You see these grade names on specifications and drawings: AH36, DH36, EH36. They look similar, but choosing the wrong one can compromise your ship’s safety and lead to project delays. The differences are critical, not just technical details.

AH36, DH36, and EH36 are high-strength marine steel grades defined by classification societies like ABS, LR, and DNV. The letter (A, D, E) indicates the minimum impact toughness at low temperatures. The number (36) indicates the minimum yield strength in ksi. DH36 is tougher than AH36, and EH36 is the toughest of the three.

I supply these grades to shipbuilders around the world. Every day, I help project managers and fabricators understand which grade fits their specific need. Using DH36 where AH36 would work costs extra money. Using AH36 where EH36 is specified risks failing inspections. Let me clear up the confusion and show you how to choose correctly.

What is the difference between EH36 and DH36?

Both EH36 and DH36 are high-strength grades. They have the same minimum yield strength. The key difference is not in their static strength, but in their ability to handle shock and cold. This difference becomes vital in harsh operating environments.

The main difference between EH36 and DH36 is their impact toughness at very low temperatures. EH36 steel is required to maintain higher impact energy (toughness) at lower testing temperatures (like -40°C or -60°F) compared to DH36. This makes EH36 suitable for ships operating in Arctic or severe cold regions.

Toughness: The Decisive Factor in Extreme Environments

Yield strength tells you how much load the steel can hold before it bends permanently. Toughness tells you how much energy it can absorb before it cracks. In freezing oceans, steel can become brittle. Toughness prevents catastrophic brittle fracture.

A Side-by-Side Technical Comparison

The requirements are set by rules from societies like Lloyd’s Register (LR) or the American Bureau of Shipping (ABS). Here is a typical comparison.

| Property / Requirement | DH36 Steel | EH36 Steel | Practical Implication |

|---|---|---|---|

| Minimum Yield Strength | 355 MPa (or 36 ksi) | 355 MPa (or 36 ksi) | Both grades are equally strong for normal structural design. The load-bearing capacity is the same. |

| Typical Impact Test Temperature | -20°C (-4°F) | -40°C (-40°F) | EH36 is tested at a much colder temperature, simulating Arctic conditions. |

| Minimum Charpy V-Notch Impact Energy | Often 34 Joules at -20°C | Often 34 Joules at -40°C (or higher energy at -20°C) | This is the core difference. EH36 must remain ductile and crack-resistant at temperatures where DH36 is not required to be tested. |

| Chemical Composition (Typical) | Similar base, but EH36 has tighter control on impurities and may have added alloys like Nickel (Ni) for low-temperature performance. | Tighter limits on elements like Carbon, Sulfur, and Phosphorus. May include Nickel, Niobium, Vanadium. | The cleaner chemistry and special alloys give EH36 its superior low-temperature toughness. |

| Production Process | Controlled rolling (TMCP) is common. | Requires more stringent TMCP or often Quenching & Tempering (Q&T) heat treatment. | Q&T processing refines the steel’s microstructure, enhancing toughness. This makes EH36 more expensive to produce. |

Application Guidelines: When to Specify EH36 Over DH36

Choosing between them is a safety and economic decision based on the vessel’s service.

-

Vessel Type and Route: This is the primary driver. EH36 is specified for:

- Ice-class vessels (icebreakers, Arctic supply ships).

- Ships operating in high-latitude routes (e.g., North Atlantic in winter, Southern Ocean).

- Offshore platforms in cold regions.

- Critical areas of large container ships where extra safety margins are needed.

-

Rules of the Classification Society: The ship’s designer follows the rules of the chosen class society (e.g., DNV, ABS, LR). These rules will mandate specific grades for specific structural locations based on the vessel’s intended service notation (like "ICE-1A" or "POLAR"). You do not choose arbitrarily; you follow the design specification.

-

Cost Consideration: EH36 is more expensive than DH36 due to its stricter production and testing. Using it where it is not required unnecessarily increases project cost. Using DH36 where EH36 is mandated will lead to rejection during material certification review.

