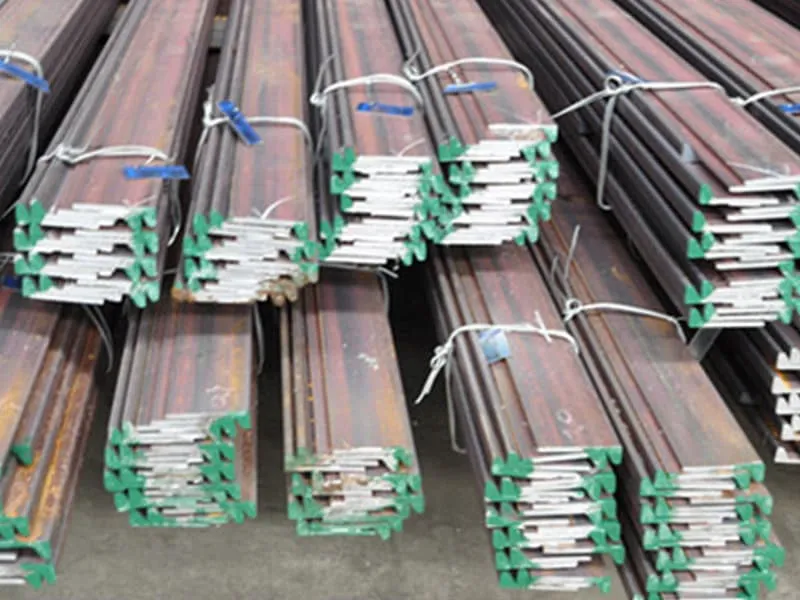

You have just received a large shipment of bulb flat steel for a new vessel. The material is expensive and critical. Poor storage causes corrosion and warping. Incorrect handling leads to damage and safety hazards. How do you protect your investment and keep the project on schedule?

Proper storage and handling of bulb flat steel require flat, dry ground with timber supports, organized stacking by size, and mechanical lifting with spreader beams. You must protect the bulb from impact, prevent moisture traps, and follow strict yard safety protocols to maintain material integrity for ship construction.

A single bent or corroded bulb flat can disrupt your production line and cost thousands in replacement and delays. Based on my experience supplying to shipyards across Asia and the Middle East, I will share practical methods that work. These methods cover why this steel is special, how to manage its dimensions, and how to avoid common mistakes with simpler flat bars.

What are bulb flats used for?

Imagine building a ship’s skeleton that must withstand ocean waves for decades. You need frames that are strong but lightweight, easy to weld, and resistant to buckling. This is the exact problem bulb flat steel1 is designed to solve in modern shipbuilding.

Bulb flat steel is primarily used as longitudinal stiffeners2 and frames in ship hulls. The bulb at the edge provides extra strength against buckling, allowing for lighter structures, easier welding, and more efficient use of space in double-bottom tanks and side shells.

The Critical Role of Bulb Flats in Marine Structures

To understand their importance, we need to look at their specific functions compared to other profiles. The unique design of bulb flats makes them ideal for key areas of a vessel.

| Primary Application | How It Functions | Why Bulb Flats Are Chosen | Typical Specifications & Grade |

|---|---|---|---|

| Longitudinal Stiffeners | Attached to the hull plating (bottom, sides, deck) to increase rigidity and prevent plate buckling under load. | The bulb provides high section modulus3 with less weight. Its flat web allows for full-length fillet welding to the plate, creating a strong bond. | Sizes like 200 x 10 mm to 400 x 15 mm. Grades: AH32, AH36, DH36 for high strength and good toughness. |

| Side Frame Members | Forms the vertical framing in cargo holds and ballast tanks. | Offers excellent torsional stiffness4. The smooth profile reduces surfaces where mud or corrosion can accumulate, which is vital for tank coatings. | Often used in larger sections. Requires good weldability and corrosion resistance per ASTM A131. |

| Double Bottom Construction | Used as floors and girders in the double-bottom space. | The shape provides maximum strength in a confined space. This optimizes the ballast water volume. | Must meet strict classification society rules (ABS, DNV, LR) for internal structures. |

| Offshore Platform Legs | Used as stiffeners on jacket legs and bracings. | Performs well under cyclic loading from waves. The design is efficient for resisting high compressive forces. | Demands higher grades like EH36/EH40 with enhanced toughness for cold environments. |

I recall a project with a shipyard in Qatar. They were constructing a series of bulk carriers. Their engineers chose bulb flats over traditional T-sections for the inner hull longitudinals. The reason was clear. The bulb flat’s design gave them a 5% weight saving per vessel without sacrificing strength. This weight saving directly increased the ship’s cargo capacity. However, they faced an issue during initial storage. Some bulbs were dented because workers used slings incorrectly. This taught us all that understanding a material’s function is not enough. You must also handle it with the right techniques to preserve that function. Proper storage with the bulb facing up and careful lifting are not just good practice; they are essential to maintain the structural properties you paid for.

