Your new L-shaped steel shipment arrives with a pile of certificates, but how do you know they’re genuine? Fake or incorrect certificates are a major risk in international steel trade. I’ve helped clients uncover fraudulent documents that could have led to structural failures.

To verify L-shaped steel supplier certificates, you must check the Mill Test Certificate (MTC) for authenticity, confirm the issuing mill is approved by the relevant classification society (e.g., ABS, LR), match the heat number on the MTC to the markings on the steel, and cross-check chemical/mechanical results against the ordered grade specifications (e.g., AH36). This multi-step audit is your best defense against substandard material.

For importers, fabricators, and project managers, certificate verification is a critical quality gate. It turns trust into verified fact. This guide will walk you through key certificates, practical checks, and on-site verification techniques to ensure you receive exactly what you paid for. Let’s start with a common certificate requested in certain markets.

What is the BIS certificate for steel products?

If you are importing steel into India, you will likely encounter the BIS certificate requirement. It’s a mandatory quality mark, not to be confused with international marine certifications. A client in Myanmar exporting to India was unaware of this, causing their shipment to be held at customs.

A BIS certificate is a product certification from the Bureau of Indian Standards (BIS), India’s national standards body. It indicates that the steel product (like angles, plates) conforms to the relevant Indian Standard (IS). For example, structural steel angles must meet IS 2062. The BIS mark on the steel is a legal requirement for sale in India, but it does not replace marine classification society certification for shipbuilding. It is a market-specific compliance mark.

Understanding BIS in the Context of Marine Steel Procurement

BIS is about national quality and consumer protection, not marine structural integrity. Here’s what you need to know.

1. Purpose and Scope of BIS:

- Goal: To ensure products sold in India meet minimum safety, quality, and performance standards.

- Applies To: Both domestic manufacturers and foreign manufacturers exporting to India.

- For Steel: Common standards include IS 2062 for hot-rolled structural steel and IS 5986 for shipbuilding steel plates (which references international norms).

2. BIS vs. Marine Classification Society Certification:

This is a crucial distinction.

- BIS Certificate: Proves the steel meets a generic national material standard. It does not guarantee the steel is suitable for a specific, safety-critical application like a ship’s hull. The testing is less rigorous than classification society rules, especially regarding toughness.

- Classification Society Certificate (e.g., ABS, DNV MTC): Proves the steel meets specific marine structural rules including mandatory impact testing, traceability, and production under an audited quality system. This is required for ship construction.

3. When is a BIS Certificate Required?

- Primarily: When the final destination of the steel is the Indian market, for use in construction, infrastructure, or general fabrication.

- Possibly Not Required: If the steel is for a ship that will be flagged outside India and built in a non-Indian shipyard, the classification society certificate (ABS, LR, etc.) is the governing document. However, if components are sourced from India, BIS may apply.

4. Verification of a BIS Certificate:

- The certificate should be issued by BIS to a licensed manufacturer.

- You can verify the license number on the BIS website.

- The steel itself should carry the BIS Standard Mark.

Practical Implications for Buyers:

| Your Project & Steel Destination | Required Certificates | Reason |

|---|---|---|

| Building a ship in Vietnam for international flag. | ABS/DNV MTC (from mill). | Compliance with international marine safety rules. |

| Supplying steel angles for a building in Mumbai, India. | BIS Certificate + Mill Test Report. | Legal requirement for sale in India. |

| Fabricator in Saudi Arabia making modules for an Indian project. | Clarify with Indian client. Likely BIS for Indian-bound goods, plus any project-specific certs. | Must meet import regulations of the destination country. |

For most international marine projects, the primary focus remains on the classification society MTC. Regardless of certificates, you must also perform physical checks to verify the material itself is genuine.

How to check original steel?