For our clients building standard tankers or bulk carriers for temperate routes, DH36 is the workhorse grade. But for a client in Norway building a specialty offshore vessel, EH36 was a strict requirement. We sourced it from a mill with Q&T capabilities and provided the full certification pack. Understanding this distinction ensures you purchase the right material for the job’s actual demands.

What is the difference between AH and DH steel?

AH and DH steels are both very common in shipbuilding. They are often used on the same vessel. The difference is not about "good" and "better," but about assigning the right material to the right job on the ship. This optimizes both safety and cost.

The key difference between AH and DH steel is the level of impact toughness required. Both have the same minimum yield strength (e.g., AH36 and DH36 both have 355 MPa yield). However, DH grade steel must meet higher impact energy (toughness) requirements at a specified low temperature, making it suitable for more critical structural locations.

Allocating Strength and Toughness Where It’s Needed

A ship is not uniformly stressed. Some areas face higher dynamic loads and colder exposure. The grade system allows designers to use tougher (and slightly more expensive) steel only where necessary.

Breaking Down the A, B, D, E Designation

The letters come from the classification society rules (ABS, LR, etc.). They form a scale of increasing toughness.

| Grade Designation | General Meaning | Key Characteristic |

|---|---|---|

| A (e.g., AH36) | Normal Strength or standard toughness grade. | Meets the basic impact test requirements. It is the default grade for many structural applications. |

| B | An intermediate grade, less common than A or D. | Has slightly higher toughness requirements than A grade. |

| D (e.g., DH36) | Higher Toughness grade. | Must demonstrate good impact toughness at low temperatures (typically -20°C). |

| E (e.g., EH36) | Extra High Toughness grade. | Must demonstrate excellent impact toughness at even lower temperatures (typically -40°C). |

How This Translates to Ship Design and Procurement

You will rarely see a ship built entirely from DH steel. A typical mix is more efficient.

-

Typical Applications on a Ship:

- AH Steel (A-grade): Used for upper deck plating, internal bulkheads, secondary supporting structures, and areas not subject to high dynamic stress or very cold exposure.

- DH Steel (D-grade): Used for the main hull framing (including L-shaped steel longitudinals and stiffeners), bottom plating, sheer strake (top side shell), and other primary strength members. These areas are critical to the ship’s global strength and are more likely to experience stress concentrations and lower temperatures.

-

The Rationale for the Mix: Using DH36 for every piece of angle steel would be overkill and wasteful. By strategically using AH36 for less critical applications, the shipyard saves significant material cost without compromising the vessel’s overall structural integrity. The design drawings will specify exactly which grade goes where.

-

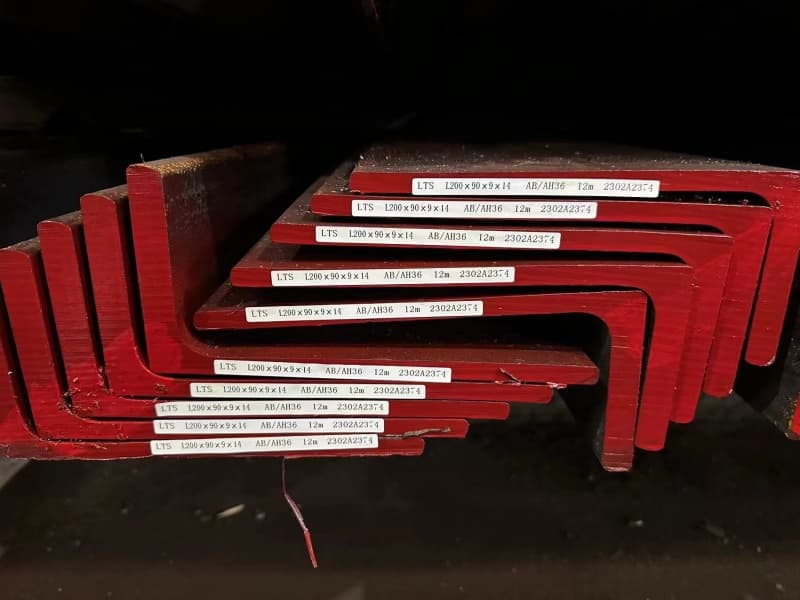

Importance for Buyers of L-Shaped Steel: When you procure marine angle steel (L-shaped steel), you must pay close attention to the grade specified on the material list. A single order might have lines for both AH36 and DH36 angles, with different quantities for each. Confusing them can lead to the wrong steel being installed in the wrong place, causing rework and delays.

