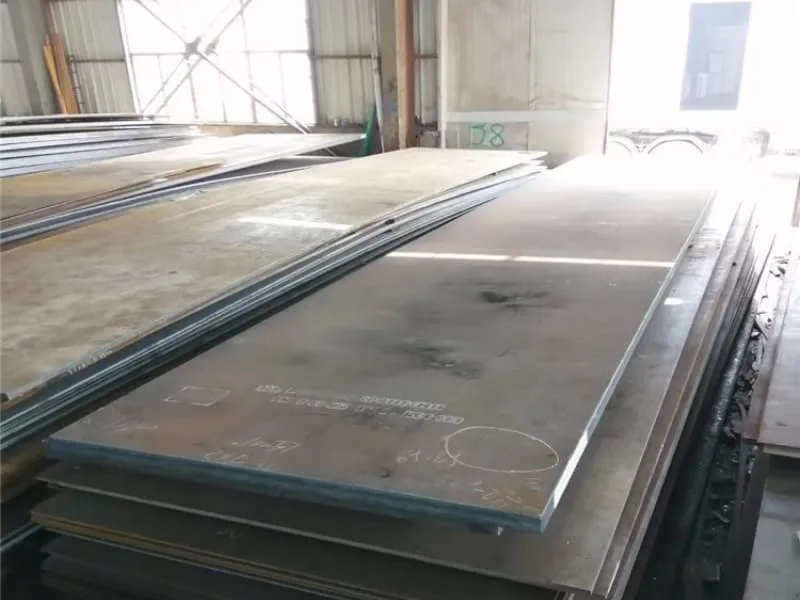

A shipment to Saudi Arabia recently arrived with damaged steel plates due to improper securing. This experience taught us the critical importance of proper marine transportation methods.

Marine steel plates are best transported using specialized flat rack containers or breakbulk ships with proper blocking, bracing, and waterproof securing. The plates must be stacked with wooden dunnage, protected from seawater exposure, and secured according to IMO regulations to prevent movement and corrosion during ocean transit.

Safe transportation ensures materials arrive in perfect condition. Let me explain the best practices for shipping marine steel plates internationally.

What is the best way to transport steel?

A shipyard in Qatar needed to transport 500 tons of marine steel plates1 from China. The choice between transport methods affected both cost and material condition.

The best way to transport steel depends on quantity and distance: container shipping2 for small orders, breakbulk for large plates, and Ro-Ro for finished structures. Marine steel plates typically use flat rack containers3 or breakbulk ships with proper securing to prevent damage and corrosion during ocean transit.

Comprehensive Steel Transport Methods

Choosing the right transport method for steel involves balancing cost, safety, and material protection. Each method serves different needs based on quantity, size, and destination.

Container Shipping Advantages

Container shipping works well for smaller steel shipments. Standard 20-foot or 40-foot containers handle plates up to certain dimensions. The containers provide good protection from weather and theft. Container ships offer frequent sailings to most ports. The method suits orders from 10 to 25 tons. Proper interior securing prevents movement during transit.

Breakbulk Shipping for Large Plates

Breakbulk shipping handles oversized steel plates effectively. The method accommodates plates longer than container dimensions. Cranes load individual plates into ship holds. Proper stowage and securing prevent damage. Breakbulk works best for shipments over 50 tons. The approach provides flexibility for irregular shapes and sizes.

Flat Rack Container Solutions

Flat rack containers combine container convenience with breakbulk flexibility. The open sides accommodate wide plates. Top loading allows crane operation. The containers provide structural support during transport. Flat racks suit plates up to 40 feet long. Proper lashing secures the load effectively.

Ro-Ro Vessel Applications

Roll-on-roll-off vessels work for certain steel products. Finished steel structures can be driven on board. The method minimizes handling damage. Ro-Ro provides quick loading and unloading. This approach suits project cargo and special shapes. Proper securing on vehicle decks is essential.

Bulk Carrier Considerations

Bulk carriers primarily handle raw materials but can transport steel. The method suits very large quantities. Proper separation from other cargo is necessary. Protection from moisture and contamination is crucial. Bulk transport offers the lowest cost per ton for massive shipments. Special precautions prevent damage during loading and unloading.

Method Selection Factors

Several factors influence transport method choice. Shipment size determines economic feasibility. Plate dimensions affect equipment compatibility. Delivery timing influences vessel selection. Port facilities at both ends affect handling options. Cost considerations balance with risk management. The optimal choice considers all these factors.

