Choosing steel for a marine project is not a simple task. The wrong choice can lead to premature failure, costly repairs, and safety risks. I’ve consulted on projects where material selection made the difference between a structure lasting decades or just a few years.

Selecting the right steel for marine engineering requires analyzing the specific environment (splash, immersion, atmospheric), mechanical loads, required toughness at operating temperatures, and balancing performance with budget. For primary structures, certified marine carbon steel (like ABS AH36) is standard; for high-corrosion areas, stainless steel (316) or duplex steels are considered. A systematic approach ensures durability and value.

For engineers, project managers, and procurement specialists, this decision is foundational. A methodical selection process protects your investment. This guide will walk you through key questions and comparisons, starting with the broadest one: what is the best steel for marine use?

What is the best steel for marine use?

There is no single "best" steel for all marine applications. The best material is the one that most precisely matches the service conditions and performance requirements of your specific project. Using a high-cost stainless steel for a submerged piling is wasteful, while using mild steel for a deck fitting leads to rapid failure.

The best steel for marine use depends on the application. For load-bearing hull structures, high-strength marine carbon steel1 like ABS AH362 or DNV NV A36 offers the optimal balance of strength, toughness, and cost. For corrosion-resistant fittings and hardware, stainless steel 3163 is superior. For specialized applications like heat exchangers, copper-nickel alloys4 or titanium may be best. The selection is always application-driven.

A Framework for Selecting the Optimal Material

To find the "best" steel, you must define the problem it needs to solve. Let’s break down the marine environment into zones and match materials to them.

1. The Structural Zone (Hull, Frames, Supports):

- Primary Need: High strength, good toughness, excellent weldability, fatigue resistance.

- Environment: Often coated and protected by cathodic protection (sacrificial anodes). Still exposed to a corrosive atmosphere.

- Best Steel: Marine-grade carbon steel. Grades like AH36 (355 MPa yield) or DH36 (355 MPa yield with enhanced toughness at -20°C) are industry standards. They are certified by classification societies (ABS, DNV) to ensure quality.

- Why it’s best: It provides the necessary structural performance at a fraction of the cost of stainless steel. Corrosion is managed through protective systems, not the base material.

2. The Splash & Atmospheric Zone (Deck Hardware, Railings):

- Primary Need: Extreme corrosion resistance, low maintenance, good appearance.

- Environment: Constant wet/dry cycles with salt, high oxygen exposure (most corrosive).

- Best Steel: Austenitic Stainless Steel, typically Grade 316. For less critical or interior applications, Grade 304 may suffice.

- Why it’s best: The chromium (and molybdenum in 316) creates a passive layer that resists saltwater corrosion. It maintains its appearance with minimal upkeep.

3. The Fully Submerged Zone (Piling, Subsea Structures):

- Primary Need: Corrosion resistance (often combined with cathodic protection), resistance to marine growth.

- Environment: Constant immersion, lower oxygen levels.

- Best Steel: Often marine carbon steel1 with robust coatings and anode systems. For critical unmanned components, duplex stainless steels5 or nickel-copper alloys like Monel may be used.

- Why it’s best: Carbon steel is cost-effective for large-scale submersion when combined with engineering protection systems. Exotic alloys are reserved for high-reliability, difficult-to-maintain parts.

Selection Matrix for Common Marine Projects:

