You are sourcing steel for a new oil tanker project. The plans specify "AH36 angle steel" for critical brackets and supports. You know A36 steel, but what does the ‘H’ mean? Using the wrong material here could fail classification society approval.

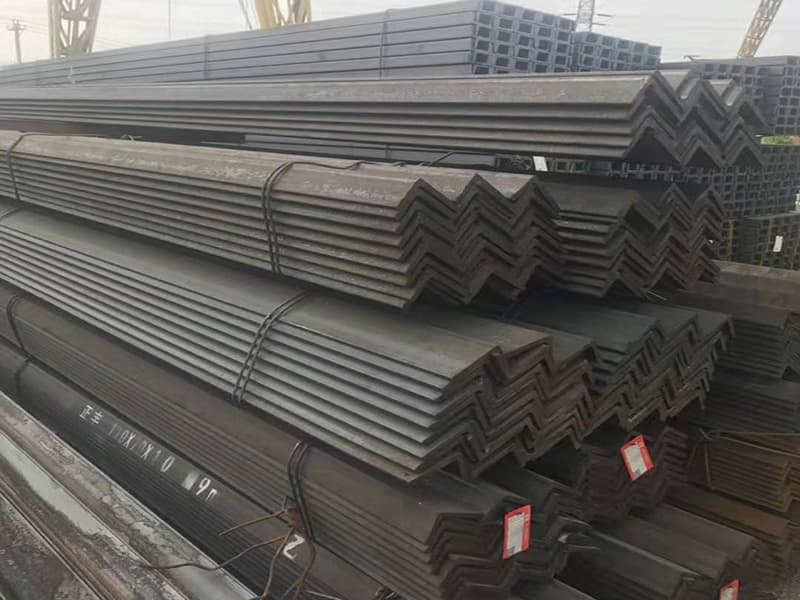

AH36 marine angle steel is a high-strength, low-alloy structural steel used in shipbuilding. The ‘A’ indicates it is a hull structural steel, ‘H’ means high tensile strength, and ’36’ denotes a minimum yield strength of 36 ksi (355 MPa). AH36 angle steel offers superior strength-to-weight ratio and good toughness for welded structures in ships, offshore platforms, and heavy marine construction.

The difference between A36 and AH36 is not just a letter. It is a fundamental difference in capability and intended use. Confusing them can lead to under-specified structures or unnecessary cost. I want to clearly explain what AH36 is, where it is used, and how it differs from its common cousin, A36. This will help you make the right material choice for your marine project. Let’s start with the basics of AH36 steel.

What is AH36 steel?

You see the code AH36 on a material list. It looks like a simple product code, but each part of that name tells a specific story about the steel’s properties and its purpose.

AH36 steel is a high tensile strength hull structural steel grade1 defined by classification societies like ABS, LR, and DNV. It is designed for critical ship components. The steel has a minimum yield strength of 355 MPa2 (or 36 ksi), offers good notch toughness, and is produced with controlled chemistry and processing3 to ensure excellent weldability for marine environments.

To truly understand AH36, we need to decode its name and look at the strict rules that govern its production. This is not commercial steel; it is class-approved steel.

Decoding the AH36 Designation

The name is a precise label. Each character has a defined meaning agreed upon by major marine classification societies worldwide.

- ‘A’: This first letter stands for Hull Structural Steel. It tells you immediately that this steel is intended for building ship hulls. There are other letter series for other purposes (e.g., ‘B’ for boiler steel), but ‘A’ is for hulls.

- ‘H’: This second letter indicates High Tensile Strength. Normal strength hull steels (like Grade A, B, D, E) do not have an ‘H’. The presence of ‘H’ means the steel has a higher minimum yield strength than normal strength grades.

- ’36’: This number indicates the minimum yield strength in the unit of kips per square inch (ksi). 1 ksi equals approximately 6.895 MPa. So, 36 ksi equals about 355 MPa. This is the key mechanical property.

The Mandatory Requirements for AH36 Steel

Producing AH36 is not a simple task. Mills must follow strict guidelines to earn approval from classification societies like the American Bureau of Shipping (ABS), Lloyd’s Register (LR), or Det Norske Veritas (DNV).

- Chemical Composition Control: The amounts of carbon, manganese, silicon, sulfur, phosphorus, and micro-alloying elements like niobium or vanadium are tightly controlled. This precise chemistry achieves the high strength while keeping the Carbon Equivalent (CEV)4 low enough for good weldability.

- Mechanical Property Testing5: Every batch of steel must pass tests. The key tests are:

- Tensile Test: To confirm the yield strength (min 355 MPa), tensile strength, and elongation.

- Impact (Charpy V-Notch) Test: To measure toughness. Samples are cooled to a specified temperature (often 0°C or -20°C) and hit with a hammer. The energy absorbed must meet a minimum value. This proves the steel won’t become brittle in cold service.

