You have ordered the highest grade marine steel plates. You have confirmed the manufacturing process and the delivery date. But are you sure the packaging will protect your valuable shipment across the ocean? A single oversight here can turn premium steel into scrap before it even reaches the dock. I have seen it happen, and the financial loss is staggering.

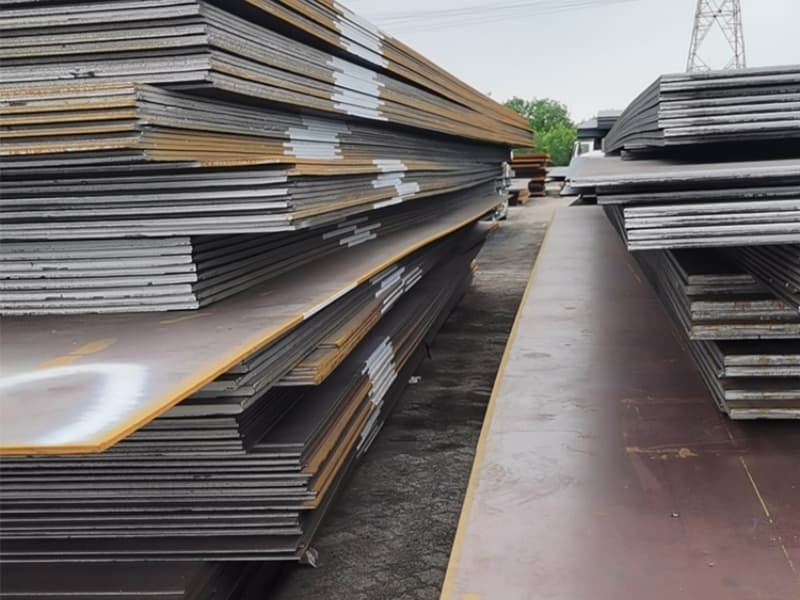

The seaworthy packing for marine steel plates must securely protect against saltwater corrosion, physical impact, and atmospheric changes during long sea voyages. The procedure is systematic, from surface preparation to final marking. Plates are made in grades like A, B, D, E, and AH/DH/EH with varying toughness, and are produced through controlled rolling or thermo-mechanical control processes to ensure strength and weldability for ship hulls and structures.

Getting the steel right is only half the battle. The journey from our mill in Liaocheng to your project site in Saudi Arabia or Mexico is long and harsh. The real test of a supplier’s reliability often lies not in the product brochure, but in the unglamorous details of how that product is prepared for the world. I want to walk you through the critical, often underestimated stages of packing and export. This knowledge will help you set the right standards with your suppliers and avoid costly surprises. Let’s break down what truly makes marine steel plate packaging ready for the sea.

What are the specifications for seaworthy packing?

Imagine your steel plates arriving with deep rust stains or, worse, bent from improper handling. The panic and project delays are immediate. The specifications for seaworthy packing are your first line of defense against this nightmare. They are not just suggestions; they are a mandatory checklist derived from decades of shipping experience.

Seaworthy packing for marine steel plates requires VCI (Vapor Corrosion Inhibitor) paper1 wrapping, robust wooden cradles2 or crates, full edge protection with angle guards3, waterproof outer layers4, and clear, indelible markings for handling5 and identification. These specifications work together to prevent corrosion, deformation, and mishandling during transit and storage.

To truly understand seaworthy packing, we need to look at the threats it defends against and the specific solutions for each.

The Three Enemies of Marine Steel in Transit

A sea voyage exposes steel to a hostile environment. We design our packaging to combat three main enemies:

- Corrosion: Salt-laden air and changing humidity are the biggest risks. Surface rust can ruin the finish and complicate welding.

- Physical Damage: Impacts from cranes, stacking pressures, and ship movement can bend or dent plates.

- Contamination and Loss: Plates can get mixed up, or markings can fade, leading to on-site confusion.