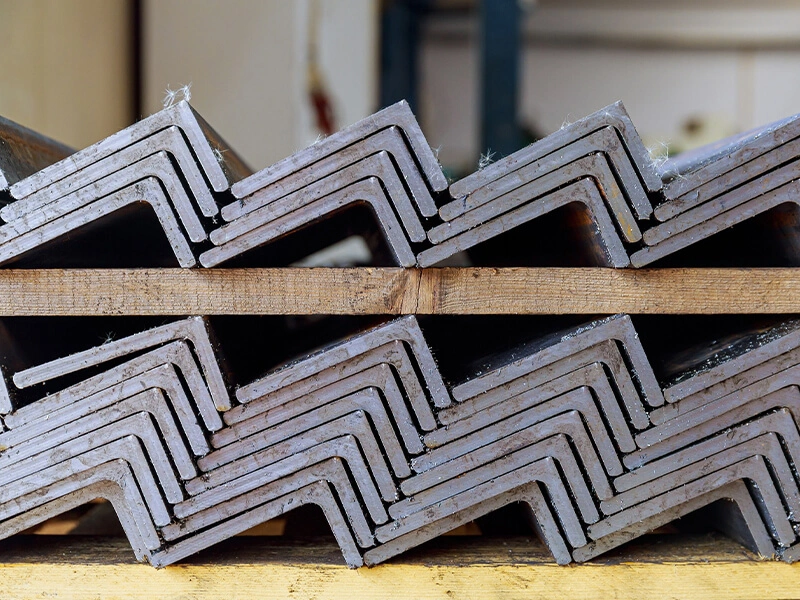

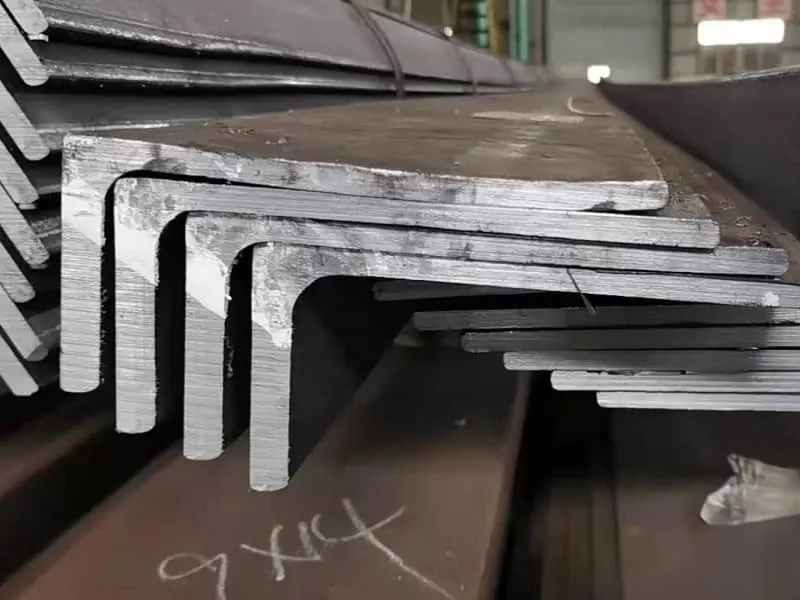

Certificates can be faked. The steel itself tells the true story. A distributor in the Philippines once received "AH36" angles with perfect paperwork, but a simple physical check revealed they were a lower-grade steel with painted-on markings.

You check for original, genuine steel by verifying the physical markings (heat number, grade stamp) match the Mill Test Certificate, performing a spark test or using a portable spectrometer for chemical analysis, checking dimensions and weight against standards, and examining the surface quality for consistency with hot-rolled material. Documentation alone is not enough; the steel must corroborate the paperwork.

A Step-by-Step Field Verification Protocol

Combine these methods for a robust check. You don’t need a full laboratory, just a systematic approach.

1. The First Check: Markings and Documentation (The Paper Trail)

This is the most important and easiest step.

- Action: Find the painted or stamped marking on the steel bundle or piece. It should show: Grade (e.g., AH36), Heat/Ladle Number, Mill Logo, Size.

- Verification: This data must exactly match the information on the Mill Test Certificate (MTC). A mismatch means the MTC does not belong to that steel. Isolate the material immediately.

2. Simple Physical and Visual Tests:

- Magnet Test: All carbon and low-alloy steels are strongly magnetic. If a magnet doesn’t stick firmly, it’s not the claimed carbon steel (could be stainless or another alloy).

- Visual Surface Check: Genuine hot-rolled steel has a characteristic blue-grey mill scale. It should be relatively uniform. Be wary of:

- Excessive red rust (can indicate poor storage or active corrosion).

- An artificially smooth or painted surface that might be hiding defects.

- Inconsistent coloring, which might suggest a mixed or non-standard batch.

- Weight/Heft: Pick up a piece. Steel is dense (~7.85 g/cm³). If it feels suspiciously light for its size, it could be a different material.

3. Semi-Quantitative Tests (For Experienced Personnel):

- Spark Test: Using a grinder, observe the spark stream.

- Low-Carbon Steel (e.g., A36, AH36): Long, straight straw-colored sparks with few forks.

