Offshore platforms and wind farms face relentless ocean forces. A mistake in steel selection here doesn’t just mean repair; it risks lives, the environment, and millions in assets.

Choosing offshore engineering steel profiles requires a careful balance of extreme strength, high fracture toughness at low temperatures, excellent weldability, and superior corrosion resistance. The selection must follow strict international standards and consider the entire structure’s lifecycle in a harsh marine environment.

I’ve supplied steel for jacket legs in the Gulf and monopiles in the South China Sea. The pressure is immense because the stakes are so high. This article will guide you through the key considerations, moving beyond textbook definitions to practical, project-tested insights.

What is engineering steel used for?

Think of engineering steel as the specialized "bone and muscle" of industrial projects. It’s not generic steel. It’s precisely formulated for jobs where failure is not an option under immense stress, fatigue, or extreme conditions.

Engineering steel1 is used to create critical load-bearing structural components that must withstand high stress, dynamic loads, impact, and harsh environments. In offshore engineering, this includes jacket legs, decks, piles, crane pedestals, and wind turbine monopiles and transition pieces.

This usage defines its entire character. Ordinary construction steel would buckle or crack under the cyclic loading of waves or the concentrated stress at a node connection. Let’s break down exactly where and why these specialized steels are non-negotiable.

The Critical Applications in Offshore Projects

Offshore structures are a symphony of specialized parts, each demanding specific steel properties. Here is a detailed look at the main applications.

Primary Structural Framing: Jackets and Topsides

This is the skeleton of fixed platforms. The steel here must handle the platform’s weight, equipment loads, and, most importantly, constant wave and wind forces.

- Jacket Legs and Braces: These large-diameter tubes form the substructure. They need high yield strength2 (e.g., S355, S420) to resist bending, and excellent through-thickness properties (Z-direction steel) to prevent lamellar tearing at heavily welded joints. Thick plates are common, often delivered in the normalized condition3 to ensure uniform properties.

- Node Connections: Where legs and braces intersect. These are the most critical and complex welded areas. Steel here requires the highest impact toughness4 (e.g., EH36, EH40) to resist crack initiation in cold water and high weldability with a strictly controlled Carbon Equivalent.

Foundation Elements: Piles and Monopiles

These components transfer all loads into the seabed. They face unique challenges.

- Driveability: During installation, piles are hammered into the seabed. The steel must have sufficient ductility and toughness5 to withstand this violent driving without cracking. Grades like S355G2+M (thermomechanically rolled) are popular for their good balance of strength and toughness.

- Corrosion and Fatigue: They are partially buried, partially in seawater, and subject to constant stress cycles. Cathodic protection6 is always used, but the steel must still have good inherent corrosion resistance and fatigue strength7.

Specialized Components

- Crane Pedestals and Heavy-Lift Areas: These points experience intense, dynamic point loads. They often use quenched and tempered (Q&T) steels like S690QL for their very high strength-to-weight ratio, allowing for stronger supports without adding excessive weight to the topsides.

- Wind Turbine Transition Pieces: The connector between the monopile and the tower. It must endure tremendous bending moments and is a hot spot for fatigue analysis. Steel grades here are similar to high-grade offshore plates, with a major focus on flawless welding procedure qualifications8.