The Seaworthy Packaging System in Detail

Our packing is a multi-layered system. Each layer has a specific job. Here is a breakdown of our standard export packaging:

| Layer | Material & Specification | Primary Function | What It Prevents |

|---|---|---|---|

| Inner Protective Layer | VCI (Vapor Corrosion Inhibitor) Paper | Creates a protective atmosphere around the steel, neutralizing corrosion. | Rust and white staining during long sea voyages. |

| Structural Support | Kiln-dried wooden cradles or crates | Provides a solid frame for stacking and lifting, prevents bending. | Deformation from stacking and point-load pressures. |

| Edge & Corner Protection | Pressed steel or plastic angle guards, corner protectors | Shields the most vulnerable parts of the plate during handling. | Bent edges, dents, and damage from slings or chains. |

| Waterproof Outer Layer | Heavy-duty waterproof plastic sheet (e.g., PP or PE) or coated woven fabric | Seals the package from rain, seawater spray, and dust. | Water ingress, condensation damage, and contamination. |

| Securing & Marking | Steel strapping, clear shipping marks (consignee, weight, dimensions, lift points) | Ensures the package stays intact and is handled correctly. | Package collapse, mishandling, and loss of identification. |

For our client in Saudi Arabia, Gulf Metal Solutions, their main pain point was inconsistent surface finish from previous suppliers. We addressed this head-on by implementing a mandatory VCI paper wrap for all their orders, regardless of destination. The feedback was clear: our packaging was the best they had received. This isn’t about adding cost; it’s about guaranteeing the product arrives in the same condition it left our factory. The wooden cradles are designed to specific load ratings, and we always mark the "lift points" clearly. This simple step prevents port workers from using incorrect lifting methods that can warp the plates. Every specification exists because a problem was solved. When you review a supplier’s packing list, look for these elements. If they are missing, you are accepting a significant risk.

What is the procedure for packing?

Knowing the specifications is one thing, but a consistent, documented procedure is what turns those specs into a reliable result every single time. A haphazard approach leads to failures, no matter how good the materials are. Our procedure is a strict, step-by-step protocol that our team follows for every export order.

The seaworthy packing procedure for marine steel plates is a sequential process. It starts with surface cleaning and inspection, followed by application of VCI paper. The plates are then mounted on wooden cradles, edges are protected, the package is strapped and wrapped in waterproof material, and finally marked with detailed shipping information for safe handling.

Let’s dive deeper into each step of this procedure. This will show you why order matters and how we maintain quality control throughout.

A Step-by-Step Walkthrough of Our Packing Line

The procedure is linear and quality-checked at multiple points. Here is how it flows:

-

Step 1: Surface Preparation & Final Inspection

Before any wrapping begins, the plate surface is cleaned of dust, oil, and debris using dry, oil-free air. This is also our final quality check point. Our inspector, and often a third-party inspector like SGS if requested, verifies the grade, dimensions, and surface quality against the mill test certificate. Only plates that pass this check move to packing. This step is crucial. Wrapping a dirty or substandard plate simply hides problems. -

Step 2: Application of Corrosion Inhibitor

The cleaned plates are immediately wrapped with VCI paper. The paper must have direct contact with the steel surface. We overlap the seams securely and tape them with waterproof tape. For very long voyages or highly corrosive environments, we sometimes add VCI powder or emitter chips inside the package for extra protection. The goal is to create a sealed micro-environment around the steel. -

Step 3: Placement on Support Structure

The wrapped plate is carefully lifted by crane and placed onto a pre-assembled wooden cradle. The cradle’s supports are aligned precisely with the plate’s recommended lifting points to avoid overhang and stress. The wood is always kiln-dried to prevent mold and has been treated according to ISPM-15 standards for international shipping to prevent pest transfer. -

Step 4: Securing and Final Protection

Steel strapping is applied around the plate and cradle at specific intervals. We use tensioners to ensure the straps are tight but not damaging. Pressed steel angle guards are then fitted onto all four edges and secured. Finally, the entire package is wrapped in a heavy-duty, waterproof plastic sheet. This sheet is heat-sealed or tightly taped to form a water-resistant barrier. -

