You are planning a shipbuilding project for 2026. Should you stick with traditional AH36 steel, or invest in new high-tech alternatives? The wrong material choice today could make your vessel obsolete and uneconomical tomorrow.

The marine steel plate market from 2025 to 2030 will be driven by demand for greener ships, stricter environmental rules, and the growth of offshore wind and LNG transport. This will increase the need for advanced high-strength steels, corrosion-resistant alloys, and digitally traceable materials.

I recently spoke with a project manager from a shipyard in Vietnam. They are building a series of container ships for a European client. The client’s specification included a requirement for "future-proof" steel with a lower carbon footprint. This was not just about the ship’s emissions, but about the steel’s own production emissions. This conversation made it clear that the market is changing. Buyers are now thinking about the total lifecycle of the vessel, starting with the steel. In this article, I will explore the key trends and answer critical questions about the materials that will shape this future.

What is marine grade steel1?

Many people see "marine grade" on a product and think it just means "waterproof." For structural steel in ships, the meaning is much more specific and vital. It is the difference between a safe voyage and a structural failure.

Marine grade steel is a category of specially manufactured steel designed for ship hulls and offshore structures. It has controlled chemistry, guaranteed impact toughness at low temperatures, and is produced under strict quality systems approved by classification societies2 like DNV, ABS, or Lloyd’s Register.

The Defining Characteristics of Marine Steel

Marine steel is not one single recipe. It is a family of steels built to survive the most challenging engineering environment on Earth: the ocean.

The Core Requirement: Toughness Over Strength

The most important property of marine steel is not its maximum strength, but its notch toughness3, especially at low temperatures.

- The Problem of Brittle Fracture: In cold seawater, a small crack in normal steel can spread very fast with little warning. This is called brittle fracture. It sank many Liberty ships in World War II.

- The Solution: Charpy Impact Testing4: Marine steels are tested by striking a notched sample with a hammer at a specific low temperature (like 0°C, -20°C, -40°C). The steel must absorb a minimum amount of energy without breaking. This is the "A", "D", "E", "F" grade you see (e.g., AH36, DH36, EH36).

Controlled Chemical Composition

Marine steels have strict limits on elements like Carbon, Sulfur, and Phosphorus.

- Low Carbon Equivalent: This ensures the steel can be welded easily in shipyards without cracking. Large, restrained welds are common in shipbuilding.

- Clean Steel Practice: Low levels of impurities (Sulfur, Phosphorus) improve toughness and reduce the risk of defects.

- Micro-alloying: Small amounts of Niobium, Vanadium, or Titanium are added. These elements help to create a fine grain structure during rolling, which increases both strength and toughness.

Classification Society Approval

This is the non-negotiable part. The steel mill’s entire production process must be audited and approved by classification societies2 like DNV, ABS, LR, or BV.

- The mill follows the society’s specific rules for that grade.

- Each plate or section receives a unique identification number and a Mill Test Certificate5 (MTC).

- This certificate is a legal document that follows the steel throughout the ship’s life.