My Client’s Application: A Real Case

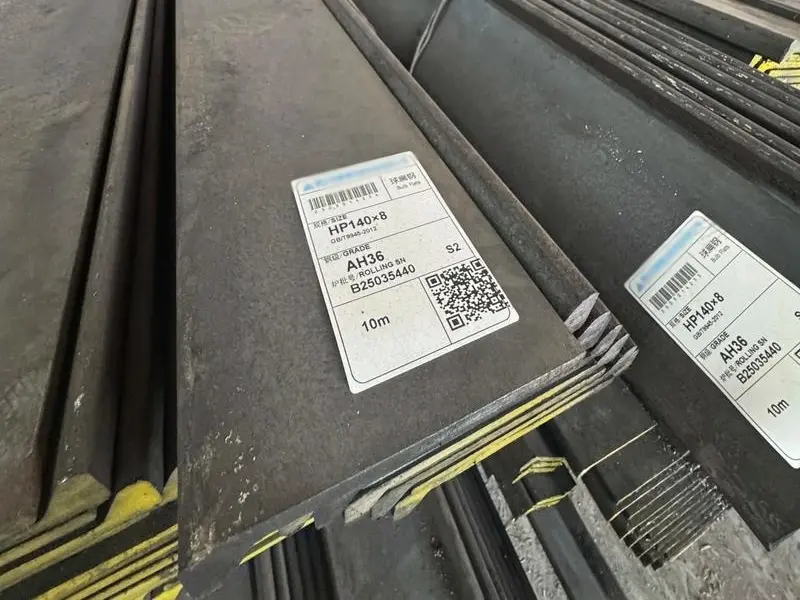

For Gulf Metal Solutions’ project, they weren’t building a full platform but were fabricating modular sections and repair components for offshore rigs in the Arabian Gulf. They needed Marine Angle Steel9 and Bulb Flat Steel for reinforcing walkways and secondary structural supports. The key requirement wasn’t ultra-high strength but consistent toughness (we specified S355J2+N) and perfect surface quality to allow for high-quality welding and coating in their fabrication yard. Our ability to provide SGS-certified, normalized plates with clean edges solved their previous quality inconsistency issues.

| Application | Typical Profiles Used | Critical Steel Properties | Common Steel Grades | Why These Properties Matter |

|---|---|---|---|---|

| Jacket Legs / Braces | Heavy plates rolled into large-diameter tubes | High Strength, Through-Thickness (Z) Quality, Good Weldability | EN 10225 S355G2+N, S420G2+M, API 2W/2H | Resists global bending moments; prevents lamellar tearing at nodes. |

| Offshore Piles / Monopiles | Very thick plates rolled into large cylinders | High Toughness, Good Fatigue Strength, Driveability | S355G2+M, S355G7+N, S460G2+M | Withstands hammering during installation; resists decades of wave-induced fatigue. |

| Topsides Decking | Plates, Sections (Beams, Angles) | High Strength-to-Weight Ratio, Fire Resistance (for living quarters) | S355, S460, Fire-resistant grades (e.g., S355M-FR) | Supports heavy equipment; safety in case of fire. |

| Crane Pedestals | Heavy plates, thick-walled tubes | Very High Yield Strength, Good Weldability | S690QL, S890QL (Quenched & Tempered) | Handles extreme dynamic loads from lifting operations. |

| Walkways, Staircases | Flat Bar, Checkered Plate, Angle Steel | Corrosion Resistance, Good Surface Finish | S355J2+Z (galvanized), Stainless Steel (316) | Ensures long-term safety and low maintenance in the splash zone. |

What are the four types of steel?

Many people talk about "steel" as one material. But for engineering, this broad category is useless. We need to classify steel by how it’s made and what’s in it, as this directly defines its capabilities and limits.

The four fundamental types of steel are: Carbon Steel1, Alloy Steel2, Stainless Steel3, and Tool Steel4. For offshore engineering, the focus is primarily on specific grades of Carbon and Alloy Steel2s, with Stainless Steel3 used for specialized non-structural components.

Understanding this classification is your first step to speaking the right language with engineers and mills. It moves you away from vague descriptions and toward precise material specifications.

A Detailed Look at Each Type in an Offshore Context

Let’s explore each type, focusing on their role in the marine world I operate in every day.

1. Carbon Steel1

This is the most common engineering steel. Its properties come mainly from the carbon content, with minimal other alloys.

- Low Carbon Steel1 (Mild Steel): Contains up to 0.3% carbon. It is ductile, tough, and easily welded. However, its strength is relatively low, and it has poor corrosion resistance. It is rarely used for primary offshore structures but may be used for temporary works or non-critical secondary items that are heavily coated.

- Medium & High Carbon Steel1: Stronger but less ductile and much harder to weld. High carbon steel is brittle. These are generally avoided in offshore structures due to poor weldability and low impact toughness, which are critical fail points.

The key point for offshore: What we often call "carbon steel" in specifications is actually High-Strength Low-Alloy (HSLA) steel5, a sub-group. HSLA steels, like S355 or API grades, have tiny, precise additions of elements like niobium, vanadium, or titanium. These additions greatly increase strength and toughness without severely harming weldability. Most offshore structural plates are HSLA steels.

2. Alloy Steel2

This steel intentionally adds significant amounts of other elements (like Chromium, Nickel, Molybdenum) to achieve specific properties.

- High-Strength Low-Alloy (HSLA): As mentioned, this is the backbone of offshore construction (S355, S420, S460).