What size are flat steel sections?

When you order bulb flats, you are not just ordering "steel." You are ordering a precise engineering component. The size directly determines its strength, weight, and where it can be used in the ship’s design. Getting the size wrong is not an option.

Bulb flat steel sizes1 are standardized by classification societies and defined by two main dimensions: the total height (from the base to the top of the bulb) and the web thickness. Common heights range from 100mm to 400mm, with thicknesses from 6mm to 20mm or more, depending on the structural requirement.

Navigating Bulb Flat Size Standards and Selection

The size is more than just numbers. It involves a system of standards, tolerances, and design choices. Here is a breakdown to guide you.

| Dimension & Standard | Description & Measurement | Importance for Storage & Handling | Common Size Examples by Region |

|---|---|---|---|

| Nominal Height (h)2 | The total height of the profile, measured from the bottom of the base to the top of the bulb. | Determines the stacking stability. Taller sections need wider timber support to prevent tipping. It also affects the required lifting beam length. | European Yards (LR/DNV): 180, 220, 280, 350 mm. Asian Yards (CCS/ABS): 200, 250, 300, 400 mm. |

| Web Thickness (t)3 | The thickness of the vertical flat section (the web). This is a critical factor for strength. | Thicker webs are heavier and more rigid. They are less prone to bending during handling but require greater lifting capacity. | Ranges from 8 mm (for lighter stiffeners) to 18 mm (for primary hull frames). |

| Bulb Dimensions4 | The bulb itself has a defined height and width, which contributes significantly to the profile’s strength. | The bulb is the most vulnerable part to impact damage. Storage and lifting must protect this rounded edge from direct contact with hard surfaces or chains. | Standardized per profile series (e.g., HP series). |

| Length (L)5 | Standard mill lengths are usually 6m, 12m, or as per project purchase order. | Dictates storage space requirements. Long lengths (12m+) need continuous, level support along their entire length to prevent sagging over time. | Typically 12 meters for shipbuilding to reduce welded joints in long stiffeners. |

| Manufacturing Tolerances6 | Standards (like EN 10067) define allowed variations in height, thickness, straightness, and twist. | During inspection, you must check these. A section with excessive camber (bow) is hard to fit and may need to be rejected. This is why you check before storage. | Straightness tolerance is strict, e.g., max 3mm bow over a 3m length. |

A client in Vietnam once received a shipment where the 300x12mm bulb flats were mixed with 280x12mm ones in the same bundle. The visual difference was small, but the mix-up caused a full day of production stoppage. Since then, we enforce a strict protocol: every bundle is clearly tagged with size, heat number, and grade. In the storage yard, we advise our clients to segregate different sizes into marked zones. This is not just about organization. Using a 280mm section where a 300mm is designed can compromise the vessel’s structural strength. Always verify the stamped or painted markings on each piece against the Mill Test Certificate and your packing list as the first step when the steel arrives at your yard.

What are bulb bar1s?

You might hear the terms "bulb flat2," "bulb bar1," and "bulb plate3" used in shipyards. Sometimes people use them to mean the same thing. However, in precise technical language and procurement, understanding the subtle differences can prevent confusion.

A "bulb bar1" is essentially another name for a "bulb flat2." It is a steel profile with a flat web and a bulb (rounded thickening) at one edge. The term "bar" emphasizes its role as a long, linear stiffening member, much like a reinforcement bar in concrete.

Terminology and Its Impact on Procurement and Standards

The different names can be linked to regional preferences, historical usage, and specific standards. Knowing this helps when reading drawings or talking to international teams.

| Terminology | Common Usage & Context | Key Standards & Specifications | Why the Distinction Matters |

|---|---|---|---|

| Bulb Flat | This is the most common and technically precise term in international shipbuilding. It describes the shape clearly: a flat with a bulb. | ASTM A131 / EN 10225: Standards for shipbuilding steel. Classification Rules (ABS, DNV): Define the required dimensions and properties. |

When you order "bulb flat2s," mills and suppliers understand the exact product. It leaves little room for misinterpretation. |

| Bulb Bar | Often used interchangeably with "bulb flat2." The word "bar" is a generic term for long steel products (like angle bar, round bar). | May appear in older shipyard documents or certain regional specifications (e.g., some Asian shipyards). | If a drawing says "bulb bar1," you must cross-reference the size table. It is safe to assume it means a bulb flat2. |

| Bulb Plate | This term is less common and can be ambiguous. It might incorrectly suggest a wide plate with a bulb, which is a different product. | Rarely used in modern technical specs. Could cause confusion. | To avoid errors, clarify with the designer. Do not assume "bulb plate3" is the same as "bulb flat2." |

| HP (High Perpendicular) Profile4 | This is an older European designation (e.g., HP 180 x 10). The "HP" refers to the profile’s high moment of inertia perpendicular to the web. | Found in legacy designs or specific naval architecture textbooks. | Modern orders use dimensional sizing (300x12mm), but you may need to translate old HP codes. |

| Technical Definition | A rolled steel section with a symmetrical or asymmetrical bulb at one end of a flat web. The bulb increases the section modulus efficiently. | The geometry is mathematically defined to provide optimal strength-to-weight ratio for stiffening. | This engineering principle is why bulb flat2s are preferred over simple flat bars for critical applications. |