- Delivery Condition: AH36 plates and sections are often delivered in the Normalized or Thermo-Mechanical Controlled Process (TMCP) condition. These heat treatments or controlled rolling processes refine the grain structure, enhancing both strength and toughness.

When we supply AH36 angle steel, we always provide the original Mill Test Certificate (MTC)6. This document is the steel’s passport. It shows the heat number, chemical analysis, and mechanical test results. For a project contractor in Qatar or a shipyard in the Philippines, this certificate is non-negotiable. They need it to present to their class surveyor to prove the material is correct. The ‘H’ in AH36 represents this entire system of guaranteed quality and traceability. It is a promise of performance, not just a strength number.

What is the application of A36 steel1?

Now, let’s look at A36 steel1. It is one of the most common and versatile structural steels in the world. You will find it in countless projects, but its role in modern shipbuilding is specific and limited.

A36 steel1 is a general-purpose carbon structural steel2 widely used in construction, bridges, buildings, and machinery. Its main applications are in non-critical, land-based structures where high strength or low-temperature toughness is not the primary concern. In marine context3s, it may be used for secondary, non-classed structures like workshop fittings or temporary supports, but not for primary hull construction.

A36 is the workhorse of the general steel industry. Its popularity comes from its balance of strength, formability, and relatively low cost. However, for the harsh marine environment, it has significant limitations.

The Widespread Use of A36 in General Industry

A36 is defined by the ASTM International standard (ASTM A364). It has a minimum yield strength of 36 ksi (250 MPa), which is actually lower than AH36’s 36 ksi (355 MPa). The naming is unfortunately confusing. A36’s strength is 250 MPa, while AH36’s is 355 MPa.

Because it is common and easy to weld and form, you will see A36 in:

- Building Frames: Beams, columns, and braces for commercial and industrial buildings.

- Bridge Components: Girders and other structural parts.

- General Fabrication: Machine bases, frames, brackets, and supports in all kinds of equipment.

- Infrastructure: Signposts, utility poles, and guardrails.

Why A36 is Not Suitable for Primary Marine Structures

For shipbuilding, especially for classed vessels, A36 has critical shortcomings:

- Lack of Notch Toughness Requirements: The ASTM A364 standard does not mandate Charpy impact testing. This means there is no guaranteed toughness at low temperatures. A ship sailing in cold waters faces a real risk of brittle fracture if made from A36 steel1.

- No Mandatory Fine Grain Practice: A36 can be made with a coarse grain structure, which is less tough and more prone to cracking.

- Lower Strength: Even though both have "36" in the name, A36’s yield strength is 250 MPa versus AH36’s 355 MPa. Using A36 would require thicker, heavier sections to achieve the same strength, making the ship less efficient.

In a marine context3, A36 angle steel might be acceptable only for non-classed, secondary applications. Examples include:

- Staircases and ladders inside the superstructure.

- Shelving and racks in storage rooms.

- Workbenches and tool stands in the ship’s workshop.

- Temporary construction aids used during the building process.

For any structural part that is part of the hull, deck, bulkhead, or main framework—and especially for parts subject to dynamic loads or cold temperatures—AH36 or other graded marine steels are mandatory. I have seen projects delayed because a fabricator used readily available A36 angles for a small bracket, only to have the class surveyor reject it during inspection. Knowing the correct application saves time, money, and ensures safety.

What is the difference between A36 and AH36 steel?

The names look similar, but A36 and AH36 are different materials for different worlds. Choosing one over the other without understanding the differences is a major technical and safety error.

The key difference is that A36 is a general structural steel for buildings and bridges, while AH36 is a high-strength marine-grade steel for ship hulls. AH36 has higher yield strength (355 MPa vs 250 MPa), mandatory impact toughness testing, stricter chemical controls, and requires classification society approval. A36 does not have these marine-specific guarantees.

The confusion is understandable because of the "36." But that is where the similarity ends. We need to compare them point by point across all important categories.

A Detailed Feature-by-Feature Comparison

This table breaks down the critical differences that matter to engineers, buyers, and class surveyors.

| Feature | ASTM A36 Steel | AH36 Marine Steel | Why the Difference Matters |

|---|---|---|---|

| Governing Standard | ASTM A36 (Commercial) | ABS, LR, DNV Rules (Marine Class) | Marine rules are far more stringent for safety at sea. |

| Primary Use | Buildings, Bridges, General Fabrication | Ship Hulls, Offshore Structures, Marine Construction | Different environments demand different material properties. |

| Minimum Yield Strength | 250 MPa (36 ksi) | 355 MPa (51 ksi) | AH36 is over 40% stronger. This allows for thinner, lighter structures in ships. |

| Tensile Strength | 400-550 MPa | 490-620 MPa | AH36 has a higher strength range. |

| Impact Toughness (Charpy) | Not Required by ASTM A36. | Mandatory. Tested at specified low temps (e.g., 0°C). | Toughness prevents brittle fracture in cold, stormy seas. This is a safety-critical difference. |

| Chemical Composition | Looser controls. Higher carbon allowed. | Tight controls. Lower carbon, controlled micro-alloys. | Tighter chemistry ensures weldability and toughness in AH36. |

| Delivery Condition | As-rolled (typically). | Often Normalized or TMCP. | Normalizing/TMCP refines grains for better properties in AH36. |

| Certification | Mill Test Report (may not be traceable). | Mill Test Certificate (MTC) with heat number, full traceability. | Traceability is essential for marine class approval and quality assurance. |

| Cost | Generally lower. | Higher, due to stricter production and testing. | The extra cost buys guaranteed performance for critical applications. |