- Higher-Carbon Steel: Brighter, shorter sparks with more bursts (star-shaped).

- Note: This requires training to interpret accurately. It can help distinguish between steel grades but not provide exact chemistry.

- Hardness Test (File Test): A standard file should "bite" into mild steel. If the file slides without cutting, the material is much harder than typical structural steel.

4. Advanced On-Site Verification (For Critical Projects):

- Portable XRF Analyzer: Many inspection companies (like SGS) use these. They can provide an approximate chemical composition in minutes, instantly verifying if the chemistry matches the claimed grade (e.g., low Carbon for AH36).

- Ultrasonic Thickness Gauge: To verify the plate or leg thickness meets the ordered dimensions and tolerances.

Field Checklist for Steel Verification:

| Check | Method | Acceptable Outcome | Red Flag |

|---|---|---|---|

| Marking Match | Compare steel stamp to MTC. | Heat number, grade, size are identical. | Any discrepancy. |

| Magnetism | Use a strong magnet. | Strong, immediate attraction. | Weak or no attraction. |

| Surface | Visual inspection. | Uniform mill scale, no deep pitting. | Heavy red rust, painted surface hiding scale, severe pitting. |

| Dimensions | Use caliper/tape measure. | Within standard tolerances (e.g., ±2mm on a 100mm leg). | Consistently undersized, especially thickness. |

These checks rely on knowing what the steel should be, which is defined by a material code or standard.

Is there a code for structural steel material?

Yes, absolutely. Every piece of structural steel, including L-angles, is produced to a specific material code or standard. This code is the legal definition of its properties. Ordering steel without specifying the code is asking for trouble. We always confirm the exact code with our clients before production.

Structural steel material is defined by standardized codes such as ASTM A36 (USA), EN 10025-2 S235JR/S355JR (Europe), JIS G3101 SS400 (Japan), and for marine use, classification society grades like ABS AH36 or DNV NV A36. These codes specify the minimum chemical composition, mechanical properties (yield strength, tensile strength), and required tests. The code on the MTC and order must match the intended application.

Navigating the World of Steel Standards

These codes are published documents that manufacturers, engineers, and buyers agree to use as a common language.

1. Common Non-Marine Structural Codes:

- ASTM A36: A general-purpose carbon structural steel used widely in the USA for buildings and bridges. Yield strength 250 MPa.

- EN 10025-2 S235JR / S355JR: European standards. ‘S’ for structural, number is yield strength in MPa, ‘JR’ indicates impact energy at room temperature.

- JIS G3101 SS400: Japanese standard for general structure. ‘SS’ for structural steel, ‘400’ indicates minimum tensile strength (not yield).

2. Marine-Specific Structural Codes (The Critical Ones):

These are the codes you will see on shipbuilding MTCs. They are often based on the above but with extra requirements.

- ABS (American Bureau of Shipping): Grades like A, B, D, E, AH36, DH36. The rules are in the ABS Rules for Materials and Welding.

- DNV (Det Norske Veritas): Grades like NV A, NV D, NV A36, NV D36. The rules are in DNVGL-CP-0178.

- LR (Lloyd’s Register): Grades like Grade A, Grade D, Grade AH36.

- Key Point: These are not just strength codes. They mandate Charpy V-notch impact testing at specified temperatures and strict chemical controls for weldability.

3. How to Use and Verify the Code:

- In Ordering: You must specify the full code. E.g., "L-Angle 150x150x12mm, Material: ABS Grade AH36".

- On the MTC: The "Standard" or "Specification" section must name this exact code (e.g., "Produced according to ABS Rules for Materials and Welding").

- On the Steel: The marked grade (e.g., AH36) is the shorthand for that code.

Code Comparison for an L-Angle:

| If you order an angle for… | Typical Material Code | What the Code Guarantees |

|---|---|---|

| A warehouse frame in Texas. | ASTM A36 | Min. yield strength 250 MPa, general weldability. |

| A building frame in Germany. | EN 10025-2 S235JR | Min. yield strength 235 MPa, impact energy at +20°C. |

| A ship’s hull frame. | ABS Grade AH36 | Min. yield strength 355 MPa, impact testing at 0°C, controlled chemistry per ABS rules, mill approval. |

| An offshore platform brace. | DNV NV D36 | Min. yield strength 355 MPa, impact testing at -20°C, through-thickness properties possible. |

Verifying that the delivered steel meets its code requires a final set of on-site quality checks, which are essential before the steel is used.

