Many shipbuilders assume local steel is always better, but global supply chains have changed. Choosing the wrong supplier for bulb flats can delay your project and increase costs. I’ve seen yards struggle with inconsistent quality and slow delivery when they don’t look at proven international options.

Chinese bulb flat steel is a strong choice for ship construction due to its competitive factory pricing, reliable quality from modern mills, full compliance with international classification society rules (ABS, LR, DNV, etc.), and efficient supply chain support for global export, especially to major shipbuilding regions.

The decision goes beyond just price. It involves understanding steel grades, manufacturing standards, and logistical reliability. This article will address common questions and misconceptions to help you evaluate Chinese marine steel objectively for your next project.

What is the best steel for ship building?

There is no single "best" steel for all ships. I hear this question often from new buyers who want a simple answer. The best steel is the one that perfectly matches the specific requirements of the vessel’s design, classification rules, and operating environment.

The best steel for shipbuilding is high-tensile, notch-tough steel that meets international classification society standards (like AH/DH/EH grades). It must have the right yield strength (often 235-460 MPa), guaranteed impact toughness at low temperatures, good weldability, and be supplied with full traceability and Mill Test Certification.

Defining "Best" in the Context of Shipbuilding

"Best" is a combination of material properties, compliance, and practical supply factors. Let’s break down the components of an ideal shipbuilding steel.

1. Material Properties: The Non-Negotiables

The steel must perform under harsh conditions. Key properties include:

- Controlled Yield and Tensile Strength: To withstand global hull bending and local loads.

- Guaranteed Low-Temperature Toughness: To prevent brittle fracture. This is indicated by the grade’s impact test temperature (e.g., D = -20°C, E = -40°C).

- Good Weldability: A low Carbon Equivalent (CEV) is essential for crack-free welding without complex pre-heat procedures.

2. Compliance and Certification

The steel is not suitable if it doesn’t meet the rules.

- Classification Society Approval: The mill must be approved by major societies like American Bureau of Shipping (ABS), Lloyd’s Register (LR), DNV, etc. This means their production process is audited and certified.

- Mill Test Certificate (MTC): Every batch must have a valid MTC. This document proves the chemical and mechanical properties meet the ordered specification.

3. Practical and Economic Factors

The "best" steel must also be viable for the project.

- Availability: Can it be supplied in the required quantities and dimensions on time?

- Cost-Effectiveness: Does it offer a good balance of performance and price?

- Supplier Reliability: Does the supplier offer technical support, consistent quality, and good logistics?

How Chinese Bulb Flat Steel Meets These Criteria

Chinese mills have invested heavily to meet global standards. Here is a comparison of common sources:

| Criteria | Traditional European/Japanese Mills | Chinese Mills (Certified) | General Regional Mills |

|---|---|---|---|

| Material Properties | Excellent, long-established. | Identical to top-tier. Grades like EH36, AH32 meet the same ISO and class society specs. | May vary; not all have low-temp toughness grades. |

| Certification | Full LR, DNV, ABS, etc. | Full LR, DNV, ABS, etc. Major mills hold all major approvals. | Limited or no international class approvals. |

| Cost | Premium price. | Competitive price. Lower production and logistics costs. | Low price, but risk is high. |

| Supply Flexibility | Can be long lead times. | High flexibility on MOQ and dimensions due to large capacity. | Variable. |

| Technical Support | Strong. | Growing rapidly. Many have export-focused engineering teams. | Often minimal. |

For a project contractor in Saudi Arabia or the Philippines, the "best" steel is the certified AH36 or DH32 bulb flat that arrives on schedule, with perfect paperwork, at a price that keeps their bid competitive. Chinese mills, through partners like us, provide exactly that package. We ensure the MTC from our Shandong mill partners is as valid and detailed as any from Europe.

Is Chinese steel as good as US steel?

This is perhaps the most common question from buyers in the Americas and Europe. There is a historical perception gap. The answer is not about nationality, but about the specific mill, its standards, and its certifications.

For marine applications, steel from certified Chinese mills is equally as good as US steel when it meets the same international classification society standards (like ABS). The quality is defined by the mill’s processes and adherence to these global specifications, not by the country of origin.

A Objective Comparison Based on Standards, Not Stereotypes

Quality in industrial steel is measurable and certified. Let’s compare based on tangible factors.

The Benchmark: Classification Society Approval

Marine steel quality is not subjective. It is judged by independent classification societies.

- A US mill selling AH36 plate for shipbuilding must be approved by ABS (or other societies).

- A Chinese mill selling the same AH36 plate must have the same ABS approval.

- To get this approval, a mill must pass strict audits of its entire process: steelmaking, rolling, heat treatment, testing, and quality management system.

