Selecting the wrong grade of steel for a marine project is a costly mistake. I’ve seen projects delayed and budgets blown because of material failures that could have been prevented. Understanding the core mechanical properties is not just technical knowledge—it’s financial and operational insurance for your shipbuilding or offshore venture.

The fundamental properties of marine steel plates you must know are yield strength, tensile strength, impact toughness (especially at low temperatures), and corrosion resistance. These properties determine how the steel will perform under the harsh conditions of the sea, including heavy loads, wave impact, and corrosive saltwater environments.

Navigating the world of marine steel specifications can feel overwhelming with all the different grades and standards. But by breaking down the key mechanical properties and the common grades associated with them, you can make confident, informed decisions for your procurement. The following sections will provide clear, actionable insights into what makes marine steel unique and how to decode the grades you encounter daily.

What are the properties of marine steel?

Every day, shipbuilders and fabricators face a constant battle against the ocean’s power. The steel they use is their first and most critical line of defense. If the core properties aren’t up to par, the entire structure is at risk from day one.

Marine steel must possess high yield and tensile strength1 to handle structural loads, excellent impact toughness2 at low temperatures to resist brittle fracture in cold waters, and enhanced corrosion resistance3 to withstand saltwater. Weldability4 is also a crucial property to ensure the integrity of fabricated structures.

A Deeper Look at the Critical Properties

When we talk about marine steel properties, we’re not just listing numbers from a datasheet. We’re talking about the real-world performance that keeps a vessel safe and operational for decades. Let’s break down why each property is non-negotiable.

1. Strength: The Backbone of the Structure

Strength in marine steel is primarily defined by two values: Yield Strength (ReH) and Tensile Strength (Rm).

- Yield Strength is the maximum stress the steel can withstand without permanent deformation. Once stress exceeds this point, the steel will not return to its original shape. For a ship’s hull bending in heavy seas, maintaining integrity below this yield point is essential.

- Tensile Strength is the maximum stress the steel can take before it fractures. The ratio between yield and tensile strength also matters for safety, indicating a material’s ability to absorb overload before failure.

For example, common shipbuilding grades like AH36 have a minimum yield strength of 355 MPa. This isn’t an arbitrary number; it’s calculated based on the stresses expected in specific structural members of a vessel.

2. Toughness: Surviving Impact and Cold

This is arguably the most critical property for safety. Toughness is a material’s ability to absorb energy and plastically deform without fracturing. In marine contexts, we measure it through Charpy V-Notch (CVN) Impact Tests5.

| Property | What It Measures | Why It’s Vital for Marine Use |

|---|---|---|

| Impact Toughness | Energy absorbed (in Joules) during a sudden impact. | Resists cracking from slamming waves, ice impact, or accidental collisions. |

| Test Temperature | Toughness is measured at specific low temperatures (e.g., -20°C, -40°C, -60°C). | Ships operate in Arctic routes or cold deep waters. Steel must remain ductile, not become brittle. |

A high CVN value at a low temperature means the steel has high fracture toughness. Grades are often designated by their test temperature (e.g., AH36 / DH36 / EH36), where ‘D’ indicates testing at -20°C and ‘E’ at -40°C.

3. Corrosion Resistance: The Longevity Factor

Saltwater is an exceptionally corrosive electrolyte. Marine steel plates often achieve corrosion resistance3 through:

- Chemical Composition6: Controlled levels of elements like Copper (Cu), Chromium (Cr), and Nickel (Ni) can improve atmospheric corrosion resistance3.

- Coatings: Primers and specialized paint systems are the primary defense, but the steel’s inherent resistance provides a safety net.

- Design: Proper detailing to avoid crevices where corrosion can concentrate is also part of material selection.

4. Weldability4: The Fabrication Essential

A ship is a welded structure. Poor weldability leads to defects, cracks, and weak joints. Weldability4 is influenced by the steel’s Carbon Equivalent (CEV or Pcm)7. A lower CEV means the steel is less prone to forming hard, crack-sensitive microstructures in the heat-affected zone during welding. Mills control this through precise chemistry and manufacturing processes like Thermo-Mechanical Control Process (TMCP).

In my experience working with clients like Gulf Metal Solutions, they prioritize suppliers who can consistently provide certified material with these properties verified. They need the paperwork—the Mill Test Certificate (MTC)8—to prove the steel meets every single one of these requirements before it even leaves the mill.