How to check the quality of steel at a site?

The steel has arrived, certificates seem okay, but you need to release it for fabrication. A final, thorough site check catches issues that might have slipped through earlier. A project in Qatar had to stop work because site measurements revealed consistently under-thickness angles.

To check steel quality on-site, perform a visual inspection for defects, measure critical dimensions (thickness, leg length) against the ordered size and standard tolerances, verify markings against the MTC, and conduct simple tests like the magnet test. For marine grades, the most important check is confirming the heat number and grade marking match the certified MTC you hold. Document all findings with photos.

A Practical On-Site Inspection Procedure

This is your last line of defense. Use a checklist and be methodical.

1. Preparation Before the Truck Arrives:

- Have the MTC, purchase order, and packing list1 ready.

- Have your inspection tools ready: Calipers, steel tape measure, straight edge, strong magnet, camera, checklist.

- Designate a qualified person to perform the check.

2. The Inspection Process (Upon Delivery):

Follow this sequence:

Step A: Documentation and Marking Check (Do this first).

- Unload a few sample bundles.

- Find the painted/stamped marking on the steel. Record the Heat Number2 and Grade.

- Immediately compare these to the MTC. This is the single most important check. If they don’t match, stop unloading and contact the supplier.

Step B: Visual and Dimensional Check3 (Sampling).

You cannot check every piece. Use a sampling plan (e.g., check 3 bundles, 2 pieces from each).

- Visual:

- Look for physical damage: bends, dents, deep scratches.

- Check surface condition: Uniform mill scale is good. Heavy, flaky red rust or pitting is not.

- Check straightness: Sight along the length. Significant bow or twist is unacceptable.

- Dimensional:

- Leg Length (A & B): Measure with a tape from the heel to the outer edge.

- Thickness (t): Use a caliper. CRUCIAL: Measure away from the rounded toe (about 20mm in). The edge is often thinner.

- Length: Check the overall length of sample pieces.

- Compare all measurements to the ordered size and the allowable tolerances in the relevant standard (e.g., EN 10056-1 for angles).

Step C: Simple Identity Tests.

- Magnet Test4: Confirm it’s ferromagnetic.

- Spark Test (optional): If trained, use it to get a rough idea of carbon content.

3. Recording and Decision Making5:

- Document Everything: Fill out your checklist. Take clear photos of markings, measurements being taken, and any defects.

- Make a Decision: Based on your findings:

- Accept: If all checks pass.

- Accept with Note: If there are minor, non-structural issues (e.g., very light surface rust).

- Reject/Quarantine: If there are major issues (wrong heat number, gross dimensional errors, excessive defects).

On-Site Inspection Checklist Summary:

| Check Item | Tool/Method | Acceptance Criteria |

|---|---|---|

| Heat & Grade Marking | Visual, compare to MTC. | Must exactly match the MTC. |

| Leg Thickness | Caliper, measure away from edge. | Within standard tolerance (e.g., ±0.6mm for 10mm thick). |

| Leg Length | Steel tape measure. | Within standard tolerance (e.g., ±2.5mm for 100mm leg). |

| Surface Condition6 | Visual. | Uniform mill scale. No deep pitting or severe rust. |

| Straightness7 | Visual or straight edge. | No obvious, severe bow or twist. |

| Magnetism | Strong magnet. | Strong attraction. |

For a rational, results-driven buyer, this process transforms risk management into a routine. It provides the objective evidence needed to accept good material or rightfully dispute substandard shipments, ensuring your project is built on a foundation of verified quality.

Conclusion

Verifying L-shaped steel supplier certificates requires a multi-layered approach: auditing MTCs and mill approvals, performing rigorous on-site physical and dimensional checks, and always matching material markings to documentation. This diligent process ensures you receive certified, genuine steel that meets your project’s exact specifications and safety requirements.

-

Understanding these documents is crucial for ensuring the steel meets specifications and standards. ↩

-

Verifying the Heat Number is essential for traceability and quality assurance in steel materials. ↩

-

Learning best practices can help ensure accurate assessments of steel quality during inspections. ↩

-

The Magnet Test is a simple yet effective method to confirm the ferromagnetic properties of steel. ↩

-

Effective documentation and decision-making processes are key to managing quality control in steel projects. ↩

-

Assessing surface condition is vital for identifying potential defects that could affect performance. ↩

-

Straightness affects the structural integrity and fit of steel components in construction. ↩