Steel Transport Method Comparison

| Method | Best For | Maximum Size | Cost Factor | Key Considerations |

|---|---|---|---|---|

| Container | Small orders, standard sizes | 40ft length | Medium | Interior securing, moisture protection |

| Breakbulk | Large plates, project cargo | No practical limit | Low to medium | Stowage planning, weather protection |

| Flat Rack | Oversized plates | 40ft length | Medium to high | External lashing, exposure management |

| Ro-Ro | Finished structures | Vessel limit | High | Deck securing, access requirements |

| Bulk Carrier | Massive quantities | No practical limit | Lowest | Contamination prevention, separation |

We help clients select the optimal transport method for their specific needs. Proper selection ensures safe delivery and cost efficiency.

How is steel transported?

A contractor from Mexico needed to understand the complete steel transport process. Knowing each step helped their logistics planning.

Steel is transported through a coordinated process involving mill loading, land transportation to port, customs clearance, ocean vessel loading, sea transit, port unloading, and final delivery. Each step requires specialized equipment and procedures to prevent damage and ensure timely arrival at destination.

Comprehensive Steel Transport Logistics

Steel transport involves multiple interconnected steps that require careful coordination. Understanding the complete process helps in planning and problem prevention.

Mill Loading and Preparation

The transport process begins at the steel mill. Cranes load plates onto trucks or rail cars. Workers place wooden dunnage between plates. Protective coatings may be applied to prevent rust. Documentation preparation starts at this stage. The loading must follow weight distribution principles. Proper initial handling prevents subsequent problems.

Land Transportation to Port

Trucks or trains move steel from mill to port. Special heavy-duty trucks handle plate weights. Route planning considers bridge capacities and road restrictions. Escort vehicles may accompany oversized loads. The transportation must comply with local regulations. Timely arrival at port avoids demurrage charges.

Port Operations and Storage

Port workers unload incoming steel trucks. The steel moves to storage areas or directly to vessels. Proper storage prevents damage from weather and handling. Documentation verification occurs at this stage. Customs inspection may be required before loading. Port efficiency affects overall transit time.

Vessel Loading and Stowage

Stevedores load steel onto vessels using cranes. Loading sequence considers vessel stability and destination order. Proper stowage prevents movement during voyage. Securing systems include lashing and blocking. Weight distribution affects vessel safety. Loading efficiency impacts port time and costs.

Ocean Transit and Monitoring

The vessel transports steel across oceans. Weather routing avoids severe conditions. Crew monitors cargo securing during voyage. Temperature and humidity controls protect steel quality. Communication systems provide position updates. Transit time depends on route and vessel speed.

Port Unloading and Customs

Destination port workers unload the vessel. Cranes transfer steel to port storage or trucks. Customs clearance procedures release the cargo. Inspection verifies condition upon arrival. Documentation completion enables cargo release. Efficient unloading minimizes port charges.

Final Delivery to Site

Local transportation moves steel to final destination. Route planning considers local conditions. Unloading at site requires proper equipment. Storage arrangements protect steel until use. The complete process typically takes 30-45 days from China to Middle East.

Steel Transport Timeline

| Stage | Duration | Key Activities | Critical Requirements |

|---|---|---|---|

| Mill Preparation | 1-2 days | Loading, documentation | Proper handling, dunnage |

| Land Transport | 2-5 days | Truck/rail movement | Route planning, permits |

| Port Operations | 3-7 days | Storage, documentation | Weather protection, organization |

| Ocean Transit | 15-30 days | Vessel movement | Securing, monitoring |

| Destination Port | 3-7 days | Unloading, customs | Equipment availability, paperwork |

| Final Delivery | 1-3 days | Local transport | Site access, unloading |

We manage the complete transport process for our clients. Our experience ensures smooth logistics from mill to destination.

How to load steel coils on a ship?

While this question focuses on coils, the principles apply to plate loading. Understanding coil loading demonstrates general steel cargo handling principles.

Steel coils are loaded on ships using specialized cranes with coil hooks, placed in predetermined stowage patterns with wooden chocks and secured with wire lashings. The loading follows specific sequence for vessel stability, with coils typically stacked no more than three high and separated by dunnage to prevent damage.

Steel Coil Loading Methodology

Steel coil loading requires specialized equipment and procedures to ensure safety and prevent damage. The principles demonstrate important cargo handling concepts relevant to all steel products.

Loading Equipment Requirements

Specialized cranes handle steel coil loading. Coil hooks attach through the coil center hole. Spreader beams distribute weight evenly. The equipment must have adequate capacity. Proper maintenance ensures safe operation. Trained operators understand coil handling techniques.

Stowage Pattern Planning

Coils are arranged in specific patterns on vessel decks or holds. The pattern considers vessel stability requirements. Weight distribution affects vessel trim and stress. Access ways must remain clear for inspection. The arrangement allows proper securing. Pattern planning prevents shifting during voyage.

Dunnage and Separation

Wooden dunnage separates coils from deck surfaces. Additional dunnage separates coil layers. The wood prevents metal-to-metal contact. Dunnage distributes weight evenly. Proper dunnage prevents corrosion and damage. The material must be clean and dry.

