You are planning your steel inventory for the next shipbuilding cycle. Will the demand for bulb flat steel grow, or will new materials replace it? Making the wrong prediction can leave you with dead stock or missed opportunities.

The market outlook for bulb flat steel from 2025 to 2030 is cautiously optimistic, driven by replacement demand for older ships, growth in specific vessel segments like LNG carriers and offshore wind vessels, and its irreplaceable role as a weight-efficient stiffener. Demand will be tempered by global economic cycles and competition from alternative fabrication methods in some niches.

The future is not just about selling more of the same product. It is about understanding the evolving drivers of demand, the competitive landscape, and where this specialized profile will remain king. To forecast its future, we must first be crystal clear about its fundamental, enduring role in shipbuilding today.

What are bulb flats1 used for?

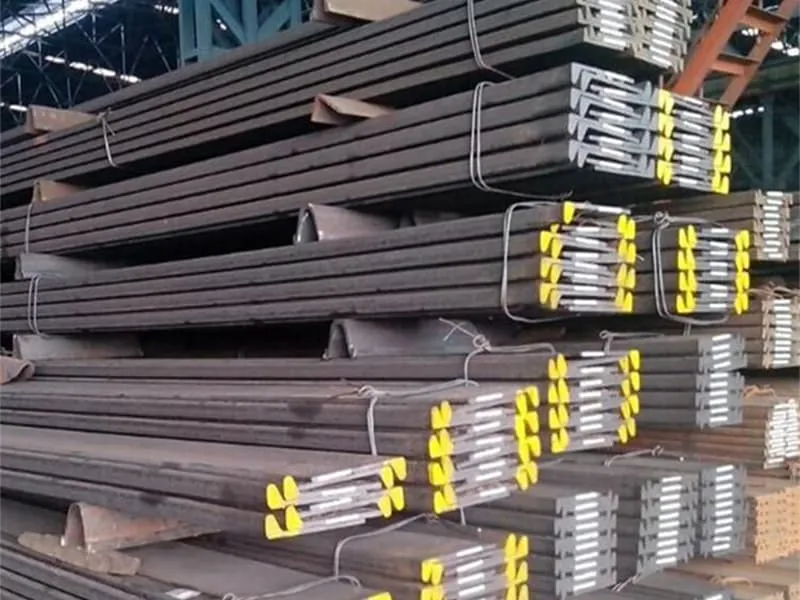

Bulb flats are not a commodity. They are a precision-engineered component for a specific structural task. Their current use defines their core market, which forms the baseline for all future projections.

Bulb flats are used almost exclusively as longitudinal and transverse stiffeners in ship hulls, decks, and bulkheads. Welded to steel plates, they form efficient T-beams2 that prevent buckling and add bending strength, making them fundamental to the structural skeleton of all large commercial vessels, from tankers to container ships.

If you look at a ship’s frame before the plates are welded on, you see a forest of bulb flats1. This is their domain. Their design is a perfect response to a classic marine engineering challenge.

The Engineering Principle: Creating an Efficient Composite Beam

A ship’s hull and decks are vast, thin steel plates. Alone, they would bend and buckle under water pressure and cargo loads. The solution is to attach stiffeners. A bulb flat, when welded perpendicular to a plate, creates a "T-beam."

- The Plate becomes the wide flange of the beam, resisting compression and tension.

- The Bulb Flat becomes the web of the beam, providing depth and shear strength.

- The Bulb (the rounded end) is the key innovation. It adds mass at the farthest point from the plate. This dramatically increases the section modulus, which is a direct measure of bending strength.

This makes the bulb flat the most weight-efficient3 profile for this job. Compared to a simple flat bar of the same weight, a bulb flat can be 30-50% stiffer. In shipbuilding, where every ton of steel weight reduces cargo capacity, this efficiency is priceless.

Universal Application Across the Merchant Fleet

The use of bulb flats1 is standardized and nearly universal in steel shipbuilding:

- Bulk Carriers & Oil Tankers: Thousands of meters of bulb flats1 are used as longitudinals on their flat-bottomed hulls and wide decks.