I worked with a new project manager from Romania who was confused by his drawing. It listed materials as "bulb bar1s." He asked me if this was a different product from the "bulb flat2s" in his cost estimate. I assured him they were the same. We then confirmed the sizes (220 x 9mm, grade DH32) and the relevant DNV standard. This small clarification sped up his purchasing process. The lesson is simple. Do not let terminology slow you down. Focus on the key parameters5: the drawn dimensions, the required steel grade, and the classification society approval. Whether your paperwork says "bulb flat2" or "bulb bar1," these three parameters must be crystal clear and match the material you receive and store.

What are the disadvantages of a flat bar?

Why don’t shipbuilders just use simple, cheap flat bars for all stiffeners? This is a logical question. The answer lies in the significant engineering trade-offs. Using a flat bar where a bulb flat is designed can weaken the ship’s structure.

The main disadvantages of using a flat bar as a stiffener are lower bending resistance1 (section modulus), higher weight for the same strength2, and a sharper edge that is harder to weld3 effectively and more prone to causing coating breakdown, leading to corrosion.

A Detailed Comparison: When a Flat Bar Fails

To make an informed material choice, you need a clear, side-by-side comparison. The following table details why bulb flats are the superior technical choice for most ship stiffening applications.

| Disadvantage of Flat Bar | Technical Explanation | Consequence in Shipbuilding | How Bulb Flat Solves the Problem |

|---|---|---|---|

| Low Section Modulus | A flat bar’s strength in bending is proportional to the square of its height. To match a bulb flat’s strength, you need a much taller and heavier flat bar. | This leads to increased steel weight, reducing cargo capacity. Or, it results in a weaker structure if the same height is used. | The bulb adds material at the furthest point from the neutral axis, dramatically increasing the section modulus with minimal added weight. |

| Inefficient Material Use | Achieving strength requires more cross-sectional area (more steel). This is not cost-efficient. | Higher material cost and increased fuel consumption for the vessel over its lifetime due to extra weight. | Provides maximum strength from a minimum amount of steel, optimizing both cost and vessel performance. |

| Poor Weld Profile | The 90-degree corner where a flat bar meets a plate creates a sharp, re-entrant angle. Welding here can lead to stress concentration and potential crack initiation. | Creates a fatigue-sensitive detail, which is risky in areas under high cyclic stress (like the hull). | The bulb’s rounded transition to the web allows for a smoother weld toe. This reduces stress concentration and improves fatigue life. |

| Coating & Corrosion Issues | The sharp corner is difficult to coat properly. Paint tends to pull away, leaving a thin layer. Moisture and dirt trap easily. | Leads to premature corrosion4 at the stiffener root, a major maintenance problem in ballast tanks. | The bulb’s shape and the fillet weld profile create a more surface-friendly area for coating application and inspection. |

| Handling & Straightness | Thin, tall flat bars are more prone to twisting and bending during handling, storage, and rolling. | Straightening damaged flat bars adds time and cost. Crooked stiffeners are hard to fit. | The bulb adds torsional stiffness5, making the profile more robust and stable during yard handling. |

A shipyard in Mexico once tried to substitute flat bars for bulb flats in a non-critical, secondary compartment to save cost. They soon found problems. The flat bars, of the same height, were not stiff enough. They vibrated noticeably. The welds at the sharp corners required extra grinding and inspection. In the end, the labor cost and delay outweighed the small material saving. They switched back to bulb flats for the next project. This example shows that the "disadvantage" of a flat bar is really about the total lifecycle cost and structural reliability6. For temporary structures or non-load-bearing fittings, flat bars are fine. But for the primary hull of an oceangoing vessel designed to last 25 years, the engineered solution—the bulb flat—is the only responsible choice. Your storage and handling protocols should reflect the higher value and precision of this superior product.

Conclusion

Correct storage and handling protect the engineered advantages of bulb flat steel. By following these methods, you ensure this critical material performs as designed, safeguarding your project’s quality, schedule, and budget.

-

Understanding lower bending resistance is crucial for evaluating structural integrity in ship design. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring this can reveal how weight impacts cargo capacity and fuel efficiency in vessels. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This resource can provide insights into welding techniques and their implications for ship durability. ↩ ↩ ↩ ↩ ↩

-

Learning about corrosion can help in selecting materials that enhance the longevity of ships. ↩ ↩ ↩ ↩

-

Understanding torsional stiffness can improve knowledge of structural stability and performance. ↩ ↩ ↩

-

This link can help you grasp the economic and safety considerations in ship design. ↩ ↩