A shipyard in Vietnam recently confused bulb flat markings, causing installation errors. Understanding these markings prevents costly mistakes.

Bulb flat steel markings include grade designation, heat number, manufacturer identification, size specifications, and classification society stamps. These markings provide complete traceability and ensure the material meets required specifications for shipbuilding applications and regulatory compliance.

Proper interpretation of bulb flat markings is essential for quality assurance. Let me explain how to read and understand these important identifiers.

What is the HS code for bulb flat steel?

An importer from Saudi Arabia faced customs delays due to incorrect HS code classification. Understanding the proper codes streamlined their import process.

Bulb flat steel typically uses HS code 7216.50 as "other angles, shapes and sections" of iron or non-alloy steel. For alloy steel bulb flats, HS code 7228.70 applies, while specific ship applications may use 7301.10 for fabricated sections or 8906.00 for complete ship parts depending on the product form.

Comprehensive HS Code Classification Guide

HS code classification for bulb flat steel depends on material composition, processing level, and intended use. Proper classification ensures smooth customs clearance and correct duty assessment.

Primary Classification – HS 7216.50

Most bulb flat steel falls under HS code 7216.50. This category covers angles, shapes, and sections not elsewhere specified. The products must be of iron or non-alloy steel. The classification applies to hot-rolled products in straight lengths. This is the most common code for standard bulb flat shipments.

Alloy Steel Classification – HS 7228.70

Bulb flats made from alloy steel use different codes. HS 7228.70 covers other alloy steel angles and shapes. The classification requires specific alloy content thresholds. Common alloying elements include chromium, nickel, or molybdenum. The code applies to both hot-rolled and cold-formed products.

Fabricated Sections – HS 7301.10

Processed bulb flats may use alternative classifications. HS 7301.10 covers sheet piling and welded sections. This applies to bulb flats that are welded or otherwise fabricated. The classification depends on the level of processing before shipment. Cut-to-length sections typically remain under 7216.50.

Ship Parts Classification – HS 8906.00

Completed ship components have separate classification. HS 8906.00 covers ships’ and boats’ parts. This may apply to bulb flats processed into specific ship components. The classification requires substantial transformation from the basic product. Most raw bulb flats do not qualify for this code.

Country-Specific Variations

Importing countries may have additional requirements. The United States uses HTSUS codes with 10 digits. The European Union employs the Combined Nomenclature system. China has 13-digit codes for detailed classification. Importers must verify destination country specifications. Using wrong codes causes customs delays and penalties.

Documentation Requirements

Proper classification requires accurate documentation. Commercial invoices must describe the product completely. Certificates of origin confirm the material source. Technical specifications help customs officers verify classification. Incorrect or incomplete descriptions lead to classification errors.

HS Code Application Guide

| Product Description | HS Code | Required Documentation | Special Notes |

|---|---|---|---|

| Standard Bulb Flat | 7216.50 | Commercial invoice, packing list | Most common classification |

| Alloy Bulb Flat | 7228.70 | Chemical analysis certificate | Verify alloy content |

| Processed Sections | 7301.10 | Manufacturing process description | For welded or fabricated products |

| Ship Components | 8906.00 | End-use certificate | For finished ship parts |

| Custom Products | Varies | Detailed technical specifications | Case-by-case determination |

We provide correct HS code guidance to all international clients. Their shipments experience smooth customs clearance with proper documentation.