- Container Ships: Critical for reinforcing the large, open deck areas that carry stacked containers.

- LNG Carriers: Used in both the primary hull and the complex support systems for the containment tanks.

- Offshore Support Vessels & Jack-up Rigs: Essential for the leg structures and hull stiffening.

This entrenched, fundamental application is the bedrock of the bulb flat market. It means demand is directly tied to global shipbuilding output4. As long as large steel ships are built, bulb flats1 will be needed. This creates a stable baseline demand but also means the market is cyclical, following the booms and busts of shipyard order books. The future question is not if they will be used, but how much and where the growth or contraction in shipbuilding will occur.

What is a bulb bar1?

You might hear the term "bulb bar1" and wonder if it’s the same as a bulb flat. The terminology can vary, but in standard marine practice, they refer to the same essential product—a specialized steel profile with a distinctive cross-section.

A bulb bar1 is another common name for bulb flat steel2. It is a hot-rolled steel section with a cross-section shaped like a vertical web with a bulb (rounded protrusion) at the tip. Standardized under specifications like EN 100673 or JIS G 3192, its key dimensions are the web height and thickness, and the bulb size.

The name describes exactly what it is: a bar with a bulb. This simple name points to its role as a raw material that is then cut and processed into stiffeners.

Standardization and Specification: The Language of Global Trade

For bulb bar1s to be used in shipyards from China to Korea to Europe, they must be interchangeable. This is achieved through international standards.

- Dimensional Standards: EN 100673 (Europe) and JIS G 3192 (Japan) define the exact series of sizes. A common designation is "Bulb Flat 300 x 12". This means a web height of 300mm and a web thickness of 12mm. The associated bulb dimensions are defined by the standard.

- Material Standards: The steel grade is specified separately. The same "300 x 12" profile can be made in Grade A, AH36, or DH40 steel, depending on the ship’s requirements.

This standardization is crucial for the future market. It means bulb flats are a globally traded commodity component4. A shipyard in the Philippines can order "EN 100673 Bulb Flat 260 x 10 in AH36 grade" from a mill in China or a stockist in Europe and know it will fit their plans. This global market fluidity affects pricing, supply chain logistics, and competitive dynamics.

The Competitive Landscape: Mills, Service Centers, and Traders

The bulb bar1 supply chain has several layers, each with a different outlook:

| Supplier Type | Role in the Market | Future Outlook & Challenge |

|---|---|---|

| Integrated Steel Mills | Produce the primary hot-rolled bulb bar1s. They have high fixed costs and long production runs. | Focus will be on cost leadership and supplying large volume projects. Their future depends on overall industrial demand. |

| Specialty Steel Mills/Re-Rollers | May focus on specific grades (e.g., high-toughness for Arctic) or custom sizes. | Positioned for niche, high-value segments like offshore wind or LNG. More resilient to general market downturns. |

| Steel Service Centers & Stockists | Purchase from mills, hold inventory, and provide processing (cutting to length, drilling). | Their role is becoming more important. Shipyards want "just-in-time" delivery of pre-cut parts to reduce their own labor. This value-added service is a growth area. |

| International Trading Companies (like us) | Connect global mills with global shipyards, manage logistics, quality assurance, and financing. | The outlook is strong for traders with deep technical knowledge and reliable mill partnerships. As projects become more global, the need for expert intermediaries grows. |

The future will favor suppliers who offer more than just the raw bar. Shipyards will increasingly seek partners who can provide certified material (BV, ABS)5, just-in-time delivery6 of pre-processed sections, and technical support. This shifts competition from a pure price game to a value-added service game. Our business model, with fast response, SGS support, and logistics management, is aligned with this trend.

What is a flat bar1 used for?

It is essential to distinguish bulb flats2 from simple flat bar1s. This comparison highlights the bulb flat’s specialized advantage and also reveals where it might face competition or substitution in the future.

