You need bulb flats for a ship repair or a small batch of barges, but every supplier seems to demand a full container load. Your project stalls before it starts. The MOQ question is a major barrier, but it has a logical explanation and practical solutions.

The Minimum Order Quantity (MOQ) for bulb flat steel depends on the mill’s production cycle and the supplier’s business model. For standard marine-grade bulb flats (e.g., HP 100×7, HP 120×8), the typical mill MOQ is 15-25 tons per size. However, flexible suppliers with access to multiple mills or stock can offer lower MOQs, sometimes as low as 3-5 tons, by consolidating orders. The key is to balance the MOQ with the most economical shipping unit, usually a 20ft or 40ft container, which holds 20-28 tons.

You now have a range for the MOQ. To plan your order effectively, you need more than just a number. You must understand the product’s identity for customs, its standard sizes for specification, its core purpose to justify the purchase, and the broader material category it belongs to. Let’s answer these foundational questions to build a complete procurement picture.

What is the HS code for bulb flat steel?

You are finalizing the import paperwork. Putting the wrong code on the declaration can lead to customs delays, incorrect duty payments, or even fines. The HS code is the universal product passport for international trade.

The Harmonized System (HS) code for hot-rolled bulb flat steel is generally 7216.50. The code 7216 covers "Angles, shapes and sections of iron or non-alloy steel." The subheading 7216.50 is for "Other angles, shapes and sections," which includes specialized profiles like bulb flats. For alloy steel bulb flats (e.g., higher grades), the code may fall under Chapter 73. Always verify the final 8-10 digit code with your local customs broker based on the exact material grade and your country’s tariff schedule.

The HS code system is logical but precise. A small error in classification can have big consequences. Understanding the logic helps you communicate better with your broker and supplier.

Decoding the HS Code for Bulb Flats

The code is built like an address, getting more specific at each level.

- Chapter 72: This is the broad category for "Iron and Steel."

- Heading 7216: This narrows it down to "Angles, Shapes and Sections… hot-rolled."

- Subheading 7216.50: This is the catch-all for shapes that aren’t standard angles, H-beams, or U-sections. Bulb flats fit here.

Critical Factors in HS Code Determination

Customs authorities don’t just look at the shape; they look at the material’s composition.

| Determining Factor | How It Influences the HS Code | Implication for Bulb Flat Buyers | Practical Advice |

|---|---|---|---|

| Material: Alloy vs. Non-Alloy | The primary split. If the steel has alloying elements (like specific amounts of Chromium, Nickel, Molybdenum) above certain thresholds, it may be classified as alloy steel under Chapter 73. | Standard carbon steel bulb flats (like Grade A) are under 7216. High-strength, low-alloy (HSLA) grades like AH36 often still classify under 7216, but it depends on local interpretation. | Provide the full Mill Test Certificate to your customs broker. The chemical analysis is the definitive proof for classification. |

| State: Hot-Rolled | Code 7216 specifies "not further worked than hot-rolled." This is the condition as it leaves the mill. | Bulb flats for shipbuilding are supplied in the hot-rolled, untreated condition. This aligns perfectly with 7216. | Ensure your supplier’s commercial invoice describes the goods as "Hot-rolled bulb flat steel sections." |

| Shape: "Other Sections" | Bulb flats have a unique profile with a bulb at the tip. They are not a standard angle or tee, so they belong to the "other" category. | This is the correct classification for their distinctive shape. There is no separate, more specific code just for bulb flats. | In your documents, use the description "Hot-rolled steel bulb flats (shipbuilding sections)." |

| Destination Country’s Rules | Each country has its own national sub-categories (8-10 digits) for assessing duty rates and enforcing import regulations. | The code for exporting from China may differ from the code for importing into Saudi Arabia or the USA. | The importer (you) is responsible for the correct import code. Collaborate with a licensed customs broker in your country. |

As an exporter, we use the standard Chinese export code (e.g., 7216500000) on our documents. This ensures smooth exit from China. However, a key part of our service is providing all the necessary documentation—detailed invoice, packing list, and MTC—so that our clients’ brokers can make the correct determination at their end. This support is crucial for avoiding the logistical headaches that can derail a project’s timeline.

What size are flat steel sections?