Is 2062 E250 mechanical property?

Many project managers and buyers from regions like South Asia and the Middle East frequently encounter IS 2062. They ask if it’s suitable for marine work, revealing a common gap between general structural steel and specialized marine grades.

While IS 2062 E2501 is a reliable Indian standard for general structural steel with defined mechanical properties, it is not specifically designed for the harsh, corrosive, and high-impact environment of marine applications2. Its properties, particularly toughness and corrosion resistance3, typically do not meet the stringent requirements of dedicated marine steel grades.

Understanding IS 2062 E2501 in the Marine Context

The confusion is understandable. IS 2062 is a ubiquitous standard for plates, sections, and bars used in construction and general fabrication across many countries. Let’s clarify what E250 offers and where it falls short for marine use.

What IS 2062 E2501 Actually Is

IS 2062 is the Indian Standard for "Steel for General Structural Purposes." The "E250" designation refers to its minimum yield strength4 of 250 MPa. The ‘E’ indicates that the steel is suitable for welding. Here are its key mechanical properties as per the standard:

| Property | Requirement for E250 Grade |

|---|---|

| Yield Strength (Min) | 250 MPa |

| Tensile Strength | 410 – 540 MPa |

| Elongation (Min) | 23% |

| Impact Test | Often specified at +27°C or 0°C, not at the low temperatures required for marine steel. |

The Critical Gap for Marine Use

- Insufficient Low-Temperature Toughness: This is the biggest differentiator. Marine grades like AH/DH/EH are mandated to pass Charpy V-Notch tests at -20°C, -40°C, or lower. IS 2062 E2501 is generally tested at much higher temperatures (like 0°C or even room temperature). In cold seawater, E250 steel has a significantly higher risk of brittle fracture.

- Lack of Specific Corrosion Considerations: The standard does not mandate chemical compositions aimed at enhancing atmospheric corrosion resistance3 for saltwater environments.

- Strength Level: For main hull structures of most sea-going vessels, a yield strength4 of 250 MPa is often considered too low. Modern shipbuilding commonly uses grades starting at 355 MPa yield (like AH36) for better strength-to-weight ratio and structural efficiency.

Appropriate vs. Inappropriate Use

- Potentially Appropriate: For non-critical, secondary structures on a vessel located in consistently warm waters, or for inland waterway barges with less stringent rules. It might be used in some superstructure areas not subject to primary loads or wave impact.

- Inappropriate and Risky: For the primary hull, bottom plating, side shells, or any structurally critical part of an oceangoing ship, oil tanker, or bulk carrier. Classification societies like Lloyd’s Register, DNV, or ABS would not approve it for these purposes.

For a marine-specific project, you should be looking to standards set by classification societies5 (like LR, ABS, DNV GL rules) or international standards like EN 10025 for S-series steels, which have marine-approved sub-grades. The takeaway is clear: never assume a general structural steel like IS 2062 E2501 is a direct substitute for a certified marine steel plate. Always consult the project specifications and relevant classification society rules.

What is grade S275 and S355 steel?

In the global steel market, especially across Europe, the Middle East, and Asia, S275 and S355 are household names. But when a client asks for "S355 for a marine project," my first question is always: "Do you need the standard S355, or the marine-grade S355?"

S275 and S355 are structural steel grades from the EN 10025 standard, defined by their minimum yield strength of 275 MPa and 355 MPa respectively. For marine applications, specific sub-grades like S355G2+M or S355N are used, which offer enhanced impact toughness and are approved by major marine classification societies for shipbuilding.

Decoding S-Grades: From Land to Sea

The S-grades are a perfect example of how a base material is engineered to meet specialized demands. Understanding the suffixes and附加 designations is the key to correct procurement.

The Base Material: S275 and S355

These grades are part of a system. The ‘S’ stands for "Structural Steel." The number indicates the minimum yield strength in MPa.

- S275: Minimum yield strength = 275 N/mm².

- S355: Minimum yield strength = 355 N/mm².

They are further divided by delivery condition and quality:

- JR (ex: S355JR): Basic impact toughness tested at room temperature (+20°C). Common for general construction.

- J0 (ex: S355J0): Impact toughness tested at 0°C.

- J2 (ex: S355J2): Impact toughness tested at -20°C.