The Practical Consequence of Mixing Them Up

Imagine using A36 angle steel to build a critical bracket on an offshore platform. The bracket might have enough strength under normal conditions. But during a winter storm, the temperature drops, and the platform is under cyclic loading. The A36 steel, with its unknown and likely poor toughness, could develop a small crack. This crack could propagate rapidly (brittle fracture), leading to a catastrophic failure.

AH36 steel is designed to prevent this. Its guaranteed toughness means it can absorb energy and deform slightly, stopping cracks from spreading easily. This is the core reason for the marine grade system. When clients like Gulf Metal Solutions ask for marine angle steel, they are not just buying shape; they are buying this package of guaranteed properties. They need the MTC to satisfy their own end clients, the shipyards. For them, the difference between A36 and AH36 is the difference between a product that can be used and one that must be rejected.

What is A36 used for?

We have established what A36 is not used for in marine projects. Now let’s focus on its legitimate and vast domain of application. Knowing this helps you avoid using it incorrectly at sea, but also recognizes its value elsewhere.

A36 steel is primarily used in the construction of buildings, bridges, and general industrial structures. It is common in structural frames, base plates, crane runways, and machinery where high impact toughness or extreme strength is not required. It is valued for its good weldability, formability, and widespread availability at a competitive price.

A36 is the "default" structural steel for many engineers and fabricators on land. Its specifications are well-known, and it is produced by countless mills globally.

The Land-Based Kingdom of A36 Steel

Its applications are everywhere in the built environment:

-

Commercial and Industrial Building Construction:

- Steel Frames: The beams (I-beams, wide-flange), columns, and bar joists that form the skeleton of warehouses, factories, and low-rise buildings.

- Bracing and Girts: Diagonal braces for stability and horizontal girts for attaching wall cladding.

- Platforms and Mezzanines: Support structures for internal floors and walkways.

-

Bridge and Infrastructure Work:

- Secondary Members: Cross-frames, lateral bracing, and connection plates in highway and railway bridges. (Note: Main bridge girders often use higher-strength steels).

- Sign Supports and Guardrails: The posts and rails along highways.

-

Heavy Equipment and Machinery:

- Machine Bases and Frames: The rigid frames for presses, conveyors, agricultural equipment, and mining machinery.

- Crane Runway Beams: The tracks for overhead traveling cranes inside factories.

-

General Fabrication and Manufacturing:

- Frames and Chassis: For trucks, trailers, and custom-built vehicles.

- Brackets, Stands, and Supports: Any custom metal fixture needed in a factory or workshop.

Why A36 Succeeds in These Roles

A36 dominates these areas for good reasons:

- Adequate Strength: For many static or moderately loaded structures, 250 MPa yield strength is sufficient.

- Easy to Work With: It can be easily sheared, punched, drilled, and bent with standard workshop equipment.

- Excellent Weldability: Its relatively simple chemistry makes it straightforward to weld using common methods like SMAW (stick welding), GMAW (MIG), or FCAW (flux-cored).

- Cost-Effective: High production volume and simpler processing keep its price low.

In our business, we sometimes get inquiries for A36 angle steel from clients who work in both marine and land-based projects. For example, a fabricator in Thailand might need A36 angles for a factory extension and AH36 angles for a dock repair project. We supply both, but we make the distinction very clear. We ensure the A36 material is labeled and documented correctly so it is not accidentally used in the marine job. Understanding the specific use case for A36 allows you to employ it effectively and safely within its intended scope, freeing up your budget for marine-grade steels like AH36 where they are truly needed.

Conclusion

AH36 marine angle steel is a specialized, high-strength material with guaranteed toughness for critical ship structures. It is fundamentally different from general-purpose A36 steel, which lacks the mandatory properties for safe marine use.

-

Explore this link to understand the diverse applications of A36 steel in construction and its significance in various projects. ↩ ↩ ↩ ↩ ↩

-

Learn about the versatility of general-purpose carbon structural steel and its role in different industries. ↩ ↩

-

Find out how A36 steel is applied in marine contexts and the limitations it faces in shipbuilding. ↩ ↩ ↩

-

Discover the specifications and importance of the ASTM A36 standard in ensuring quality and safety in steel construction. ↩ ↩ ↩

-

Understand the critical role of mechanical property testing in ensuring steel meets safety and performance standards. ↩

-

Find out why a Mill Test Certificate is essential for verifying the quality and compliance of steel products. ↩