- Conclusion: If both mills hold the same valid approval for the same grade, the steel is, by definition, produced to the same minimum quality standard.

Technological Capability

Modern Chinese steelmakers are world-leading.

- They operate the latest Basic Oxygen Furnaces (BOF), continuous casters, and Thermo-Mechanically Controlled Process (TMCP) rolling mills.

- These technologies allow precise control of chemistry and microstructure, producing steel with excellent strength and toughness.

- The equipment is often newer than that in some older US mills.

Side-by-Side Specification Comparison

Let’s take a common grade, ABS Grade AH36, as an example. The ABS rulebook defines the requirements. Any ABS-approved mill, anywhere, must meet these.

| Property | ABS Rule Requirement for AH36 | Typical US Mill Product | Typical Certified Chinese Mill Product |

|---|---|---|---|

| Yield Strength Min | 355 MPa | 360-400 MPa | 360-400 MPa |

| Tensile Strength | 490-620 MPa | 500-600 MPa | 500-600 MPa |

| Impact Energy (-20°C for ‘D’ subgrade) | ≥ 34 J | ≥ 40 J | ≥ 40 J |

| Chemical Composition (C, Mn, Si, S, P) | Must fall within ABS limits. | Within limits. | Within limits. |

| Certification | ABS MTC | Provided. | Provided. |

The table shows the products are functionally identical because they are made to the same rule.

Addressing Common Concerns

- "Inconsistent Quality": This is a risk with any uncertified supplier. The solution is to source only from class-approved mills and insist on MTCs. We mitigate this by partnering only with top-tier, audited mills.

- "Material Substitution": Reputable exporters do not do this. We offer third-party inspection (SGS/BV) at the mill before shipment for added buyer confidence.

- "Communication Barriers": This was a valid pain point. That’s why we provide dedicated English-speaking account managers, as we did for Gulf Metal Solutions, to ensure clear, responsive communication.

The evidence is clear. When you buy "US steel," you are buying from a specific mill with certain certifications. When you buy "Chinese steel," you can choose a mill with the same certifications. The quality is equivalent, but the cost structure and supply chain efficiency often differ favorably with the Chinese option.

Which type of steel is most commonly used in shipbuilding due to its strength and durability?

Walk through any major shipyard, and you will see the same grades on material tags and drawings. This commonality exists because naval architects and classification societies have standardized around a family of steels that offer the optimal balance for most vessels.

Normal Strength ‘A’ Grade steel and High Strength ‘AH’ series steels (like AH32, AH36, AH40) are the most commonly used types in shipbuilding. Their popularity is due to a successful combination of good strength (235-390 MPa yield), guaranteed toughness, excellent weldability, and standardized availability worldwide.

The Workhorses of the World’s Fleet

These steels dominate because they solve the core structural problem efficiently and reliably. Let’s explore the two main categories.

1. Normal Strength Steel (Grade A, B, D, E)

- Yield Strength: 235 MPa minimum.

- Use: This is the traditional shipbuilding steel. It is used for less critical parts of smaller vessels or in warmer waters. Its use is declining in large oceangoing ships in favor of high-strength steels, but it remains common for inner hulls, superstructures, and bulkheads.

- Grades: A, B, D, and E indicate ascending levels of impact toughness (from room temperature down to -40°C for Grade E).

2. High Strength Steel (Grades AH, DH, EH, FH)

This is the true industry standard for main hull structures.

- Naming: The ‘H’ stands for High tensile strength.

- Strength Levels: The number indicates the minimum yield strength in ksi (kilo-pounds per square inch).

- 32: 32 ksi ≈ 315 MPa

- 36: 36 ksi ≈ 355 MPa (This is the single most common grade for large vessels)

- 40: 40 ksi ≈ 390 MPa

- Toughness Levels: The first letter again indicates toughness: AH (standard), DH (-20°C), EH (-40°C), FH (-60°C).

Why AH36 is the King

A combination of factors makes AH36 (and its DH/EH variants) the default choice:

- Optimal Strength-to-Weight: A 355 MPa yield offers significant weight savings over 235 MPa steel. This translates directly to more cargo capacity (deadweight).

- Cost-Effectiveness: It is stronger than normal steel but does not require the extreme alloying and processing of ultra-high-strength steels (>460 MPa), keeping it relatively affordable.

- Excellent Weldability: The chemistry of AH36 is carefully controlled to ensure it can be welded easily in shipyard conditions.

- Universal Availability: Every major steel-producing country and approved mill can produce AH36 to classification standards. This gives shipyards and buyers supply chain flexibility.