| Project Component | Environment | "Best" Steel Choice | Key Reason |

|---|---|---|---|

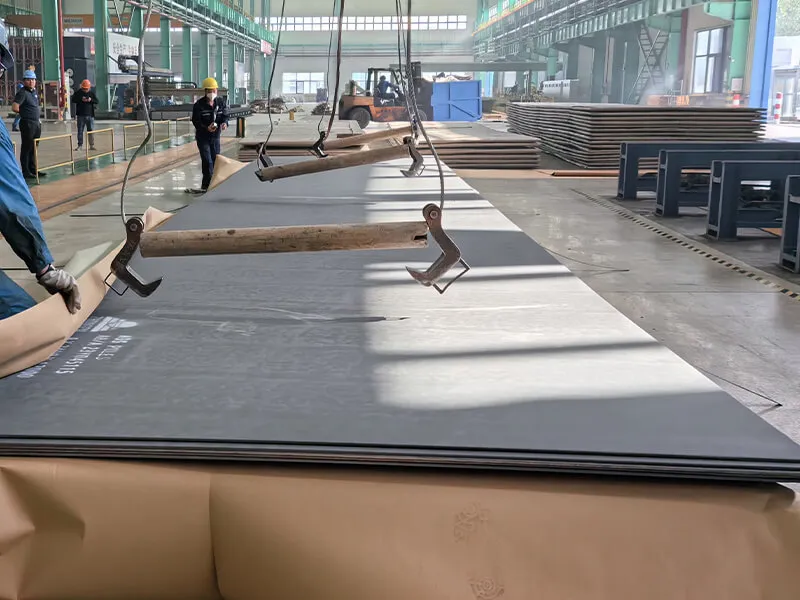

| Ship Hull Plate | Immersed/Splash, Structural | ABS AH362/DH36 Plate | Certified strength & toughness; cost-effective for primary structure. |

| Offshore Platform Leg | Splash/Immersed, Structural | API 2H Grade 506 or DH36 | High strength for waves, with required toughness. Protected by coatings/anodes. |

| Port Jetty Walkway Handrail | Atmospheric/Splash, Non-structural | Stainless Steel 316 | Maximum corrosion resistance for safety and low maintenance. |

| Seawater Pump Casing | Fully immersed, Wear | Cast Bronze or Duplex Stainless | Combines corrosion resistance with erosion resistance. |

| Coastal Building Structural Frame | Coastal Atmospheric, Structural | Hot-dip galvanized carbon steel or Weathering Steel (A588) | Balanced cost and corrosion protection for an atmospheric environment. |

For a rational decision-maker, the "best" steel is the one that delivers the required service life at the lowest total lifecycle cost. This often leads to questions about specific stainless grades, like 304.

Is 304 stainless steel ok for marine use?

This is a common and important question. The short answer is: it depends on the exposure and your expectations. I’ve seen 304 stainless used successfully on boat interiors but fail rapidly on exterior deck fittings in the Middle East. The environment dictates the answer.

Grade 304 stainless steel1 can be acceptable for marine use in mild, sheltered, or intermittent exposure conditions, such as indoor boat fittings or galley equipment. However, for continuous exposure to salt spray, splash zones, or submerged applications, Grade 304 is prone to pitting and crevice corrosion2. In these harsh marine environments3, Grade 3164 is the recommended and much more reliable choice. The added molybdenum5 in 316 makes the critical difference.

Understanding the Limitations of 304 in a Saltwater Environment

Both 304 and 316 are "austenitic" stainless steels, but their chemical difference has a major impact on performance.

The Chemistry Difference:

- 304 (18/8 Stainless): Contains 18% Chromium and 8% Nickel. Chromium provides the basic corrosion-resistant oxide layer.

- 316: Contains 16-18% Chromium, 10-14% Nickel, and 2-3% Molybdenum. This molybdenum5 (Mo) is the key.

Role of Molybdenum:

Molybdenum significantly increases stainless steel’s resistance to pitting and crevice corrosion2, which are the primary failure modes in chloride-rich environments like seawater. Chloride ions can break down the passive layer on 304, leading to localized deep pits.

Practical Guidelines for Using 304 in Marine Contexts:

Where 304 Might Be Acceptable (Lower Risk):

- Interior Applications: Cabinetry, trim, non-structural parts inside a vessel or coastal building where salt accumulation is minimal.

- Temporary or Low-Exposure Items: Tools, equipment used intermittently and washed down.

- Aesthetic Features in Sheltered Areas: Where appearance is key and the environment is controlled (e.g., indoors, under cover).

Where You Should Avoid 304 (High Risk):

- Deck Hardware: Cleats, railings, stanchions, ladders.

- Fasteners in Exposed Locations: Bolts, screws holding down exterior components.

- Piping Carrying Seawater.

- Any component in the constant splash zone or subject to salt spray.

Consequences of Using 304 Where 316 is Needed:

You might see rust stains, pitting, and eventually, component failure. This is not just cosmetic; it can compromise structural integrity (e.g., a railing post) or cause leaks (e.g., in a fitting).