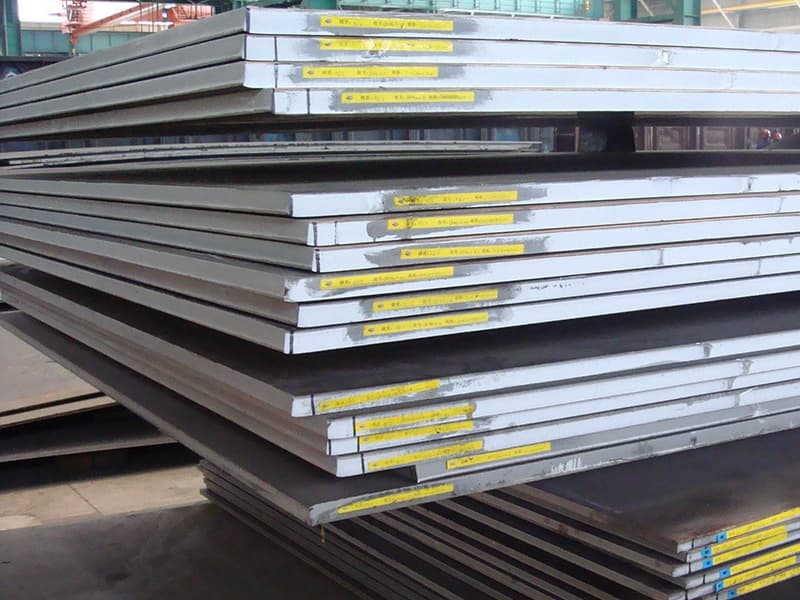

Step 5: Marking and Documentation

This is the communication step. We stencil or attach waterproof labels with clear, indelible markings. These include the consignee info (your company/Gulf Metal Solutions), purchase order number, plate grade, dimensions, gross/net weight, and most importantly, the center of gravity and lifting diagram. A copy of the packing list is placed in a waterproof pouch attached to the package. For us, the procedure doesn’t end at the warehouse door. Our export team manages the documentation—commercial invoice, packing list, bill of lading, certificate of origin, and the mill test certificate. We ensure these documents are perfectly aligned with the package markings to smooth customs clearance at your port, whether it’s Dammam, Jebel Ali, or Lazaro Cardenas.

What are the grades of marine steel plates?

Choosing the wrong grade of steel for a ship’s hull is like building a house with the wrong foundation. The consequences can be catastrophic. Marine steel plates are classified into grades that primarily define their toughness, or ability to absorb energy and resist brittle fracture, especially in cold temperatures.

Common marine steel plate grades include A, B, D, E, and the high-strength AH, DH, EH series. Grade A is for general use, while B, D, and E offer increasing levels of notch toughness at lower temperatures. The ‘H’ denotes high tensile strength for critical structural parts like the keel and sheer strake.

The alphabet soup of grades (A, B, D, E, AH32, DH36, etc.) has a very logical meaning. Let’s decode it to understand how to select the right material for the right part of the ship.

Decoding the Grade Designation System

The grade tells a story about the steel’s chemical composition and mechanical properties. The system is standardized by classification societies like ABS, LR, DNV, and BV.

-

The Basic Grades (A, B, D, E): These are normal strength hull structural steels. The letter indicates the testing temperature for impact toughness.

- Grade A: No required impact test. Used for internal structures and areas not subject to high stress or cold temperatures.

- Grade B: Impact tested at 0°C. A versatile, commonly used grade for many hull sections.

- Grade D: Impact tested at -20°C. Used for more critical parts and ships operating in colder waters.

- Grade E: Impact tested at -40°C. Reserved for the most critical parts like the sheer strake (top side) in large vessels and ships for Arctic service.

-

The High-Strength Grades (AH, DH, EH, FH): The ‘H’ stands for High tensile strength. These grades have a higher yield strength (e.g., 32 kgf/mm² for AH32, 36 for DH36, 40 for EH40) compared to normal strength grades. This allows for the use of thinner plates, reducing ship weight and increasing cargo capacity, while maintaining or improving toughness.

- AH32/DH36/EH40: The number indicates the minimum yield strength in kgf/mm². An EH36 plate has both high strength (-40°C toughness).

Application Guide: Matching Grade to Function

Selecting the grade is a balance of technical requirement, regulation, and cost. Here is a practical guide:

| Vessel Type / Structural Area | Recommended Grade(s) | Reasoning |

|---|---|---|

| Small Craft, Inland Barges | A, B | Lower stress, less exposure to extreme open ocean conditions. |

| Midship Hull Plating (Bulk Carrier) | B, D (Normal Strength) or AH32, DH36 (High Strength) | Subject to bending and wave loads. Choice depends on design and operating zone. |

| Keel, Bottom Shell, Sheer Strake | D, E or DH36, EH40 | These are critical, high-stress areas. The keel takes grounding loads; the sheer strake is key to hull girder strength. High toughness is mandatory. |

| Polar Code Vessels (Ice Class) | E, EH, FH grades with special normalized or TMCP delivery | Extreme low-temperature toughness is required to resist brittle fracture in ice-impact conditions. |

For a project contractor in Qatar building offshore support vessels, we typically recommend DH36 for the main hull. It provides the perfect balance of high strength for fuel efficiency and excellent low-temperature toughness for Persian Gulf operations. Understanding grades allows you to have an informed conversation with your naval architect and ensure you are not over-specifying (wasting money) or under-specifying (creating risk). We always supply the full mill test certificate matching the grade, so you have the proof for class approval.