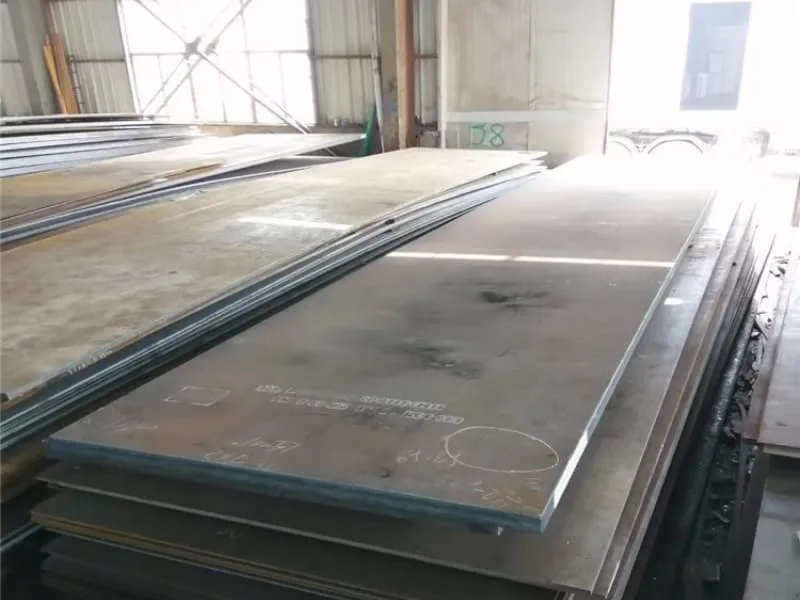

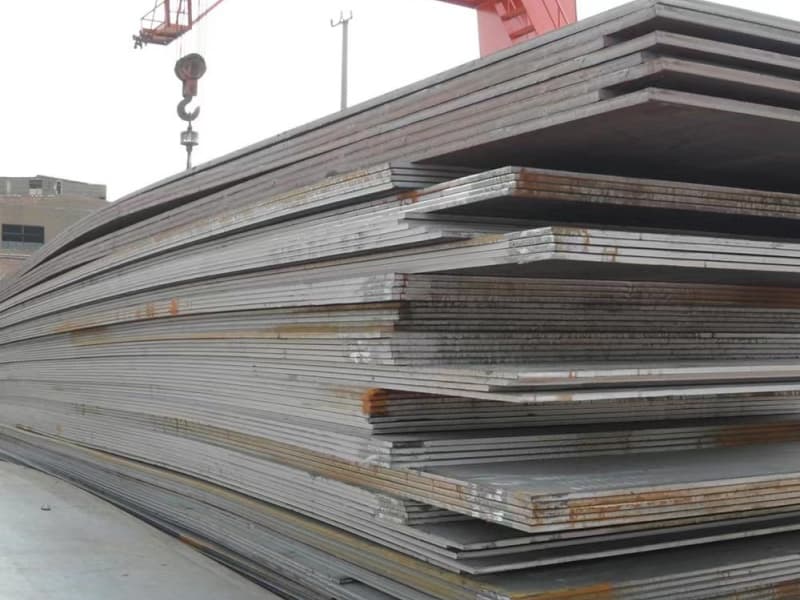

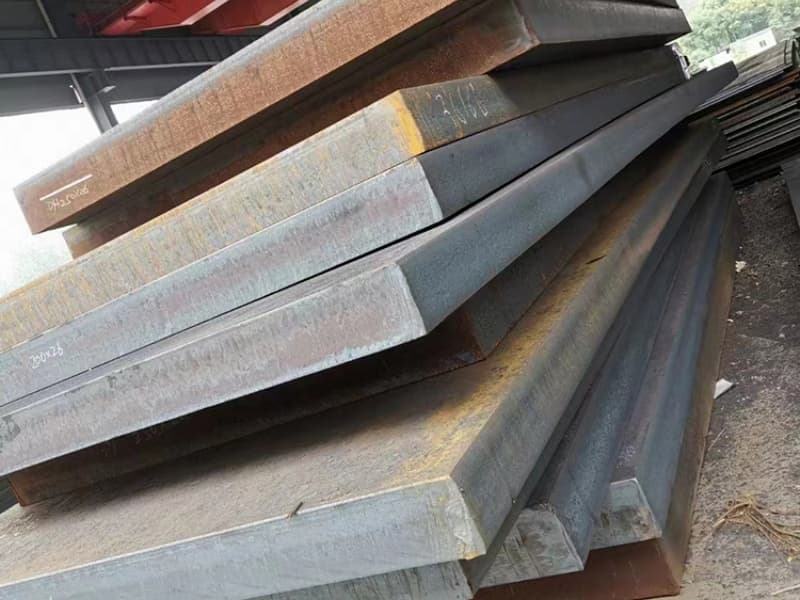

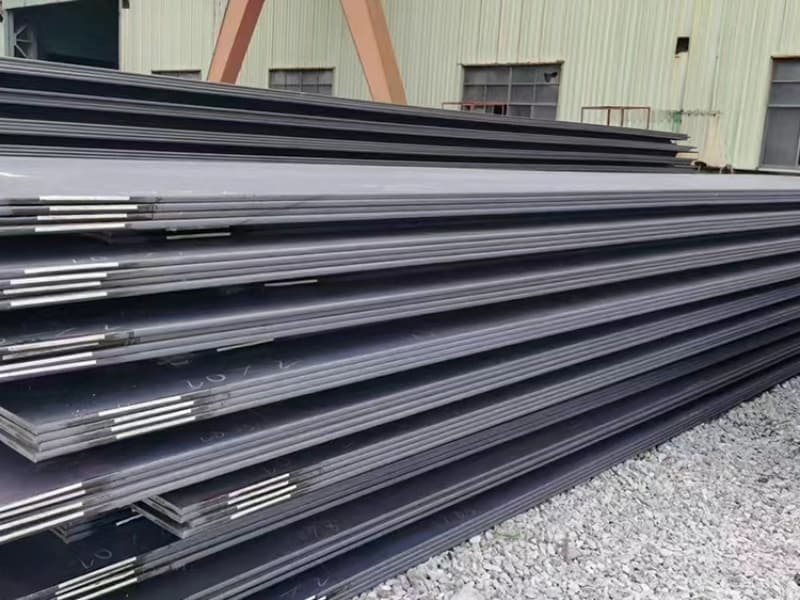

Common Grades and Their Uses

- Normal Strength: Grade A, B, D, E (Yield strength ~235 MPa). Used for less critical parts.

- High Strength: AH32/36, DH32/36, EH32/36/40 (Yield strength 315-390 MPa). The workhorses for hulls of tankers, bulk carriers, and container ships. The letter (A, D, E) indicates the temperature for impact testing.

- Extra High Strength / Special Grades: Grades with yield strength above 420 MPa, or special grades for Arctic service (ice class) or very thick plates.

Here is a simple table to summarize:

| Feature | Ordinary Structural Steel (e.g., S355) | Marine Grade Steel (e.g., DH36) |

|---|---|---|

| Primary Purpose | General construction (buildings, bridges) | Withstand dynamic ocean loads and low temperatures |

| Key Property | Yield Strength | Notch Toughness at Low Temperature |

| Quality Control | Mill’s own standard | Strict class society rules (DNV, ABS, etc.) |

| Certification | Mill Certificate (may be generic) | Class-approved Mill Test Certificate5 with traceability |

| Typical Use | Beams, columns | Ship hull, offshore platform legs |

Looking ahead: The future of marine steel is not just about maintaining these properties. It is about enhancing them while reducing environmental impact. We see a trend towards steels with even better toughness-to-weight ratios and steels made via processes with lower CO2 emissions (like electric arc furnaces using scrap). The definition of "marine grade" is starting to include a sustainability dimension.

Is 304 stainless steel1 ok for marine use?

This is a very common and costly misunderstanding. People see "stainless steel" and assume it is perfect for the sea. For many marine applications, especially structural ones, 304 stainless is a poor and risky choice.

304 stainless steel1 is generally NOT ok for primary structural marine use in saltwater. While it resists rust better than carbon steel, it is susceptible to pitting and crevice corrosion2 in chloride-rich environments like seawater, leading to localized failure. It is acceptable only for short-term, non-critical, or fully exposed and washed applications.