Recommendation for Project Specifiers:

For any exterior, permanently installed marine component, specify 316 or 316L as the default. The small additional material cost is insignificant compared to the cost of replacement, repair, or liability from failure. This leads directly to the next question: is 316 considered a true "marine grade"?

Is 316 steel marine grade1?

The term "marine grade1" can be confusing. In the context of stainless steel for fittings and hardware, 316 is universally accepted as the standard "marine-grade stainless steel2." However, in the context of primary hull structural steel, "marine grade1" refers to carbon steels like AH36. A supplier once tried to sell us "marine grade1 316 angles" for ship frames, which was a fundamental misunderstanding of the terms.

Yes, for stainless steel applications, AISI 3163 (and its low-carbon variant 316L) is considered the standard marine-grade stainless steel2 due to its addition of molybdenum, which provides superior resistance to pitting and crevice corrosion4 in chloride (saltwater) environments compared to grade 304. It is the default choice for exposed marine fittings, railings, and hardware, but it is not used for primary hull structures due to cost and different mechanical properties.

Defining "Marine Grade" in Two Contexts

Clarifying this terminology is crucial for clear communication in projects.

1. Marine Grade for Structural Steel (Hulls, Offshore):

- Refers to: Carbon and low-alloy steels certified to classification society rules (ABS, DNV, etc.).

- Examples: ABS Grade AH36, DNV NV D36, EN 10025 S355G7+N.

- Primary Property: Certified yield strength, toughness, and weldability.

- Cost: Relatively low.

2. Marine Grade for Corrosion-Resistant Alloys (Fittings, Hardware):

- Refers to: Stainless steels and other alloys selected for corrosion resistance5.

- Examples: AISI 3163/316L, Duplex 2205, Aluminum 5083-H116.

- Primary Property: Resistance to pitting, crevice, and stress corrosion cracking.

- Cost: Significantly higher than structural carbon steel.

Why 316 is the Marine-Grade Stainless Champion:

- Proven Performance: Decades of use in marine environments have proven its reliability.

- Availability: It is widely produced and available in all standard forms (sheet, plate, bar, tube, fittings).

- Fabricability: It can be welded, machined, and formed, though it requires procedures different from carbon steel.

Limitations and Advanced Options:

Even 316 has limits. In warm, stagnant seawater with high chloride content, or under applied stress, it can still suffer from corrosion.

- For More Demanding Applications: Duplex Stainless Steels6 (e.g., 2205, 2507) offer roughly twice the yield strength of 316 and even better corrosion resistance5, especially to chloride stress corrosion cracking. They are used in offshore oil & gas, desalination plants, and chemical tankers.

- For Extreme Conditions: Super Duplex and 6% Molybdenum Austenitic Steels (e.g., 254 SMO) are used.

Application Guide for 316 Stainless Steel:

| Application | Suitability of 316 | Notes |

|---|---|---|

| Deck Railings & Hardware | Excellent | The standard choice. Ensure good drainage to avoid crevices. |

| Boat Fittings (Cleats, Pulleys) | Excellent | Standard for quality marine hardware. |

| Seawater Piping (Flow-through) | Good, but not ideal for stagnant flow. | For flowing seawater; stagnant conditions can cause pitting. Copper-nickel is often preferred. |

| Propeller Shaft | No. Requires higher strength. | Special high-strength stainless alloys or bronze are used. |

| Hull Plating for a Yacht | Theoretically possible, but economically impractical. | Cost would be astronomical compared to marine aluminum or fiberglass. |

Understanding that 316 is a type of stainless steel, which is one of the four main steel categories, helps place it in the broader material universe.

What are the 4 types of steel?

Knowing the four basic families of steel is essential for any technical buyer or specifier. It provides the foundational language for material selection. A project manager in the Philippines was reviewing a bill of materials that listed "steel" without qualification; we had to clarify whether it was carbon, alloy, or stainless.

The four fundamental types of steel are Carbon Steel1, Alloy Steel2, Stainless Steel3, and Tool Steel4. They are classified by their chemical composition: Carbon steel is primarily iron and carbon; Alloy steel adds other elements for strength; Stainless steel has over 10.5% chromium for corrosion resistance; Tool steel is very hard for cutting and forming. Marine engineering5 primarily uses carbon and stainless steels.

