Record all data.

Step 3: Documentation & Marking Verification (The Paper Trail)

This links the physical steel to its certified properties.

- Compare Markings: Each bundle and often each piece should have a painted or tagged marking. It shows the grade (e.g., ABS AH36), heat number, size, and sometimes the mill logo. This marking must exactly match the information on the MTC.

- Audit the MTC: Ensure the MTC is original or a certified true copy. Check that the heat number, grade, dimensions, and test results (yield strength, impact values) are present and conform to your purchase order requirements.

Here is a quick field checklist for your team:

| Inspection Area | What to Look For | Acceptable/Not Acceptable |

|---|---|---|

| Visual: Packaging | Broken straps, torn waterproof paper. | Not Acceptable: Packaging failed, exposing steel to elements. |

| Visual: Surface | Uniform mill scale vs. patchy red rust or pitting. | Acceptable: Tight mill scale. Not Acceptable: Widespread active rust or deep pits. |

| Dimensional: Leg Length | Measured value vs. ordered size (e.g., 100mm). | Acceptable: Within standard tolerance (e.g., ±2.5mm). Not Acceptable: Consistently undersized. |

| Document: Marking | Painted grade/heat number on steel. | Acceptable: Matches MTC exactly. Not Acceptable: Missing, unclear, or mismatched. |

This structured approach gives you objective facts. You can use these facts to accept the shipment or to file a formal claim with evidence. It turns a subjective opinion into a professional quality assessment.

What are methods of inspection?

Knowing you need to inspect is one thing. Knowing how to inspect is another. The methods you choose determine what flaws you will find. Relying only on a visual check might miss internal inconsistencies or incorrect chemistry. You need a combination of methods.

Common inspection methods for steel include visual testing (VT) for surface defects, dimensional inspection with tools, destructive testing (taking samples for lab analysis), and non-destructive testing (NDT) like ultrasonic testing (UT) to check internal quality without damaging the material. For delivered marine angle steel, VT and dimensional inspection are standard, while NDT may be used for critical applications.

Choosing the Right Inspection Method for the Job

Not every method is needed for every delivery. Your choice depends on the project’s criticality, the material’s value, and the risks involved.

1. Visual Testing (VT)

- What it is: The most basic and widely used method. It involves looking at the steel with the naked eye or with magnifying glasses or borescopes.

- What it finds: Surface cracks, laminations, rust, pitting, rolling defects, weld defects (if applicable), and incorrect marking.

- For marine angle delivery: This is your first and mandatory step. Check every bundle as it is unloaded.

2. Dimensional and Geometric Inspection

- What it is: Using manual tools (calipers, tapes, micrometers, profilometers) or laser scanners to measure physical dimensions.

- What it finds: Deviations in thickness, width, length, straightness, flatness, and cross-sectional shape.

- For marine angle delivery: This is your second mandatory step. Verify leg length, thickness, and straightness against the order and standard tolerances (ASTM A6, EN 10056).

3. Destructive Testing (DT)

- What it is: Taking actual samples from the delivered material and testing them to destruction in a lab. This is what the mill does to generate the MTC.

- What it finds: Exact yield strength, tensile strength, elongation, impact toughness (Charpy test), and chemical composition.

- For marine angle delivery: You almost never do this upon delivery. You rely on the mill’s MTC. However, for extremely high-value projects or in case of a major dispute, you might send a sample piece to an independent lab. This is costly and time-consuming.

4. Non-Destructive Testing (NDT)

- What it is: A group of methods to evaluate the material without causing damage. Common types include:

- Ultrasonic Testing (UT): Uses sound waves to find internal flaws like inclusions or laminations.

- Magnetic Particle Testing (MT): Finds surface and near-surface cracks in ferromagnetic steel.

- Dye Penetrant Testing (PT): Finds surface-breaking cracks.

- What it finds: Internal voids, inclusions, hidden cracks, and lack of fusion in welds.

- For marine angle delivery: Not standard for routine shipments. It is specified for critical components in offshore platforms, submarine pipelines, or areas subject to high fatigue stress. If your project specs require it, you must arrange it.

