Picture this. You are ready to buy a large order of marine angle steel, but you send out an RFQ and receive quotes that are confusing, incomplete, or just not comparable. This frustrating situation wastes time and creates risk for your project. A poorly written request for quotation sets the stage for miscommunication and future problems.

To get the most useful and comparable quotes for marine steel, your RFQ must be clear, detailed, and professional. It should act as a precise blueprint that tells potential suppliers exactly what you need, how you need it, and under what terms. This ensures you receive accurate, apples-to-apples bids from qualified manufacturers.

I have been on both sides of the RFQ process—first as a project manager needing materials and now as a supplier at cnmarinesteel.com. I have seen how a great RFQ can streamline a project and how a vague one can lead to costly delays. The difference often comes down to a few key details. Let’s break down exactly how to craft a request that gets you the right quote from the right partner, ensuring your shipbuilding or marine construction project stays on budget and on schedule.

How do you write a request for quotation?

You might think writing an RFQ is just about asking for a price. That approach often leads to vague answers and more back-and-forth emails. A good RFQ does more than ask for a price; it starts a professional dialogue. It filters out unqualified suppliers and attracts serious partners who can meet your specific needs.

Writing an effective request for quotation involves structuring a formal document that clearly outlines your technical, commercial, and logistical requirements. This document invites suppliers to provide a binding price and terms for supplying the specified goods or services. A well-structured RFQ makes comparison easy and reduces negotiation time later.

The Step-by-Step Blueprint for Your Marine Steel RFQ

Think of your RFQ as a project instruction manual. The goal is to give every supplier the exact same information so their quotes are based on identical criteria. This is not just about getting a price; it is about finding a reliable partner for your marine project. Here is how to build your RFQ, step by step.

1. Start with a Clear Subject Line and Introduction

Your email subject line should be specific. Instead of "Quote Request," use "RFQ for 50MT Grade A Marine Angle Steel for Shipbuilding Project – [Your Company Name]." This immediately tells the supplier the product and scale. In the introduction, briefly introduce your company and the project. This context helps the supplier understand your level of seriousness.

2. Provide Detailed Product Specifications

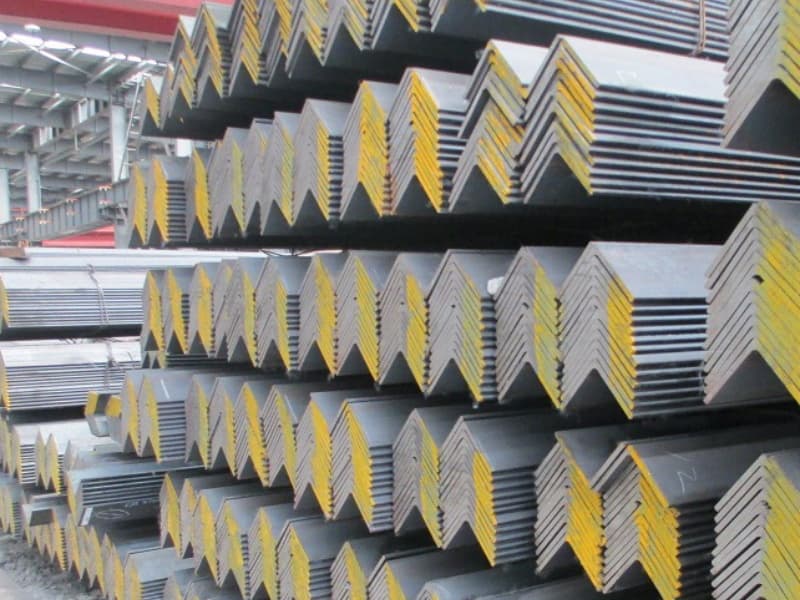

This is the core of your RFQ. For marine angle steel1, vagueness is your enemy. You must specify every detail a mill or fabricator needs to know.