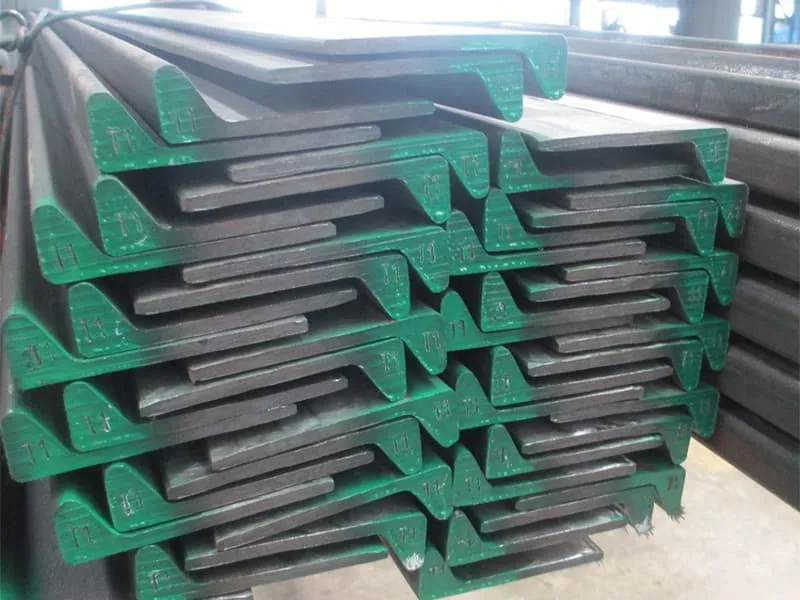

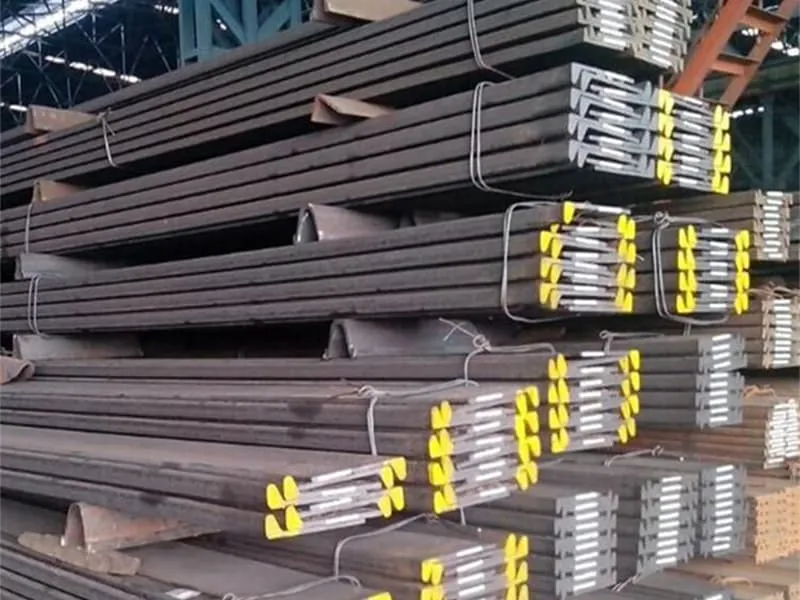

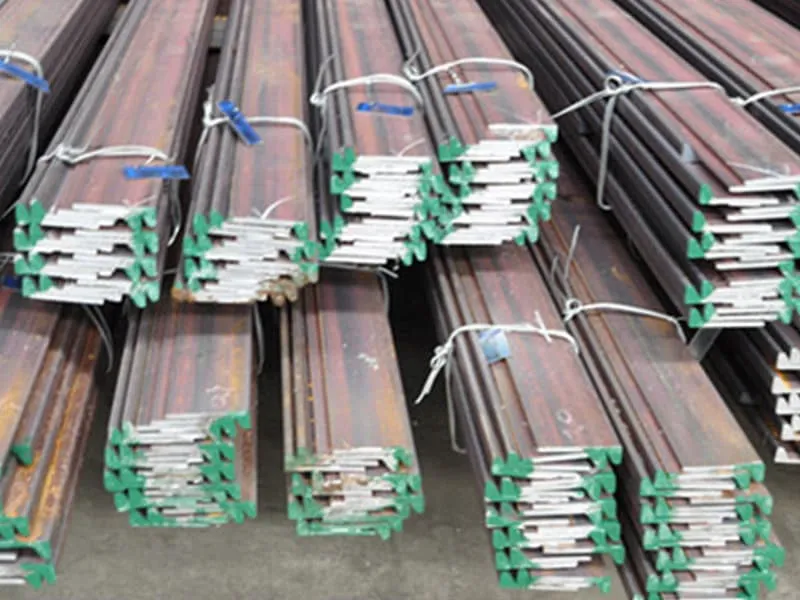

Application in Bulb Flats

When you order bulb flats, you are most likely ordering them in these common grades:

- HP200 x 10 in AH36: For general stiffeners.