Why 304 Stainless Fails in the Marine Environment

304 stainless (also known as 18/8 stainless: 18% Chromium, 8% Nickel) is an excellent material for many things. But seawater is a uniquely aggressive environment.

The Mechanism of Failure: Localized Corrosion

In fresh water or mild atmospheres, 304 forms a stable passive layer. Saltwater (chlorides) breaks down this layer in specific spots.

- Pitting Corrosion: Chloride ions attack weak points in the passive layer, creating deep, small pits. These pits can penetrate the metal rapidly from the inside, while the surface still looks shiny. This is very dangerous because it is hard to detect.

- Crevice Corrosion: This occurs in gaps—under gaskets, bolt heads, or weld splatter. Stagnant seawater in the crevice becomes depleted in oxygen. The chemistry changes, and the passive layer breaks down, causing severe localized attack.

For a ship’s hull or structural frame, this type of hidden, localized corrosion is unacceptable. It compromises strength without obvious warning signs.

Comparing 304 to Actual Marine Materials

Let’s put 304 in context with the materials actually used in shipbuilding:

- Hull Plating: Uses coated marine carbon steel3 (AH36, etc.). The steel is thick, and it is protected by a robust coating (paint) system, often with sacrificial anodes (zinc). The coating is the primary barrier; the steel is the strong, tough, and cost-effective core.

- Propellers, Shafts, Seawater Pipes: Often use specialized copper alloys4 (bronze, cupronickel) or high-grade stainless steels like 316L or duplex steels. These are chosen for their superior resistance to flowing seawater and biofouling.

- Deck Railings, Cleats, Trim: 304 stainless can be used here because these parts are fully exposed to air and rain, which can wash salts away. They are also non-critical for structural integrity.

When Might 304 Be Considered?

There are limited, careful uses:

- Interior fittings on boats (sinks, galley equipment) where contact with saltwater is minimal and occasional.

- Temporary fixtures or tools.

- Components in a controlled environment that are regularly cleaned and maintained.

