Global shipyards face tight budgets and strict deadlines. The wrong steel choice can increase costs and delay your project. Chinese marine L-shaped steel offers a solution that balances quality, cost, and reliability.

Chinese L-shaped steel for ships is a competitive choice due to certified quality meeting ABS/DNV standards, cost-effectiveness from scale production, and reliable supply chains. Major shipbuilding nations like Vietnam and Saudi Arabia import it for its consistent performance, good weldability, and availability in high-tensile grades like AH36 and DH36.

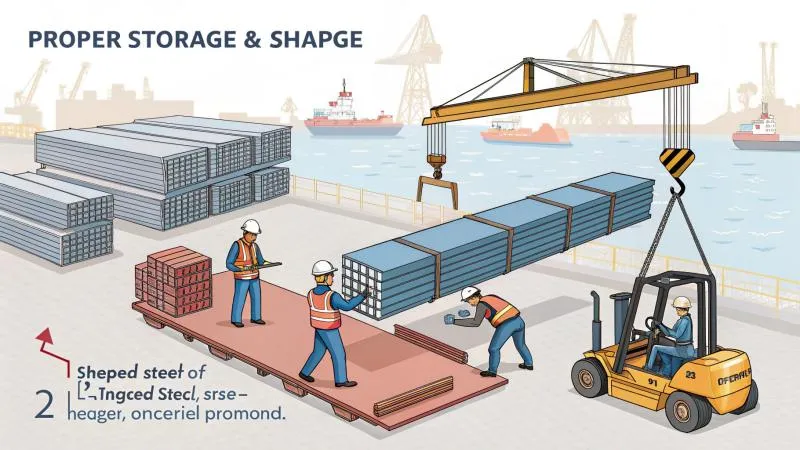

I speak with shipbuilders every week. Many initially worry about "Chinese quality." But after working with a reputable supplier, their view changes. Our client from Saudi Arabia, Gulf Metal Solutions, is a perfect example. They chose us for consistent quality and clear communication. Let’s examine why Chinese marine angles are a smart engineering and business decision.

What type of steel is used in ship construction?

Building a ship is like building a floating city. It needs a skeleton that is strong, tough, and weldable. Ordinary construction steel would fail in the harsh marine environment.

Ships use special marine-grade steel. This includes high-strength, low-alloy (HSLA) steel plates for the hull and rolled sections like L-shaped angles and bulb flats for the internal frame. Common grades are A, B, D, E, AH, DH, and EH classes per classification societies like ABS and LR, with specified yield strength and impact toughness.

Marine steel is not one single type. It is a family of materials designed for different parts of the ship and different operating conditions.

Categorizing Ship Steel by Form and Function

We can break down ship steel into two main categories: by product form and by mechanical grade.

| Category | Specific Types | Primary Function in Ship | Key Properties Needed |

|---|---|---|---|

| By Product Form | Plates: Thick, flat steel. | Forms the outer skin (shell) and major decks of the ship. | High strength, good toughness, excellent corrosion resistance. |

| Sections (Profiles): L-shaped angles, bulb flats, T-bars. | Forms the internal skeleton (frames, stiffeners, brackets). | High strength-to-weight ratio, good weldability, consistent dimensions. | |

| By Mechanical Grade | Normal Strength (Grade A, B, D, E): Yield strength ~235 MPa. | Used for less critical parts and smaller vessels. | Good weldability and basic toughness. |

| High Strength (Grade AH, DH, EH, FH): Yield strength 315-460 MPa+ (e.g., AH36=355 MPa). | Used for main hull structure of large commercial ships. | Higher strength, better toughness at low temperatures, good weldability. |

The L-shaped angle bar (or simply "angle") is one of the most common rolled sections. It is used to connect plates, build frames, and create brackets. Its simple 90-degree shape makes it versatile and easy to fabricate.

The Critical Role of L-Shaped Angles in Shipbuilding

Think of a ship’s frame. The large plates need support to prevent buckling from water pressure. Longitudinals (running front to back) and transverses (running side to side) made from angles and bulb flats provide this support. Angles are also used to create "brackets" – triangular pieces that connect beams and frames at joints, distributing stress.

The quality of these angles directly affects the ship’s structural integrity. A batch of angles with inconsistent leg lengths or poor toughness can lead to welding problems and weak points in the frame. This is why classification societies have strict standards for these profiles, and why sourcing from certified mills is non-negotiable. Chinese mills that supply to us hold these exact certifications (ABS, LR, DNV, BV), so the angles you receive are produced under the same strict controls as those from more expensive regions.