- K2 (ex: S355K2): Impact toughness tested at -20°C (an alternative to J2).

- N (ex: S355N): Normalized rolled steel with improved toughness.

The Marine Evolution: S355G2+M and S355G3+M

This is where general structural steel becomes marine steel. The ‘G’ stands for "Grade for offshore and marine applications." The numbers (2, 3) correspond to different impact test temperature requirements.

- S355G1+M: Not common.

- S355G2+M: Tested at -20°C. Equivalent to shipbuilding grade ‘D’ (e.g., DH36).

- S355G3+M: Tested at -40°C. Equivalent to shipbuilding grade ‘E’ (e.g., EH36).

The "+M" denotes that the product is supplied in the thermomechanically rolled condition (TMCP), which provides a fine-grained structure, excellent toughness, and good weldability without needing a separate heat treatment step.

Comparative Table: S355JR vs. S355G2+M

| Feature | S355JR (General Structural) | S355G2+M (Marine & Offshore) |

|---|---|---|

| Standard | EN 10025-2 | EN 10225 / EN 10025-4 (Formerly) |

| Min. Yield Strength | 355 MPa (16mm< thickness ≤ 40mm) | 355 MPa |

| Tensile Strength | 470 – 630 MPa | 470 – 630 MPa |

| Impact Test Temp. | +20°C | -20°C |

| Typical Min. Impact Energy | 27 J at +20°C | 40 J at -20°C |

| Common Use | Buildings, bridges, general fabrication. | Ship hulls, offshore platforms, nodes. |

| Classification Approval | Usually not approved for primary marine structures. | Approved by LR, DNV, ABS, etc., for specific applications. |

Why the Distinction Matters for Your Business

Choosing S355JR over S355G2+M for a marine project because of a slightly lower price is a severe compromise on safety and compliance. The enhanced, guaranteed low-temperature toughness of the 'G' grade is what prevents catastrophic brittle fracture in the North Sea or the Atlantic.

Our production partners regularly supply S355G2+M and G3+M to projects in Qatar, Saudi Arabia, and Romania for offshore modules and ship repairs. The Mill Test Certificates always explicitly state the grade with the full designation and the required Charpy values at the specified low temperature. This traceability and certification are what our B2B clients—the fabricators and project contractors—require to satisfy their own customers and regulatory bodies.

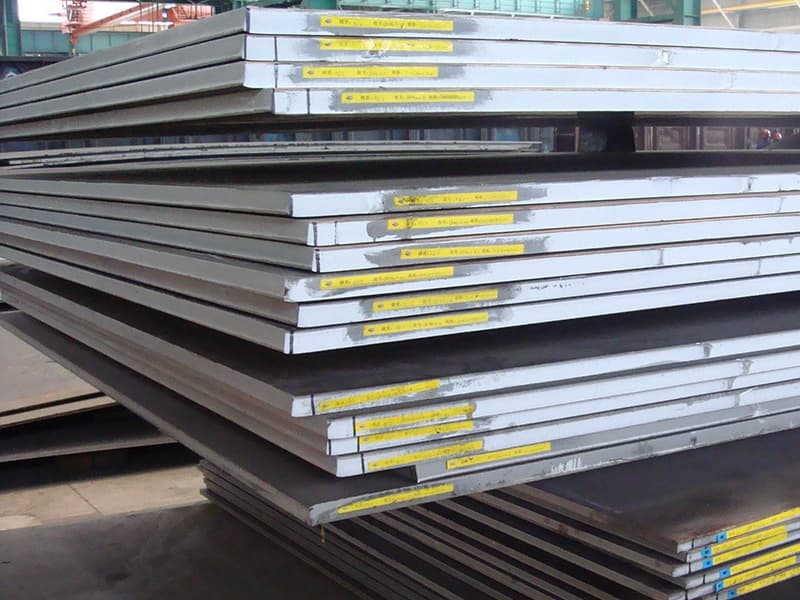

What are the grades of marine steel plates1?

Walking through a shipyard, you'll hear a mix of grade names: AH36, DH32, E40, S355G32. It sounds like alphabet soup. For a new buyer, this can be the most confusing part. But each letter and number tells a specific story about the steel's capability.

Marine steel plates are graded primarily through two systems: classification society grades3 (like ABS Grade A, AH36, EH40) and European standard grades4 (like S235G2, S355G32). These grades systematically define the steel's yield strength5, impact toughness test temperature6, and specific application within a vessel's structure.