In our daily work, we process orders that clearly separate AH and DH grades. For example, a shipyard in Vietnam might order 50 tons of DH36 angles for hull longitudinals and 20 tons of AH36 angles for internal deck supports. We pack and label them separately. Our clients appreciate this attention to detail because it prevents costly mix-ups at their fabrication site. Knowing the difference between AH and DH is fundamental to executing a procurement plan correctly.

What is the difference between A36 and AH36 steel?

This confusion is very common. The names look almost the same. But A36 and AH36 are completely different materials for completely different purposes. Mixing them up is one of the most serious and dangerous mistakes a buyer can make.

A36 is a general-purpose structural steel grade defined by the ASTM standard in the USA. AH36 is a high-strength marine steel grade defined by classification societies like ABS. A36 has lower yield strength (250 MPa vs. 355 MPa) and has NO required impact toughness testing for marine service. AH36 is specifically engineered for shipbuilding with guaranteed strength and toughness.

Why They Are Not Interchangeable: A Critical Warning

Using A36 steel in a marine structure designed for AH36 is a failure waiting to happen. The structure will be weaker and could fail in a brittle manner in cold water.

A Detailed Comparison of Two Different Worlds

Let’s put their specifications side by side to see the stark contrast.

| Specification | ASTM A36 Steel (General Purpose) | ABS AH36 Steel (Marine Grade) | Consequence of Substitution |

|---|---|---|---|

| Governing Standard | ASTM A36 (American Society for Testing and Materials) | ABS Rules (American Bureau of Shipping) / Other IACS society rules. | Different rulebooks. Marine classification societies do not accept ASTM A36 for hull structures. |

| Minimum Yield Strength | 250 MPa (36 ksi) | 355 MPa (51 ksi) | An AH36 part is about 40% stronger than an A36 part of the same size. Using A36 makes the structure under-strength. |

| Impact Toughness Requirement | Not required by the ASTM A36 standard. | Required. Must pass Charpy V-Notch test at a specified temperature (e.g., 0°C or -20°C depending on thickness). | A36 steel can become brittle in cold seawater. AH36 is guaranteed to remain tough. This is a major safety issue. |

| Chemical Composition | Limits for Carbon, Manganese, etc., but not optimized for weldability or toughness in thick sections. | Strict limits on Carbon Equivalent (CE) for weldability. Low Sulfur and Phosphorus for toughness. | A36 may be harder to weld without cracking in thick shipbuilding applications. |

| Certification & Traceability | Mill Test Certificate (MTC) is common. No mandatory third-party survey. | Requires a Classification Society Certificate (ABS, DNV, etc.) with heat number traceability and often surveyor involvement. | AH36 has a full pedigree. A36 has basic paperwork. The traceability chain is vital for marine insurance and class approval. |

The Root of the Confusion and How to Avoid It

The confusion comes from the "36" in both names.

- In ASTM A36, the "36" refers to the minimum yield strength in kilo-pounds per square inch (ksi), which is 36 ksi (approximately 250 MPa).

- In ABS AH36, the "36" also refers to the minimum yield strength in ksi, but here it is 36 ksi (approximately 250 MPa) for the base "A" grade? Wait, no. This is the tricky part. For AH/DH/EH grades, the number ’36’ actually denotes a minimum yield strength of 355 MPa (which is about 51 ksi). The numbering system between ASTM and marine grades is not aligned. AH36 is much stronger than A36.

The Golden Rule for Buyers: When you are working on a marine project, you must specify and purchase steel according to the classification society grade (AH36, DH36, ABS, DNV, LR). Never assume ASTM A36 is an acceptable substitute. Any reputable marine steel supplier will immediately question an order for A36 for shipbuilding.

We have had inquiries from new clients asking for A36 for "marine use." Our first response is always to ask for the project specifications and the required classification. We then explain the critical differences. Educating our clients protects their projects and builds trust. For a professional like the buyer from Gulf Metal Solutions, this distinction is clear, and they would never risk their reputation or a vessel’s safety with the wrong material.