- HP240 x 11 in DH36: For critical stiffeners in colder waters.

- HP300 x 12 in EH36: For ice-class vessel stiffeners or high-stress areas.

Our export patterns confirm this. Orders to Vietnam for bulk carriers, to Romania for tankers, and to Saudi Arabia for service vessels overwhelmingly specify AH32 or AH36 for plates and bulb flats. The mills we work with have these grades in constant production, ensuring quick turnaround. This commonality is an advantage for buyers. It means the material is a commodity produced to a global standard, which increases competition and keeps prices in check.

What is the main advantage of using high tensile steel1 for ship building?

Shipowners always want to carry more cargo and use less fuel. Naval architects have a direct tool to achieve this: high tensile steel1. The advantage is simple in theory but profound in its impact on the economics of shipping.

The main advantage of using high tensile steel1 (HTS) in shipbuilding is weight reduction2. For the same structural strength, HTS allows the use of thinner plates and lighter stiffeners (like bulb flats). This lowers the ship’s lightweight, increasing its cargo capacity (deadweight) and improving fuel efficiency.

The Engineering and Economic Impact of Weight Savings

Weight reduction is not a minor benefit; it is a fundamental design driver. Let’s quantify the impact.

The Principle of Structural Efficiency

High tensile steel has a higher yield strength (e.g., 355 MPa for AH36 vs. 235 MPa for Grade A). According to basic beam theory, the required thickness of a plate under bending is inversely proportional to the square root of the yield strength.

- Simplified Example: To achieve the same bending strength, a plate made of AH36 (355 MPa) can be about 22% thinner than a plate made of Grade A (235 MPa) steel.

- This scaling applies to stiffeners as well. An HP200 bulb flat in AH36 can often replace a larger, heavier section in normal strength steel.

Direct Economic Benefits

- Increased Deadweight Tonnage (DWT)3: This is extra earning capacity. If a ship’s structural weight is reduced by 500 tons, it can carry 500 more tons of cargo. For a bulk carrier, this is directly additional revenue per voyage.

- Improved Fuel Efficiency4: A lighter ship requires less engine power to move at the same speed. This reduces fuel consumption, which is the largest operating cost for a vessel.

- Potential for Larger Hull Dimensions: Alternatively, designers can use the weight savings to build a larger hull (greater volume) within the same displacement limit, allowing more cargo that is light but bulky.

Considerations and Trade-offs

High tensile steel is not a free lunch. Its use requires careful design and fabrication.

- Higher Material Cost5: HTS costs more per ton than normal strength steel.

- Increased Sensitivity to Stress Concentrations: HTS is less forgiving of poor design details or welding defects. Notch effects are more critical.

- Special Welding Procedures6: Welding may require stricter control of heat input and pre-heat to avoid hard zones and cracking.

- Greater Stiffness Requirement: Thinner plates are more prone to buckling. Stiffeners (like bulb flats) must be spaced closer together, which can offset some weight savings.

Practical Example: Bulb Flat Selection

A designer chooses between two options for a deck stiffener:

- Option 1 (Normal Strength): A heavy, tall bulb flat, maybe HP280, in Grade A steel.

- Option 2 (High Tensile): A smaller, lighter bulb flat, like HP200, in AH36 steel.

Both provide the required strength. Option 2 is lighter and takes up less space. The saved weight adds to cargo capacity. Over the 25-year life of a vessel, the cumulative value of this extra cargo space far outweighs the slightly higher initial cost of the AH36 steel.

For a rational, results-driven buyer like the manager at Gulf Metal Solutions, this is the language they understand. They are not just buying "steel." They are buying a performance metric—kilograms saved, tons of cargo gained. When they supply AH36 bulb flats to a shipyard, they are contributing to a more profitable vessel for the end owner. Our job is to ensure the HTS we supply is certified and consistent, so those calculated performance benefits are realized in the real world.

Conclusion

Chinese bulb flat steel offers a compelling combination of international quality standards, competitive pricing, and reliable supply, making it a rational and strategic choice for cost-conscious, quality-driven shipbuilders worldwide.

-

Explore the advantages of high tensile steel, including weight reduction and improved fuel efficiency, crucial for modern shipbuilding. ↩ ↩ ↩

-

Understanding weight reduction’s role can help you grasp its significance in enhancing cargo capacity and fuel efficiency. ↩

-

Learn about Deadweight Tonnage and its direct impact on a ship’s earning capacity and operational efficiency. ↩

-

Discover how improved fuel efficiency can significantly reduce operational costs for shipping companies. ↩

-

Explore the financial aspects of high tensile steel, including its higher material costs and long-term benefits. ↩

-

Understanding the welding requirements for high tensile steel is essential for ensuring structural integrity in shipbuilding. ↩