Walking through a busy shipyard in Vietnam, I noticed how marine angle steel forms the skeleton of every vessel. This structural component is more important than most people realize.

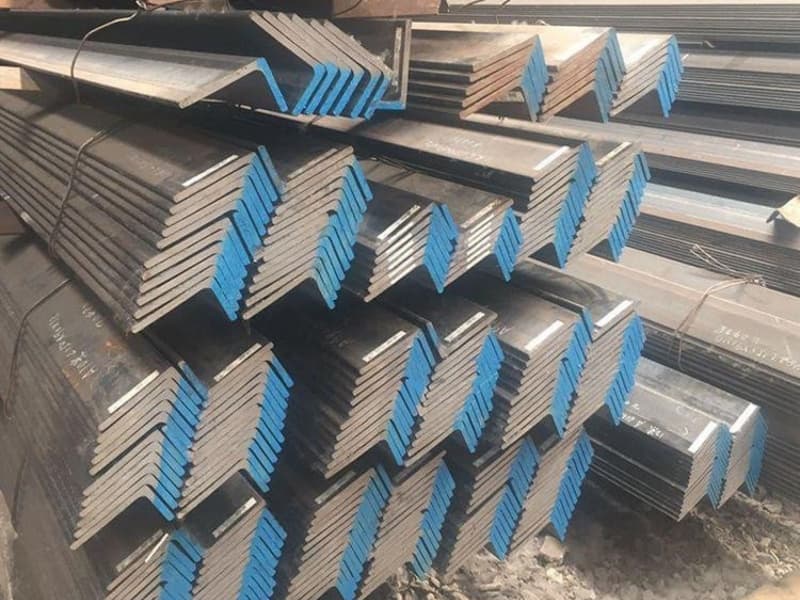

Marine angle steel serves as the primary framework in ship hulls, providing structural integrity and distributing stress throughout the vessel. Its L-shaped design offers superior strength-to-weight ratio, making it ideal for withstanding ocean pressures while maintaining hull shape under extreme conditions.

The choice of steel materials can determine a ship’s lifespan and safety. Let me explain why marine angle steel is so crucial and answer your most common questions.

What type of steel is used in ship hulls?

Last month, a client from Saudi Arabia asked why we recommend specific steel grades for hull construction. The answer involves both safety regulations and practical experience.

Ship hulls primarily use marine-grade AH36, DH36, and EH36 steel plates with marine angle steel for framing. These materials offer excellent toughness, corrosion resistance, and weldability. The steel must meet international classification society standards like ABS, DNV, and LR for maritime use.

Understanding Ship Hull Steel Requirements

Building a ship hull requires specific steel properties. The ocean environment demands materials that can handle multiple challenges. I’ll break down the main steel types and their applications.

Grade Classifications Explained

Shipbuilding steels come in different strength levels. AH36 is the most common for commercial vessels. DH36 offers better impact resistance at lower temperatures. EH36 provides the highest toughness for arctic operations. Each grade serves different environmental conditions.

Chemical Composition Matters

Marine steels contain controlled amounts of carbon, manganese, and other elements. Too much carbon makes welding difficult. Too little reduces strength. The balance ensures both strength and workability. Our mills adjust compositions based on vessel requirements.

Classification Society Standards

International organizations set strict rules for ship steel. American Bureau of Shipping (ABS) has one standard. Det Norske Veritas (DNV) has another. Lloyd’s Register (LR) has its own requirements. All ensure safety and quality.

Common Ship Hull Steel Applications

| Steel Type | Typical Use | Key Properties |

|---|---|---|

| AH36 Plates | Main hull plating | Good strength, standard toughness |

| DH36 Plates | Cold environment vessels | Better impact resistance |

| EH36 Plates | Ice-class ships | Highest toughness level |

| Marine Angle Steel | Frames and ribs | Structural support, stress distribution |

| Bulb Flat Steel | Longitudinal stiffeners | Efficient strength-to-weight ratio |

We supply these materials to shipyards across Southeast Asia and the Middle East. Our clients in Qatar and Philippines confirm that using the right steel grades prevents structural failures. Proper material selection is the first step in building a safe vessel.

What is the best steel for ship building?

A shipowner in Mexico once tried to save money by using cheaper steel. The repair costs after two years exceeded the initial savings. This experience taught me about true value.

The best steel for shipbuilding balances strength, toughness, and corrosion resistance. Marine-grade AH36/DH36 steel plates combined with marine angle steel provide optimal performance. The steel must have good weldability, impact resistance at service temperatures, and consistent quality throughout each batch.

Evaluating Shipbuilding Steel Quality

The "best" steel depends on the vessel type, route, and operating conditions. I consider several factors when recommending materials to our clients. Let me explain what makes steel suitable for shipbuilding.

Strength Requirements

Ship steel must handle various stresses. Wave action creates constant movement. Cargo weight adds pressure. The steel needs high yield strength and tensile strength. AH36 steel offers 355 MPa yield strength, which meets most commercial needs.

Toughness Characteristics

Brittle steel cracks in cold water. Good ship steel maintains toughness at low temperatures. We test impact resistance at -20°C or lower. This ensures safety in different climate conditions.

Weldability Factors

Ships require extensive welding. The steel must weld easily without special procedures. Carbon equivalent value indicates weldability. Lower values mean better welding performance. Our steel maintains CE below 0.41 for most grades.