What is the main advantage of using steel in construction?

Builders have many material choices: wood, concrete, aluminum. For massive structures like ships and skyscrapers, steel has one overwhelming advantage that others cannot match.

The main advantage of steel in construction is its exceptional strength-to-weight ratio. Steel is very strong for its weight. This allows builders to create large, durable structures with less material, enabling wider spans, taller buildings, and lighter, stronger ships that can carry more cargo.

This high strength-to-weight ratio is the key. It unlocks several other benefits that make steel the dominant material for heavy construction and shipbuilding.

How High Strength-to-Weight Ratio Creates Multiple Benefits

The core advantage creates a chain reaction of positive effects. Let’s see how this one property leads to others.

| Derived Advantage | How It Comes from Strength-to-Weight Ratio | Practical Impact in Shipbuilding |

|---|---|---|

| Design Flexibility | Strong, slender members can span long distances without intermediate supports. | Ship designers can create large, open cargo holds without many internal columns, maximizing usable space. |

| Speed of Construction | Steel members are prefabricated off-site and quickly bolted or welded together. | Ship blocks can be built in parallel in different yards and then assembled, drastically cutting build time. |

| Predictability & Safety | Steel’s properties are consistent and well-understood. Engineers can calculate loads and stresses precisely. | Shipowners and insurers have confidence in the vessel’s structural safety under defined conditions. |

| Ease of Modification & Repair | Steel structures can be cut, welded, and reinforced relatively easily. | Ships can be lengthened, repaired after damage, or retrofitted with new equipment during their lifetime. |

| Recyclability | At end-of-life, steel can be melted down and reused indefinitely without quality loss. | Old ships are scrapped, and their steel is recycled into new products, reducing environmental impact. |

Compare this to concrete. Concrete is strong in compression but weak in tension. It is also much heavier. A concrete ship of the same size as a steel ship would be vastly heavier, meaning it could carry much less cargo. Steel’s combination of strength and lightness is unique for large-scale structural applications.

The Specific Case for L-Shaped Steel Angles

The L-angle profile uses this principle efficiently. By putting material along two legs at a 90-degree angle, it creates a section that resists bending in multiple directions. It is a simple, cost-effective way to turn strong steel sheet into a versatile structural component.

When you source these angles from China, you get this fundamental advantage at a scale and cost that is hard to match. Chinese mills produce millions of tons of structural angles annually. This massive scale brings down the unit cost through efficient, continuous production lines. For a shipbuilder, this means you can access a reliable supply of a fundamental building block without paying a premium, allowing you to focus your budget on other critical areas like advanced propulsion systems or cargo handling equipment.

What are the main advantages of choosing higher tensile steel grade AH over ordinary mild steel grade A?

You are designing a new bulk carrier. You can use Grade A steel or Grade AH36 steel. The choice seems technical, but it has a direct impact on the ship’s earning power and operating cost.

Choosing higher tensile steel grade AH over mild steel Grade A offers two main advantages: weight reduction and increased strength. AH36 has a yield strength of 355 MPa, about 50% higher than Grade A (235 MPa). This allows designers to use thinner plates and lighter sections, reducing the ship’s structural weight. A lighter ship can carry more cargo or use less fuel.

The move from Grade A to AH36 is a major step in modern ship design. It is not just about strength; it is about economic efficiency.

A Detailed Comparison: Performance and Economic Impact

Let’s put the two grades side-by-side to see the full picture.

| Comparison Criteria | Ordinary Mild Steel (Grade A) | Higher Tensile Steel (Grade AH36) | Advantage for AH36 |

|---|---|---|---|

| Yield Strength | 235 MPa | 355 MPa | +51% stronger. |

| Typical Use | Non-critical structures, small craft, interior fittings. | Main hull structure of large commercial vessels (tankers, bulk carriers, container ships). | Enables construction of larger, more efficient ships. |

| Weight Saving Potential | Baseline. No significant weight saving. | Can reduce structural weight by 15-25% for the same strength requirement. | More cargo capacity or better fuel efficiency. |

| Material Cost | Lower cost per ton. | Higher cost per ton (premium of 10-25%). | Higher initial material cost. |

| Overall Project Cost | Heavier structure may increase fuel costs over the ship’s life. | Higher material cost is offset by long-term operational savings (fuel) and increased revenue (cargo). | Better lifetime economics. |

| Weldability | Very good. | Still very good, but may require slightly more care with welding procedures. | Similar, with proper procedure. |

The economic calculation is clear. The extra cost for AH36 steel is an investment. It pays back over the vessel’s 20-30 year life through lower fuel bills. For example, a 10% reduction in hull weight for a large tanker can save thousands of tons of fuel per year.