The critical takeaway: Never substitute 304 stainless for a specified marine-grade carbon steel or a more resistant alloy like 316L in a critical, submerged, or splash zone application. The cost of 304 is higher than coated carbon steel, and its performance in saltwater is worse. It is the worst of both worlds for primary structures.

Which is better, 304 or 316 stainless steel1 marine grade?

If you must use stainless steel in a marine environment, the choice between 304 and 316 is one of the most important decisions you will make. Getting it wrong guarantees premature failure and expensive replacements.

For marine grade applications2, 316 stainless steel1 is definitively better than 304. The key difference is the addition of 2-3% Molybdenum3 in 316, which dramatically increases its resistance to pitting and crevice corrosion in chloride environments like seawater4.

A Detailed Breakdown of the Superiority of 316

The small addition of Molybdenum3 (Mo) changes everything. It is like adding a specialist defender to a sports team.

The Role of Molybdenum3

Molybdenum3 strengthens the passive chromium oxide layer on the steel’s surface. More importantly, it helps this layer re-form quickly if it gets damaged. In the presence of chlorides, this means:

- The onset of pitting corrosion is delayed.

- The rate of pit growth is slowed down significantly.

- Resistance to crevice corrosion is greatly improved.

This makes 316 (and its low-carbon variant 316L) the minimum acceptable stainless steel for prolonged exposure to saltwater.

Quantitative Comparison: PREN Value

Engineers use a number called the Pitting Resistance Equivalent Number (PREN)5 to compare stainless steels.

- Formula: PREN = %Cr + 3.3 x %Mo + 16 x %N

- 304 Stainless: Typically has ~18% Cr, 0% Mo. PREN ≈ 18.

- 316 Stainless: Typically has ~16% Cr, 2% Mo. PREN ≈ 24.

A higher PREN means better pitting resistance. The jump from 18 to 24 is significant. For harsh marine use, a PREN above 25 is often recommended, which is why even better steels like Duplex (PREN >35) exist.

Application-Based Guidance

You should choose based on the severity of the environment:

- Atmospheric / Splash Zone (e.g., deck hardware, railings): 316 is strongly preferred. 304 may suffer from surface pitting and staining over time, especially in polluted or humid ports.

- Intermittent Immersion / Waterlines: 316 is required. 304 will fail quickly due to cyclic wetting and drying, which concentrates salts.

- Full Immersion / Seawater Piping: 316 is often the baseline, but for critical, long-life components, more advanced grades like 316L, 6Mo austenitic steels (e.g., 254 SMO), or Duplex steels (2205) are used. 304 is completely unsuitable.

- High-Temperature or Stagnant Seawater: This is the worst condition. Only high-Molybdenum3 grades or non-ferrous alloys should be used.

Cost vs. Performance Analysis

Yes, 316 costs more than 304. But you must consider the total lifecycle cost6.

- Initial Cost: 316 is about 20-40% more expensive per kg than 304.

- Failure Cost: If a 304 component fails in a seawater4 pipe, the cost of replacement, downtime, and potential collateral damage is enormous.

- Maintenance Cost: 316 requires less frequent inspection, cleaning, and replacement.

Here is a decision table:

| Condition | Recommended Material | Why 304 is a Bad Choice |

|---|---|---|

| Land-based, inland | 304 is often sufficient. | – |

| Coastal architecture, railings | 316 is recommended. | 304 may pit and stain, requiring frequent cleaning. |

| Boat deck fittings, cleats | 316 is required. | 304 fittings can seize or corrode at contact points. |

| Seawater pumps, valves, pipes | 316L or better (Duplex). | 304 will suffer rapid pitting and crevice corrosion, leading to leaks. |

| Ship hull structure | Not used. Use coated AH/DH/EH steel. | 304 is not strong/tough enough and will corrode. |

Future trend: As operational costs and environmental regulations tighten, the maritime industry is moving towards more durable materials. We see increased interest in Duplex stainless steels7 (like 2205) for specific components. They offer twice the yield strength of 316 and much higher corrosion resistance8 (PREN >35), which can allow for thinner, lighter parts. While 316 is the "better" choice today, the future for demanding applications points beyond it.

Will 304 stainless steel1 rust in saltwater?

Yes, it will. The word "stainless" is misleading. It does not mean "stain-proof," especially in the brutal test of saltwater. The rust may not look like the red flakes on carbon steel, but the corrosion damage is real and often more dangerous.

