Have you ever wondered what gives massive ship hulls their incredible strength against powerful ocean forces? The secret lies in the hidden framework that supports the hull plating.

Marine L-shaped steel, or angle bar, forms the critical stiffening framework in ship hull construction. It reinforces hull plates against water pressure, supports deck structures, and creates the rigid framing system that maintains hull integrity under heavy loads and harsh marine conditions.

This fundamental component works tirelessly behind the scenes. Let me show you how L-shaped steel becomes the backbone of modern ship construction.

What type of steel is used in ship hulls?

Walking through a shipyard, you see massive steel plates being shaped into hull forms. But the real strength comes from the specialized steel that must withstand decades of ocean punishment.

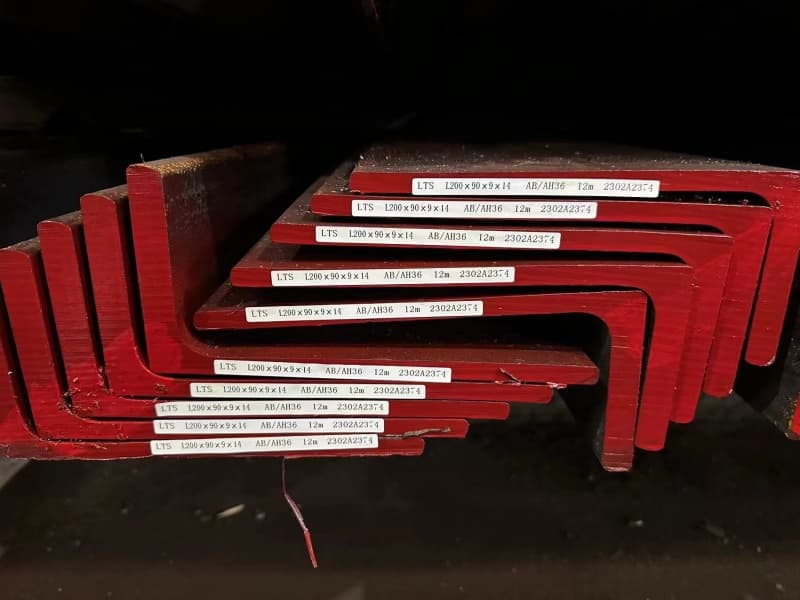

Ship hulls use high-strength, low-alloy steels1 certified by classification societies like ABS, DNV, or LR. Common grades include AH36, DH36, and EH362, which provide excellent toughness, corrosion resistance3, and weldability4. These steels maintain structural integrity under dynamic loading and harsh marine environments.

Comprehensive Analysis of Ship Hull Steel Requirements

The steel used in ship hulls represents some of the most rigorously tested materials in the construction industry. These steels are specifically engineered to address the unique challenges of marine service, where failure is not an option. The selection process involves balancing multiple competing requirements to achieve optimal performance.

The fundamental requirement for hull steel is exceptional toughness. Ships encounter dynamic loading from waves, cargo operations, and machinery vibrations. The steel must absorb energy without brittle fracture, especially in cold waters where ordinary steel becomes dangerously brittle. Classification societies mandate Charpy V-Notch impact testing5 at temperatures matching the vessel’s operational range.

Corrosion resistance is equally critical. Saltwater creates an extremely aggressive environment that attacks steel through multiple mechanisms. Hull steels incorporate alloying elements and controlled manufacturing processes to enhance corrosion resistance3. Additional protection comes from coatings and cathodic protection systems, but the base material must inherently resist marine corrosion.

Weldability demands careful attention in hull steel selection. Ship construction involves extensive welding operations, and the heat input can affect material properties. Hull steels maintain controlled chemical compositions with limited carbon equivalents to ensure good weldability4 without preheating or post-weld heat treatment in most cases.