| Specification Category | What to Include | Example for Marine Angle Steel |

|---|---|---|

| Material Standard & Grade | The exact standard (e.g., ABS, LR, DNV, GL) and grade (e.g., AH32, DH36). | "Material: LR Grade AH36 Marine Angle Steel" |

| Dimensions & Tolerances | Leg lengths, thickness, and length. Specify if tolerances are per a specific standard. | "Size: 200mm x 200mm x 20mm, Length: 12 meters, Tolerances per EN 10056-1" |

| Quantity | The total net weight (metric tons) and the number of pieces. | "Quantity: 50 Metric Tons, approx. 417 pieces (based on 120kg/piece)" |

| Technical Requirements | Any special requirements like impact testing temperature, Z-direction properties, or surface treatment. | "Charpy V-Notch Impact Test: -20°C longitudinal. Surface: Blast cleaned to Sa 2.5." |

3. Outline Packaging and Marking Requirements

Marine steel is expensive and needs protection. Specify your packaging needs to avoid damage during ocean freight.

- Packaging: "Each piece to be bundled securely with steel straps. Ends to be protected with plastic caps. Bundles must be suitable for open-sea container shipment."

- Marking: "Each piece must be marked with heat number, grade, size, and our purchase order number using paint or tags."

4. Define Commercial and Logistics Terms

This section tells the supplier how you want to do business. Clarity here prevents misunderstandings later.

- Incoterms: State your preferred term (e.g., FOB Shanghai, CFR Dammam, CIF Felixstowe).

- Destination Port: Specify the exact port of discharge.

- Payment Terms: State your standard terms (e.g., 30% T/T deposit, 70% against copy of shipping documents).

- Delivery Time: Give a clear required delivery window (e.g., "Delivery required within 8 weeks from order confirmation").

- Validity of Quote: Request how long the quoted price is valid (e.g., "Price valid for 30 days").

5. Request Specific Supplier Information

Ask the supplier to provide more than just a price. You are evaluating them as a potential partner.

- Request a detailed proforma invoice breaking down the cost (product, packing, inland freight, etc.).

- Ask for mill certificates or their quality control process.

- Inquire about their experience with similar projects or supplying to your region.

From my experience, when a client like Gulf Metal Solutions sends us an RFQ with this level of detail, we can provide a comprehensive quote within hours. It shows they are professional and know what they want, which makes us prioritize their request. A detailed RFQ is the first step toward a smooth, successful partnership.

What is a formal request for a quote?

Many buyers confuse a simple email asking "what’s your price?" with a formal RFQ. That informal approach might work for small, standard items, but it is inadequate for engineered materials like marine steel. An informal request leaves too much open to interpretation, which can lead to disputes over quality, delivery, or cost later on.

A formal Request for Quote (RFQ)1 is a structured, detailed business document used in B2B transactions to solicit fixed-price bids from potential suppliers for specific products or services. It is a key part of professional procurement, creating a clear, auditable record of requirements and responses. For project-critical materials, it is the standard way to ensure fairness, accuracy, and accountability.

Understanding the "Formal" in RFQ: It’s About Process and Protection

Why go through the trouble of making it "formal"? The formality is not about using fancy language; it is about establishing a clear, fair, and legally sound procurement process. For high-value, technically specific products like marine angle steel, this formality protects both the buyer and the supplier.

The Core Components of Formality

A formal RFQ is characterized by several key elements that distinguish it from a casual inquiry:

-

Structured Document Format: It is not a loose collection of questions in an email. It is typically a numbered document (often a PDF or a dedicated portal submission) with clear sections: Introduction, Specifications, Commercial Terms, Submission Instructions, and sometimes terms and conditions. This structure ensures nothing is missed.

-

Binding Nature: When a supplier submits a quote in response to a formal RFQ, that quote is usually a binding offer for a set period. This means if you accept it within the validity period, they are obligated to supply at that price and those terms. This gives you certainty in your project budgeting.

-

Creates an Audit Trail: In corporate or government procurement, the RFQ and all submitted quotes become part of the official project audit trail2. This demonstrates due diligence, fair competition, and justification for selecting a particular supplier. It is essential for transparency.

-

Facilitates Accurate Comparison: Because all suppliers are responding to the exact same detailed specifications and terms, you can compare their quotes directly. You are comparing apples to apples on price, quality, delivery, and service, not guessing if one supplier’s "Grade A" is the same as another’s.

The Buyer’s and Supplier’s Perspective on Formality

- For You (The Buyer): Formality reduces risk. It minimizes the chance of receiving the wrong material. It forces you to clarify your own requirements thoroughly before engaging suppliers. It also gives you leverage; if a supplier fails to meet the specifications outlined in their accepted quote, you have a clear document to reference.