A Detailed Overview for Engineering Selection

Each type serves distinct purposes. Placing your marine component in the right category is the first step to narrowing down choices.

1. Carbon Steel1

This is the most common and cost-effective type. It is primarily iron with carbon as the key alloying element.

- Subcategories:

- Low Carbon (Mild Steel): 0.6% C. Very hard, brittle. Used for springs, blades.

- Marine Use: Marine-grade steels6 like AH36 are High-Strength Low-Alloy (HSLA)7 carbon steels. They have tiny, precise additions of elements like Niobium but are fundamentally carbon steels, designed for hull strength and toughness.

2. Alloy Steel2

Carbon steel with significant additions (>1%) of elements like Chromium, Nickel, Molybdenum, or Vanadium.

- Purpose: To enhance specific properties: hardenability, strength, wear resistance.

- Example: 4140 steel (Chromium-Molybdenum). Used for high-strength shafts, gears, and landing gear in aviation.

- Marine Use: Used in high-stress machinery components in the engine room (crankshafts, gears), not typically for hull structure.

3. Stainless Steel3

Defined by a minimum 10.5% Chromium, which forms a passive corrosion-resistant layer.

- Key Families:

- Austenitic (300 series): Non-magnetic, excellent corrosion resistance. 304 and 316 belong here.

- Ferritic (400 series): Magnetic, less corrosion resistant, cheaper.

- Martensitic (400 series): Magnetic, can be hardened, used for cutlery.

- Duplex: Mixed austenitic-ferritic structure; very high strength and corrosion resistance.

- Marine Use: 316 austenitic for fittings; Duplex grades for demanding offshore/chemical applications.

4. Tool Steel4

Very high carbon and alloy content (Tungsten, Cobalt, Vanadium) for extreme hardness and wear resistance.

- Use: Cutting tools, dies, molds.

- Marine Use: Essentially none in ship structure; used in shipyard workshops for fabrication tools.

Quick-Reference Comparison Table:

| Steel Type | Key Elements | Primary Property | Cost Relative to Mild Steel | Marine Engineering Example |

|---|---|---|---|---|

| Carbon Steel1 (e.g., A36, AH36) | Fe, C, Mn | Strength, Toughness, Weldability | 1x (Base) | Ship hull, frames, offshore platform jacket. |

| Alloy Steel2 (e.g., 4140) | Fe, C, Cr, Mo | High Strength, Hardenability | 2x – 4x | Propulsion system shafts, turbine blades. |

| Stainless Steel3 (e.g., 316) | Fe, Cr (min 10.5%), Ni, Mo | Corrosion Resistance | 5x – 10x | Deck railings, pumps, valves, chemical tank linings. |

| Tool Steel4 | Fe, High C, W, Co, V | Extreme Hardness | 10x+ | Cutting tools in fabrication shop. |

For a marine engineer, the practical world largely involves Carbon Steel1 for the main structure and Stainless Steel3 for corrosion-critical appendages. A complete supplier understands this and can provide the right material from the right category, along with the necessary certification (like SGS reports for carbon steel or mill test certs for stainless), to ensure your project is built on a foundation of correct, reliable materials.

Conclusion

Selecting the right steel for marine projects is a systematic process: use certified marine carbon steel (AH36/DH36) for primary structures, specify 316 stainless for corrosion-prone fittings, understand material limitations (like 304 in salt spray), and apply knowledge of the four basic steel types to make informed, durable, and cost-effective choices.

-

Explore this link to understand the versatility and applications of Carbon Steel in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about Alloy Steel’s unique properties and how it enhances performance in demanding applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the various types of Stainless Steel and their specific uses, especially in marine engineering. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how Tool Steel is essential for manufacturing cutting tools and its significance in fabrication. ↩ ↩ ↩ ↩ ↩ ↩

-

Delve into the materials crucial for Marine engineering and how they impact design and safety. ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the importance of Marine-grade steels in ensuring durability and safety in marine structures. ↩ ↩ ↩

-

Explore HSLA steel’s properties and why it’s preferred for marine applications requiring strength. ↩