The manufacturing process significantly influences hull steel performance:

- As-Rolled: Basic production for less critical applications

- Normalized: Heat treatment for improved toughness and consistency

- TMCP: Thermo-Mechanical Controlled Processing6 for optimal properties

Here’s a breakdown of hull steel applications:

| Hull Area | Typical Steel Grades | Key Requirements |

|---|---|---|

| Bottom Plating | AH36, DH36, EH36 | High strength, impact resistance, corrosion protection |

| Side Shell | AH32, AH36, DH36 | Fatigue resistance, weldability4, dimensional stability |

| Deck Plating | AH36, DH36 | Strength, stiffness, surface quality |

| Ice Belt | EH36, FH36 | Exceptional low-temperature toughness |

We recently supplied EH36-grade steel for an ice-class vessel operating in Arctic waters. The steel required certified impact toughness at -60°C to ensure safety when encountering ice and extreme cold temperatures during polar operations.

What is the primary material used in the construction of modern ship hulls?

When you look at a massive container ship or oil tanker, you’re essentially looking at a sophisticated steel structure designed to conquer the oceans. The primary material has remained consistent for good reasons.

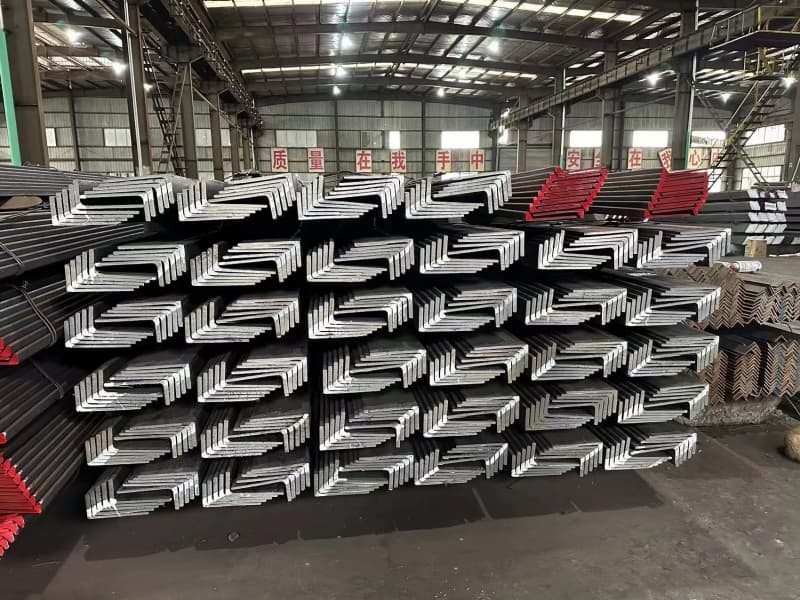

High-strength steel plates1 and sections form the primary material in modern ship hull construction. Marine-grade steel plates2 create the watertight envelope, while L-shaped steel3 and other sections provide the stiffening framework. These materials combine to create hulls that withstand extreme marine conditions.

Detailed Examination of Modern Ship Hull Materials

The dominance of steel in ship hull construction results from its unique combination of strength, durability, and cost-effectiveness. While alternative materials like aluminum and composites find use in specific applications, steel remains the workhorse for most commercial vessels due to its proven performance and established supply chains.

Steel plates typically constitute 85-90% of the hull material by weight. These plates form the outer shell that contains the cargo and resists water pressure. The plate thickness varies throughout the hull, with the bottom plating being thickest to withstand slamming forces and the deck plating designed for specific cargo loads. Plate dimensions have increased significantly, with modern mills producing plates up to 5 meters wide and 25 meters long.

Structural sections4 complement the plates by providing the necessary stiffening. L-shaped steel3 serves as the primary stiffening member in most hull designs. The angle sections attach perpendicular to the plates, creating a T-shaped configuration that dramatically increases bending resistance. Additional sections like bulb flats and T-bars provide specialized functions in specific areas.