- For Us (The Supplier): A formal RFQ is actually welcome. It shows the buyer is serious and organized. It allows us to prepare an accurate quote quickly because all necessary information is provided. There is no need for 15 clarifying emails. We know exactly what is expected, so we can confidently commit to a price and delivery schedule.

In our business, a formal RFQ is the starting point for all major projects. When a large importer or project contractor from Saudi Arabia or Vietnam sends a formal RFQ, we mobilize our technical and commercial teams immediately. We review the specs against mill capabilities, check production schedules, and calculate precise logistics costs. The formality of the document signals a significant opportunity, and we respond with the same level of professionalism and detail. It sets the tone for the entire business relationship.

What should a request for quote include?

An incomplete RFQ is like giving a builder half a blueprint. You will not get the house you wanted. For marine steel, missing key details can result in quotes for the wrong grade, unsuitable packaging, or unexpected extra charges. This leads to delays, wasted time re-quoting, and potential cost overruns for your project.

A comprehensive marine steel RFQ1 should include five critical sections: precise technical specifications2, clear quantity and unit details, specific packaging and marking instructions3, defined commercial and delivery terms (Incoterms, payment, timeline), and a request for the supplier’s supporting documentation. This completeness ensures you receive actionable, comparable quotes.

The Essential Checklist: Building Your Complete RFQ Document

Let’s dive deeper into each of these five sections. Think of this as your RFQ checklist. Missing any one can create a gap that leads to problems.

1. Technical Specifications: The Heart of the RFQ

This is non-negotiable. You must be ultra-specific.

- Product Description: "Marine Angle Steel" is too vague. Use the full technical name: "Lloyd’s Register (LR) Certified, Grade AH36, Equal Leg Angle Steel."

- Detailed Dimensions: Leg width x leg width x thickness x length. Example:

200 x 200 x 20 x 12000 mm. - Material Standards: Specify the classification society (e.g., ABS, DNV, BV) and the exact grade. If you need it to meet multiple society rules, state that.

- Certification Requirements: Do you require the original mill certificates (MTC)? Should they be 3.1 or 3.2? Will you send a third-party inspector like SGS? State this clearly.

- Additional Testing: Are there requirements for Charpy impact tests, chemical analysis reports, or non-destructive testing? List them.

2. Quantity and Unit Information

Be precise to avoid confusion on pricing.

- Total Net Weight: In metric tons (e.g., 85.50 MT).

- Number of Pieces: This helps the supplier plan production and packing.

- Unit of Sale: Is the price quoted per metric ton (MT) or per piece? Make this clear.

3. Packaging, Marking, and Shipping Details

How the steel is prepared for transport is crucial, especially for ocean voyages.

- Packaging: Specify bundling, waterproof wrapping (if needed), edge protection, and strapping requirements. For example, "Bundles must be compact, with steel straps every 2 meters. All sharp edges must be capped."

- Marking: Require clear, paint-stenciled markings on each piece or bundle with heat number, grade, size, and your project ID.

- Shipping Instructions: State your preferred Incoterm (e.g., FOB Tianjin, CFR Jebel Ali). Provide the exact destination port and address for delivery if needed.

4. Commercial Terms and Conditions

This defines the business rules.

- Price Validity: "This quoted price must be valid for a minimum of 45 days."

- Payment Terms: State your standard terms (e.g., "30% deposit by T/T, 70% balance against copy of shipping documents").

- Delivery Schedule: Give a required delivery date or a window (e.g., "Must be ready for shipment by October 25, 2023").

- Incoterms Version: Specify the year (e.g., "Incoterms® 2020").

5. Requested Supplier Response Details

Tell the supplier how to quote and what extra info to provide.

- Quote Format: "Please provide a detailed Proforma Invoice."

- Breakdown of Costs: Request a line-item breakdown: material cost, testing cost, packing cost, inland freight, etc.

- Supporting Documents: Ask for a company profile, quality control certificate, or examples of similar past shipment documents.

- Lead Time: Ask them to confirm their production and shipping lead time based on your requirements.