You are looking at a technical drawing or a supplier’s catalog. The term "size" for a bulb flat is not a single number. It describes the key dimensions that define its structural capability. Ordering the wrong size makes the material useless.

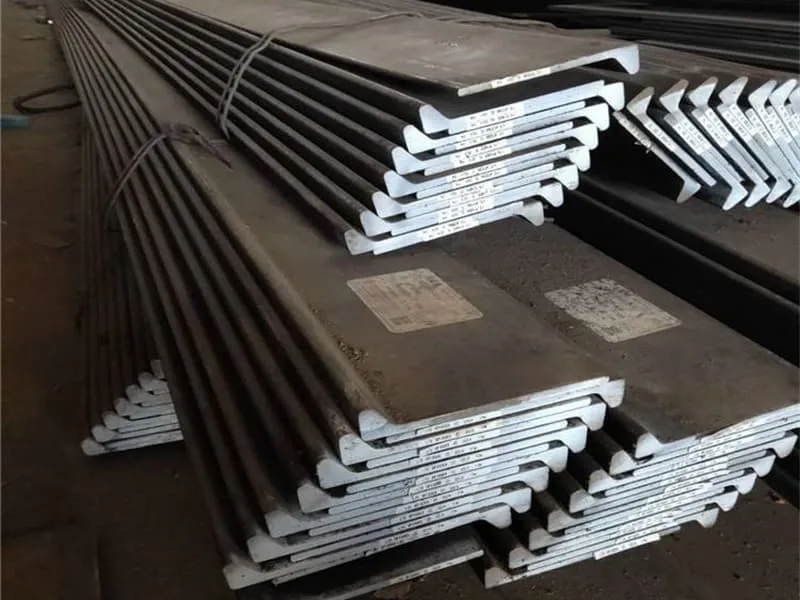

Flat steel sections, like bulb flats, are sized by their key profile dimensions. For a bulb flat, the size is denoted as "HP [Height] x [Thickness]" (e.g., HP 120×8). The "Height" is the total depth from the base of the flange to the tip of the bulb. The "Thickness" is the web thickness. Standard sizes range from small sections like HP 80×6 to large ones like HP 300×12. The flange width is also standardized relative to the height. Always refer to classification society tables (ABS, DNV) or standards like GB/T 3107 for exact dimensions.

"Size" encompasses several controlled dimensions that together give the section its strength properties. Understanding these dimensions is critical for engineers and buyers alike.

The Anatomy of a Bulb Flat Size Designation

The simple code "HP 100×7" tells you two main things, but a full specification includes more.

- Nominal Size (HP 100×7): "HP" often stands for "Holland Profile," a common historical term. "100" is the nominal height in mm. "7" is the web thickness in mm.

- Detailed Dimensions: Each nominal size has defined dimensions for the flange width, bulb height, and bulb radius.

Standard Bulb Flat Size Ranges and Applications

This table shows common size ranges and where they are typically used in shipbuilding.

| Size Category | Typical Size Range (HP Height x Thickness) | Common Dimensions (Flange Width ~) | Primary Applications in Shipbuilding |

|---|---|---|---|

| Small Bulb Flats | HP 80×6, HP 100×7, HP 120×8 | Flange width: 10-12mm. | Stiffeners for light bulkheads, superstructure decks, and smaller compartments on tugs, fishing vessels, and yachts. |

| Medium Bulb Flats | HP 120×8, HP 140×8, HP 160×9, HP 180×9, HP 200×10 | Flange width: 12-15mm. | The most common range. Used as primary longitudinal stiffeners for the hull, main decks, and bulkheads of cargo ships, tankers, and bulk carriers. |

| Large Bulb Flats | HP 220×10, HP 240×11, HP 260×11, HP 280×12, HP 300×12 | Flange width: 15-18mm. | Used in the bottom and side shells of very large vessels (VLCCs, large container ships) and in critical areas of offshore platforms where extreme loads are expected. |

The MOQ is directly tied to size. Mills roll specific sizes in production runs. A less common, large size like HP 280×12 may have a higher effective MOQ because the mill runs it less frequently. A popular size like HP 120×8 is produced more often, making it easier for a supplier to offer a lower MOQ from stock or a partial mill run. When clients like Gulf Metal Solutions plan their orders, they try to consolidate needs into a few standard sizes to meet the mill’s MOQ efficiently and get the best price. This is a smart strategy for project-based fabricators.