Yes, 304 stainless steel1 will rust in saltwater. It does not rust uniformly like carbon steel. Instead, it suffers from localized pitting corrosion2 and crevice corrosion3, which creates small, deep holes and attacks hidden areas while the majority of the surface may still appear shiny and intact.

Understanding the "Rust" on Stainless Steel

The corrosion of 304 in seawater is insidious. It does not give you a clear, visible warning over a large area.

The Types of Corrosion to Expect

- Pitting Corrosion: This is the main form of "rust." You will see small, dark spots or holes on the surface. If you scratch one, you might find a deep cavity underneath. The pit can act as a stress concentrator, leading to crack initiation and structural failure. The photo often shows a shiny piece of metal with a few tiny holes that have penetrated completely through.

- Crevice Corrosion: This happens where oxygen cannot easily reach—under bolts, washers, gaskets, or in weld seams. The metal in the crevice becomes active and corrodes aggressively, often causing parts to seize together or welds to leak. The surface outside the crevice looks fine.

- Stress Corrosion Cracking (SCC): In warmer seawater and under tensile stress (like in a loaded bolt or a pressured pipe), 304 can develop fine cracks. This is a sudden and catastrophic failure mode.

Factors That Accelerate the Process

The speed of corrosion depends on several conditions:

- Temperature: Warmer seawater dramatically increases corrosion rates4. A 304 part in the Gulf of Thailand will fail much faster than one in the Baltic Sea.

- Stagnation: Stagnant water in pockets or pipes allows chlorides to concentrate and oxygen levels to drop, accelerating crevice and pitting attack.

- Pollution: Seawater with industrial pollutants or sulfides is even more aggressive.

- Biofouling: Barnacles and other marine growth5 create their own crevices and acidic environments under them, attacking the steel.

Real-World Evidence and Consequences

I have seen this firsthand. A client in the marina business bought 304 stainless bolts for deck hardware. After one season, many were seized and snapped upon removal. The crevice under the nut was completely corroded. The bolt looked fine from the side, but it was useless.

For a shipowner, using 304 in the wrong place can lead to:

- Leaking pipes or tanks.

- Failure of critical safety equipment like railings or ladders.

- Seized valves and machinery, requiring expensive cutting and rework.

- Contamination of cargo (in chemical tankers) from pinhole leaks.

Comparison with Carbon Steel Rust

It is helpful to contrast the two:

| Corrosion Type | On Carbon Steel (e.g., AH36) | On 304 Stainless Steel |

|---|---|---|

| Appearance | General, uniform red/brown rust layer over large areas. | Localized shiny surface with isolated deep pits or hidden crevice attack. |

| Progression | Relatively slow and predictable. Can be monitored by thickness gauging. | Unpredictable and rapid penetration at specific spots. Hard to monitor visually. |

| Prevention | Relies on a protective coating system (paint) + cathodic protection (anodes). Effective and standard practice. | Relies on the alloy’s own passive layer. This layer fails in chloride-rich, low-oxygen spots. |

| Result if Unprotected | Generalized thinning. | Localized perforation or cracking. |

The bottom line for the future: As the industry focuses on durability and reducing lifecycle maintenance, the use of 304 stainless in any saltwater application is being phased out. Specifications are becoming stricter. The trend is towards specifying 316L as a minimum, and increasingly towards higher-performance alloys for critical systems. Knowing that 304 will rust in saltwater is the first step in making smarter, more future-proof material selections.

Conclusion

The future marine steel market demands smarter materials: tougher, greener, and more corrosion-resistant. Choosing the right steel today is an investment in a vessel’s efficiency, compliance, and profitability for decades to come.

-

Explore the properties of 304 stainless steel to understand its limitations and applications in marine settings. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about pitting corrosion to better understand its impact on stainless steel and how to prevent it. ↩ ↩ ↩ ↩ ↩

-

Discover the causes of crevice corrosion to protect your stainless steel installations from hidden damage. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Investigate how environmental factors influence corrosion rates to make informed material choices. ↩ ↩ ↩ ↩ ↩

-

Learn about the impact of marine growth on stainless steel to improve your maintenance strategies. ↩ ↩ ↩ ↩

-

Understand the concept of lifecycle cost analysis to make informed decisions about material investments. ↩

-

Discover why Duplex stainless steels are gaining popularity for marine applications due to their superior strength and corrosion resistance. ↩

-

Explore the key factors that influence corrosion resistance, vital for selecting the right stainless steel for marine environments. ↩