Method Selection Guide for Importers:

| Your Situation / Requirement | Recommended Inspection Methods | Reason & Practical Note |

|---|---|---|

| Routine delivery of marine angles for general shipbuilding. | VT + Dimensional Inspection. | This is the standard, cost-effective combination to verify condition and size. It catches 95% of delivery issues. |

| High-value order for critical offshore structure nodes. | VT + Dimensional + Specific NDT (e.g., UT of every piece). | Project specifications often mandate NDT to ensure internal integrity for safety-critical parts. |

| Dispute with supplier over material grade. | VT + Review MTC + Possible Destructive Testing (lab). | First, audit the MTC and markings. If doubt remains, cutting a sample for independent lab analysis is the definitive proof. |

| Checking for surface cracks after long-term storage. | VT + MT or PT. | If you suspect cracking from handling or environmental stress, MT or PT can confirm it. |

Our advice to clients in Vietnam, Mexico, and Saudi Arabia is this: For most marine angle steel deliveries, a thorough Visual and Dimensional inspection, backed by a valid PSI report, is sufficient. It balances cost, time, and risk effectively. The key is to perform these methods systematically, not casually. This leads us to the final tool: a concrete checklist.

What is the checklist of inspection?

A checklist turns a vague idea of "checking the steel" into a repeatable, foolproof process. Without one, your team might forget a critical step. I provided a simple checklist template to a new wholesaler in Thailand, and they told me it prevented them from accepting a shipment with mismatched heat numbers.

A marine angle steel inspection checklist should cover four areas: 1) Document Verification (MTC, packing list, PSI report), 2) Visual & Packaging Check, 3) Dimensional Measurement, and 4) Marking & Traceability. Using this checklist ensures no critical aspect is overlooked and provides a clear record for acceptance or claim.

Building and Using Your Custom Inspection Checklist

Your checklist should be a living document, tailored to your specific order and requirements. Here is a detailed breakdown of what to include.

Part 1: Document Verification (Do this first, before unloading)

- Mill Test Certificate (MTC): Received? Is it original/certified copy? Does the grade (e.g., ABS AH36) match the PO?

- MTC Details: Check heat number, chemical analysis, mechanical test results (yield, tensile, elongation), and impact test values (for D/E grades). Are they within specified limits?

- Packing List: Does it match the actual number of bundles and total weight?

- Pre-Shipment Inspection Report: If you ordered one, review it now. Compare its findings to what you see.

- Certificate of Origin: For customs clearance.

Part 2: Visual & Packaging Inspection

- Container/Truck Condition: Is it damaged? Is it dry inside?

- Packaging: Are bundles tightly strapped? Is waterproof paper intact? Is there proper blocking and bracing to prevent movement?

- Surface Condition: Is the mill scale uniform? Is there excessive red rust? Look for pitting, deep scratches, dents, or heavy corrosion.

- Straightness: Perform a visual "sight-along" check on sample pieces from several bundles. Is there obvious bending or twisting?

Part 3: Dimensional Inspection (Sampling)

Record measurements for [X] bundles, [Y] pieces per bundle.

- For each sample piece:

- Leg A Length: Ordered: __ mm. Measured: __ mm. Within Tolerance? (Y/N)

- Leg B Length: Ordered: __ mm. Measured: __ mm. Within Tolerance? (Y/N)

- Thickness (t): Ordered: __ mm. Measured (away from edge): __ mm. Within Tolerance? (Y/N)

- Overall Length: Ordered: __ m. Measured: __ m. Within Tolerance? (Y/N)

Part 4: Marking & Traceability

- Bundle Tags: Does the information on the bundle tag match the MTC and PO? (Heat No., Grade, Size).

- Piece Marking: Do individual pieces have painted/stamped markings? Do they match the bundle tags and MTC?

- Quantity Verification: Do the total number of bundles and pieces approximately match the packing list? (Perform a count).

Action & Sign-Off:

- Photos Taken: Have you taken clear photos of any damage, markings, and measurement setups?

- Non-Conformities Listed: Document any and all issues found in detail.

- Disposition: Based on findings, the inspector recommends: [ ] Accept [ ] Accept with Note [ ] Hold for Review [ ] Reject.

- Signatures: Inspector: ___ Date: __.

How to Use This Checklist Effectively:

- Customize it: Before the shipment arrives, fill in the "Ordered" dimensions and specific grade requirements.

- Train your team: Ensure the person doing the inspection understands how to use calipers and what the tolerances are.

- Document everything: Use the checklist as a worksheet. Attach photos to it. This packet becomes your objective evidence.

- Communicate immediately: If you find major issues, contact your supplier (like us) right away with the checklist and photos. A good supplier will want to solve the problem quickly.

For our clients who value communication and results, this checklist is more than paper. It is a risk management tool. It ensures the "stable quality" they expect is the quality they actually receive, closing the loop on the entire supply chain process from our mill in Shandong to their fabrication yard.

Conclusion

A rigorous delivery inspection—using defined methods and a detailed checklist—is your final and most important quality control. It verifies certification, condition, and dimensions, protecting your project from costly delays and ensuring your marine steel is ready for fabrication.