What are bulb flats used for?

You see this odd-shaped steel and wonder why it exists. Why not use a simple flat bar or an angle? The unique design of a bulb flat solves a specific engineering problem with brilliant efficiency.

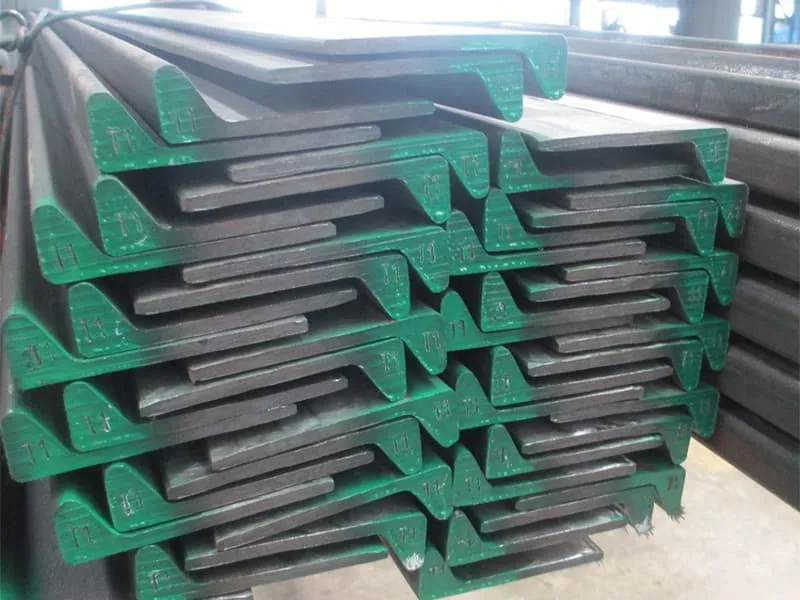

Bulb flats are used primarily as longitudinal stiffeners in ship and offshore construction. They are welded perpendicular to hull plates, deck plates, and bulkhead plates. The bulb provides a high section modulus (bending resistance) with minimal weight, efficiently strengthening large steel panels against water pressure, cargo loads, and dynamic forces. This design allows for thinner, lighter hull plates while maintaining structural integrity, directly reducing vessel weight and improving fuel efficiency.

The bulb flat is not just a piece of steel; it is a performance-optimized structural component. Its use is dictated by the harsh economics and physics of marine engineering.

The Engineering Principle Behind the Bulb

The goal is to resist bending. Material placed farther from the neutral axis contributes more to bending resistance (moment of inertia).

- Efficiency: A flat bar of the same weight as a bulb flat would have its material close to the plate (neutral axis), providing little extra stiffness. The bulb takes a small amount of material and puts it far away, greatly increasing strength.

- Practicality: Compared to a T-bar, the bulb flat has a streamlined shape that is easier to coat with paint and less prone to trapping debris or water.

Specific Applications in Marine Structures

Beyond just "stiffeners," bulb flats have precise roles.

| Application Area | How Bulb Flats Are Used | The Engineering Benefit | Alternative (Less Efficient) |

|---|---|---|---|

| Ship Hull Bottoms & Sides | Welded longitudinally (fore-aft) to the outer shell plating. | Resists the immense, uniform pressure of the water. Preents the plate from buckling inward between transverse frames. | Using a much thicker hull plate alone, which would be extremely heavy and expensive. |

| Decks & Internal Decks | Run longitudinally to support deck cargo weight (containers, bulk goods) and distribute loads to the main frames. | Provides the necessary stiffness to span between transverse beams without excessive deflection under heavy loads. | Using closely spaced, smaller angles or flat bars, which would require more welding and weight. |

| Bulkheads & Walls | Used vertically or horizontally to stiffen watertight or structural walls inside the vessel. | Prevents the large, flat panel of the bulkhead from vibrating or deforming under water pressure (for tanks) or mechanical loads. | Using a built-up "T" section from a flat bar and a flange plate, which requires more fabrication labor. |

| Offshore Platform Legs & Jackets | Used as bracing members and stiffeners on large tubular legs and complex jacket structures. | Provides high strength-to-weight ratio in a corrosive, high-load environment where every kilogram matters for floatation and stability. | Using heavier standard structural sections like channels or beams. |

Understanding this primary use is crucial when discussing MOQ. The MOQ for bulb flats is inherently linked to the scale of shipbuilding. Mills produce them in batches suitable for constructing entire vessel sections. A small repair order of 2 tons is economically challenging for a mill set up for 25-ton batches. This is why finding a supplier with "flexible MOQ" is so valuable—they bridge the gap between massive production runs and the real-world needs of shipyards, repair docks, and fabricators working on multiple smaller projects.