Corrosion Resistance

Seawater attacks steel aggressively. Marine grades have better corrosion resistance than regular steel. The composition includes elements that slow down rust formation. Proper coating systems enhance this natural resistance.

Ship Steel Selection Guide

| Vessel Type | Recommended Steel | Key Considerations |

|---|---|---|

| Container Ships | AH36 plates + marine angle steel | High strength, good weldability |

| Oil Tankers | DH36 plates + marine angle steel | Better toughness, corrosion resistance |

| Bulk Carriers | AH36 plates + marine angle steel | Cost-effective, reliable performance |

| Fishing Vessels | EH36 plates + marine angle steel | Extreme condition durability |

| Luxury Yachts | Special marine grades | Appearance, finishing quality |

Our mill partners in Shandong produce consistent quality ship steel. We ship to Vietnam, Malaysia, and Thailand regularly. The feedback from these markets helps us refine our recommendations. The right steel choice ensures vessel longevity and operational safety.

Why common steel is used in shipbuilding?

I visited a shipyard in Pakistan where they attempted to use construction steel for a small vessel. The results were disappointing and costly. This shows why specialized materials matter.

Common steel lacks the specific properties needed for marine environments. Shipbuilding requires controlled chemistry, guaranteed toughness, and certified quality. Common steel may have inconsistent properties, poor weldability, and inadequate corrosion resistance for saltwater exposure.

The Limitations of Common Steel in Marine Applications

Many clients ask if they can use cheaper common steel. The short answer is no for structural components. Let me explain the technical reasons behind this requirement.

Chemical Composition Differences

Common steel has variable chemical content. This affects performance in marine conditions. Ship steel has controlled amounts of carbon, manganese, silicon, and other elements. The controlled composition ensures consistent behavior during fabrication and service.

Toughness Requirements

Common steel may become brittle in cold seawater. Ship steel maintains impact resistance at low temperatures. We conduct Charpy V-notch tests to verify toughness. Common steel often fails these tests.

Quality Certification

Ship steel comes with mill certificates and classification society approval. Common steel lacks these quality assurances. The certification process ensures every batch meets strict standards. This is crucial for insurance and safety compliance.

Weldability Concerns

Common steel often has high carbon equivalent. This causes welding problems. Cracks may appear in welded joints. Ship steel has optimized chemistry for better welding performance. Proper weldability prevents structural failures.

Performance Comparison Table

| Property | Common Steel | Marine Steel |

|---|---|---|

| Impact Toughness | Variable, often inadequate | Guaranteed at low temperatures |

| Chemical Control | Basic requirements | Strict composition limits |

| Quality Certification | Mill test certificate only | Classification society approval |

| Corrosion Resistance | Basic, insufficient for seawater | Enhanced marine grade protection |

| Weldability | Often problematic | Optimized for shipyard conditions |

We explain these differences to all our clients. A contractor in Romania learned this lesson the hard way. Now they only use certified marine steel for their ship repair projects. The initial higher cost prevents much larger expenses later.

What is the best method to protect a ship’s hull from corrosion?

After inspecting vessels in Thailand and Myanmar, I’ve seen both successful and failed corrosion protection systems. The best approach combines multiple methods for maximum effectiveness.

The best corrosion protection combines cathodic protection with high-quality coating systems. Zinc anodes sacrifice themselves to protect the steel, while epoxy coatings provide a physical barrier. Regular maintenance and proper material selection complete the comprehensive protection strategy.

Comprehensive Corrosion Protection Strategy

Ship hulls face constant attack from seawater, bacteria, and mechanical damage. A single protection method is never enough. I recommend layered protection based on vessel type and operating conditions.

Coating Systems Explained

Modern marine coatings work through multiple mechanisms. Epoxy primers provide excellent adhesion. Antifouling topcoats prevent marine growth. The coating thickness must be sufficient and uniform. We recommend specific coating systems for different vessel types.

Cathodic Protection Basics

This method uses electrical currents to protect steel. Sacrificial anodes made of zinc or aluminum corrode instead of the hull. Impressed current systems use external power sources. Both methods require proper design and installation.

Material Selection Importance

Some steels resist corrosion better than others. Marine-grade steel has better inherent resistance. The composition includes copper and other elements that slow down corrosion. Proper steel choice reduces maintenance needs.

Maintenance Practices

Regular inspection identifies coating damage early. Docking surveys allow thorough assessment. Prompt repair prevents corrosion from spreading. Good records help plan maintenance schedules.

Corrosion Protection Methods Comparison

| Method | How It Works | Best Applications | Limitations |

|---|---|---|---|

| Epoxy Coatings | Physical barrier against seawater | Entire hull surface | Requires perfect application |

| Zinc Anodes | Sacrificial corrosion | Hull underwater areas | Regular replacement needed |

| Impressed Current | Electrical protection | Large vessels | Higher initial cost |

| Antifouling Paint | Prevents biological growth | Operating hull | Environmental concerns |

| Corrosion-resistant Steel | Better material properties | New construction | Higher material cost |

Our clients in Saudi Arabia and Qatar face extreme corrosion conditions. High water temperatures and salinity accelerate damage. We help them choose the right combination of protection methods. The goal is always maximizing hull life while minimizing maintenance costs.

Conclusion

Marine angle steel forms the essential framework of ship hulls, working with specialized steel plates to create vessels that withstand ocean forces. Proper material selection and corrosion protection ensure long service life and operational safety.