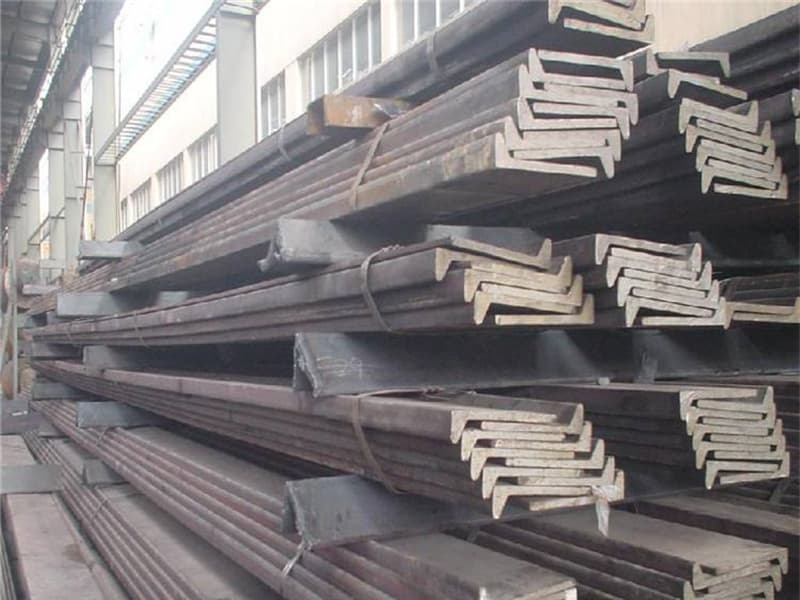

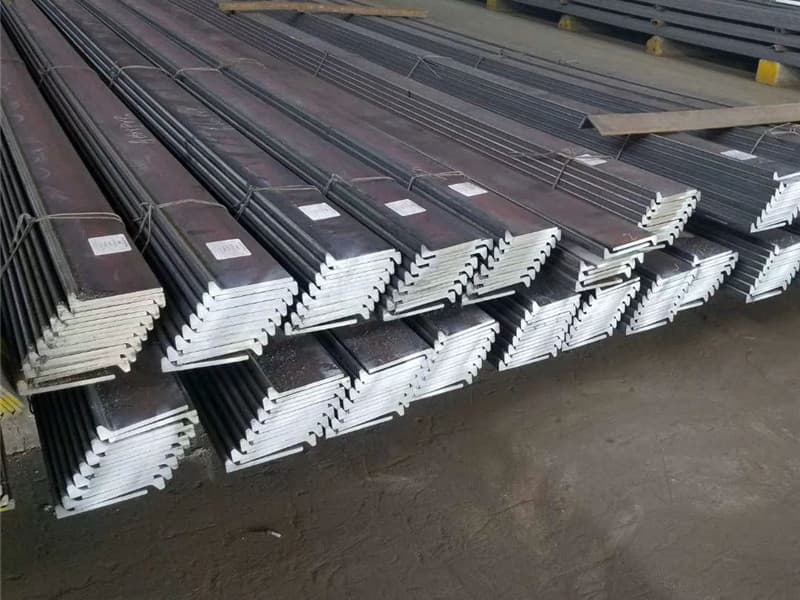

What sizes does flat steel come in?

A fabricator from Mexico needed to understand standard flat steel sizes for their structural calculations. Knowing available dimensions optimized their design efficiency.

Flat steel is available in widths from 20mm to 300mm and thicknesses from 3mm to 50mm, with standard sizes including 25x3mm, 50x6mm, 75x10mm, 100x12mm, and 150x16mm. Bulb flat steel adds bulb dimensions with standard series like 200×10, 250×12, and 300x14mm following international standards.

Comprehensive Size Specifications and Applications

Flat steel sizes follow established standardization that ensures material availability and design consistency. Understanding these sizes helps in proper material selection and procurement planning.

Standard Flat Bar Dimensions

Regular flat bars follow predictable size progressions. Widths typically increase in 5mm increments from 20mm to 100mm. From 100mm to 300mm, 10mm or 25mm increments are common. Thickness progressions usually follow 3, 4, 5, 6, 8, 10, 12, 16, 20, 25, 30, 40, and 50mm. These standardized sizes ensure wide availability from multiple suppliers.

Bulb Flat Steel Size Series

Bulb flats have additional dimensional parameters beyond basic flat bars. The size designation typically indicates web height and thickness. Common series include 200×10, 220×11, 250×12, 280×13, and 300x14mm. The bulb dimensions are proportional to the web size. Standardization ensures consistent section properties across manufacturers.

Length Standards and Variations

Standard lengths facilitate transportation and fabrication. 6 meters serves as the most common standard length. 9 meters and 12 meters are also widely available for larger projects. Length tolerances typically allow ±100mm variation for cutting allowances. Custom lengths are possible but may incur additional costs and longer lead times.

Weight Calculations and Implications

Standard sizes enable accurate weight estimation for logistics planning. Weight per meter depends on width, thickness, and bulb dimensions. For example, a 250×12 bulb flat weighs approximately 36.5 kg/m. These calculations help in transportation planning, cost estimation, and structural design considerations.