Which manufacturing processes are used for plates?

Two plates can have the same chemical grade but perform very differently in a shipyard. The reason often lies in how they were made. The manufacturing process—how the steel is rolled and treated—fundamentally shapes its internal structure, strength, and weldability. For marine plates, the two key processes are Controlled Rolling (CR) and Thermo-Mechanical Control Process (TMCP).

Marine steel plates are primarily manufactured using Controlled Rolling (CR) or the more advanced Thermo-Mechanical Control Process (TMCP). CR uses precise temperature control during rolling, while TMCP combines controlled rolling with accelerated cooling to produce plates with superior strength and toughness without heavy alloying, making them easier to weld.

To appreciate why TMCP has become the gold standard for modern shipbuilding, we need to compare it with traditional methods and understand its direct benefits for fabricators and shipowners.

The Evolution: From Normalizing to TMCP

Historically, to achieve higher strength, mills would add more carbon and alloys like manganese and niobium. However, this made the steel harder to weld and more prone to cracking. Then came heat treatment like normalizing (reheating and cooling), which improved properties but added cost and energy use.

-

Controlled Rolling (CR): This was a big step forward. The steel is rolled within specific, lower temperature ranges. This refines the grain structure of the steel, making it tougher and stronger than conventional hot-rolled steel. It’s a good, reliable process for many grades.

-

Thermo-Mechanical Control Process (TMCP): This is the advanced version. TMCP takes CR and adds a final, critical stage: Accelerated Cooling (AcC). Immediately after the final rolling pass, the plate is rapidly cooled using high-pressure water jets. This "locks in" the fine grain structure created during rolling and can create even stronger microstructures.

Why TMCP is a Game-Changer for Shipbuilders

The advantages of TMCP plates are not just theoretical; they translate into real benefits on the shipyard floor and for the vessel’s life.

- Better Weldability: Because TMCP achieves high strength through physical processing rather than high carbon content, the plates have a lower Carbon Equivalent (CEV). A lower CEV means the steel is much less sensitive to welding, reducing the risk of cold cracking. This allows shipyards to weld faster, with less pre-heating, saving significant time and energy costs.

- Weight Saving: TMCP can produce thinner plates for the same strength level. Using thinner, stronger plates for decks and hulls reduces the overall steel weight of the vessel. This directly increases cargo capacity or improves fuel efficiency—a major operational cost saving.

- Enhanced Toughness: The fine, uniform grain structure from TMCP provides excellent toughness, especially in the heat-affected zone (HAZ) next to welds. This is critical for structural integrity in rough seas.

For our clients like manufacturers in Vietnam and the Philippines, weldability is a top concern. When we supply TMCP-processed DH36 plates, their feedback is always about the smooth welding experience and the reduced need for expensive, low-hydrogen electrodes. It makes their fabrication process more efficient and predictable. We work closely with certified mills that specialize in TMCP production to ensure we can deliver these performance advantages consistently. When you specify marine steel, always ask about the manufacturing process. Opting for TMCP, even at a slight premium, often pays for itself through savings in fabrication and superior long-term performance.

Conclusion

Choosing the right marine steel involves more than just the grade. True reliability comes from understanding the seaworthy packaging, the precise packing procedure, the meaning behind the steel grades, and the advantages of modern manufacturing like TMCP.

-

Explore this link to understand how VCI paper protects steel from corrosion during transit, ensuring your materials arrive in perfect condition. ↩

-

Learn about the significance of wooden cradles in preventing deformation and ensuring safe transport of heavy steel plates. ↩

-

Discover how angle guards protect vulnerable edges of steel plates from damage during handling and transport. ↩

-

Find out how waterproof layers prevent water ingress and contamination, safeguarding your steel products. ↩

-

Understand the importance of clear markings in preventing mishandling and ensuring proper identification of steel packages. ↩