The material selection process involves multiple considerations:

- Classification Requirements: Mandatory compliance with society rules

- Operational Profile: Matching material properties to service conditions

- Fabrication Considerations: Ensuring compatibility with shipyard capabilities

- Lifecycle Costs5: Balancing initial cost against maintenance requirements

Modern hull construction utilizes advanced steel grades:

- Conventional Strength: 235 MPa yield strength for non-critical areas

- High Strength: 315-390 MPa yield strength for primary structure

- Extra High Strength: 460 MPa and above for specialized applications

The table below shows material distribution in a typical hull:

| Material Type | Percentage by Weight | Primary Functions |

|---|---|---|

| Steel Plates | 85-90% | Watertight envelope, primary structure |

| L-Shaped Steel | 5-8% | Stiffening, framing, support systems |

| Other Sections | 3-5% | Specialized supports, foundations |

| Joinery Materials | 1-2% | Interior structures, accommodations |

Our shipments to shipyards in Vietnam and the Philippines typically include both plates and L-shaped sections in matching grades. This ensures consistent performance throughout the hull structure and simplifies welding procedures during construction.

What is the hull steel structure1?

The hull steel structure1 represents one of the most complex engineering achievements in modern construction. It’s not just a steel box but a carefully engineered system designed to handle immense forces.

The hull steel structure1 is the skeletal framework of a ship, comprising steel plates, stiffeners, frames, and girders. This integrated system resists water pressure, distributes cargo loads, and maintains hull shape under various operating conditions. L-shaped steel2 forms the primary stiffening members throughout this structure.

Comprehensive Guide to Hull Steel Structure Components

The hull steel structure1 functions as a massive composite beam that must withstand both global and local loads. Global loads affect the entire hull, such as hull girder bending when waves pass along the ship’s length. Local loads act on specific areas, like water pressure on bottom plating or cargo weight on deck structures.

The primary structural elements work together to create a efficient load-bearing system. Bottom shell plating forms the foundation, resisting upward water pressure and slamming forces from waves. Side shell plating provides transverse strength and protects against lateral impacts. Deck plating completes the hull girder’s upper flange, resisting compression and tension during bending.

Longitudinal members run parallel to the ship’s centerline and provide primary strength against hull girder bending. These include keel plates, center girders, side girders, and longitudinal stiffeners attached to plating. L-shaped steel2 typically serves as longitudinal stiffeners, creating a rigid connection to the plating that prevents buckling.

Transverse members provide lateral stability and distribute loads across the hull structure. These include floors in the bottom, side frames along the shell, and beams supporting the decks. The spacing of transverse members3 follows classification society rules based on vessel size and service requirements.

Key structural connections4 require special attention:

- Bracket Connections: Reinforce frame intersections and stress concentrations

- Scalloped Connections: Provide access while maintaining structural continuity

- Butt Welds: Join plates end-to-end with full penetration welds

- Fillet Welds: Attach stiffeners and other secondary members

The hull structure varies by vessel type:

- Single Hull: Traditional design with single bottom and side shell

- Double Hull: Modern standard with protective spaces along sides and bottom

- Double Bottom: Additional protection against bottom damage

- Ice Class: Reinforced structure for ice navigation

Here’s how L-shaped steel2 integrates into hull structure:

| Structural Area | L-Shaped Steel Function | Typical Sizes |

|---|---|---|

| Bottom Longitudinal | Stiffens bottom plating against water pressure | L200×200×16 to L300×300×20 |

| Side Frame Stiffeners | Supports side shell plating | L150×150×12 to L250×250×18 |

| Deck Beam Support | Reinforces deck plating under cargo loads | L120×120×10 to L200×200×15 |

| Bulkhead Stiffeners | Prevents buckling of watertight partitions | L100×100×8 to L180×180×14 |

We recently supplied L-shaped steel2 for a series of bulk carriers where the hull structure required precise dimensional control. The angles needed to maintain straightness within strict tolerances to ensure proper fit-up during the automated welding processes used in modern shipyards.