A flat bar1 is a general-purpose, rectangular steel strip. It is used for a vast range of applications: fabricating brackets, frames, and supports in machinery; as a base plate; for repair work; and in construction. In shipbuilding, it is used for non-critical, small-scale stiffening, ledges, or fabrication3 where the high efficiency of a bulb flat is not required.

The flat bar1 is the versatile multi-tool. The bulb flat is the specialized scalpel. Understanding where each is appropriate reveals the boundaries of the bulb flat market.

The Versatility of the Flat Bar: A Contrast in Philosophy

Flat bars are defined by their width and thickness (e.g., 100mm x 10mm). Their use is driven by simplicity and availability.

- Fabrication: They are easy to cut, drill, and weld into any custom shape. This makes them ideal for making brackets, gussets, and small frames within a ship’s engine room or superstructure.

- Low-Efficiency Stiffening: For small plates or in non-critical areas, a simple flat bar1 welded on edge can be a sufficient stiffener. It is a straightforward, low-cost solution.

- Pads and Doublers: Used to reinforce areas around openings or under equipment feet.

The Future Competitive and Supplementary Dynamics

The relationship between bulb flats2 and flat bar1s is not just about difference; it informs future market pressures.

- Substitution Threat (Low): For primary hull stiffening, the bulb flat’s weight efficiency is so superior that substitution by a flat bar1 is not economically or technically feasible. It would require a much heavier flat bar1, increasing steel cost and reducing cargo deadweight. This core market is safe.

- Competition from Fabricated Sections (Medium): In some areas, particularly in offshore construction or complex nodes, shipyards might fabricate a "T-section" by welding a flat bar1 to a plate. This can be done when the required size is non-standard or for complex geometries. Advanced automated welding makes this more feasible. This could capture some demand at the edges of the bulb flat market, especially for one-off projects.

- Complementary Relationship (High): Flat bars and bulb flats2 are often used together. A ship structure uses bulb flats2 for the main longitudinal stiffeners and flat bar1s (often cut from plate) for the connecting brackets, doublers, and secondary elements. Demand for flat bar1s often correlates with demand for bulb flats2, as both are part of the same steel tonnage going into a ship.

The Broader Market Driver: Steel Intensity and Design Trends

The most significant factor for the future of both bulb flats2 and flat bar1s is the trend in ship design.

- The Efficiency Drive: New regulations (like EEXI, CII) force shipowners to improve fuel efficiency. One key method is lightweighting4—using less steel or higher-strength steel to reduce hull weight. This trend strongly favors bulb flats2 because they are the most weight-efficient solution. It may also increase the use of higher-strength grades like AH40 or DH40, which carry a price premium.

- Modular Construction: Increased use of prefabricated blocks in shipbuilding could standardize bulb flat lengths and specifications, favoring mills and service centers that can deliver large batches of pre-cut material.

Therefore, the future of the bulb flat market is less threatened by flat bar1s and more shaped by macro trends in ship design, environmental regulation, and construction methodology. The bulb flat’s inherent efficiency makes it a beneficiary of the industry’s drive towards greener, more efficient shipping.

Conclusion

The bulb flat steel market will see stable demand tied to shipbuilding cycles, with growth driven by ship replacement and green shipping trends. Its future is secure in primary hull stiffening, but suppliers must adapt by offering certified materials, processed solutions, and expert global supply chain management.

-

Explore the diverse applications of flat bars in various industries, enhancing your understanding of their versatility. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about bulb flats and their specialized uses compared to flat bars, crucial for understanding material selection in shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the fabrication techniques involving flat bars, essential for custom shapes in construction and machinery. ↩ ↩ ↩ ↩ ↩

-

Understand the concept of lightweighting in ship design, a key trend for improving fuel efficiency and reducing costs. ↩ ↩ ↩

-

Explore the significance of certified materials like BV and ABS in ensuring quality and compliance in steel production. ↩

-

Understand the concept of just-in-time delivery and its importance in modern manufacturing and supply chains. ↩