The Role of Chinese Mills in Supplying AH-Grade Angles

This is where Chinese manufacturing shines. Producing consistent, certified AH36-grade steel requires advanced process control. Chinese mills invested heavily in this technology over the past two decades.

Today, they can produce AH36 and DH36 L-shaped angles with the same chemical and mechanical consistency as mills in Japan or Korea, but at a lower cost point. This has democratized access to high-tensile steel. Smaller shipyards in emerging markets can now build more competitive, efficient vessels because they can source affordable, high-grade steel.

When Gulf Metal Solutions orders marine angles from us, they almost always specify AH36 or DH36. Their clients, the shipyards, demand it. They trust our supply because every batch comes with a Mill Test Certificate from a certified mill, proving it meets the AH36 standard. This allows their fabricators to work with confidence, knowing the material will perform as expected in the final structure.

Why is high tensile steel used in ships?

The ocean is a harsh place. Ships face constant stress from waves, wind, and cargo loads. Using stronger steel is not an option; it is a necessity for safety, efficiency, and regulatory compliance.

High tensile steel is used in ships primarily to reduce structural weight. Lighter hulls allow ships to carry more cargo (increased deadweight) or use less fuel for the same speed. This strength also improves structural safety by providing a higher margin against the extreme stresses encountered in heavy seas and for large, modern vessel designs.

The use of high-tensile steel is a response to multiple pressures: economic, regulatory, and technical. Let’s explore these drivers.

The Multifaceted Drivers Behind High-Tensile Steel Adoption

The shift to high-tensile steel is driven by more than just a desire for strength. It solves several modern challenges.

| Driving Factor | The Challenge | How High-Tensile Steel Helps |

|---|---|---|

| 1. Economic Efficiency (Fuel & Cargo) | Fuel is a major operating cost. Shipping lines want to maximize profit per voyage. | A lighter ship uses less fuel. Alternatively, weight saved on the structure can be used to carry more paying cargo. |

| 2. Regulatory Pressure (EEDI/EEXI) | The IMO’s Energy Efficiency Design Index (EEDI) mandates lower CO2 emissions per ton-mile for new ships. | Using lighter, stronger steel is one of the most effective ways to improve a new ship’s EEDI score without changing the engine. |

| 3. Design Trends (Larger Ships) | Container ships and tankers keep getting larger to achieve economies of scale. | High-tensile steel allows for larger spans and structures without a proportional increase in weight, making mega-ships feasible. |

| 4. Operational Safety | Ships face severe weather, dynamic loads, and potential grounding. | Higher strength provides a greater safety factor, allowing the structure to withstand unexpected overloads. |

| 5. Ice Class Requirements | Ships operating in polar regions face impact from ice. | Grades like DH36 and EH36 offer superior toughness at low temperatures, preventing brittle fracture. |

The regulatory point is crucial. Rules like EEDI have made high-tensile steel almost mandatory for new builds. Ship designers must use every available technology to hit emission targets, and advanced materials are at the top of the list.

Sourcing High-Tensile L-Angles: The Chinese Supply Chain Advantage

For a shipyard, specifying AH36 steel is one thing. Reliably procuring thousands of tons of it in the form of L-angles, bulb flats, and plates is another. This is the logistical challenge where China’s integrated supply chain offers a decisive advantage.

First, scale and availability. Chinese mills produce high-tensile marine grades in huge volumes. You can source all your steel profiles—plates, angles, bulbs—from the same region, often from mills that supply each other. This simplifies logistics and quality assurance.

Second, cost competitiveness. The scale of production keeps costs down. The total cost of a ship’s steel structure, including high-tensile angles, is lower when sourced from China, improving the project’s overall financial viability.

Third, export readiness. The entire ecosystem, from mills to ports like Qingdao and Tianjin, is optimized for exporting large volumes of steel. This means reliable lead times and shipping schedules, which is critical for shipyard project planning.

Our business model is built on this advantage. We act as the reliable link between these efficient Chinese mills and international shipbuilders. We ensure the high-tensile steel you order is not just affordable and available, but also certified, well-packaged, and delivered according to your schedule. This turns a complex procurement challenge into a straightforward, dependable process.

Conclusion

Chinese L-shaped steel for shipbuilding combines certified high-tensile quality with the economic benefits of scale production. This offers global shipyards a reliable, cost-effective solution to build stronger, lighter, and more efficient vessels in a competitive market.