Tolerance Standards by Specification

International standards define acceptable dimensional variations. Width tolerances typically range from ±1mm for smaller sizes to ±3mm for larger sections. Thickness tolerances vary from ±0.3mm for thin sections to ±1.0mm for thicker materials. Straightness tolerances ensure the material suits fabrication requirements without excessive straightening.

Regional Size Preferences

Different markets may prefer specific size ranges. European standards follow strict metric dimensions. American standards sometimes use inch-based sizing with metric equivalents. Asian standards often follow Japanese or European practices. Understanding regional preferences helps in material sourcing for specific markets.

Common Flat Steel Size Applications

| Size Range | Typical Sizes | Common Applications | Weight Range (kg/m) |

|---|---|---|---|

| Small | 20×3 to 50×6 | Brackets, supports | 0.5 – 2.5 |

| Medium | 55×6 to 100×12 | Framing, connections | 2.6 – 9.5 |

| Large | 105×10 to 200×16 | Beams, heavy supports | 8.5 – 25.0 |

| Bulb Flats | 200×10 to 300×14 | Ship stiffeners, piling | 25.0 – 45.0 |

| Special | Custom sizes | Unique applications | Varies |

We maintain comprehensive size inventories to meet diverse client needs. Projects in Philippines and Thailand benefit from standard size availability and reliable supply.

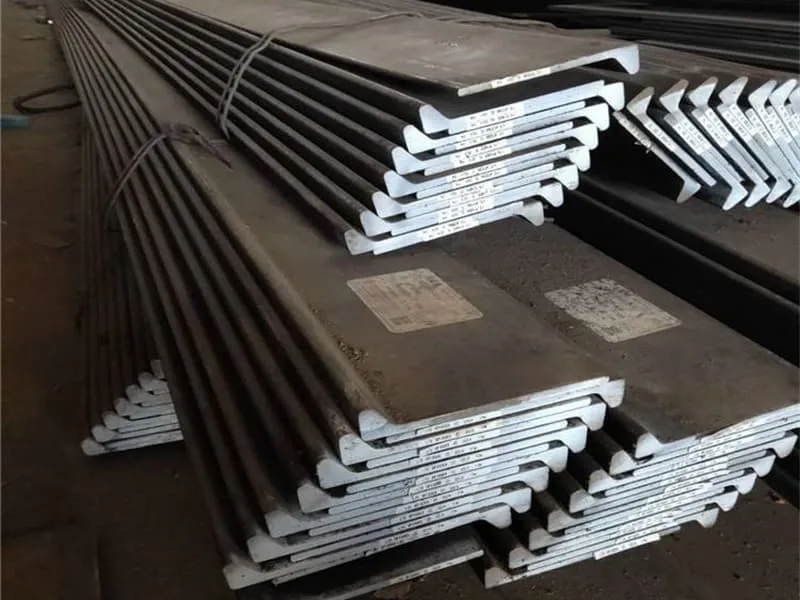

What is a bulb flat?

A naval architect from Romania asked about bulb flat applications in their new vessel design. Understanding the profile’s advantages informed their structural decisions.

A bulb flat is a steel profile with a flat web and a bulb-shaped tip, designed to provide maximum section modulus with minimal weight. This unique shape offers superior strength-to-weight ratio compared to standard flat bars, making it ideal for longitudinal stiffeners in ship hulls and other applications requiring efficient structural reinforcement.

Bulb Flat Profile Characteristics and Advantages

The bulb flat profile represents an optimized structural shape that delivers exceptional performance in specific applications, particularly in shipbuilding and marine structures.

Profile Geometry and Design

The bulb flat combines a rectangular web with a semicircular bulb. The web provides the primary vertical dimension for stiffness. The bulb adds significant material at the extreme fiber where stress is highest. This configuration maximizes the section modulus, which determines bending resistance. The shape evolved through structural optimization studies.

Manufacturing Process

Bulb flats are typically hot-rolled in specialized mills. The process involves passing heated steel billets through shaped rolls. The rolls gradually form the bulb and web geometry. Controlled cooling ensures consistent mechanical properties. Some manufacturers offer asymmetric bulbs for specific applications. The process requires precise temperature and pressure control.

Structural Efficiency

The bulb flat’s design provides exceptional structural efficiency. The bulb placement maximizes the moment of inertia. This allows smaller sections to carry equivalent loads compared to flat bars. Weight savings can reach 20-30% for equivalent strength. The efficiency reduces material costs and vessel weight.