What is AH36 steel1?

Now that we have distinguished it from others, let’s focus on AH36 itself. It is the foundation grade for much of modern shipbuilding. Understanding its specific role helps you see why it’s so widely specified.

AH36 is a high-strength, marine-grade structural steel2. The "A" indicates it meets standard impact toughness requirements. The "H" means it is high-strength. The "36" indicates a minimum yield strength of 355 MPa3 (51 ksi). It is certified by classification societies like ABS, LR, or DNV for use in ship hulls and offshore structures.

The Workhorse of the Shipyard: Properties and Production

AH36 is not exotic. It is a reliably produced, cost-effective material that balances strength, toughness, and weldability for a vast range of marine applications.

The Technical Profile of AH36 Steel

Here is what goes into making and certifying AH36.

| Aspect | Details for AH36 |

|---|---|

| Mechanical Properties | – Yield Strength (ReH): ≥ 355 MPa (51 ksi). – Tensile Strength (Rm): 490 – 620 MPa. – Elongation: Typically ≥ 21%. – Impact Toughness: Meets minimum Charpy V-Notch energy (e.g., 34 J) at a specified test temperature (often 0°C for thicker plates). |

| Chemical Composition | Controlled to ensure weldability and strength. Key limits include: – Carbon Equivalent (CE): Typically limited to ~0.41% to prevent welding cracks. – Low Sulfur & Phosphorus: Improves toughness. – Added micro-alloys like Niobium (Nb) or Vanadium (V) for strength through grain refinement. |

| Production Process | Most modern AH36 is produced via Thermomechanical Controlled Processing (TMCP)4. The steel is rolled under precise temperature controls. This process eliminates the need for expensive heat treatment while achieving the required strength and toughness. |

| Standard Forms | Available as plates, sections (angles, bulb flats – "L-shaped steel"), and bars. For angles, common sizes like 200x200x20mm or 150x150x12mm are produced in AH36 grade. |

Primary Applications of AH36 L-Shaped Steel

In the form of angles and bulb flats, AH36 is used extensively.

- Ship Hull Construction: It is used for secondary stiffeners and framing where the design does not call for the higher toughness of DH36. This includes many internal brackets, deck stiffeners, and bulkhead stiffeners.

- Offshore Structures: Used in jacket legs, bracings, and platform decks where the specified grade is "A" grade high-strength steel.

- Fabrication of Marine Equipment: Used for cranes, winch foundations, and other equipment mounted on ships or offshore platforms.

Why It’s a Popular Choice for Buyers

For rational, results-driven procurement managers, AH36 represents optimal value in many cases.

- Cost-Effectiveness: It provides high strength (355 MPa yield) at a lower cost than DH36 or EH36, because its toughness requirements are less stringent.

- Availability: It is a standard grade produced in large quantities by certified mills5 worldwide, ensuring stable supply and competitive pricing.

- Proven Performance: Decades of use in thousands of vessels have proven its reliability for its intended applications.

When clients come to us for marine L-shaped steel, AH36 is often a large part of their order. Our role is to ensure the steel we supply is genuinely AH36 from a certified mill, accompanied by the proper classification certificates. We also help them decide if their application truly requires AH36 or if a different grade is needed. This consultative approach, combined with fast response and SGS inspection support, is what turns a simple material purchase into a reliable partnership for their ongoing projects.

Conclusion

Choosing the correct marine steel grade—AH36, DH36, or EH36—is a fundamental decision that balances strength, toughness, cost, and safety requirements for your specific vessel and its operating environment.

-

Explore this link to understand the essential properties and applications of AH36 steel in shipbuilding and offshore structures. ↩

-

Learn about the significance of high-strength, marine-grade structural steel in various marine applications and its benefits. ↩

-

Discover why a yield strength of 355 MPa is crucial for structural integrity in marine environments. ↩

-

Find out how TMCP enhances the properties of steel, making it suitable for demanding applications. ↩

-

Learn about the role of certified mills in ensuring quality and compliance in steel production. ↩