Which type of steel would be most suitable for constructing parts of a ship that need to withstand extreme temperatures and pressures?

Ships operating in extreme environments face challenges that push materials to their limits. The steel selection for these applications requires careful consideration of multiple performance factors.

For extreme temperatures and pressures, EH36/FH36 grades1 or specialized low-temperature steels2 are most suitable. These steels offer certified impact toughness at -40°C to -60°C, high yield strength3 (355-390 MPa), and enhanced through-thickness properties for critical structural connections in ice-class vessels and offshore applications.

Detailed Analysis of Steel for Extreme Marine Conditions

Ships operating in extreme environments demand steels with specialized properties that go beyond standard marine grades. The definition of "extreme" varies by application, but generally includes very low temperatures, high dynamic loads, or combinations of challenging conditions that standard steels cannot reliably withstand.

For low-temperature applications, the primary concern is brittle fracture resistance. As temperatures decrease, steel transitions from ductile to brittle behavior, losing its ability to absorb energy through plastic deformation. EH36 and FH36 steels address this through carefully controlled chemical compositions and manufacturing processes that ensure adequate Charpy impact values at service temperatures as low as -60°C.

High-pressure applications require steels with excellent strength-to-weight ratios and fatigue resistance. Offshore structures, submarine components, and specialized vessels encounter pressures that demand materials with high yield strength3 and good toughness. TMCP steels4 often provide the optimal combination of properties for these applications, offering high strength without compromising weldability or toughness.

Through-thickness properties become critical in highly constrained connections where lamellar tearing can occur. Z-quality steels5 undergo additional testing to verify adequate reduction of area in the through-thickness direction, preventing separation under high restraint conditions. This property is essential in critical structural connections where failure could have catastrophic consequences.

Specialized applications may require even more advanced materials:

- NV 420/500: Higher strength steels for weight-critical applications

- Stainless Clad: Corrosion-resistant surfaces for chemical carriers

- Quenched & Tempered: Ultra-high strength for specific components

- Cryogenic Steels6: For LNG carrier containment systems

The selection process for extreme condition steels involves:

- Temperature Analysis: Determining minimum service temperatures

- Load Assessment: Identifying peak pressures and dynamic loads

- Corrosion Evaluation: Assessing chemical exposure and protection methods

- Fabrication Review: Ensuring compatibility with construction methods

Here’s a comparison of steels for extreme conditions:

| Steel Grade | Temperature Rating | Yield Strength | Key Applications |

|---|---|---|---|

| EH36 | -40°C impact tested | 355 MPa | Winter navigation, cold regions |

| FH36 | -60°C impact tested | 355 MPa | Ice-breaking, Arctic operations |

| EH40/FH40 | -40°C to -60°C | 390 MPa | High-strength ice class vessels |

| Special Grades | -80°C and below | 355-460 MPa | LNG carriers, specialized applications |

We supplied FH36-grade L-shaped steel for an ice-breaking research vessel operating in Antarctic waters. The material required additional testing and documentation to verify performance at the extreme temperatures encountered during scientific missions in polar regions.

Conclusion

Marine L-shaped steel plays a fundamental role in ship hull construction, providing the stiffening framework that ensures structural integrity under demanding marine conditions. Proper material selection is crucial for vessel safety and performance.

-

Explore the unique properties of EH36/FH36 grades that make them ideal for extreme marine conditions. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how low-temperature steels enhance safety and performance in extreme cold conditions. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the significance of high yield strength in ensuring structural integrity under pressure. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how TMCP steels provide optimal strength and toughness for demanding marine applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how Z-quality steels prevent lamellar tearing in critical structural connections. ↩ ↩ ↩

-

Explore the specialized properties of Cryogenic Steels for safe LNG transport. ↩ ↩