Marine Applications

Shipbuilding represents the primary application for bulb flats. They serve as longitudinal stiffeners in hull construction. The profile reinforces plates against water pressure. Bulb flats work in bottom structures, side shells, and decks. Their efficiency supports larger unsupported spans between frames. This reduces the number of transverse frames required.

Connection and Fabrication

Bulb flats offer good fabrication characteristics. The flat web surface facilitates welding to plates. The bulb provides natural alignment during assembly. Standard cutting and drilling methods work effectively. The shape accommodates common connection details. These features simplify construction and reduce labor costs.

Alternative Applications

Beyond shipbuilding, bulb flats serve other industries. Offshore platforms use them as bracing members. Bridge construction employs them in certain deck systems. Heavy industrial structures utilize their efficient shape. The applications leverage the profile’s strength-to-weight advantages.

Bulb Flat Advantage Analysis

| Characteristic | Bulb Flat | Equivalent Flat Bar | Advantage |

|---|---|---|---|

| Section Modulus | High | Lower | Better bending resistance |

| Weight | Lower | Higher | Material savings |

| Fabrication | Good | Excellent | Slightly more complex |

| Availability | Specialized | Widely available | Requires specific sourcing |

| Cost | Higher per kg | Lower per kg | Better value per strength |

We supply bulb flats to shipyards across our export markets. Clients appreciate the structural efficiency and performance benefits.

What is a bulb bar?

A contractor from Qatar confused bulb bars with other steel sections. Clarifying the terminology prevented specification errors in their project.

A bulb bar is another term for bulb flat steel, referring to the same profile with a flat web and bulb-shaped tip. The terminology varies by region and industry, with "bulb bar" commonly used in European standards while "bulb flat" predominates in Asian and American contexts for the identical structural steel section used in shipbuilding.

Bulb Bar Terminology and Regional Variations

The terminology for bulb-shaped steel sections varies across different markets and standards organizations. Understanding these variations prevents confusion in international projects.

Terminology Origins and Evolution

The term "bulb bar" originated in European maritime industries. It describes the bulb-like appearance at the section’s tip. "Bulb flat" became popular in American and Asian markets. Both terms refer to identical products with the same dimensional and mechanical properties. The terminology difference reflects regional language preferences rather than technical distinctions.

Standard Designations

Different standards organizations use varying terminology. DIN standards typically use "bulb flat" (Grundflachstahl). JIS standards employ similar terminology. British standards may use both terms interchangeably. Classification societies like ABS and LR primarily use "bulb flat." The underlying technical requirements remain consistent across terminology variations.

Regional Usage Patterns

Geographical patterns influence terminology preference. European suppliers often use "bulb bar" in documentation. American and Asian manufacturers prefer "bulb flat." International projects may encounter both terms. Understanding this variation helps in interpreting specifications and documentation from different sources.

Technical Specification Consistency

Despite terminology differences, technical specifications remain consistent. Dimensional standards follow international norms. Mechanical properties meet classification society requirements. Testing and certification processes are identical. The performance characteristics do not vary with terminology.

Documentation and Communication

Proper communication requires understanding both terms. Purchase orders should specify the preferred terminology. Technical drawings should use consistent terminology. Suppliers should confirm understanding of requirements. Clear communication prevents misunderstandings in international transactions.

Industry Adoption Trends

The industry shows movement toward standardized terminology. "Bulb flat" appears to be gaining wider international acceptance. New standards increasingly use this terminology. However, both terms remain in active use. Professionals should recognize and understand both expressions.

Terminology Comparison Table

| Term | Common Usage Regions | Standard References | Industry Preference |

|---|---|---|---|

| Bulb Flat | Asia, Americas | ABS, JIS, DIN | Increasing globally |

| Bulb Bar | Europe, Middle East | Some European standards | Traditional maritime |

| Bulb Plate | Occasionally used | Rare in standards | Limited usage |

| Bulb Angle | Incorrect usage | Not applicable | Misnomer to avoid |

We ensure clear communication with all international clients. Our documentation uses terminology appropriate for each market while maintaining technical accuracy.

Conclusion

Understanding bulb flat steel markings, specifications, and terminology ensures proper material selection and application. This knowledge supports quality assurance and efficient project execution in shipbuilding and structural applications.