- Quenched and Tempered (Q&T) Alloy Steels6](https://www.qcforge.com/forging-innovations-blog/is-alloy-steel-strong/)[^2]s: These steels (like S690QL) undergo a heat treatment process (quenching then tempering) to achieve very high strength levels. They are used for critical, highly stressed parts like crane components or special forgings on a platform.

- Corrosion-Resistant Alloys7: Some alloy steels, like ASTM A588, add copper, chromium, and nickel for better atmospheric corrosion resistance. They might be used for parts of the topsides structure.

3. Stainless Steel3

Defined by a minimum of 10.5% Chromium, which forms a passive, self-repairing oxide layer for corrosion resistance.

- Austenitic (e.g., 304, 316): Non-magnetic, excellent corrosion resistance. 316/L is the "marine grade" used for handrails, instrument housings, bolts in splash zones, and piping systems. It is not used for primary structure due to cost and lower strength.

- Duplex (e.g., 2205): A mix of austenitic and ferritic structures. It has higher strength than 316 and better resistance to chloride stress corrosion cracking. It is used for critical seawater piping, heat exchangers, and sometimes for fasteners in extremely aggressive environments.

4. Tool Steel4

Very hard, wear-resistant steel used for cutting, drilling, or shaping other materials. It has high carbon and alloy content. You will not find tool steel in offshore structures. It is used in the fabrication process (e.g., cutting blades, drill bits) but not as part of the final installation.

The Offshore Reality: A Blend

A single offshore platform uses a blend. The jacket might be S355G2 (HSLA Alloy), the crane boom S690QL (Q&T Alloy), the handrails 316 Stainless, and the temporary construction shackles made from medium carbon steel. The specification process is about choosing the right type and grade for each precise function.

What does a steel engineer do?

The term "steel engineer" can be confusing. On an offshore project, it’s not one person but a vital function shared between the fabricator’s team, the design consultancy, and even informed suppliers like us.

A steel engineer (or structural/materials engineer) ensures the selected steel meets all design, fabrication, and safety requirements. Their work spans specifying grades, approving welding procedures, reviewing test certificates, and solving on-site material problems.

When Gulf Metal Solutions has a technical query, they don’t just speak to a salesperson. They speak to our technical team that performs this engineering liaison role. This gap in support was a major pain point with their previous suppliers.

The Multifaceted Role in the Offshore Supply Chain

The steel engineering function is a bridge between theoretical design and physical reality. Here’s what this role involves at different stages.

Stage 1: Design and Specification

- Material Selection: They work with the structural designer to choose the appropriate steel grade for each component based on load calculations, environmental conditions, and codes (ISO, DNV, API).

- Specification Writing: They translate the choice into a detailed Material Take-Off (MTO)1 and Purchase Specification, listing standards, grades, dimensions, tolerances, delivery conditions, and required testing (Charpy, DWTT, NDT).

Stage 2: Procurement and Supplier Liaison

- Technical Bid Evaluation: They review supplier offers not just on price, but on technical compliance2. Does the mill’s standard match the project spec? Can they provide the required certifications (e.g., DNV GL, ABS approval)?

- Clarifying Technical Queries: A good supplier will ask technical questions. The steel engineer answers them. For example, "The spec calls for impact testing3 at -40°C transverse. Our standard is longitudinal. Is this acceptable?" Resolving these details upfront prevents costly rejection later.

- Reviewing Mill Documentation: This is a critical duty. They meticulously check the Mill Test Certificates (MTCs)4 and Third-Party Inspection Reports against the project specification before approving the material for shipment.

Stage 3: Fabrication and Construction

- Welding Procedure Qualification (WPQ): They approve the Welding Procedure Specifications (WPS)5. The steel’s chemical composition (especially CEV) directly dictates the pre-heat requirements and welding parameters.

- Material Traceability: They ensure steel is properly marked and tracked from receipt, through cutting, to final erection. This is crucial for quality assurance and any future investigation.

- Non-Conformance Resolution6: If a plate fails an ultrasonic test or has a surface defect, the steel engineer assesses the severity. They decide if it can be repaired (ground out), used in a less critical area, or must be rejected.

How We Support This Role as a Supplier:

We act as an extension of our client’s engineering team. For a client in Mexico, we provided not just the S460 steel plates but also the mill’s recommended welding guidelines and full historical MTCs for a similar heat for their WPQ trials. This proactive support speeds up their fabrication process. We bridge the gap between the Chinese mill’s production data and the international project’s engineering requirements. Our English-speaking technical sales reps are trained to understand these engineering conversations, which directly addressed Gulf Metal Solutions’ complaint about a "lack of English-speaking support staff."