What are the 4 types of steel?

You hear terms like "carbon steel," "alloy steel," and "stainless steel." Where does bulb flat steel fit in? This basic classification helps you understand the material’s fundamental nature, its properties, and its cost.

The four main types of steel, classified by chemical composition, are: 1) Carbon Steel (basic iron and carbon, most common), 2) Alloy Steel (added elements like Cr, Ni, Mo for strength/hardness), 3) Stainless Steel (high Chromium for corrosion resistance), and 4) Tool Steel (very hard, for cutting tools). Bulb flats for marine use are typically made from Carbon Steel or High-Strength Low-Alloy (HSLA) Steel, which is a subcategory of Alloy Steel. They are not made from stainless or tool steel.

This classification is the starting point for all material selection. Each type has a core purpose, and choosing the wrong type is a fundamental error.

Where Bulb Flats Fit in the Steel Family

Bulb flats are a product form (a shape) that can be made from different material types. In marine applications, the material type is very specific.

- Carbon Steel: Basic, economical. Used for non-critical or inland waterway structures. Not typical for modern ocean-going ships.

- High-Strength Low-Alloy (HSLA) Steel: This is the standard. It has small, controlled additions of elements like Manganese, Niobium, Vanadium, and Copper to increase strength and toughness without requiring heat treatment in some cases. Marine grades (AH, DH, EH) are HSLA steels.

- Stainless Steel: Used for specific corrosive environments on ships (like chemical tankers), but stainless bulb flats are rare and extremely expensive due to rolling challenges.

- Tool Steel: Never used for structural sections.

A Detailed Look at Steel Types for Marine Structures

This table clarifies the differences and shows why HSLA steel is the chosen material for bulb flats.

| Steel Type | Key Characteristics | Common Marine Applications | Use in Bulb Flats? |

|---|---|---|---|

| Carbon Steel (e.g., S235, A36) | Properties mainly from carbon content. Good strength, ductile, weldable, but corrodes easily and has lower toughness. | Non-critical secondary structures, some inland barge construction. | Possible for low-specification work, but not recommended for classed ocean-going vessels due to inadequate toughness. |

| High-Strength Low-Alloy (HSLA) Steel | Enhanced strength and toughness through micro-alloying. Better atmospheric corrosion resistance than plain carbon steel. Often normalized. | The standard for all primary ship structures: hull plates, frames, and bulb flats. Grades: AH32, DH36, EH40, etc. | Yes, this is the standard. Provides the required yield strength (e.g., 355 MPa for DH36) and, crucially, the mandatory impact toughness for service in cold waters. |

| Stainless Steel (e.g., 316/L) | Excellent corrosion resistance due to high Chromium (and often Nickel) content. Austenitic structure. | Chemical tanker linings, piping, pumps, valves, exterior fittings on passenger ships. | Very rarely. The cost is prohibitive for primary structure, and the rolling process for the bulb shape is difficult with stainless. |

| Tool Steel | Very high hardness and wear resistance. Used for cutting, forming, or shaping other materials. | Drill bits, cutting tools, die components in the shipyard workshop. | No. It is not a structural material and is not produced in bulb flat profiles. |

When you specify bulb flat steel, you are almost always specifying an HSLA steel of a particular marine grade. This directly impacts the MOQ. Producing HSLA steel requires tighter process control and often normalization heat treatment, which mills do in dedicated heats. This is a key reason the MOQ exists—to make a single heat and rolling run economically viable. Our "competitive factory price" is based on sourcing these HSLA bulb flats efficiently from our partner mills, passing on the savings from planned, volume production to our clients who can meet reasonable MOQs.

Conclusion

The MOQ for bulb flat steel is shaped by mill production economics for HSLA steel. To navigate it, understand the product’s HS code, specify standard sizes, recognize its critical structural role, and know it is made from high-performance marine-grade steel, not basic carbon steel.