Securing Systems

Wire rope lashings secure coils in position. Turnbuckles provide tension adjustment. Shackles connect lashings to deck rings. The securing must withstand vessel motions. Regular inspection during voyage ensures integrity. Proper tension prevents movement but allows for expansion.

Loading Sequence Considerations

Loading sequence affects vessel stability. Heavier coils typically load first. Distribution considers multiple factors. The sequence must maintain vessel balance. Loading plans are prepared in advance. The chief officer supervises the operation.

Safety Precautions

Multiple safety measures protect workers and cargo. Personal protective equipment is mandatory. Clear communication prevents accidents. Weather conditions affect loading operations. Emergency procedures are established in advance. Safety inspections occur throughout the process.

Coil Loading Best Practices

| Aspect | Requirement | Purpose | Common Issues |

|---|---|---|---|

| Equipment | Certified cranes, proper hooks | Safe handling | Equipment mismatch, wear |

| Stowage | Predetermined patterns | Stability, access | Poor planning, congestion |

| Dunnage | Clean, adequate wood | Damage prevention | Insufficient, contaminated |

| Securing | Proper tension, inspection | Movement prevention | Loose lashings, corrosion |

| Sequence | Planned order | Vessel balance | Improper weight distribution |

| Safety | PPE, procedures | Accident prevention | Complacency, poor communication |

While we primarily ship plates, understanding coil loading principles helps comprehensive cargo knowledge. The securing concepts apply to all steel products.

How to secure steel road plates?

A project manager from Philippines needed to secure steel plates during road transport. The principles apply to sea transport securing as well.

Steel road plates are secured using chain binders, wire rope, and webbing straps with edge protectors, distributing tension points and preventing movement. For sea transport, additional waterproof protection and corrosion prevention measures are necessary to withstand ocean conditions and long transit durations.

Comprehensive Steel Securing Methods

Proper securing of steel plates prevents movement and damage during transport. The methods vary based on transport mode but share common principles of distribution and tension management.

Land Transport Securing

Truck transport requires specific securing methods. Chain binders provide high tension capability. Webbing straps protect plate surfaces. Edge protectors prevent strap damage. Tension must be adequate but not excessive. Regular inspection during long trips ensures security. The methods prevent shifting during road movement.

Sea Transport Additional Requirements

Ocean transport demands more robust securing. Marine environments cause corrosion concerns. Vessel motion creates dynamic forces. Long duration requires durable materials. Waterproof protection prevents rust formation. The securing must withstand weather extremes. International regulations govern marine securing.

Lashing Materials and Equipment

Different lashing materials serve different purposes. Wire rope offers high strength and durability. Chain provides excellent abrasion resistance. Synthetic webbing protects surface finishes. Shackles and connectors must match strength ratings. Tensioning devices require proper calibration. Material selection considers environmental conditions.

Load Distribution Principles

Proper distribution prevents point loading. Tension should spread across multiple points. Weight must transfer to structural members. Avoid concentrating forces on weak areas. Distribution protects both cargo and transport vehicle. The principles apply regardless of transport mode.

Corrosion Prevention Measures

Marine transport requires corrosion protection. Protective coatings shield steel surfaces. Desiccants control humidity in enclosed spaces. Proper drainage prevents water accumulation. Regular inspection identifies early corrosion. The measures maintain steel quality during transit.

Regulatory Compliance

International regulations govern steel transport. IMO guidelines specify securing requirements. Classification societies provide additional standards. Flag state regulations must be followed. Port state control enforces compliance. Understanding regulations prevents problems and delays.

Steel Securing Method Comparison

| Method | Best Application | Strength | Surface Protection | Marine Suitability |

|---|---|---|---|---|

| Chain Binders | Heavy plates, land transport | Very high | Poor | Limited due to corrosion |

| Wire Rope Lashings | Marine transport, breakbulk | High | Fair | Excellent with coating |

| Webbing Straps | Finished surfaces, container | Medium | Excellent | Good with protection |

| Steel Strapping | Bundle securing, interior | Low to medium | Good | Limited due to rust |

| Specialized Fixtures | Project cargo, unusual shapes | Custom | Varies | Case by case |

We implement appropriate securing methods for all shipments. Our experience ensures materials arrive in perfect condition.

Conclusion

Safe marine steel plate transport requires proper method selection, careful loading procedures, and robust securing systems. Following international standards and best practices ensures materials arrive undamaged and ready for shipbuilding applications.

-

Explore this link to understand the properties and applications of marine steel plates in various industries. ↩

-

Learn about the benefits of container shipping for steel transport, including cost efficiency and protection. ↩

-

Find out how flat rack containers provide flexibility and support for oversized steel during transport. ↩