What is the most common engineering steel?

If you walk through any major offshore fabrication yard in Qatar or Malaysia, one grade family will dominate the material yards. It’s the workhorse, the default starting point for a vast range of structural components.

The most common engineering steel for offshore structures is the S355 series1, particularly grades like S355J2, S355K2, S355G2, and S355G3. These high-strength low-alloy (HSLA) steels2 offer an optimal balance of strength, toughness, weldability, and cost for many primary and secondary structural elements.

Its popularity isn’t an accident. It represents a sweet spot that engineering codes and decades of practice have settled on. But "S355" is not one steel; it’s a performance bracket with important variations.

Understanding the Ubiquity and Variations of S355

Let’s break down why S355 is so prevalent and how to choose the right variant for your project.

Why S355 is the Offshore Workhorse:

- Sufficient Strength: A minimum yield strength of 355 MPa (51 ksi) is adequate for a huge portion of a platform’s structural members. Using a higher strength steel (like S690) adds cost and complexity where it’s not needed.

- Excellent Weldability: The chemical composition of S355 grades is carefully controlled to keep the Carbon Equivalent Value (CEV)3 low. This makes it easier and safer to weld, reducing the risk of cold cracking, which is a primary concern in thick offshore sections.

- Good Toughness: Standard grades offer guaranteed impact toughness4 (the "J2" or "K2" designation), which is essential for structures in cold waters.

- Cost-Effectiveness and Availability: It is produced in massive quantities worldwide by many certified mills. This competition and scale make it the most economically viable option for large tonnage orders.

- Standardization: It is fully incorporated into all major international design codes (EN, ISO, DNVGL), so engineers are very familiar with its design properties and behavior.

Navigating the S355 "Alphabet":

You must specify the correct suffix. Ordering just "S355" is incomplete and risky.

- S355J2 / S355K2: These are standard structural grades per EN 10025-2. "J2" guarantees impact toughness4 at -20°C, "K2" at -20°C with slightly higher impact energy values. They are typically delivered as-rolled (+AR) or normalized (+N). Common for topsides buildings, walkways, and secondary structures.

- S355NL / S355ML: The "N" and "M" refer to the delivery condition. Normalized (N) or Thermomechanically Rolled (M). The "L" means tested for low-temperature impact toughness4 (at -50°C or -60°C). These are more refined and used for more critical applications.

- S355G2 / S355G35: This is the crucial offshore designation (EN 10225). These grades have tighter control on composition and properties. G2 is for service down to -20°C, G3 for down to -40°C. They often have mandatory through-thickness (Z) testing requirements. This is the true offshore workhorse for primary structures like jackets and piles.

- +N, +M, +Q: Always specify the condition. +N (Normalized) is common for thick plates to ensure uniform properties. +M (Thermomechanically rolled) offers good properties without the extra heat treatment, often at a lower cost.

A Note on Regional Equivalents:

While S355 (EN Standard) is dominant in Europe and many global projects, other standards have equivalents:

- USA: ASTM A572 Grade 506 (50 ksi yield = 345 MPa, very close).

- API: API 2W Grade 50.

- Japan: SM490.

A competent supplier like us can navigate these equivalents. For a project in Thailand sourcing from Chinese mills, we might propose the cost-effective and available Q355B (the GB standard equivalent) for non-critical parts, with full documentation showing its comparability to S355J2, subject to engineer approval. This flexibility can offer significant savings without compromising performance for the intended use.

Conclusion

Choosing offshore steel profiles demands precision. Understand the application, know the four steel types, engage with engineering expertise, and leverage common, proven grades like S355 as your foundation.

-

Explore the properties of S355 series steel to understand its applications and benefits in offshore structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about HSLA steels and their advantages in construction, particularly in offshore applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding CEV is crucial for welding and material selection in structural engineering. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the significance of impact toughness in ensuring the safety and durability of offshore structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the specific applications and properties of S355G2 and S355G3 grades for offshore structures. ↩ ↩ ↩ ↩

-

Explore ASTM A572 Grade 50 as an alternative to S355 and its suitability for various engineering projects. ↩ ↩ ↩ ↩

-

Discover the importance of Corrosion-Resistant Alloys in enhancing durability in construction. ↩ ↩

-

Discover the role of welding procedure qualifications in ensuring structural integrity. ↩

-

Learn about the applications and benefits of Marine Angle Steel in offshore projects. ↩