Our case study client, Gulf Metal Solutions, excels at this. Their RFQs always include SGS inspection as a requirement, precise packaging specs for the Middle East climate, and clear CFR Dammam port terms. Because their RFQ is complete, we can confirm quickly if we can meet all conditions, and the project moves forward without surprises. A complete RFQ is the strongest foundation for a successful order.

What mistakes should I avoid in my RFQ?

Even with a checklist, common pitfalls can undermine your RFQ. These mistakes send the wrong signal to suppliers. They might think you are not serious, that your project is disorganized, or that you do not understand the product. This can result in fewer quotes, higher risk premiums in the pricing, or attracting less reliable suppliers.

The biggest mistakes to avoid in an RFQ are being vague on specifications, ignoring packaging and logistics terms, focusing solely on the lowest price without considering quality, and failing to provide clear context about your project and company. These errors lead to inaccurate quotes, communication breakdowns, and increased project risk.

A Critical Look at Common RFQ Pitfalls and Their Consequences

Let’s analyze these common errors. Understanding why they are problematic helps you avoid them naturally.

Mistake 1: Vagueness in Technical Requirements1

This is the most critical error.

- The Error: Writing "Marine Grade Steel" or "Shipbuilding Angle."

- The Consequence: Suppliers will either ask for clarification (delaying the process) or will quote for the most common, basic grade they have. You might get a quote for commercial-grade steel instead of classified hull structural steel. The price will look good, but the material will be wrong and potentially dangerous for your application.

- The Fix: Always use the full, standardized terminology. Refer to the specific classification society and grade. Provide a technical data sheet if possible.

Mistake 2: Omitting Packaging and Incoterms2

Many buyers focus only on the product and forget how it gets to them.

- The Error: Not mentioning how the steel should be packed or what shipping terms you need.

- The Consequence: You may receive a price for EXW (Ex-Works) from the factory gate, but then face huge unexpected costs for inland freight in China, port fees, and ocean freight. Alternatively, the steel may arrive damaged because it was packed for short-distance trucking, not a 4-week sea voyage.

- The Fix: Always state your required Incoterm (e.g., FOB, CIF) and destination. Include clear, project-specific packaging instructions.

Mistake 3: The "Lowest Price Only" Mindset

While cost is important, it should not be the only factor for engineered materials.

- The Error: Sending an RFQ that emphasizes "we will choose the lowest bid" without highlighting quality requirements.

- The Consequence: You will attract suppliers who cut corners. The true cost of rework, project delays, or component failure at sea dwarfs any initial savings on material. It also discourages high-quality mills from bidding, as they know they cannot compete on price alone with trading companies that may not control quality.

- The Fix: Frame your RFQ around "best value" or "meeting all technical and commercial requirements." Ask for quality certifications and mill documents as part of the quote.

Mistake 4: Lack of Project Context and Professionalism3

An RFQ that looks like a mass-produced, generic email blast gets a generic response.

- The Error: A sparse email with just a part number and "please quote."

- The Consequence: Your request gets deprioritized. Sales teams receive dozens of these daily. They will respond to the detailed, professional RFQs first because they signal a higher probability of a real, valuable order.

- The Fix: Include a brief introduction: "We are [Company Name], a shipyard in Vietnam, working on a new bulk carrier project. We require the following materials for hull construction." This immediately establishes credibility.

I see Mistake 4 often. When we receive a one-line email, it goes to the bottom of the pile. But when we receive a well-formatted RFQ from a company like Gulf Metal Solutions, with their logo, clear project name, and full details, it gets assigned to a dedicated manager immediately. The quality of your RFQ directly influences the quality and speed of the response you receive. Avoiding these mistakes is not just about getting a better quote; it’s about building a better supply chain relationship from the very first interaction.

Conclusion

A well-crafted RFQ is your most powerful tool for sourcing marine angle steel. It ensures clarity, attracts reliable partners, and protects your project from costly errors and delays.

-

Understanding the impact of vague specifications can help you craft clearer RFQs, ensuring you receive accurate quotes and avoid costly mistakes. ↩ ↩ ↩ ↩

-

Learn how proper packaging and Incoterms can prevent unexpected costs and ensure your materials arrive safely and on time. ↩ ↩ ↩

-

Explore how a well-structured RFQ can enhance your credibility and improve supplier engagement, leading to better outcomes. ↩ ↩