%[marine steel plate grades chart comparison](https://cnmarinesteel.com/wp-content/uploads/2025/10/Marine-steel-plate-19.webp "marine steel plate grades classification")

Navigating the Marine Steel Grading Systems

To make an informed choice, you need to understand the logic behind the naming conventions. Let's map out the two dominant systems.

1. Classification Society Grades (ABS, LR, DNV, etc.)

Most oceangoing vessels are built under the rules of a classification society. Their grades are the global lingua franca of shipbuilding. The format is typically: Letter(s) + Number + (Optional Letter).

- The First Letter(s): Indicates general application or strength level. 'A' is mild steel, 'AH' is higher strength steel. Some societies use 'D' for ordinary strength, 'E' for higher strength.

- The Number: Indicates the minimum yield strength5 in ksi (kilo-pounds per square inch). This is a critical point often missed.

- 32 = 32 ksi ≈ 315 MPa yield strength5

- 36 = 36 ksi ≈ 355 MPa yield strength5

- 40 = 40 ksi ≈ 390 MPa yield strength5

- The Last Letter (Optional): Indicates impact test temperature. This is paramount.

- No letter or 'A': Basic impact requirements.

- 'D': Tested at -20°C.

- 'E': Tested at -40°C.

- 'F': Tested at -60°C.

Example Decoding:

- AH36: Higher strength steel, 355 MPa yield, standard toughness.

- DH36: Higher strength steel, 355 MPa yield, tested at -20°C.

- EH36: Higher strength steel, 355 MPa yield, tested at -40°C.

Different societies have slight variations (e.g., LR uses 'A', 'D', 'E', 'F'; ABS uses 'A', 'D', 'E', 'F', 'AH', 'DH', 'EH' for higher strength). The rulebooks provide detailed tables.

2. European Standard Grades (EN 10025 / Formerly EN 10225)

As discussed earlier, this system uses the 'S' for structural and 'G' for marine/offshore.

These are widely accepted and often cross-approved by classification societies.

Grade Selection Based on Vessel Location and Part

The grade is not chosen at random. It follows a logical plan based on the stress and temperature the plate will experience.

| Vessel Structural Part | Typical Grade Examples | Reasoning |

|---|---|---|

| Inner Bottom, Midship Deck (Moderate stress, colder exposure) | AH36, DH32, S355G2+M | Requires good strength and toughness at moderately low temperatures. |

| Bottom Shell, Keel (High stress, direct contact with cold water) | DH36, EH36, S355G32+M | Highest stress area. Requires superior strength and excellent toughness at low temperatures (-20°C to -40°C). |

| Superstructure, Internal Decks (Lower stress, protected) | Grade A, S235JR | Where strength and low-temp toughness requirements are less critical. |

| Arctic Ice-Class Vessels7 | EH40, FH32, FH40, S420G2+M | Requires the highest strength and the best toughness at extremely low temperatures (-40°C to -60°C). |

The Procurement Takeaway

When you procure marine steel, you don't just order "ship plate." You order a specific grade defined by a recognized standard or classification society rule. This specification is part of your contract and is verified by the Mill Test Certificate8. For our clients, whether they are building a container ship in Vietnam or repairing an oil tanker in Saudi Arabia, providing the correct, certified grade is the foundation of trust. It ensures their project meets design specs, passes surveys, and, most importantly, operates safely for its entire lifespan.

Conclusion

Knowing the mechanical properties and grading systems for marine steel is essential for making safe, compliant, and cost-effective procurement decisions. It transforms a complex specification sheet into a clear blueprint for your project's success.

-

Explore the diverse applications of marine steel plates in shipbuilding and offshore structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the applications and benefits of S355G3 steel in marine and offshore structures. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the importance of classification society grades in ensuring ship safety and compliance. ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how European standard grades ensure quality and safety in marine steel production. ↩ ↩ ↩ ↩ ↩ ↩

-

Understand yield strength and its critical role in selecting the right steel for marine applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how impact toughness test temperature affects the performance of marine steel in harsh conditions. ↩ ↩

-

Understand the unique requirements and specifications for vessels designed to navigate icy waters. ↩ ↩

-

Learn about the significance of Mill Test Certificates in verifying steel quality and compliance. ↩ ↩